Elastic plate out-throwing type seed belt arranging and cleaning for wheat after rice

A springboard, wheat seed technology, applied in the fields of farming machinery, agricultural machinery, agricultural machinery and machinery, etc., can solve the problems of poor seed belt cleaning effect, soil adhesion and blockage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

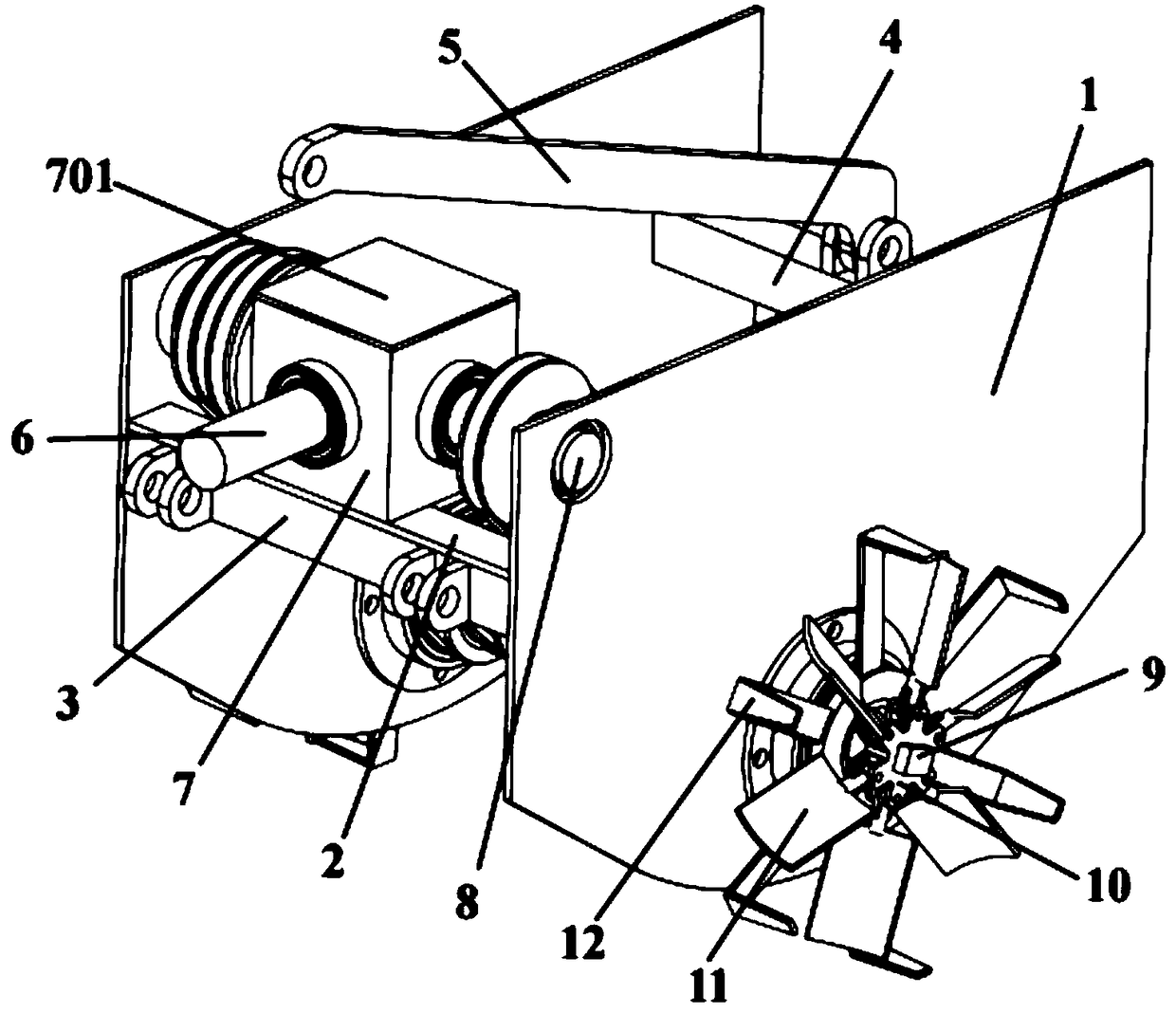

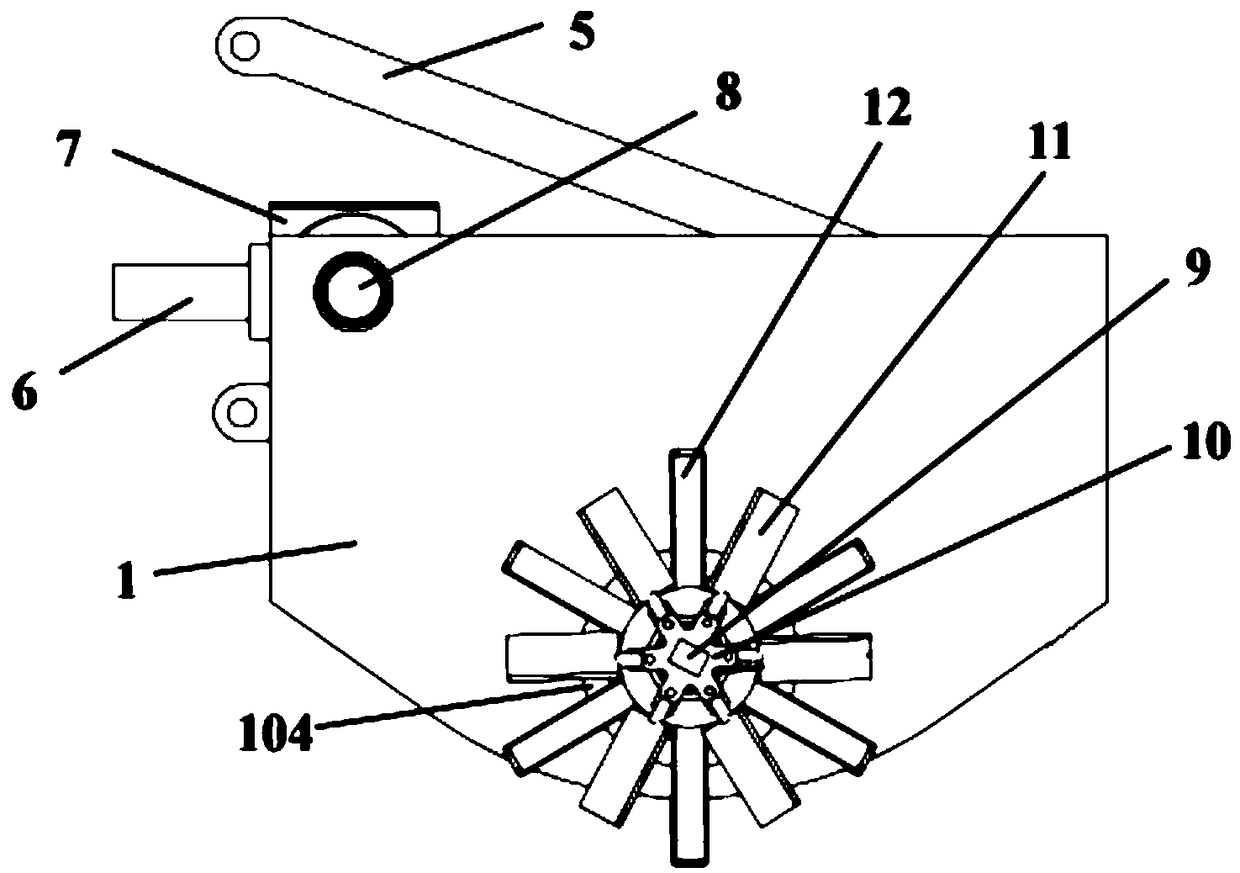

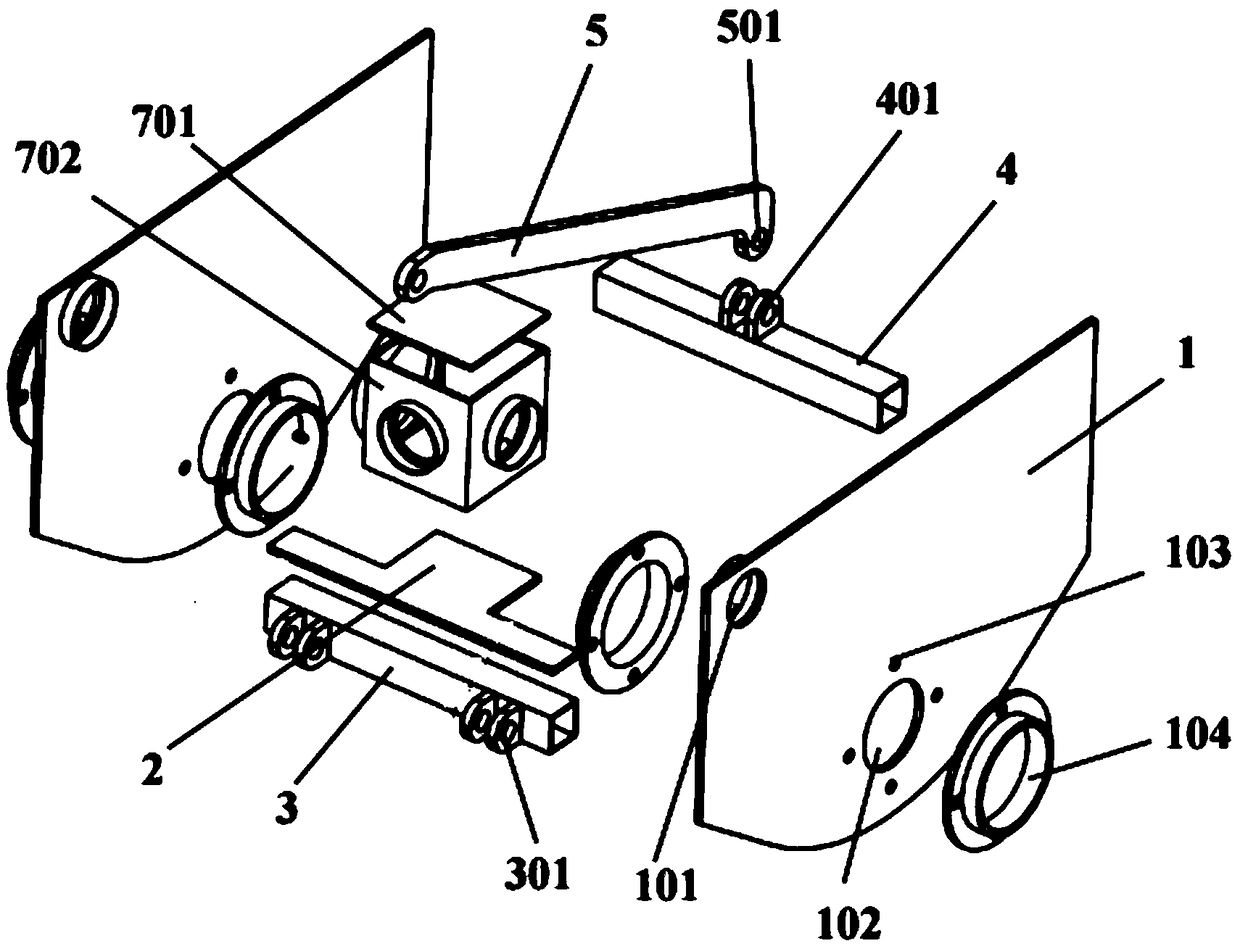

[0030] The specific structure and working process of the present invention will be described below in conjunction with the accompanying drawings and embodiments.

[0031] Such as Figure 1A The three-dimensional structure diagram of the rice stubble and wheat seed belt cleaning machine with spring plate thrown out, Figure 1B The side view and the figure 2 As shown in the exploded diagram of the basic structure of the rice stubble and wheat seed belt cleaning machine thrown outside the spring plate, the spring plate thrown rice stubble and wheat seed belt cleaning machine consists of a coupling device, a transmission device, and a seed belt installed on the frame. The belt cleaning device and the spring plate throwing device are composed. The spring plate throwing type rice stubble and wheat seed belt cleaning machine is connected with the tractor's suspension device and traction device through the hitch device, and the power of the tractor is transmitted to the seed belt thr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com