Patents

Literature

83results about How to "Increase cleaning strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

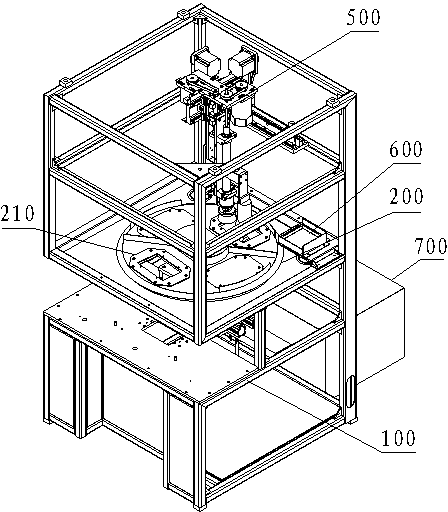

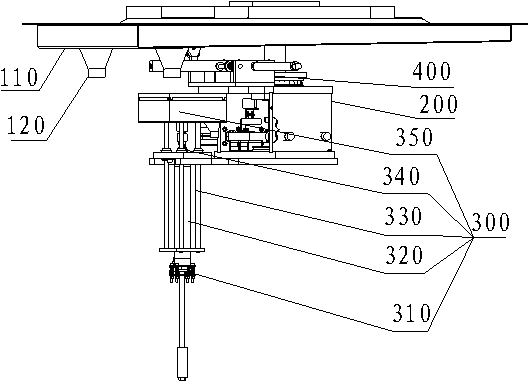

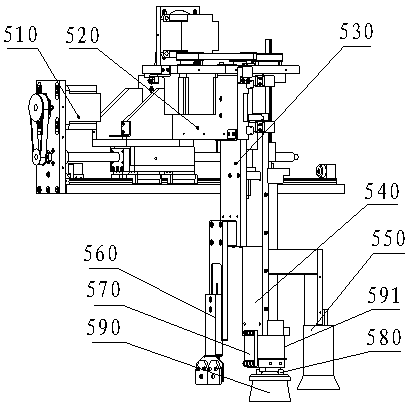

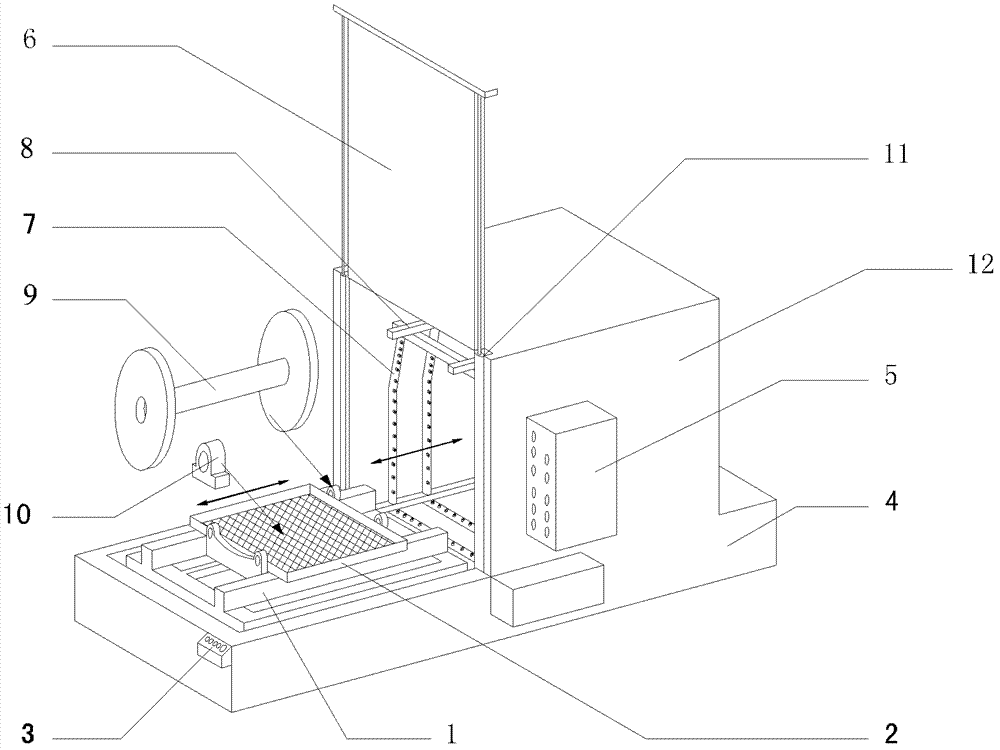

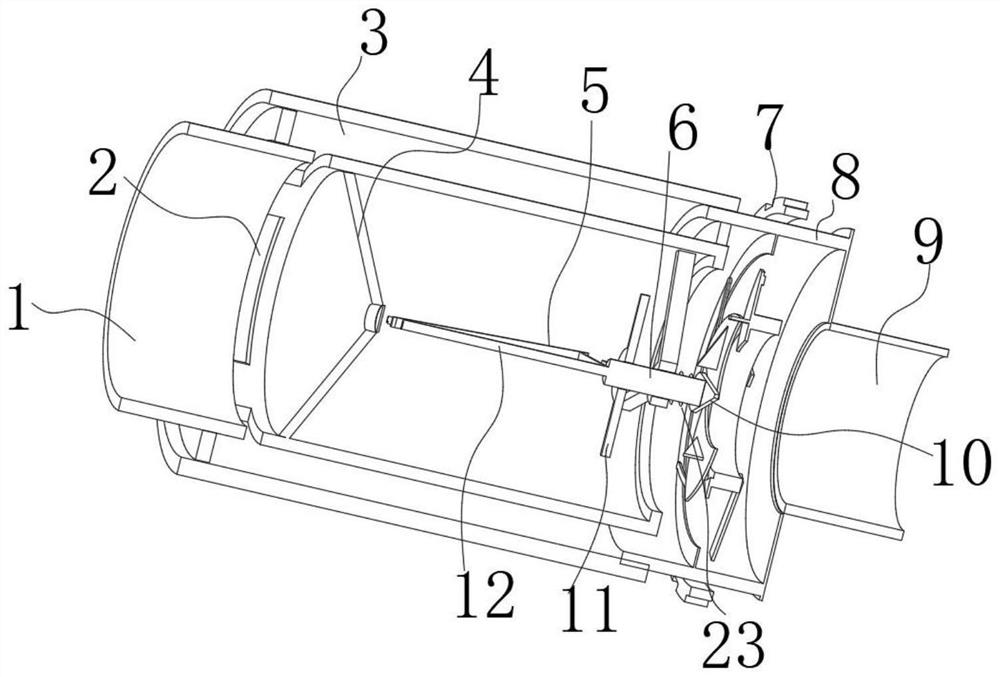

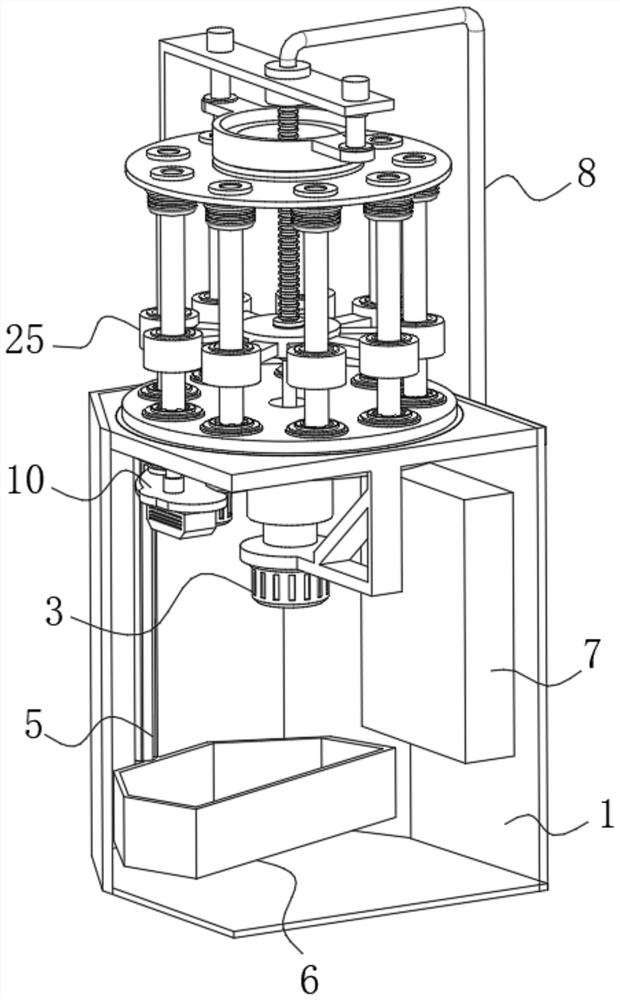

Automatic cleaning device and method for copper mould

InactiveCN103212554AWash thoroughlyAvoid damageDrying gas arrangementsCleaning processes and apparatusEngineeringCopper

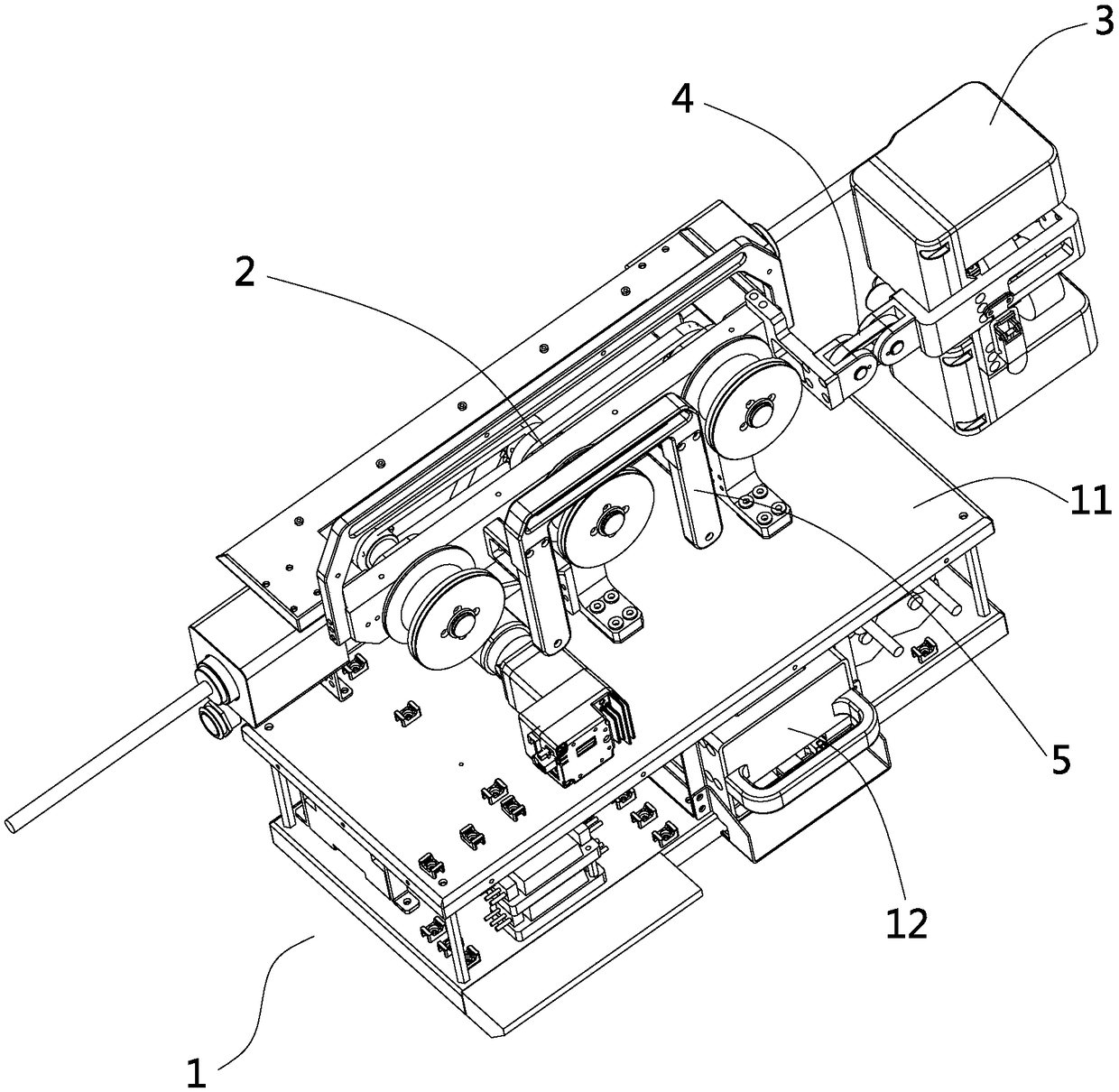

The invention discloses an automatic cleaning device and method for a copper mould. The automatic cleaning device for the copper mould comprises a rack, and a cleaning mechanical arm arranged on the rack, wherein an upper blowing device for blow-drying the upper surface of the copper mould, a cleaning module for cleaning the copper mould, and a drying device for drying the copper mould are integrally arranged on the cleaning mechanical arm; the cleaning mechanical arm also comprises an X-axis transmission part, a Y-axis transmission part and a Z-axis transmission part; and the X-axis transmission part, the Y-axis transmission part and the Z-axis transmission part respectively drive and control the cleaning mechanical arm to move in an X-axis direction, a Y-axis direction and a Z-axis direction. The automatic cleaning device for the copper mould can be used for cleaning the copper mould with a complex curved surface in all directions, and has high drying efficiency and cleaning efficiency, cycle use of cleaning solution is realized, pollution to the environment is reduced, and the cost is reduced.

