High-pressure water jet cleaning machine for industrial machinery parts

A high-pressure water jet and industrial machinery technology, applied in the field of cleaning machines, can solve the problems of uncertain water jet pressure field distribution, restrictions on the application and promotion of water jet cleaning technology, and lack of equipment, so as to improve the cleaning speed and cleaning quality, Reduce the consumption of water and electric energy, the effect of high cleaning quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

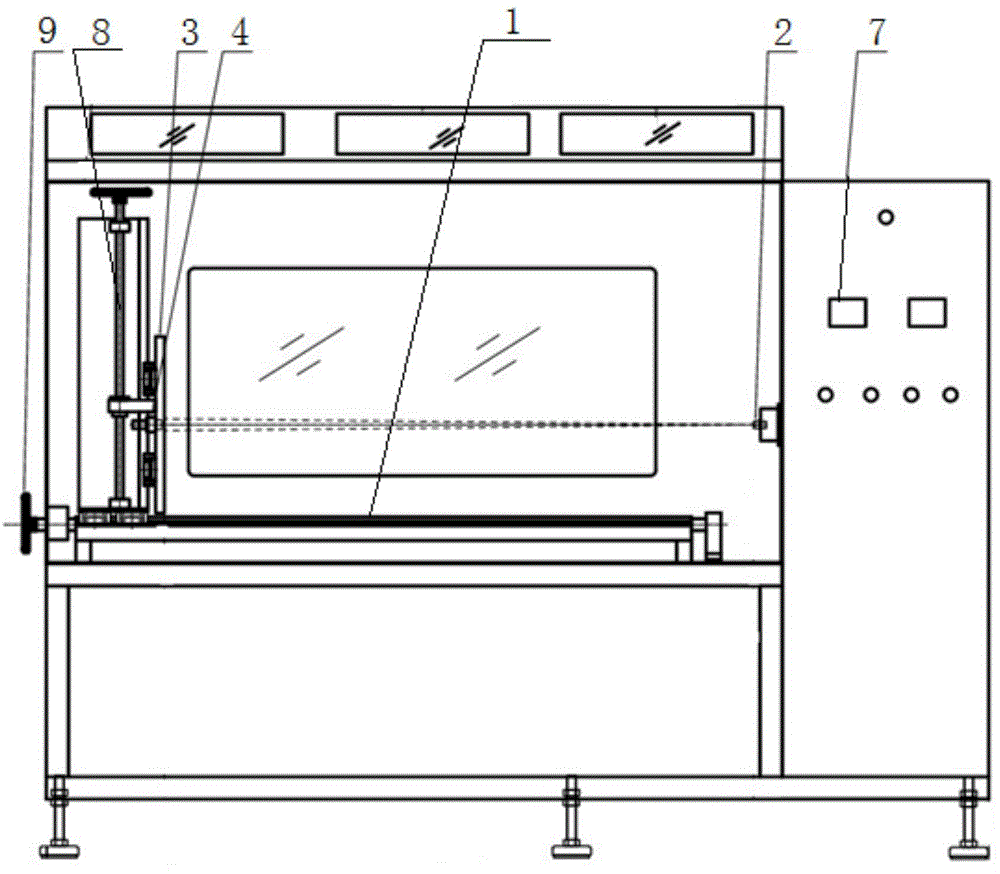

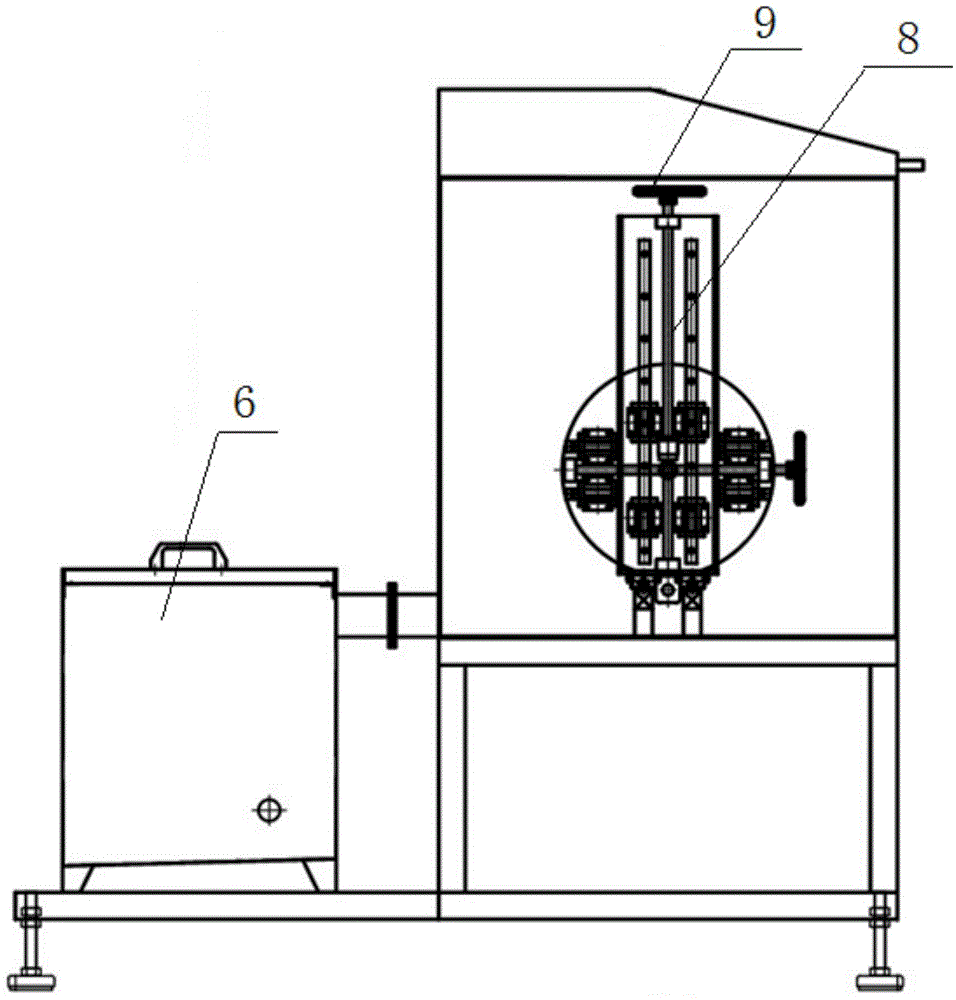

[0027] As shown in the drawings, a high-pressure nozzle 2 is installed on one side of the cleaning table 1, and a moving target surface device 3 that can move up, down, left, and right, and forward and backward is provided on the opposite side of the cleaning table 1, and the moving target surface device 3 It is provided with a pressure sensor 4 capable of measuring water pressure and a clamping piece capable of clamping parts to be cleaned; the high-pressure nozzle 2 is connected with the high-pressure jet pump 5 through a pipeline, and the water tank 6 is filled with cleaning water to start the high-pressure The jet pump 5 draws the water in the water tank 6, applies high pressure and sends it to the high pressure nozzle 2 through the high pressure pipeline. The bottom of the cleaning table 1 is provided with a return pipe that flows back into the wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com