Washing method and device for biological chip

A technology of biological chips and cleaning devices, which is applied in biological testing, preparation of samples for testing, material inspection products, etc. Large and other problems, to avoid errors, low cost, and meet the needs of cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

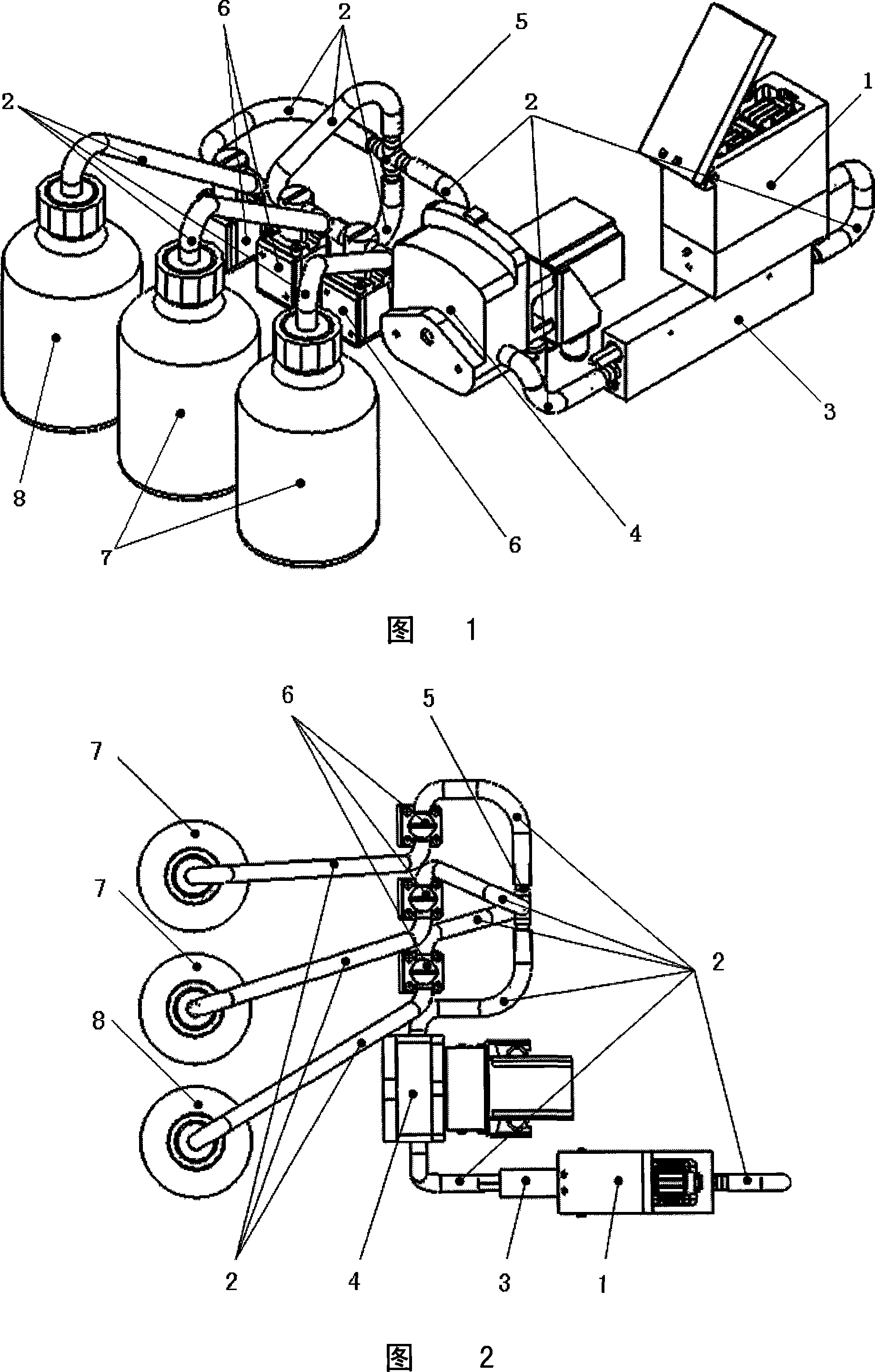

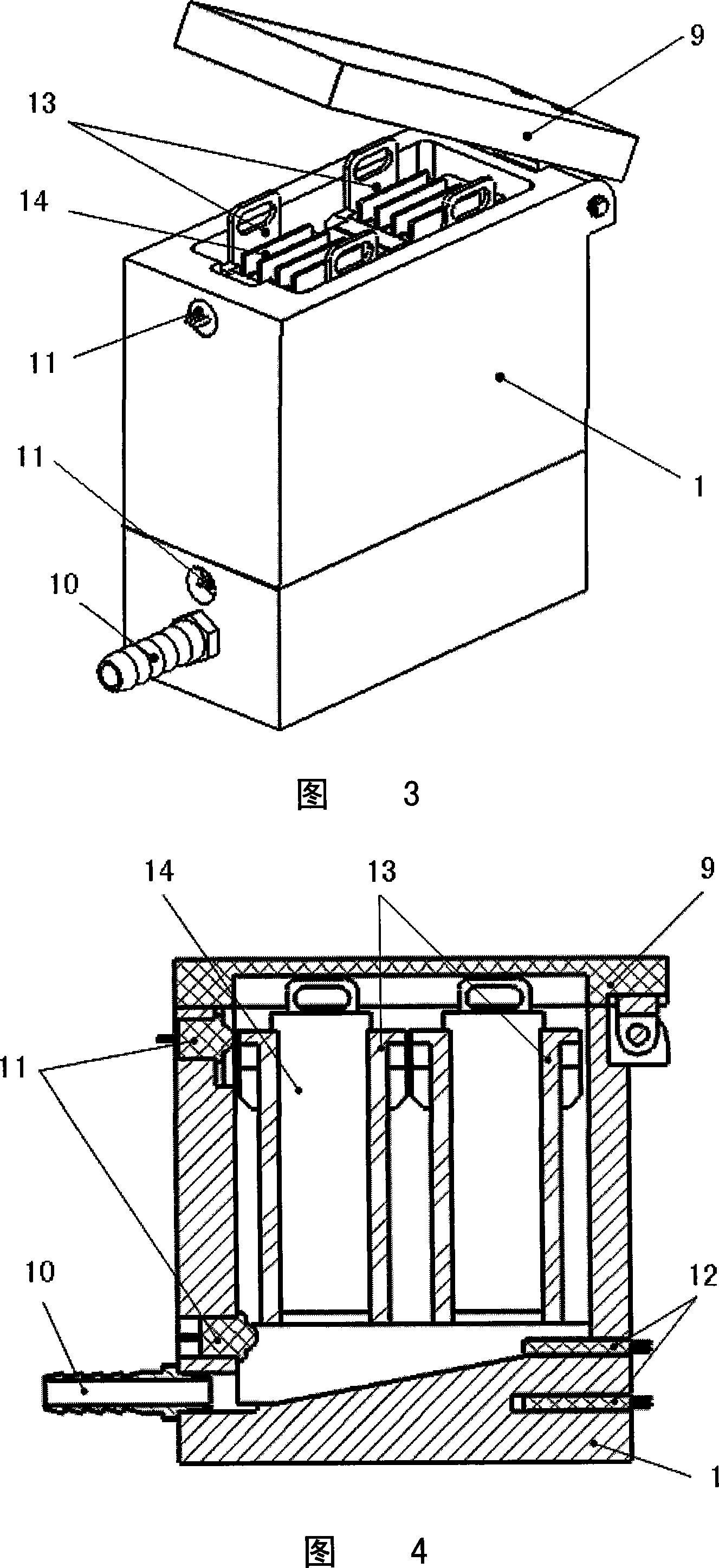

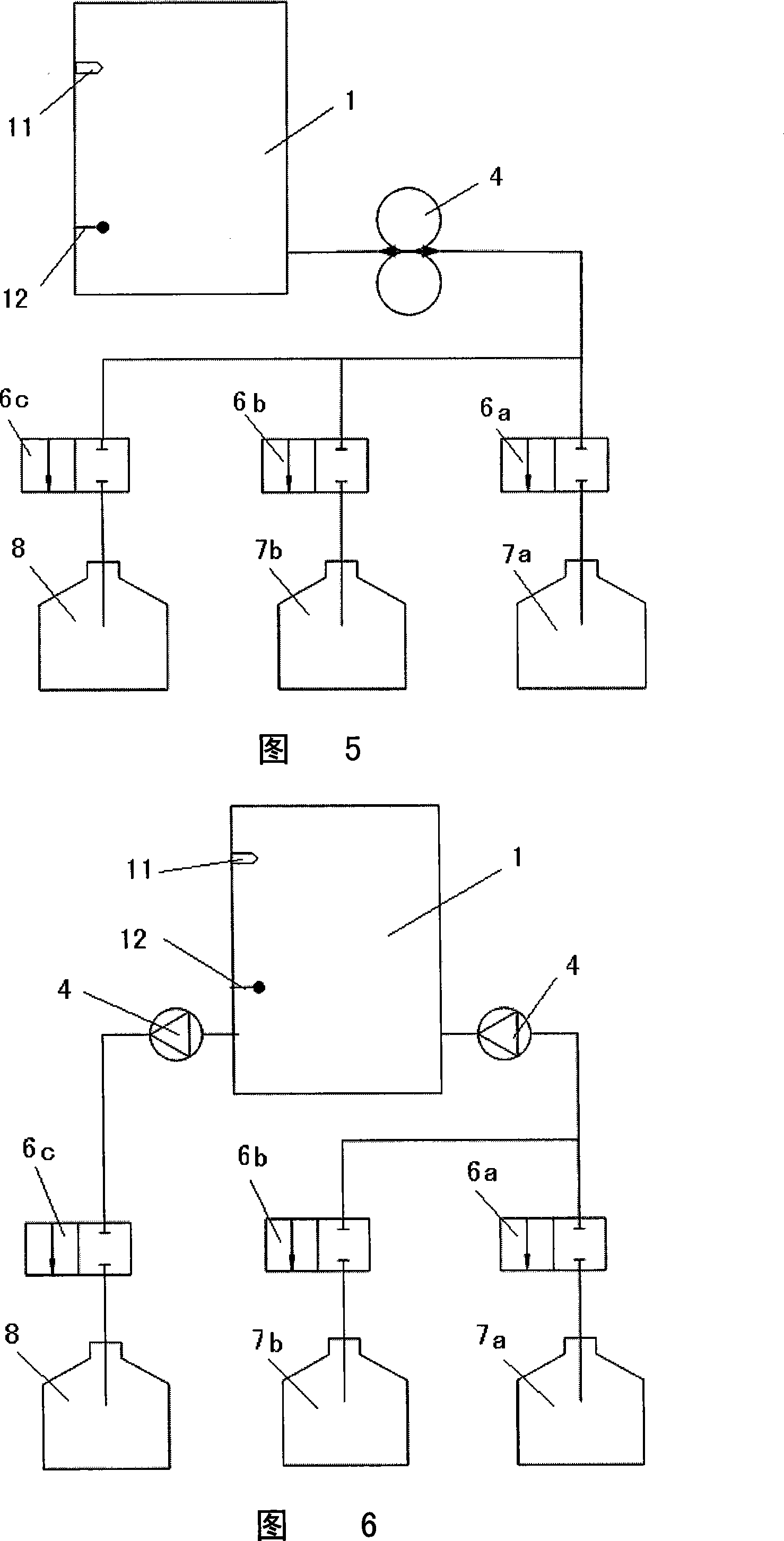

[0024] As shown in Figures 1 and 2, the present invention includes a cleaning chamber 1, several pipelines 2, a heating element 3, a liquid pump 4, a four-way joint 5, three valves 6, two washing liquid bottles 7, and a waste liquid bottle 8 and control circuits. The three interfaces in the four-way connector 5 are respectively connected to one end of the three valves 6 through the pipeline 2, and the other ends of the three valves 6 are respectively connected to the two washing liquid bottles 7 and the waste liquid bottle 8 through the pipeline 2, and the four-way connector 5 The remaining interface is connected to one end of a liquid pump 4 through the pipeline 2, and the other end of the liquid pump 4 is connected to the cleaning chamber 1 through the pipeline 2. If the cleaning process needs to be carried out at a certain temperature, it can be co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com