Owner:深圳市中科创安科技有限公司

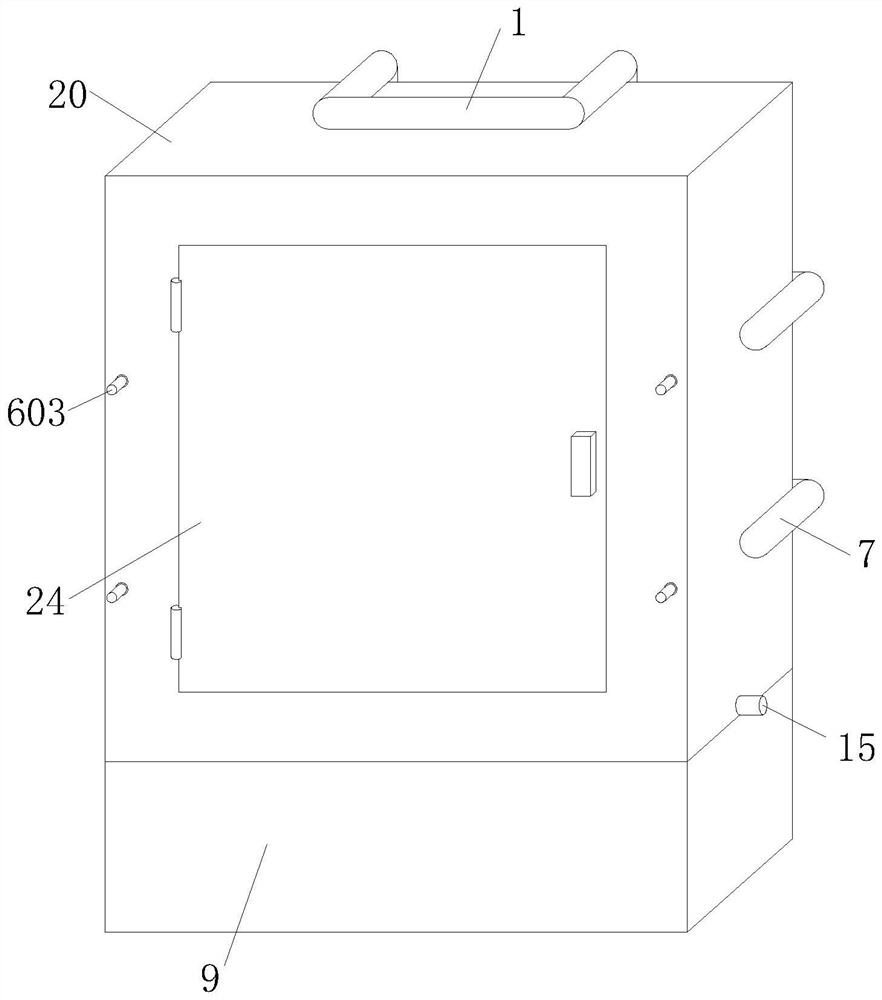

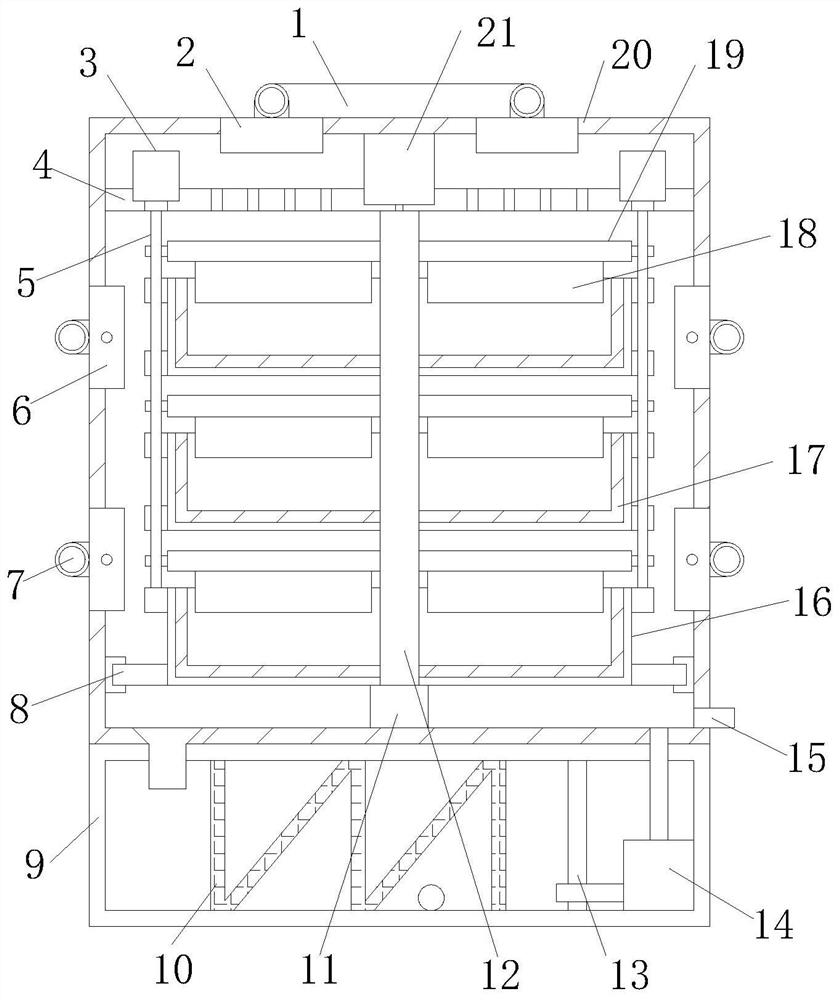

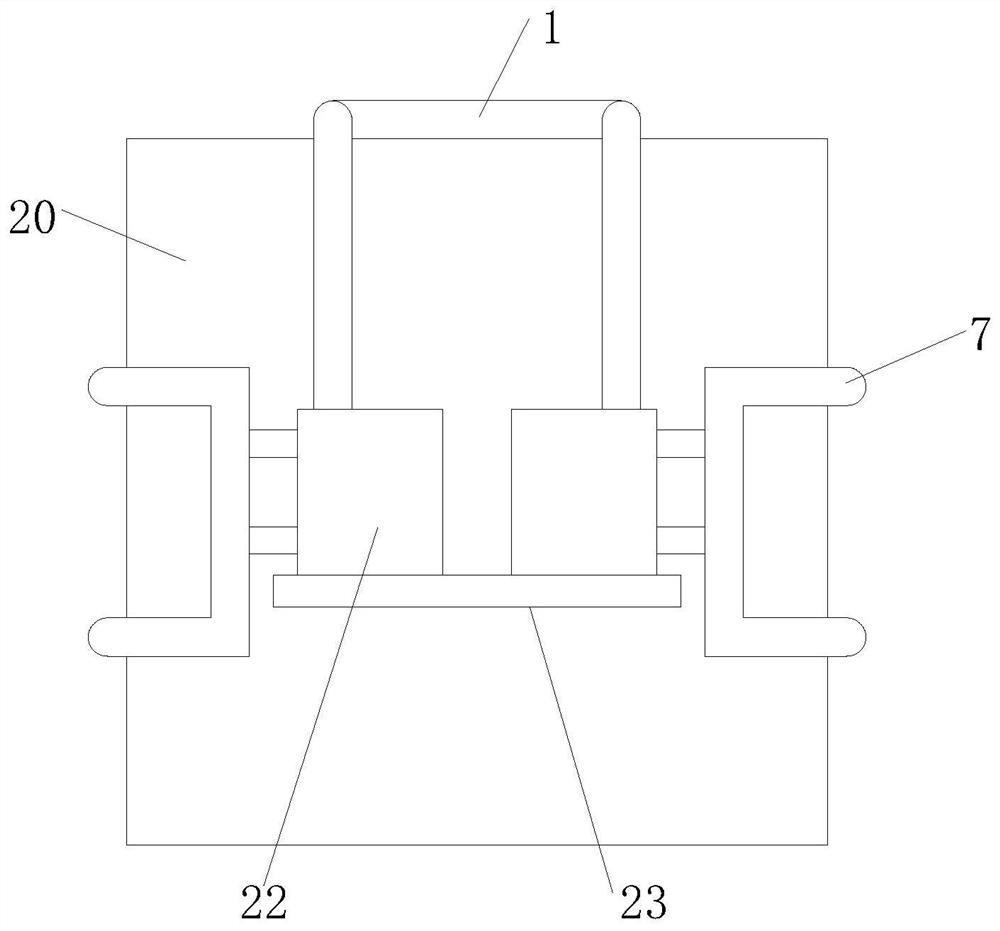

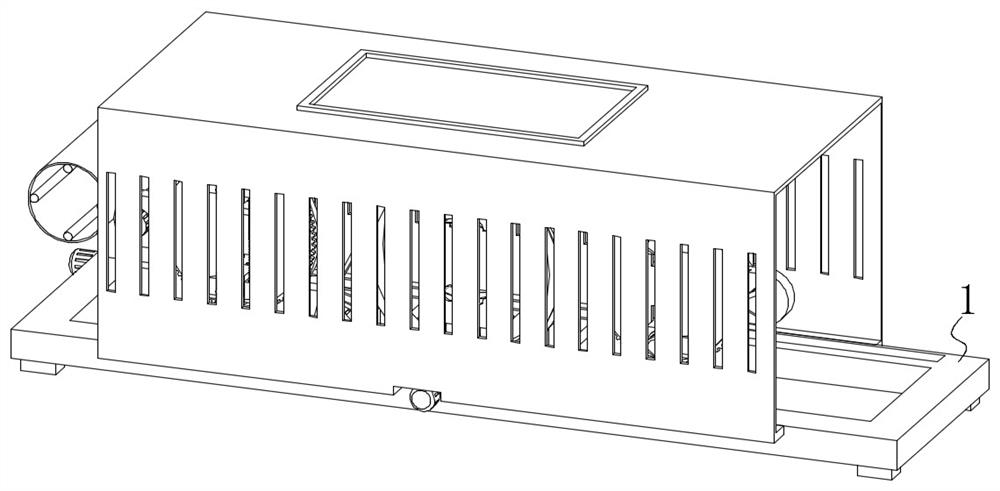

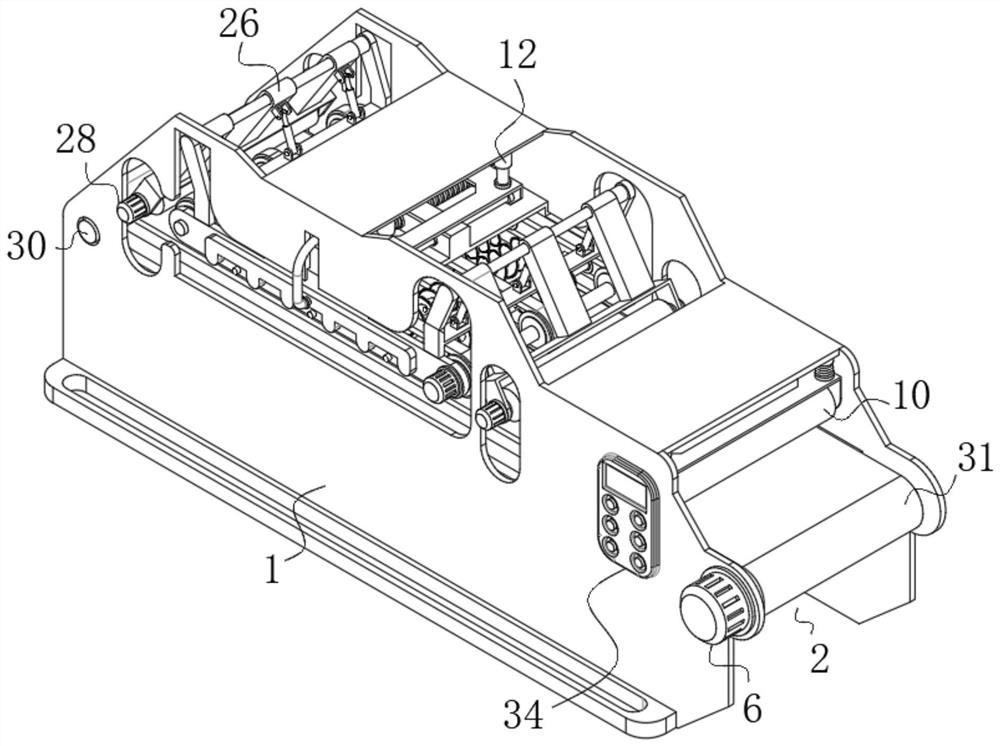

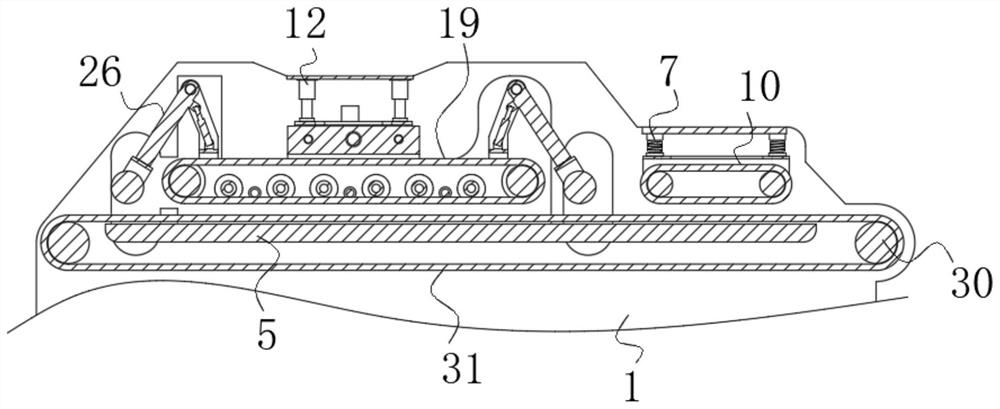

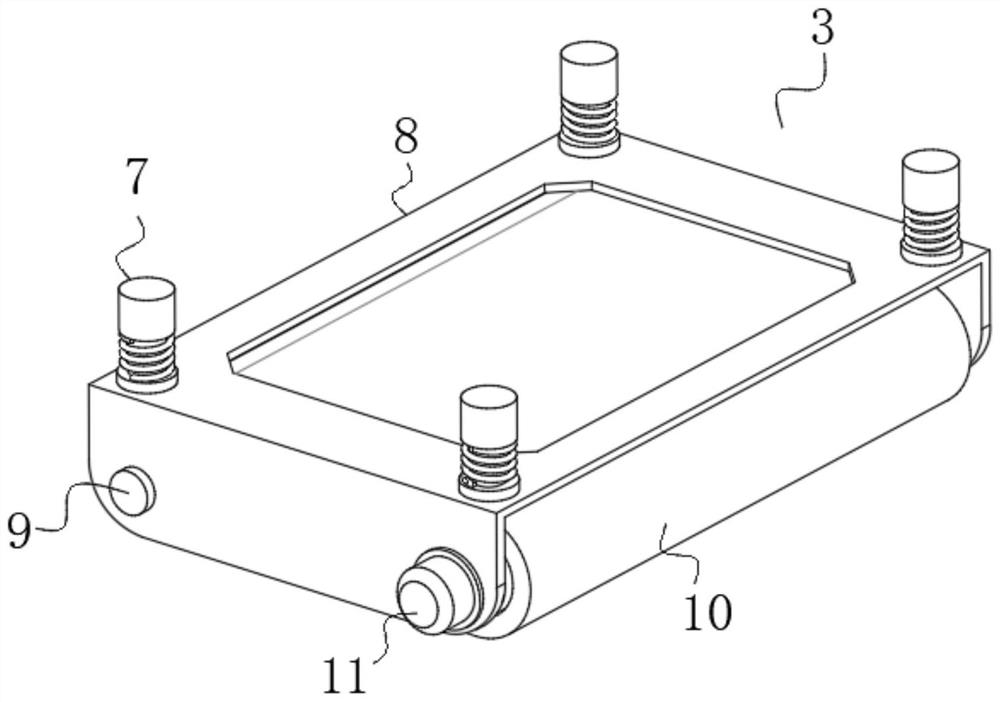

Cleaning, drying, detecting and packing equipment

InactiveCN111921978AImprove turnoverIncreased auto disengagement rateDrying solid materials without heatDrying gas arrangementsElectric machineryStructural engineering

The invention discloses cleaning, drying, detecting and packing equipment and relates to the technical field of packing equipment. The cleaning, drying, detecting and packing equipment comprises two symmetrical bases. The top faces of the two bases are each fixedly connected with a damping buffer part, wherein the damping buffer parts are connected with each other through a connecting rod. The topends of the two damping buffer parts are fixedly connected with a cleaning and drying mechanism. The cleaning and drying mechanism comprises an outer shell. The top ends of the two damping buffer parts are fixedly connected with the outer shell. The surface of the outer shell is fixedly connected with a feeding hopper and a main driving motor through connecting pieces. According to the cleaning,drying, detecting and packing equipment, by means of design of the cleaning and drying mechanism, the device can complete the cleaning and drying process of to-be-packed materials one time in an automated manner; in the cleaning operation process, by means of the design of a vibration motor and an ultrasonic transducer, a water body can generate violent oscillation; and the oscillation effect of the water body is achieved, on one hand, the flow rate of the materials can be increased, and on the other hand, the automatic separation rate of stains on the surfaces of the materials can be effectively increased.

