Suction nozzle and pulse gas path control system and sweeping car comprising same

A gas path control and pulse technology, applied in the field of road sweepers, can solve the problems of ground garbage residue, insufficient negative pressure adsorption capacity, and unsatisfactory garbage cleaning effect of road sweepers, so as to meet cleaning needs and improve negative pressure suction. Pick up ability and ensure the effect of road cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] It should be noted that the features in the various embodiments of the present invention may be combined with each other in the absence of explicit limitation or conflict. The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0024] In order to overcome the defects of the road sweeper in the prior art, the present invention provides an improved suction nozzle and a related pulse air path control system.

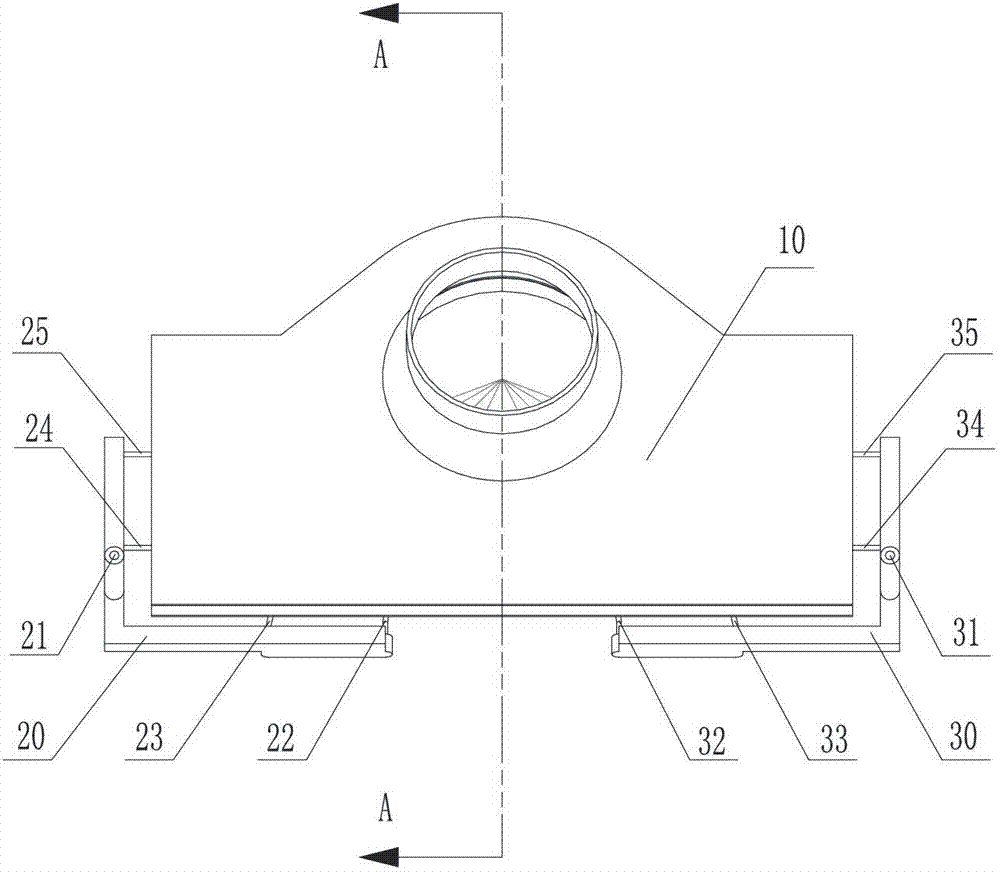

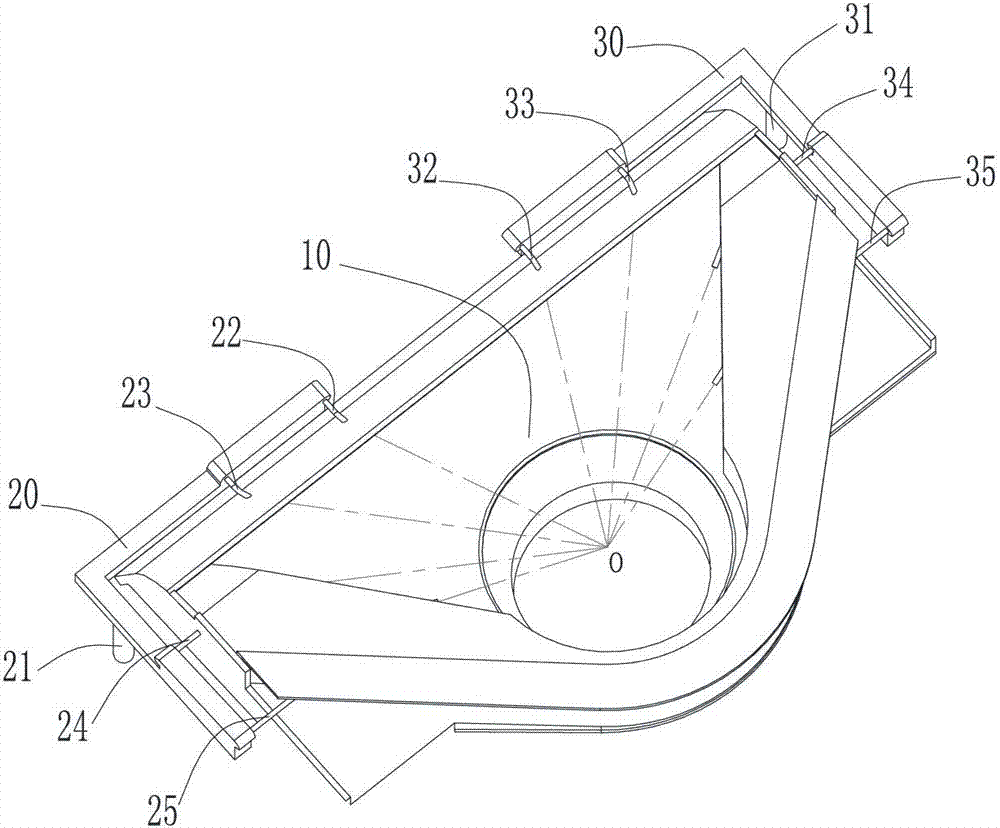

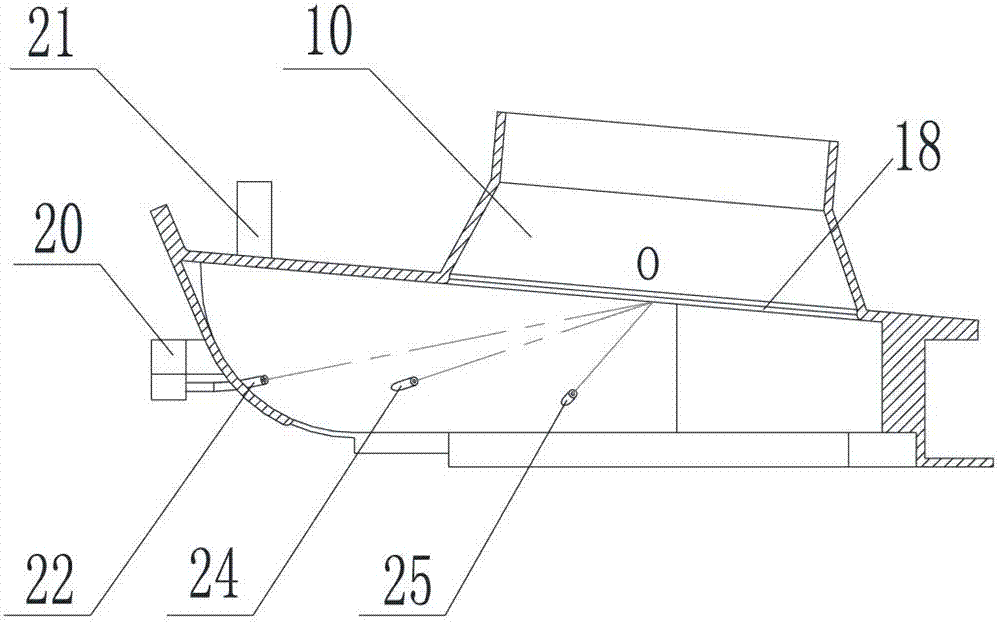

[0025] figure 1 It is a top view of the suction nozzle of the embodiment of the present invention, figure 2 It is the bottom view of the suction nozzle of the embodiment of the present invention, image 3 yes figure 1 A sectional view along line A-A, Figure 4 is a schematic diagram of the first part of the pulse jet device of the embodiment of the present invention, Figure 5 is a schematic diagram of the second part of the pulse jet device of the embodiment of the present invention.

[0026] Such as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com