Reagent bottle cleaning method, reagent bottle reagent recycling method and reagent bottle cleaning system

A recovery method and cleaning system technology, applied in the direction of cleaning methods and appliances, separation methods, chemical instruments and methods, etc., can solve the problems of increasing the risk of environmental pollution, increasing costs, difficult reagent bottles, etc., to achieve fast and efficient cleaning operations, Avoid the effect of high cost and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

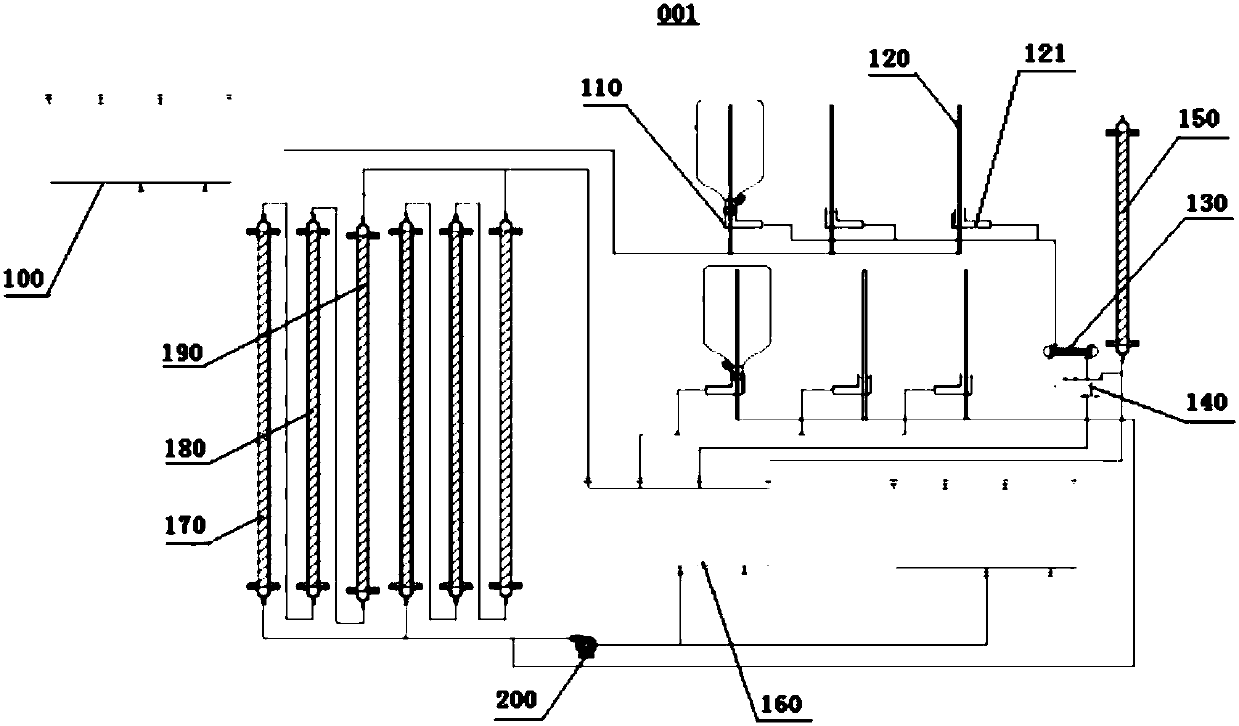

[0038] This embodiment reclaims the chromatographically pure tert-butyl methyl ether reagent bottle, which adopts figure 1 Shown reagent bottle cleaning system 001, and make according to following preparation method:

[0039] S101. Perform reagent flushing on the tert-butyl methyl ether reagent bottle; the reagent flushing is to use tert-butyl methyl ether to flush the reagent bottle, the flushing time is 1.5 min, and the flushing pressure is 0.3 MPa.

[0040] S102, connect the reagent bottle after the reagent flushing to the sealing plug 110, then open the valve (not shown in the figure) and use the nitrogen in the inert gas tank 100 to purge the flushed reagent bottle, the pressure of the inert gas purge is 0.5MPa , the inert gas purging time is 2min.

[0041] S103. Use the cryocooler 130 to collect the tail gas purged by the inert gas and condense and recover the reagent. The condensation temperature of the cryocooler 130 is -10°C.

[0042] S104. Pass the reagent condense...

Embodiment 2

[0044] This embodiment reclaims the chromatographically pure acetone reagent bottle, which adopts figure 1 Shown reagent bottle cleaning system 001, and make according to following preparation method:

[0045] S201. Perform reagent flushing on the acetone reagent bottle; wherein the reagent flushing is to flush the reagent bottle with acetone, the flushing time is 2 minutes, and the flushing pressure is 0.2 MPa, and then the rinsed reagent bottle is placed downward for 2 minutes.

[0046] S202. Seal the reagent bottle after the reagent flushing with the sealing plug 110, then open the valve and use the nitrogen in the inert gas tank 100 to purge the flushed reagent bottle. The pressure of the inert gas purge is 0.6MPa, The time is 1min.

[0047] S203. Use the cryocooler 130 to collect the tail gas purged by the inert gas and condense and recover the reagent. The condensation temperature of the cryocooler 130 is 0°C.

[0048] S204. Pass the reagent condensed and recovered by ...

Embodiment 3

[0050] This embodiment reclaims the chromatographically pure isopropanol reagent bottle, which adopts figure 1 Shown reagent bottle cleaning system 001, and make according to following preparation method:

[0051] S301. Rinse the isopropanol reagent bottle with reagent; the reagent rinse is to use isopropanol to rinse the reagent bottle, the rinse time is 1.5min, and the rinse pressure is 0.3MPa, and then the rinsed reagent bottle is placed downwards 2min.

[0052] S302. Seal the reagent bottle after the reagent flushing with the sealing plug 110, then open the valve and use the nitrogen in the inert gas tank 100 to purge the flushed reagent bottle. The pressure of the inert gas purge is 0.4MPa, The time is 1.5min, and the inert gas is filtered through a 200nm sieve before purging the reagent bottle with an inert gas.

[0053] S303. Use the cryocooler 130 to collect the tail gas purged by the inert gas and condense and recover the reagent. The condensation temperature of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com