Owner:马鞍山金瓦格机械科技有限公司

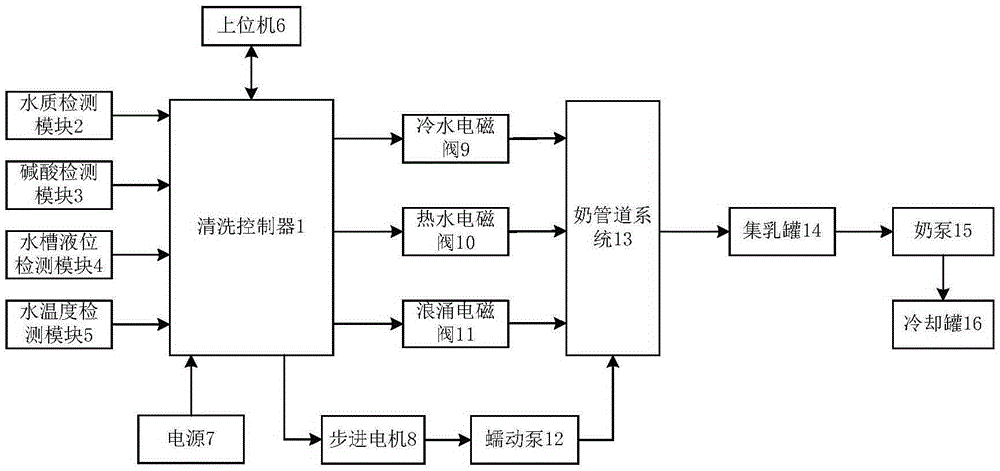

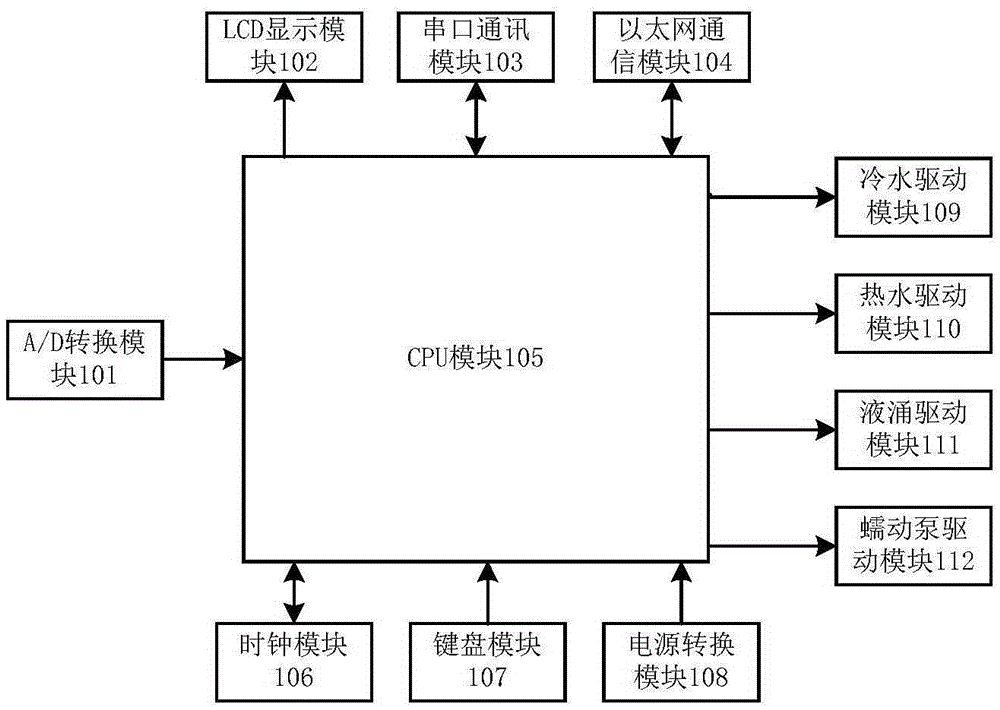

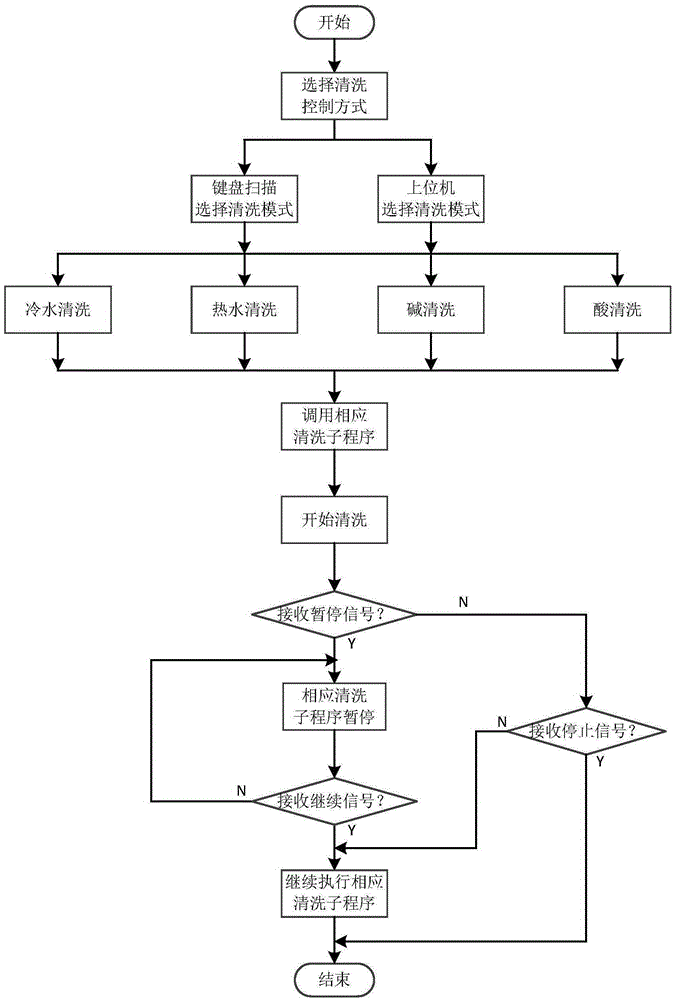

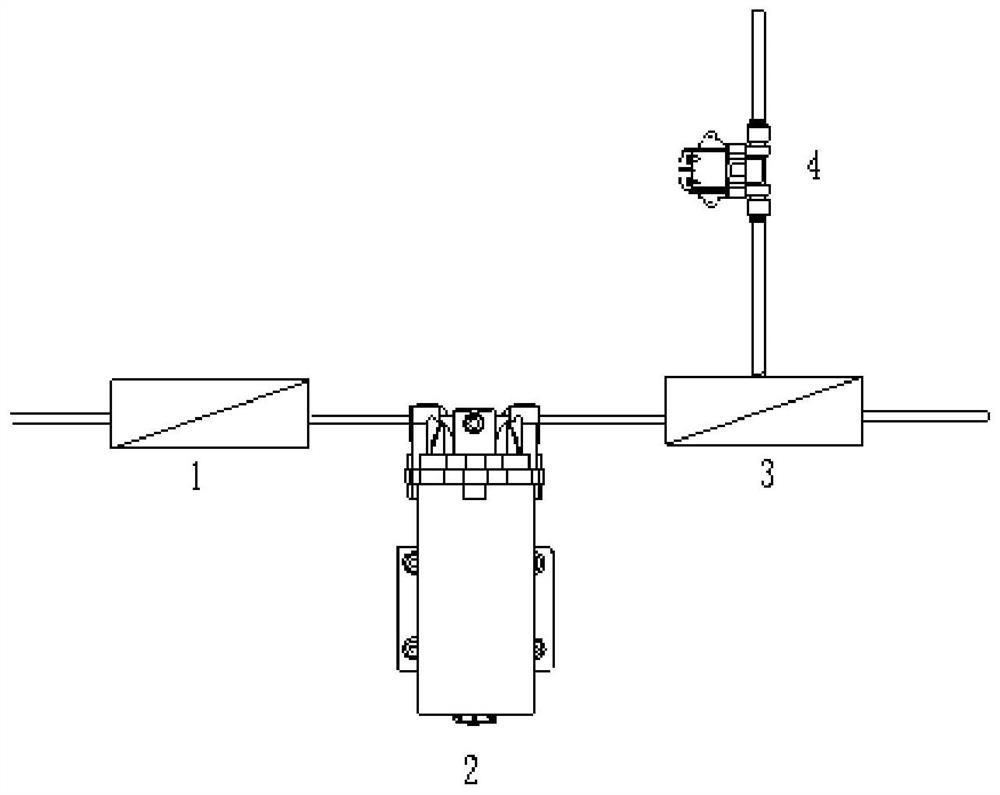

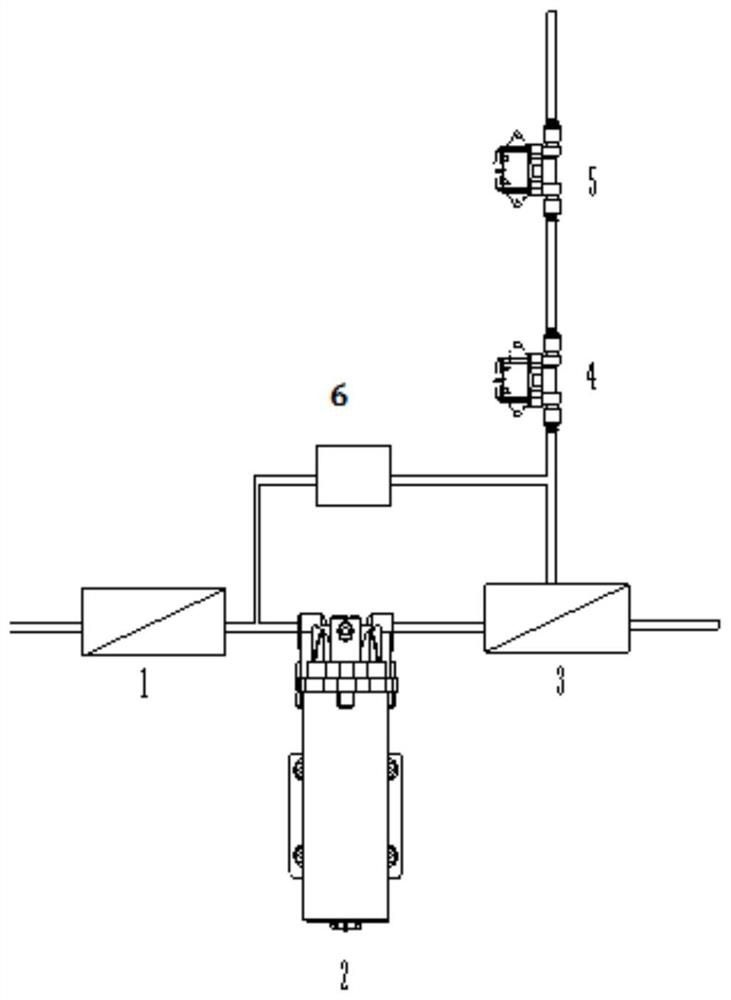

Full-automatic detection cleaning controller for milking machine, and control method of full-automatic detection cleaning controller

InactiveCN105353810ACheck cleaning qualityImprove cleaning qualitySimultaneous control of multiple variablesMilking devicesEngineeringThermal water

Aiming at the effective cleaning of milking equipment before and after milking, the invention provides a controller, and the controller has a function of automatic detection of cleaning quality, has a function of memorizing a characteristic programmable mode, has adjustable parameters, has functions of automatic detection, quick and