Dry-cleaning and water-washing hybrid solar panel cleaning device

A technology for solar panels and cleaning devices, which is applied in the directions of cleaning methods, cleaning methods and utensils, photovoltaic modules, etc. using tools, can solve the problems of difficult cleaning work, high overall energy consumption, high cost, etc., and achieves reuse of water resources. , The operation is simple and convenient, and the effect of solving the cleaning problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

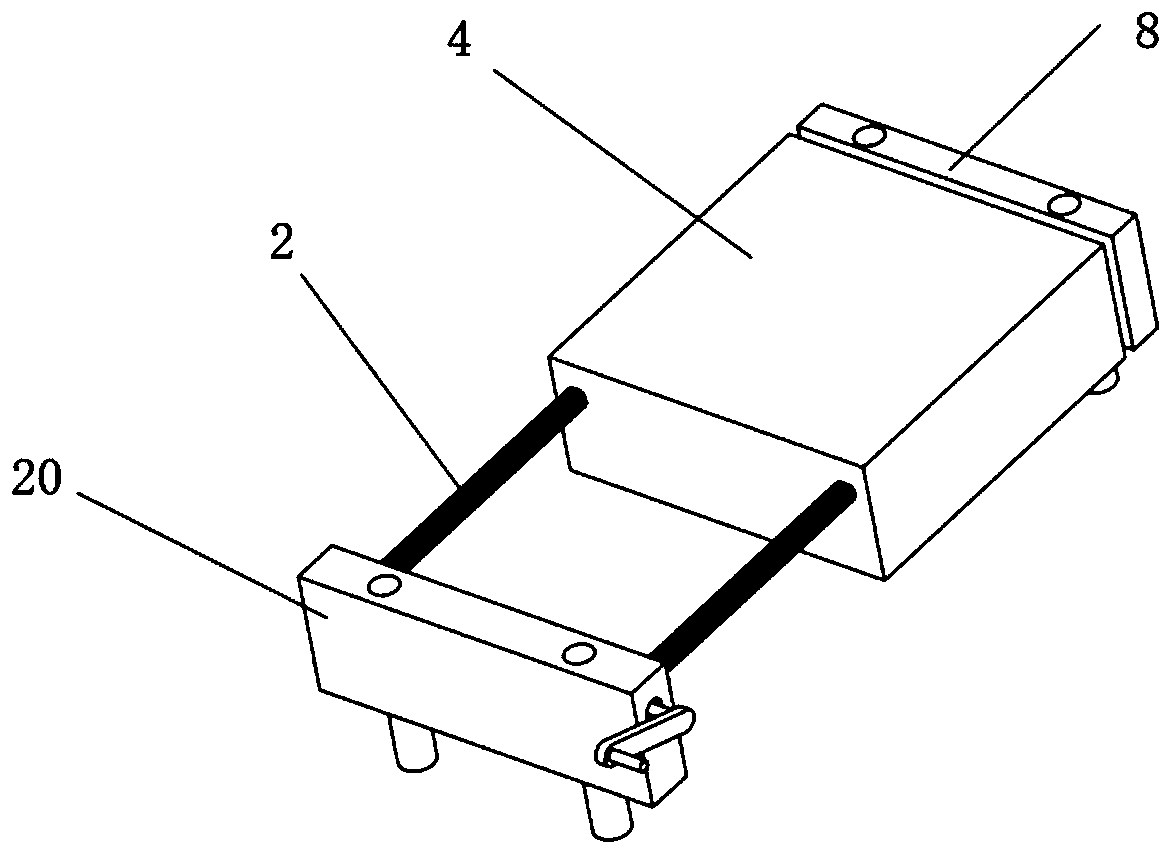

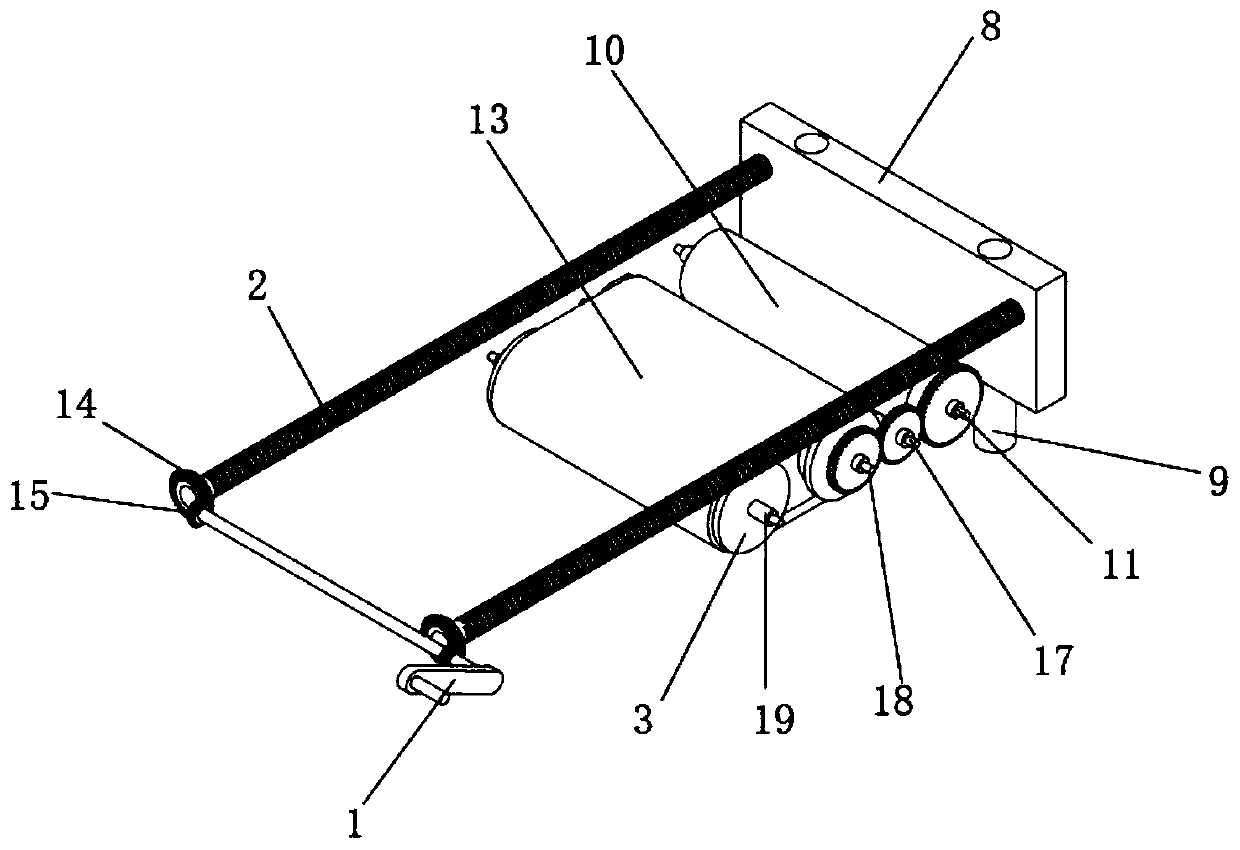

[0025] The specific structure of a solar panel cleaning device mixed with dry water washing of the present invention is:

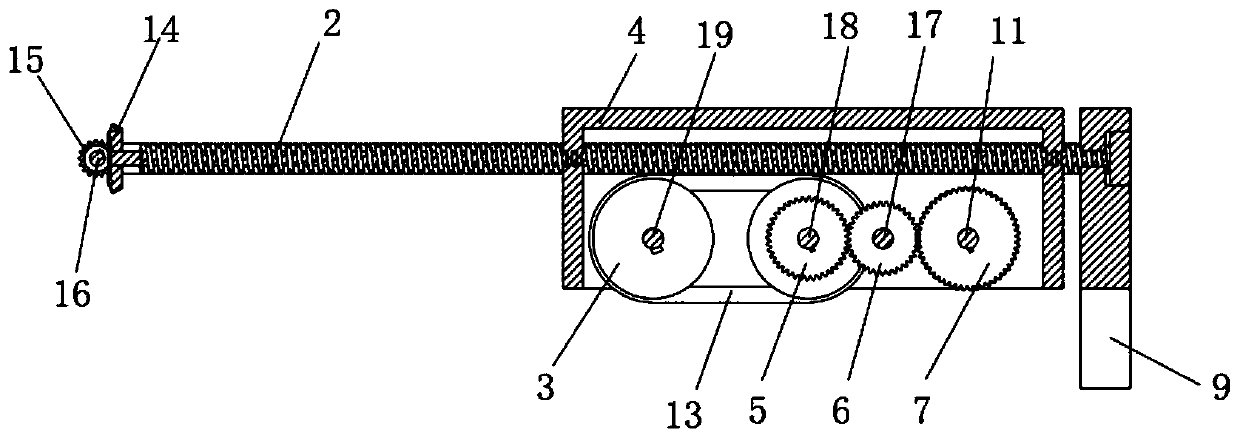

[0026] Both ends of the horizontal shaft 16 are fixed in the casing 20 through bearings, a handle 1 is fixed on one end of the horizontal shaft 16, and two driving bevel gears 15 are arranged on the horizontal shaft 16; two screw screws 2 are parallel and the front ends are fixed to the casing 20 through bearings , and the end point is fixed with a transmission bevel gear 14, the other end of the lead screw 2 and the baffle 8 are fixed through bearings; the driving bevel gear 15 is perpendicular to the transmission bevel gear 14 and meshes with each other; the casing 20 and the lower side of the baffle 8 are fixed with two a roller 9.

[0027] The box body 4 is a cuboid structure without a bottom plate, and the front and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com