Photovoltaic array washing vehicle and photovoltaic array washing method thereof

A technology for photovoltaic arrays and cleaning vehicles, which is applied to cleaning methods and utensils, cleaning methods using tools, cleaning methods using liquids, etc. The effect is uniform and consistent, reducing oil and water consumption, and facilitating timely processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The technical solution proposed by the present invention will be further explained below in conjunction with the accompanying drawings and embodiments, but it is not intended to limit the present invention.

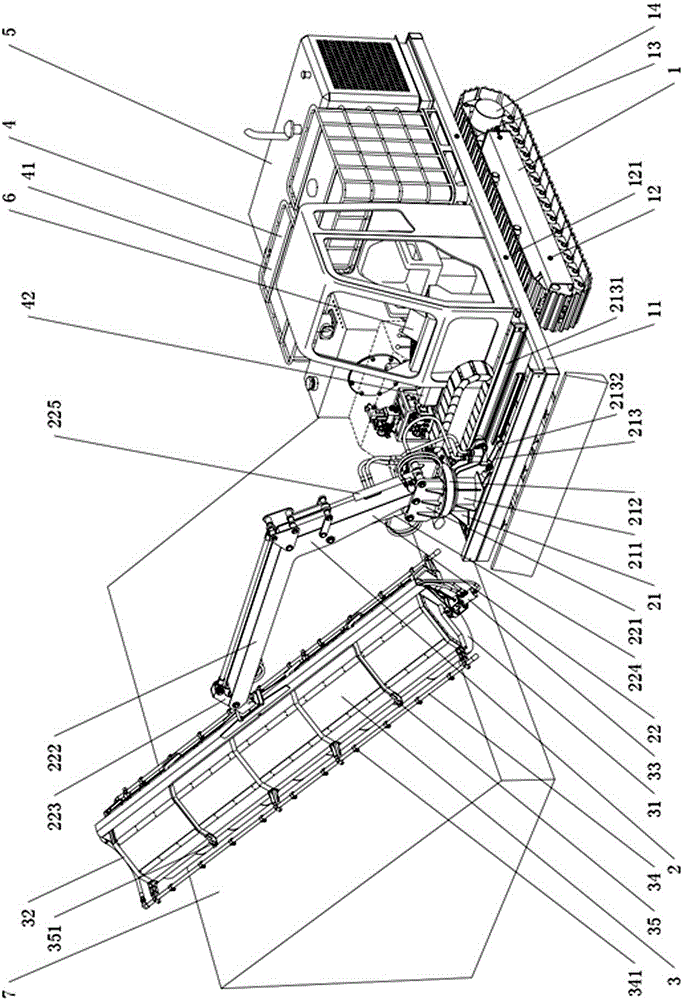

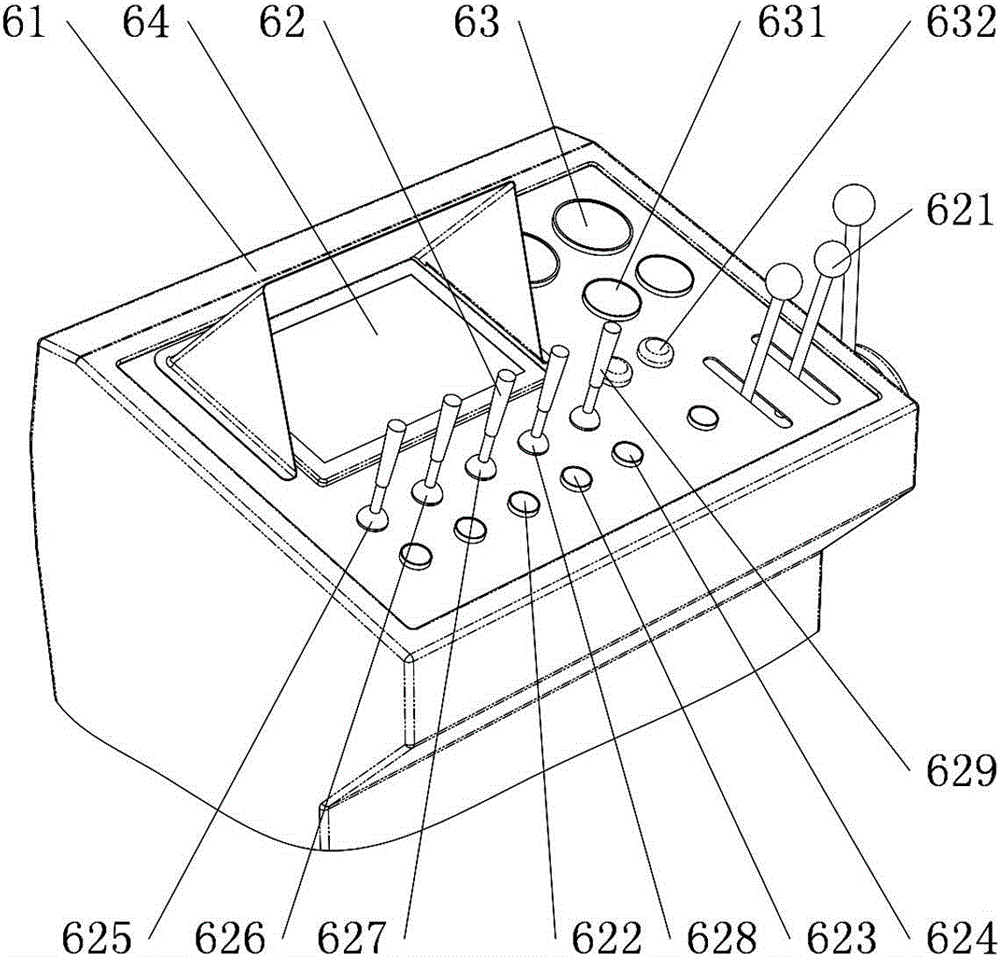

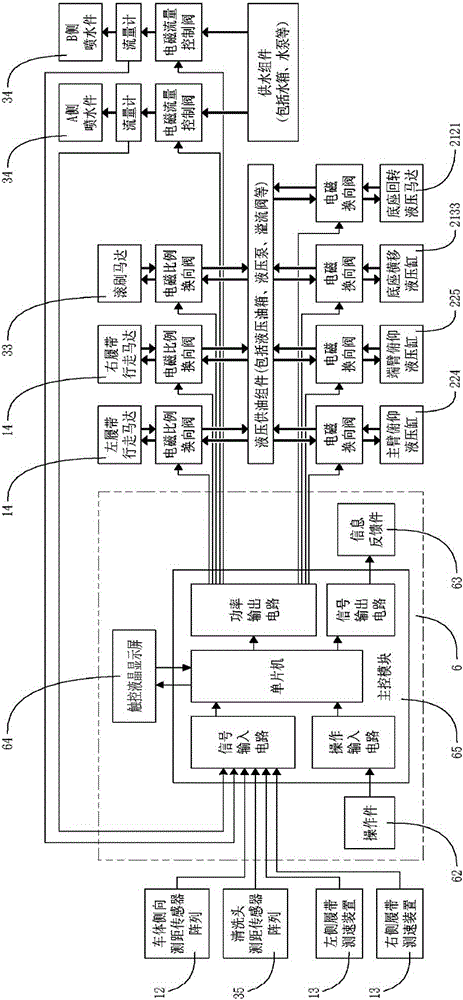

[0041] A photovoltaic array cleaning vehicle is composed of a crawler-type traveling chassis 1 , a cleaning head support positioning unit 2 , a cleaning head unit 3 , a water supply unit 4 , a power unit 5 , and an operation control unit 6 .

[0042] The crawler motors 14 on both sides of the crawler chassis 1 are respectively controlled by two electromagnetic proportional reversing valves, and the two electromagnetic proportional reversing valves are connected with the main control module 65 of the operation control unit 6 through cables. Corresponding crawler speed measuring devices 13 are provided on both sides of the crawler type traveling chassis 1 close to the crawler traveling motor 14 , and the crawler speed measuring devices 13 are connected to the main con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com