convenient checking and communication with an upper computer, employs a surge cleaning mode, and has modes: cold water cleaning, hot water cleaning, alkali cleaning and acid cleaning. After cleaning, a system automatically cuts off the power, and the mode can be called as a one-key cleaning mode. The controller is suitable for various types of milking equipment, can improve the cleaning quality of the milking equipment and the quality of raw milk, can alleviate the labor intensity of a worker, reduces the unnecessary cleaning time, and saves the energy.

Owner:CHINA AGRI UNIV

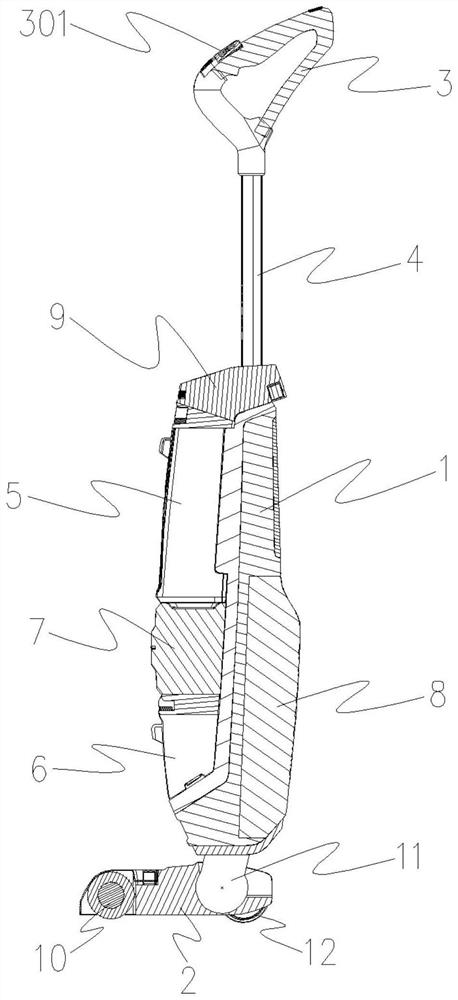

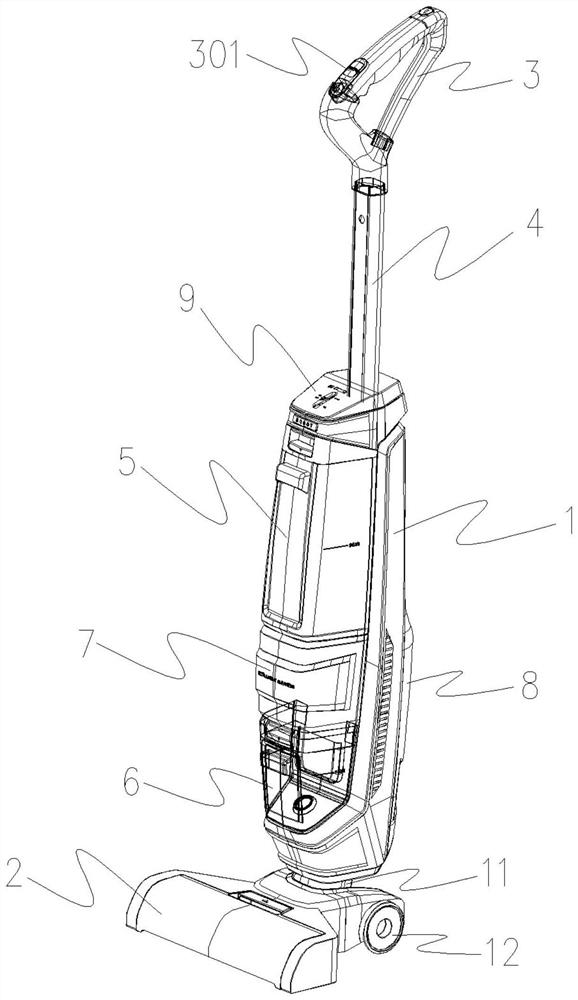

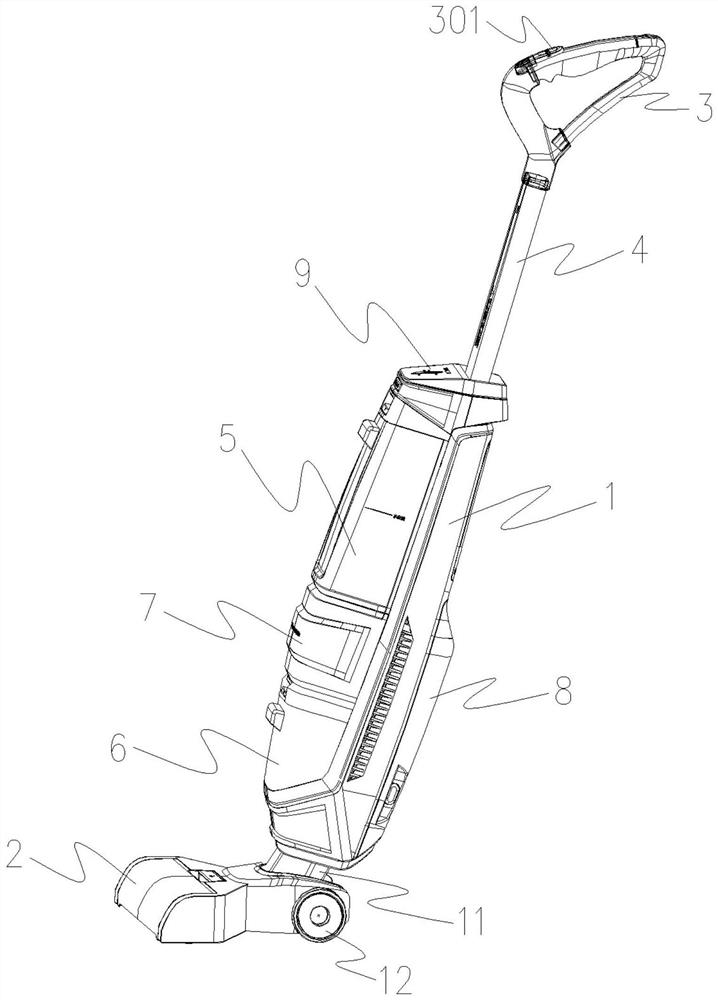

Household floor cleaning device

PendingCN112493940AEasy to view in real timeEasy to operateCarpet cleanersFloor cleanersHome useSewage

