Heating and heat preservation method of aluminum alloy melt

An aluminum alloy melt, heating and heat preservation technology, used in metal processing equipment, casting melt containers, manufacturing tools, etc., can solve melt leakage, affect the continuity and stability of production, hinder the bottom slag removal operation of the molten pool, etc. problem, to achieve the effect of low cost, convenient slag removal operation, and improved slag removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described in detail below in conjunction with an aluminum alloy melting method using the present invention. Wherein, the descriptive terms such as up, down, left, right, etc. are used for the description, with the purpose of helping readers to understand, but not intended to limit.

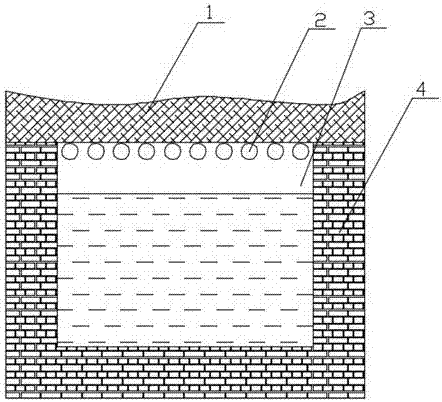

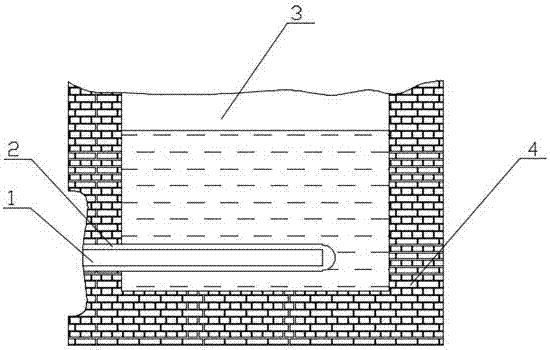

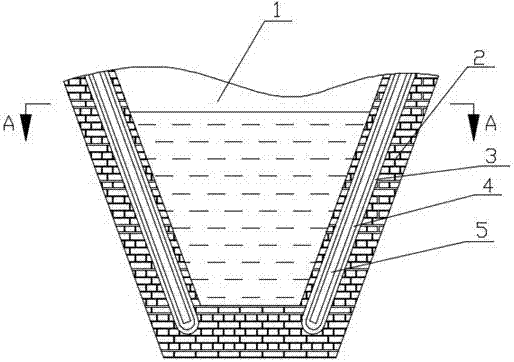

[0051] When implemented, such as image 3 and Figure 4 Shown:

[0052] A method for heating and insulating an aluminum alloy melt, comprising the step of heating and insulating the aluminum alloy melt;

[0053] In the step of heating and holding the aluminum alloy melt, an aluminum alloy melt heating and holding device is used to heat and hold the melt. The aluminum alloy melt heating and holding device includes a furnace body 2, an electric heating element, and a temperature controller (Fig. not shown in the figure) and a temperature sensor (not shown in the figure); the interior of the furnace body 2 has a cavity, and the cavity constitutes the me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com