High-efficient cleaning machine for sunlight greenhouse film

A solar greenhouse and washing machine technology, applied in the direction of greenhouse cultivation, cleaning methods and tools, cleaning methods using tools, etc., can solve the problems of affecting the use effect, restricting the development of vegetable greenhouse planting, and increasing the production cost of vegetable farmers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

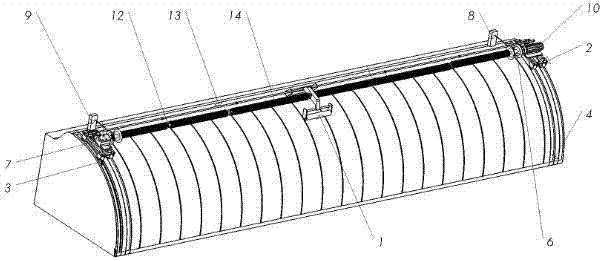

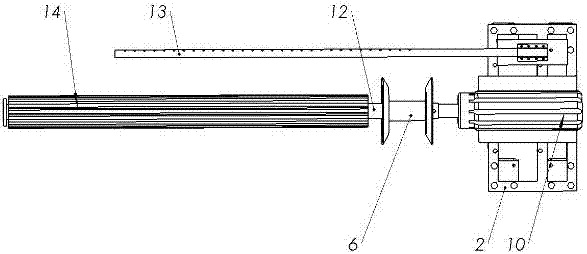

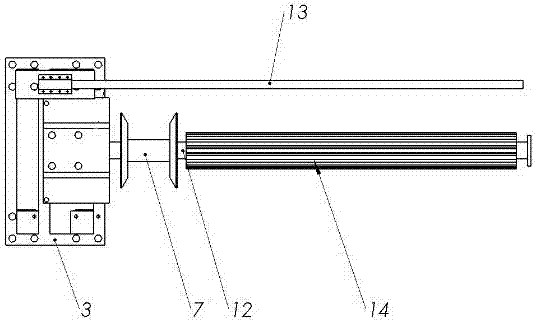

[0025] Such as figure 1 A solar greenhouse film high-efficiency cleaning machine is shown, including a cleaning shaft 12 arranged along the length of the greenhouse and provided with a brush 14 on the surface, and the brush 14 is covered and fixed on the outer surface of the cleaning shaft 12 by a snap-in Velcro. When the cleaning shaft rotates, the hairbrush 14 is driven to rotate, and the dust on the surface of the greenhouse film is cleaned.

[0026] One end of the cleaning shaft 12 is connected with a forward and reverse motor 10 slidingly connected to the side wall of the greenhouse through the base 2, and the forward and reverse motor drives the cleaning shaft 12 to rotate. The other end of the cleaning shaft 12 is rotatably connected with a support 3 that is slidingly connected to the wall on the other side of the greenhouse. For reducing friction, the support 3 is fixed with a bearing that is sleeved on the cleaning shaft. As an optimized solution, the bottom surface ...

Embodiment 2

[0031] The difference between this embodiment and Embodiment 1 is that it also includes a water spray pipe 13 fixedly connected to the base 2 and the bracket 3 at both ends, and the water spray pipe 13 is provided with a water spray pipe axially distributed along the side of the greenhouse film. Spray holes.

[0032] Also in order to meet the use of solar greenhouses of different lengths, the water spray pipe 13 in this embodiment includes several short pipes, the two ends of the short pipes are fixedly connected with flanges, and the adjacent flanges of adjacent short pipes are fixedly connected by bolts. , Determine the number of short pipes according to the actual length of the greenhouse used to achieve the purpose of adjusting the length of the sprinkler pipe.

[0033] The horizontal working width of the cleaning machine of the present invention is adjustable, and the cleaning brushes, water spray pipes and cleaning shafts can be freely replaced according to the needs of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com