The invention relates to a household floor cleaning device which comprises a body, a cleaning head assembly, a handle assembly and a connecting rod, the cleaning head assembly is connected with the body, the handle assembly is connected with the body through the connecting rod, the body is provided with a clear water tank and a sewage tank, the sewage tank is located above the clear water tank, the clear water tank is configured to provide clear water, the sewage tank is configured to recover sewage, and the gravity center of the household floor cleaning device is gradually raised in the cleaning process. According to the household floor cleaning device, the gravity center of the household floor cleaning device is located at the lower position before cleaning is started, user operation isquite easy, no load bearing feeling exists, a user can observe the dirt degree of floor in time through the clear water tank, the water spraying amount and the cleaning strength are increased according to the actual situation, the problem of repeated cleaning caused by insufficient cleaning degree is solved, and a user can check the condition in the sewage tank in real time, so that the user experience is greatly enhanced.

Owner:SENKEINO TECH CO LTD

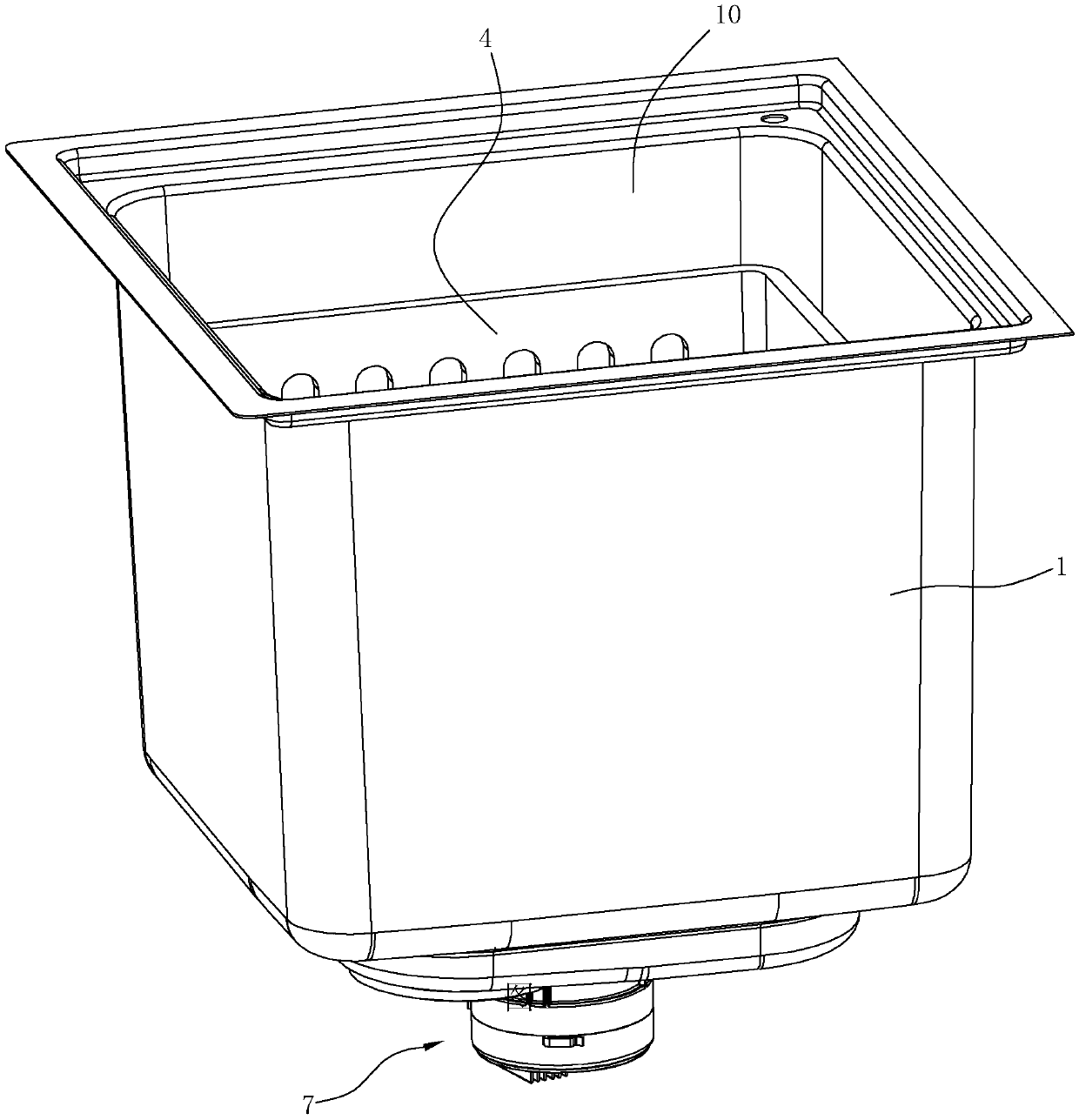

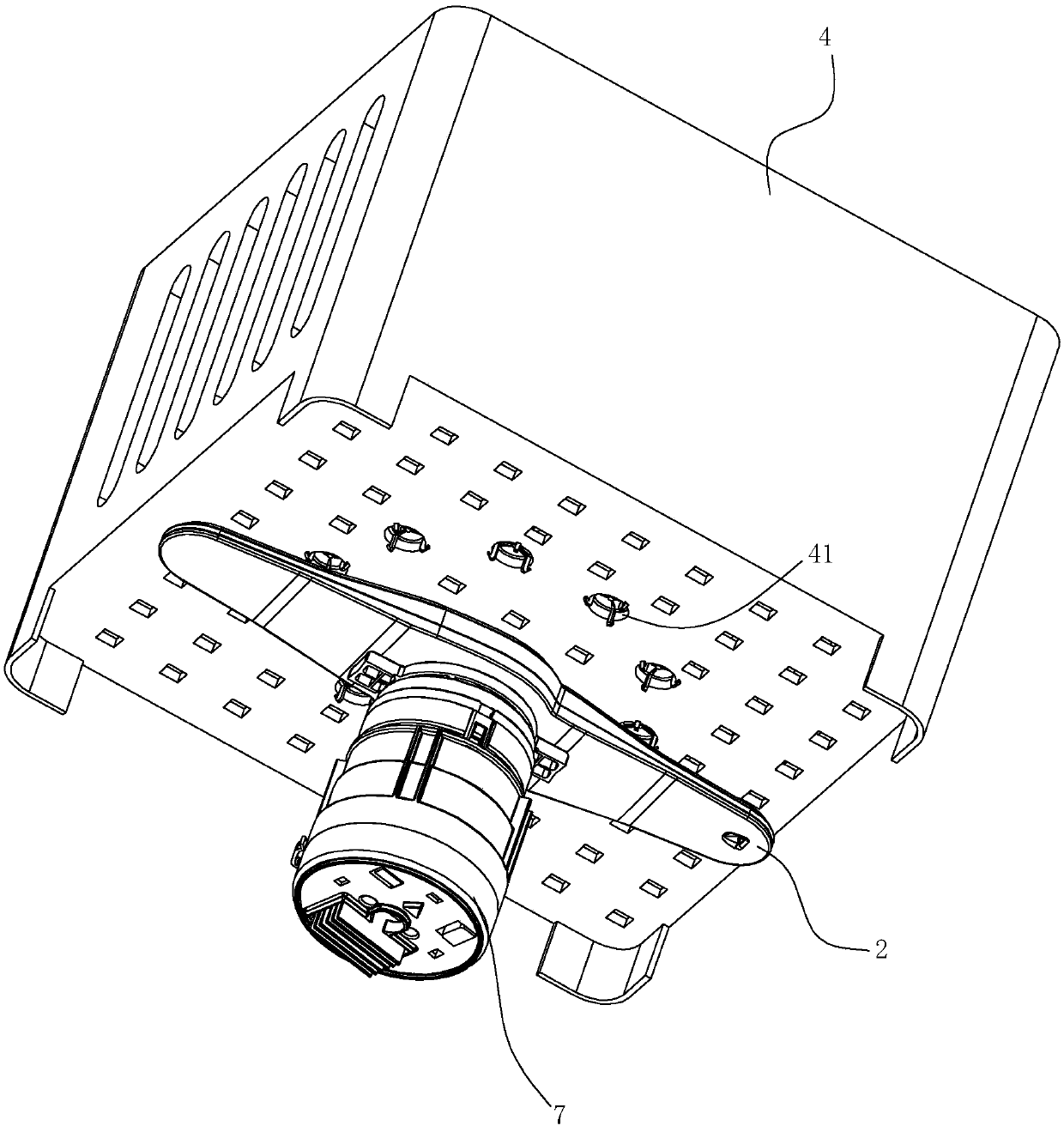

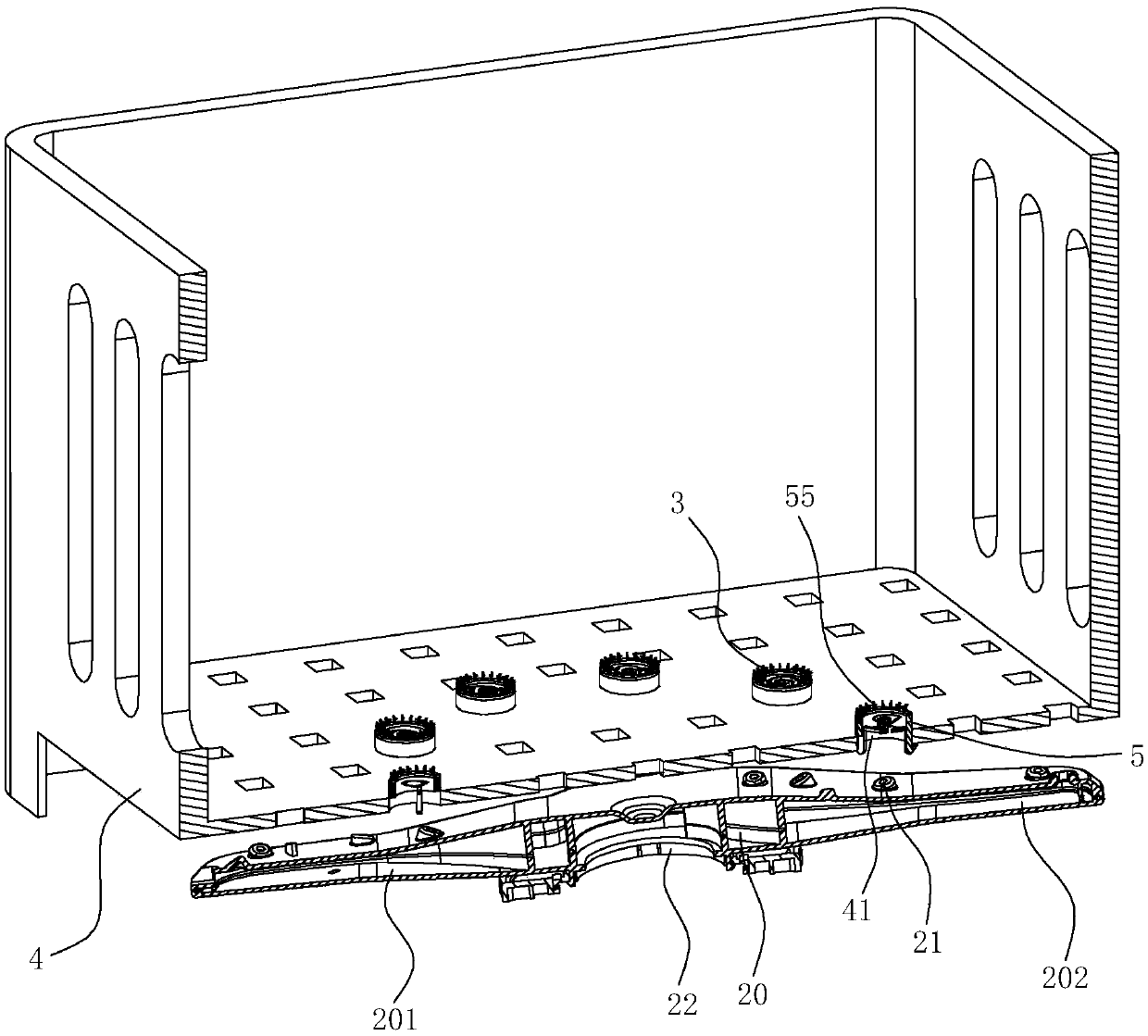

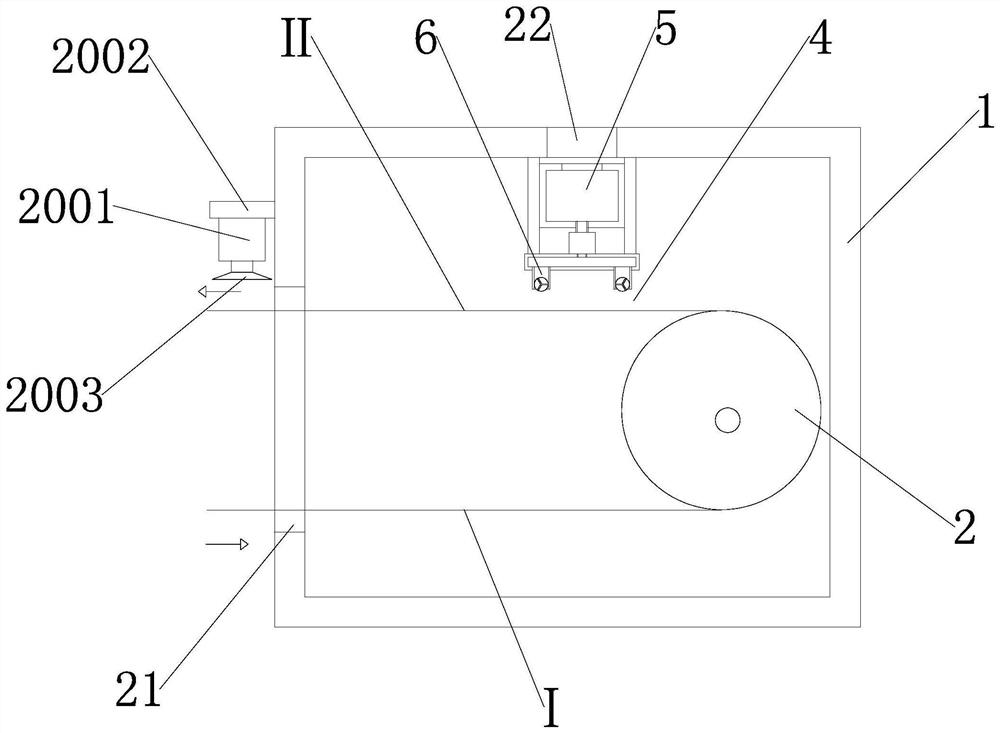

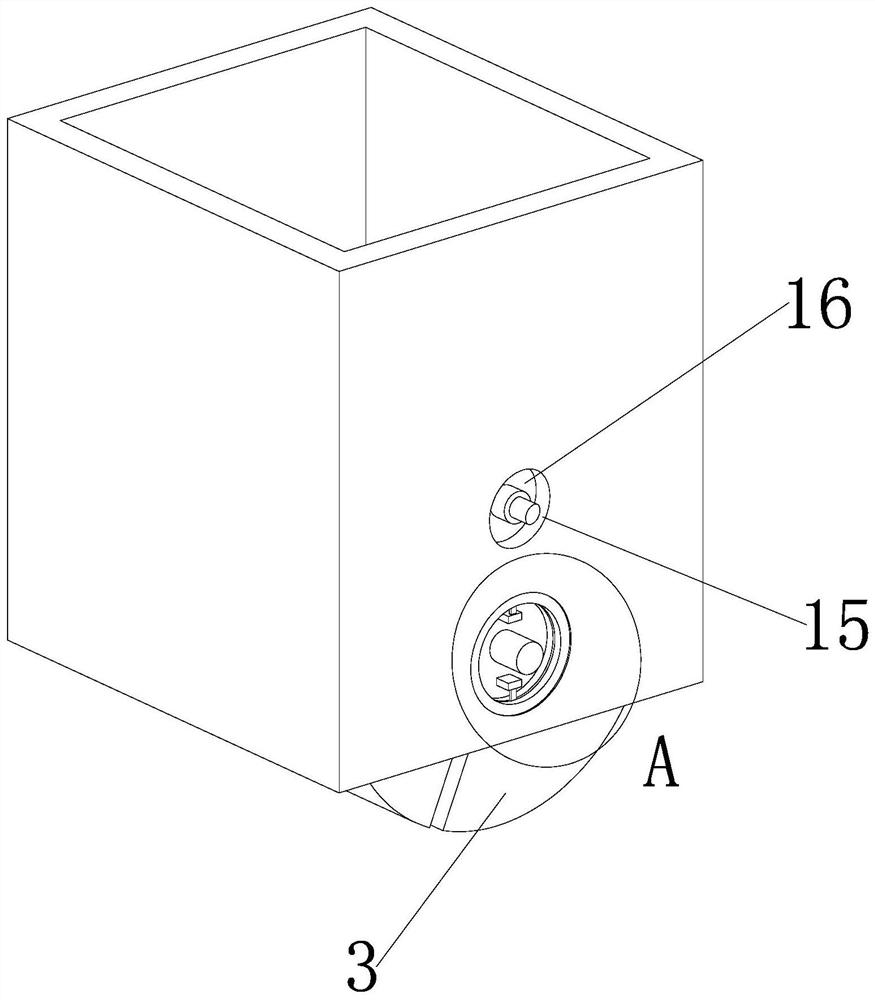

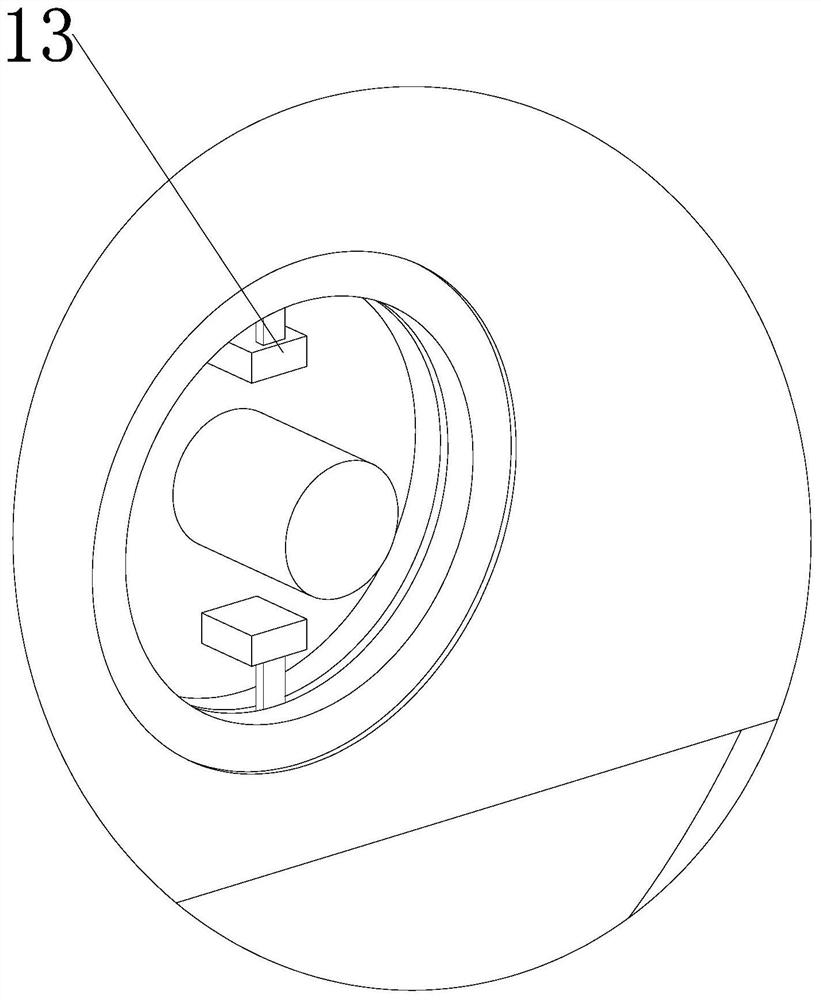

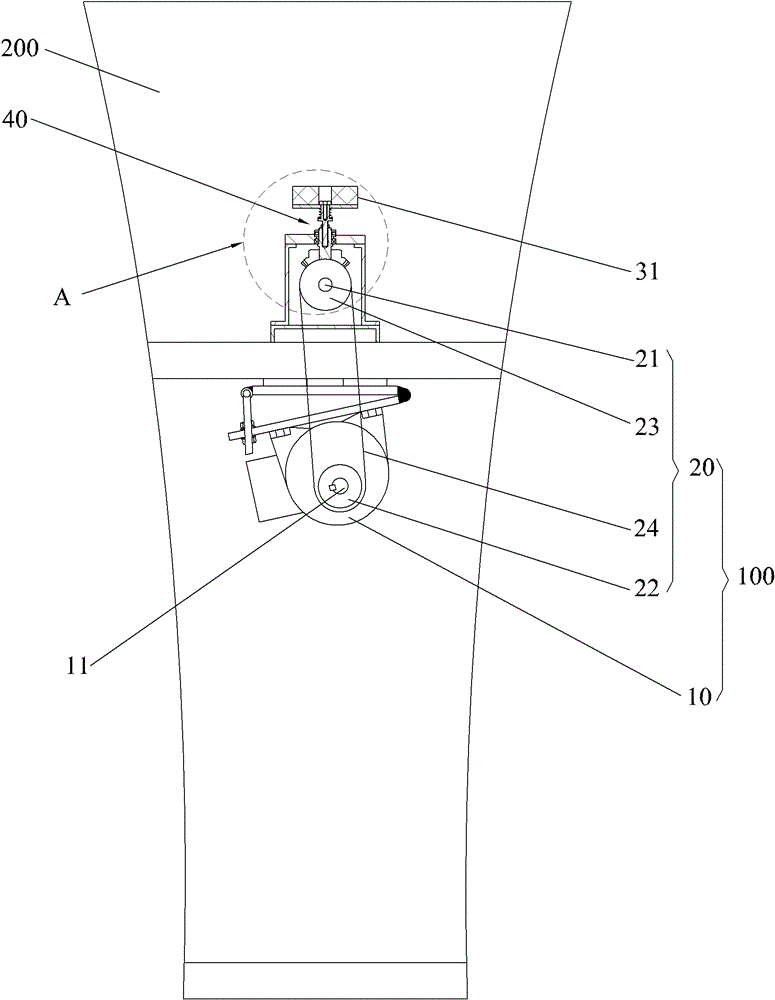

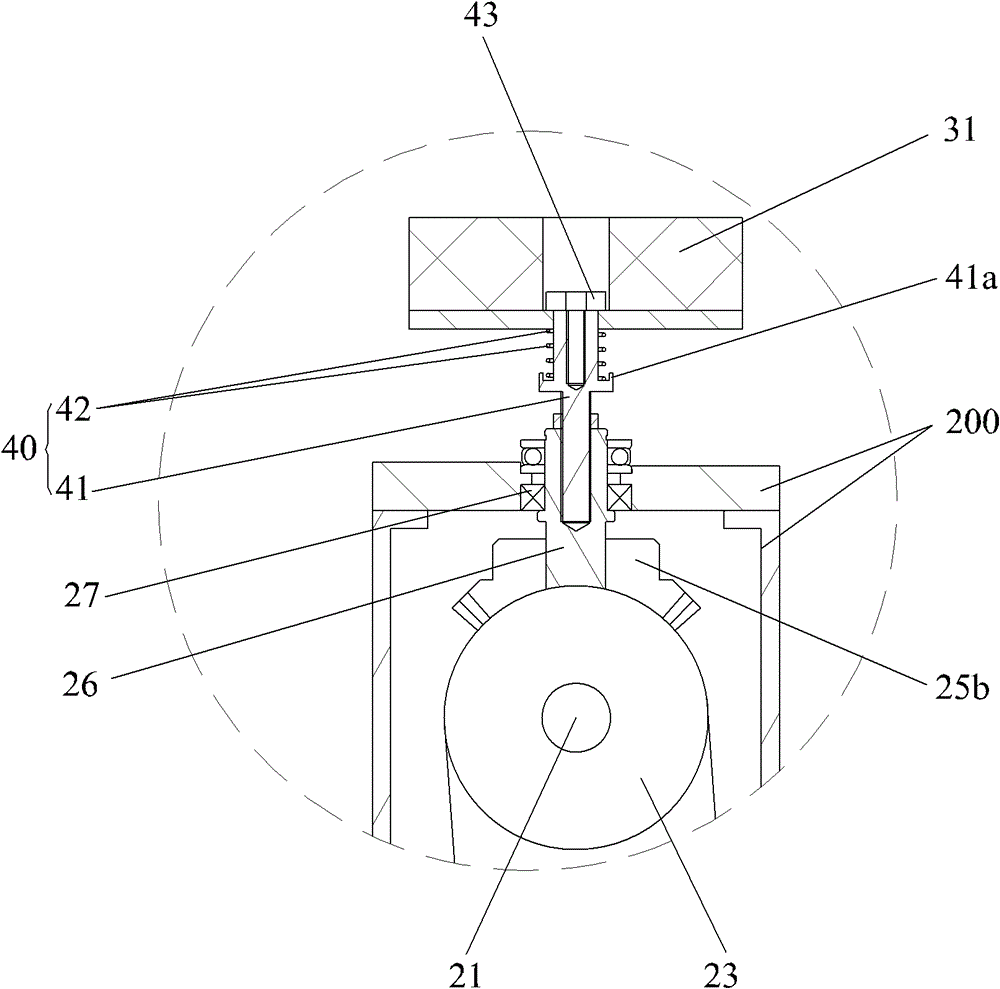

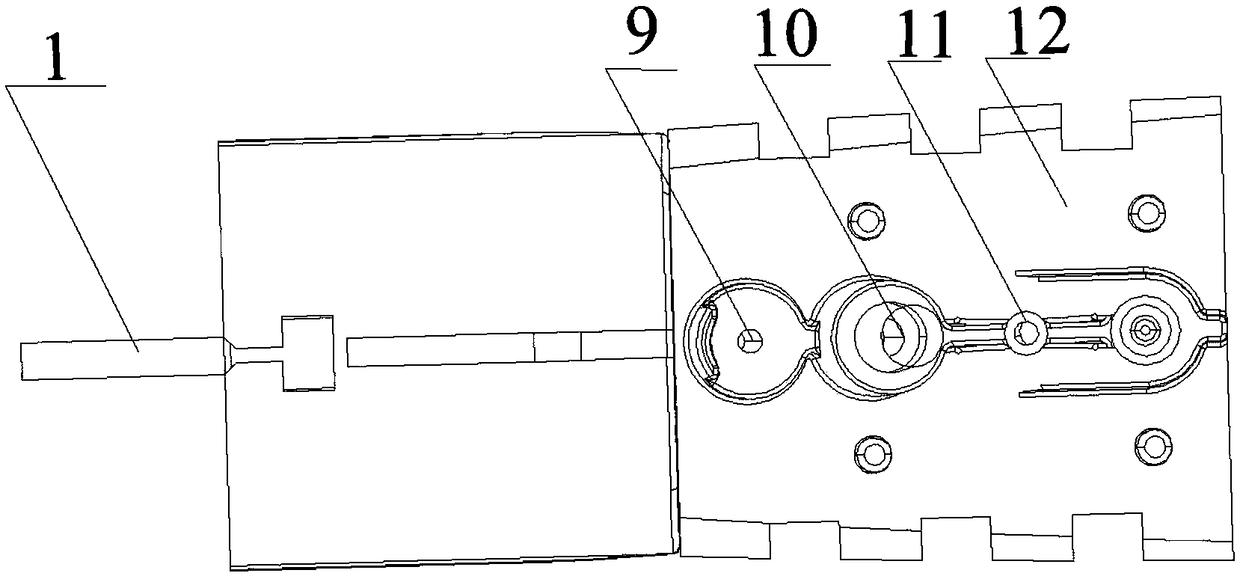

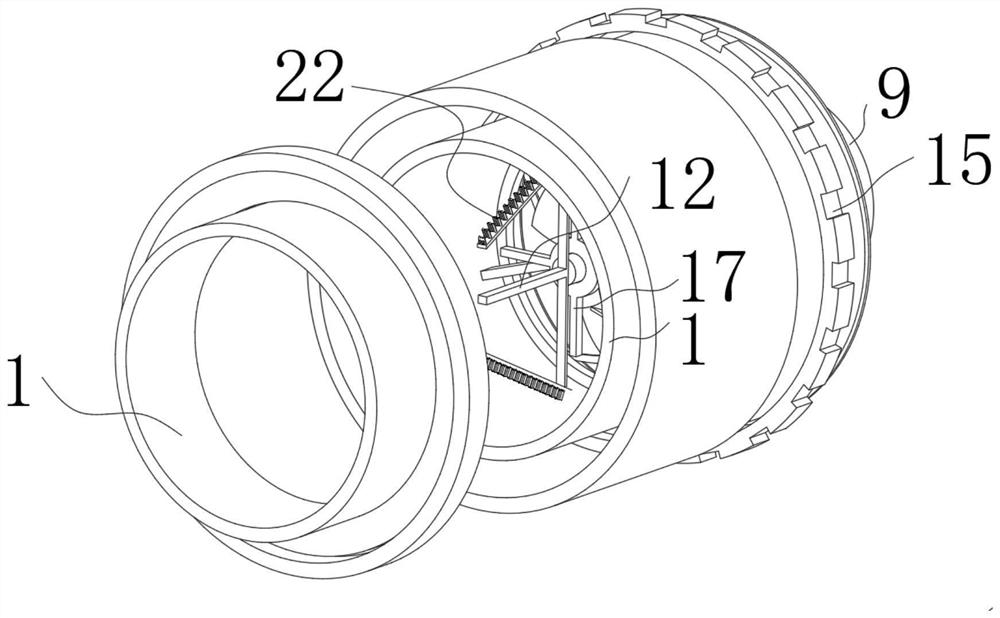

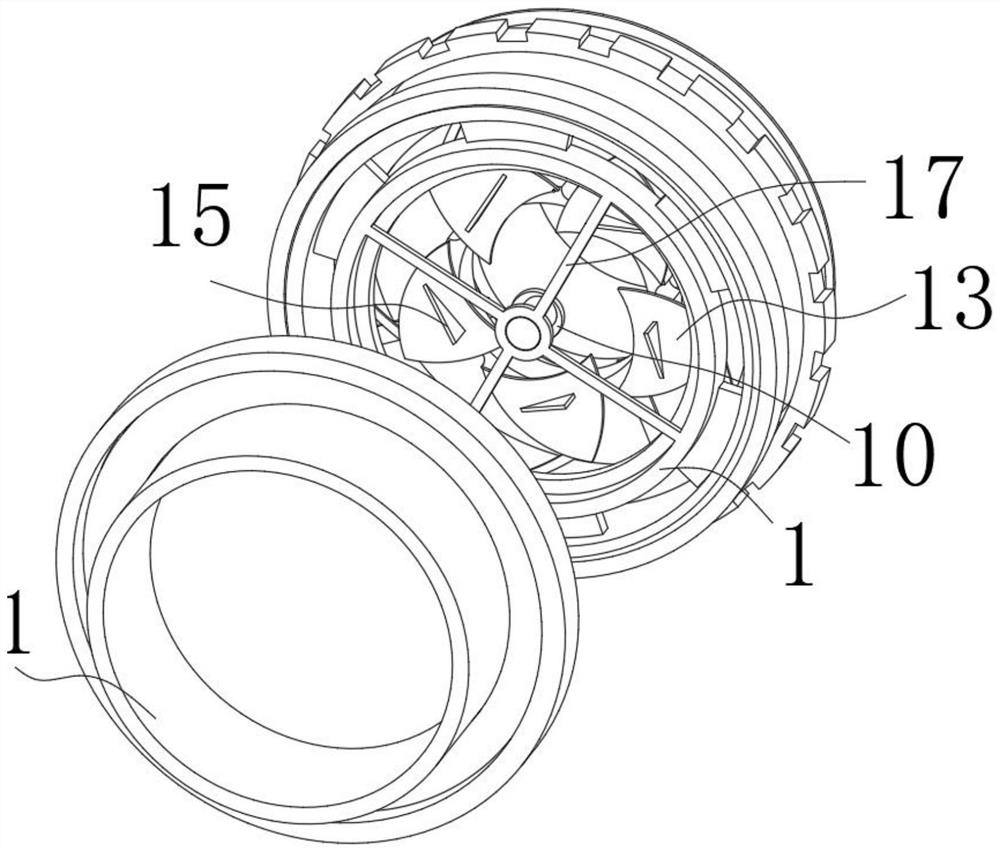

Cleaning machine

