Full-automatic detection cleaning controller for milking machine, and control method of full-automatic detection cleaning controller

A control method and controller technology, applied in the direction of non-electric variable control, milking device, control/regulation system, etc., can solve the problem of inability to automatically detect the cleaning quality, water temperature of the tank liquid level, cleaning time cannot be set by itself, milking The problem of cleaning the milk machine is not clean, so as to reduce labor intensity, realize intelligence, and increase cleaning intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

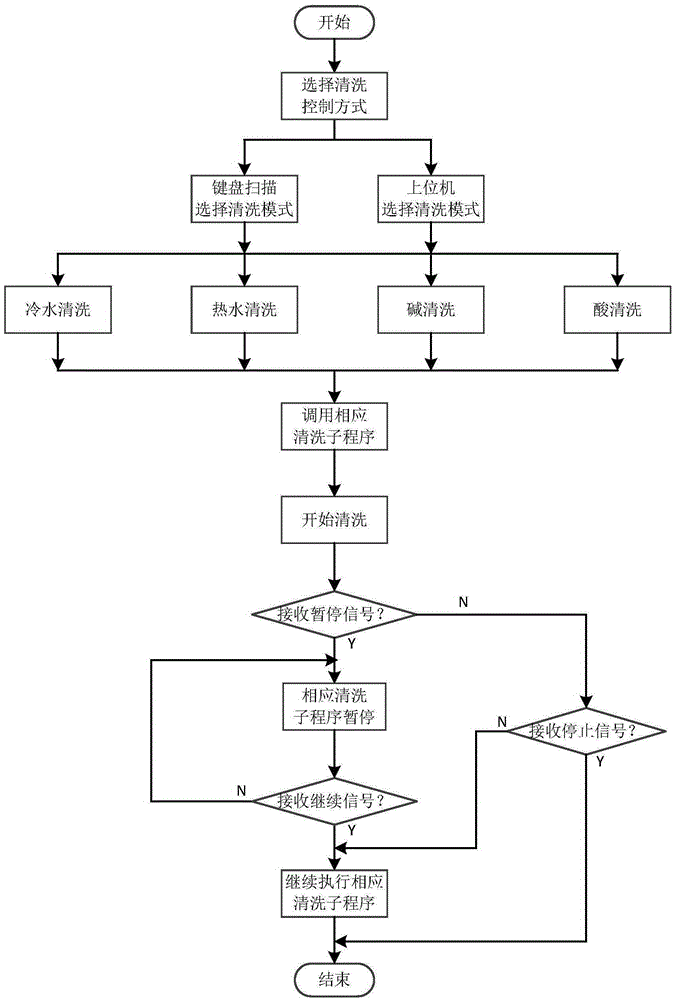

[0026] In order to describe the technical solution of the present invention more clearly, the present invention will be described in detail below in conjunction with the drawings and specific embodiments.

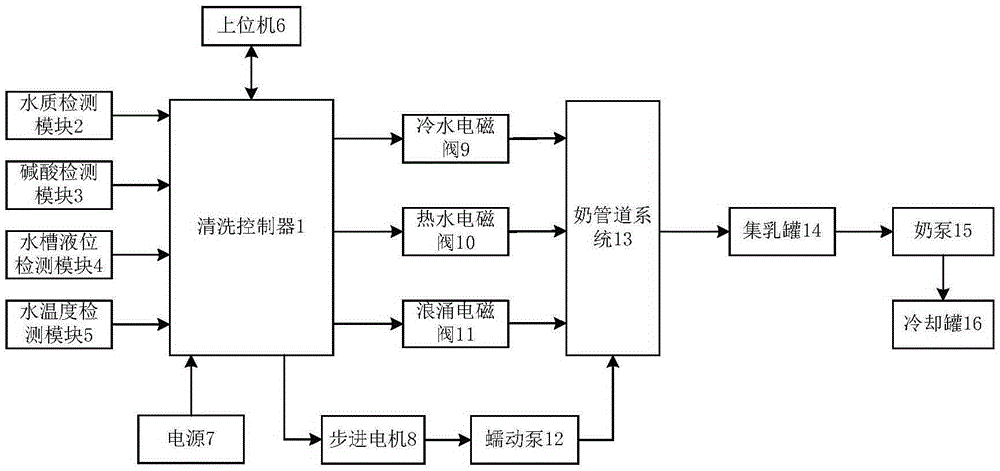

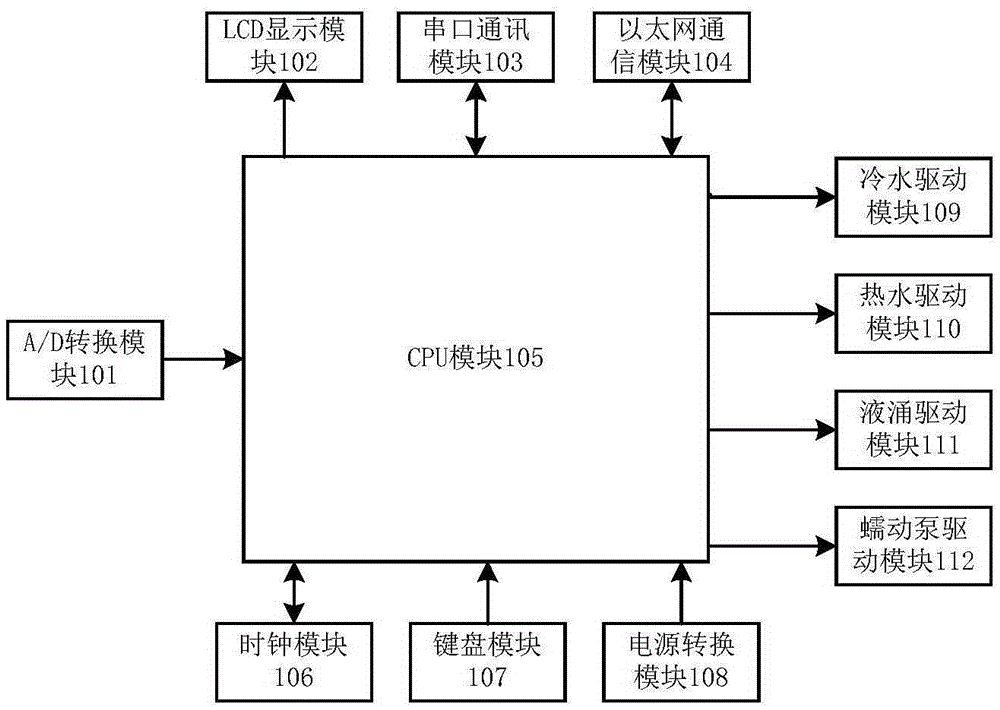

[0027] Such as figure 1 As shown, the cleaning controller (1), water quality detection module (2), alkali acid detection module (3), water tank liquid level detection module (4), water temperature detection module (5), upper computer (6), power supply ( 7), stepping motor (8), cold water solenoid valve (9), hot water solenoid valve (10), surge solenoid valve (11), peristaltic pump (12), milk pipeline system (13), connecting milk collection tank (14), milk pump (15), cooling tank (16).

[0028] Further, the cleaning controller (1) is connected with the upper computer (6), the stepper motor (8), the cold water solenoid valve (9), the hot water solenoid valve (10), the surge solenoid valve (11); the water quality detection module ( 2), alkali-acid detection module (3), tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com