PendingCN109965815AIncrease cleaning strengthImprove cleaning effectTableware washing/rinsing machine detailsImpellerEngineering

The invention relates to a cleaning machine which comprises a box body, a spraying arm and a cleaning basket used for containing fruit and vegetables or bowls and dishes, wherein the spraying arm is rotationally arranged in the box body; water outlet holes through which waterflow is sprayed out are formed in the spraying arm; the cleaning basket is arranged in the box body and is positioned abovethe spraying arm; through holes communicating with an inner cavity of the cleaning basket are formed in the bottom of the cleaning basket; each through hole corresponds to any one water outlet hole formed in the spraying arm; and an impeller capable of rotating under the impact effect of the waterflow sprayed out from the water outlet holes is formed in the through hole. The through holes arrangedin a way of corresponding to the water outlet holes are formed in the bottom of the cleaning basket; the impeller is arranged in the through hole; in the use process, the spraying arm rotates to a position until the water outlet hole is aligned with the through hole, the waterflow sprayed out from the through hole impacts the impeller and is ejected into the cleaning basket; the waterflow can directly flush the bowls and dishes or fruit and vegetables in the cleaning basket; the impeller rotates under the impact effect of the waterflow; turbulent flow is formed in a small range region corresponding to the impeller; the cleaning intensity of the waterflow on the fruit and vegetables or bowls and dishes is enhanced; and the cleaning effect is improved.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Textile cloth cleaning device

ActiveCN112709020AIncrease the cleaning areaImprove cleanlinessLiquid/gas/vapor removal by gas jetsTextile treatment by spraying/projectingWater flowMechanical engineering

In order to solve the technical problem that in the prior art, a cleaning device with the fixed water outlet angle of a spray head cannot effectively remove dirt on the surface of textile cloth, a textile cloth cleaning device is provided. The textile cloth cleaning device comprises a shell; a tightening cylinder and a flushing mechanism are arranged in the shell; a spraying gap exists between the flushing mechanism and the textile cloth; the flushing mechanism comprises a water supply assembly and a water spraying assembly; the water supply assembly comprises a water tank and a water pump; the water spraying assembly comprises a spraying head pipe and a spraying head; the spraying head comprises a body and a water spraying flow channel; the water spraying flow channel comprises a water inlet flow channel and a water outlet flow channel; one end of the water inlet flow channel communicates with the spray head pipe, and the other end of the water inlet flow channel communicates with one end of the water outlet flow channel; the other end of the water outlet flow channel faces the textile fabric; the water pump conveys cleaning liquid in the water tank into the spray head pipe, and the cleaning liquid in the spray head pipe only flows outwards along the water spraying flow channel; and a driving assembly for driving the spray head to rotate is arranged on the spray head pipe. Multiple times of repeated sweeping and cleaning of the cloth in the same water outlet period can be achieved through the single spray head.

Owner:SHAOXING UNIV YUANPEI COLLEGE

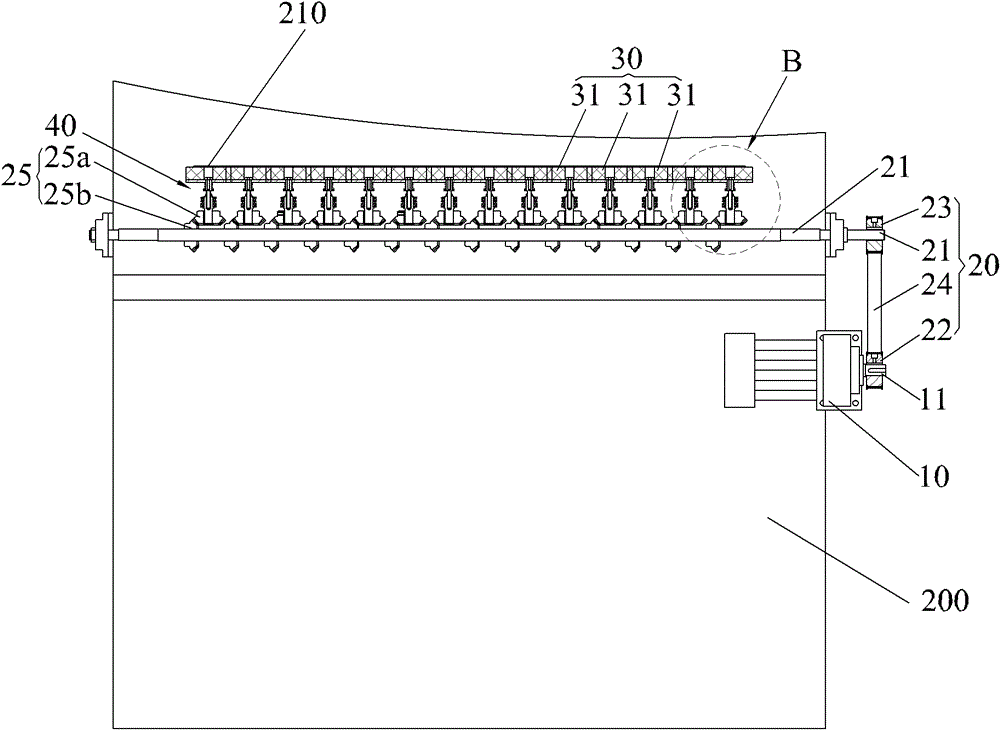

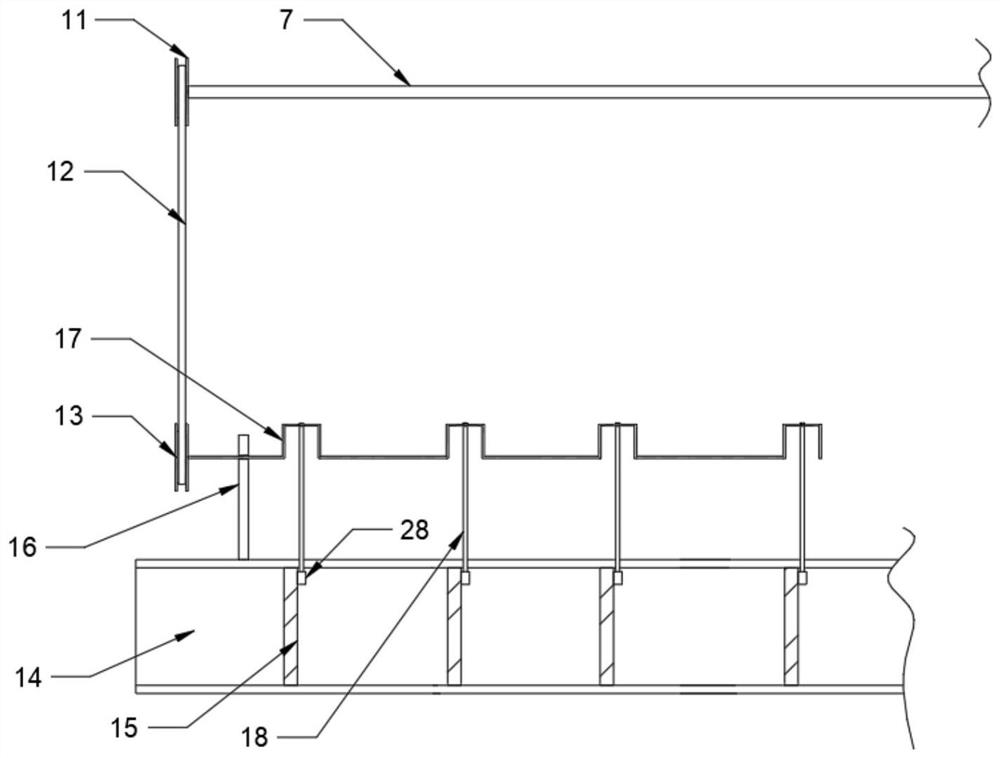

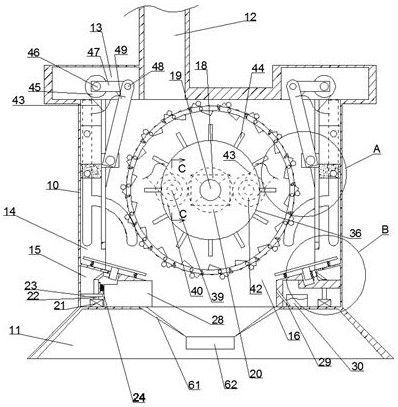

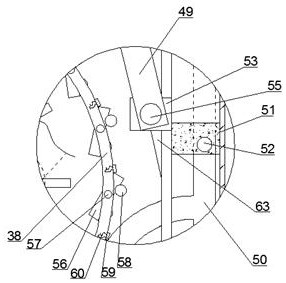

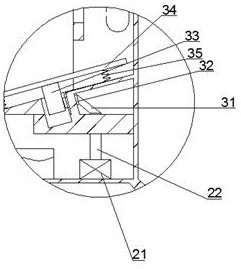

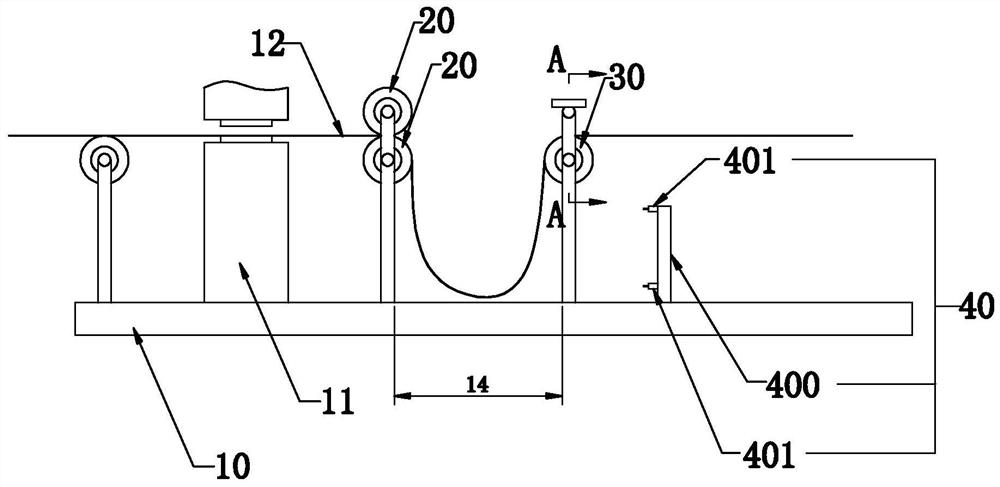

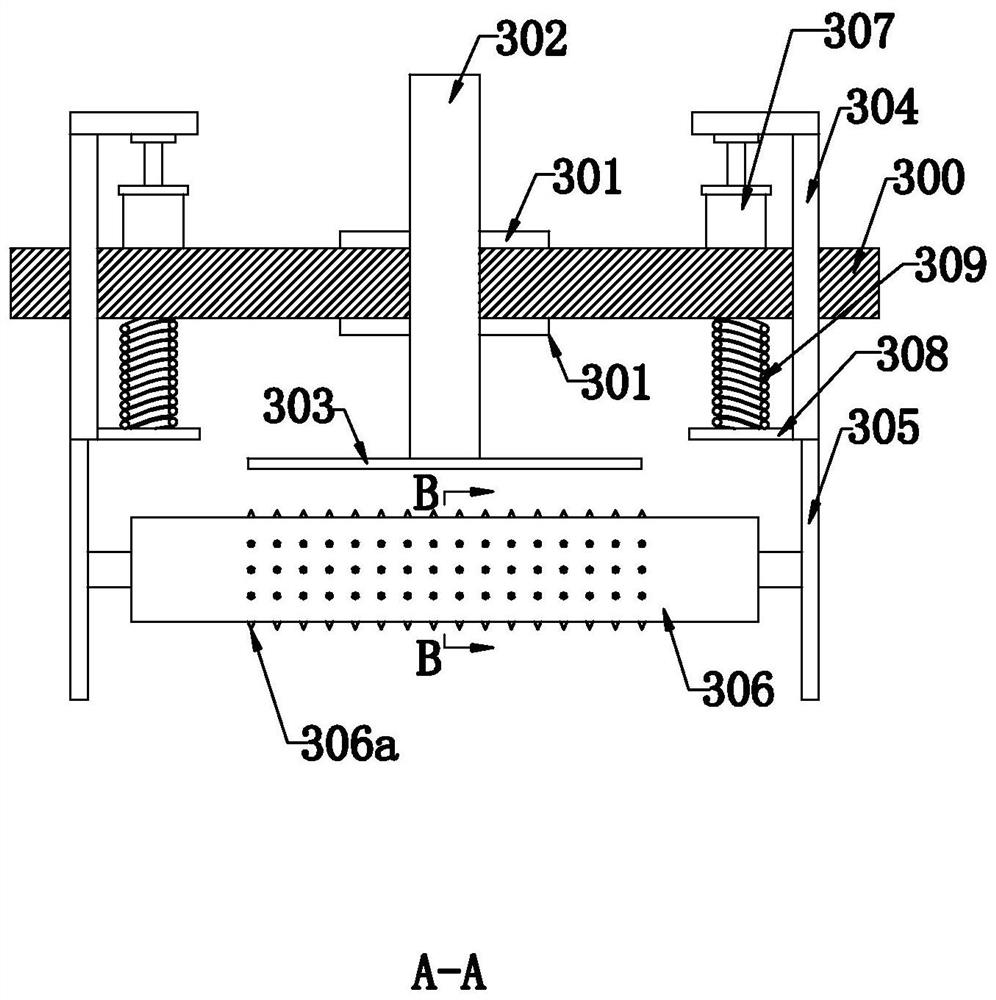

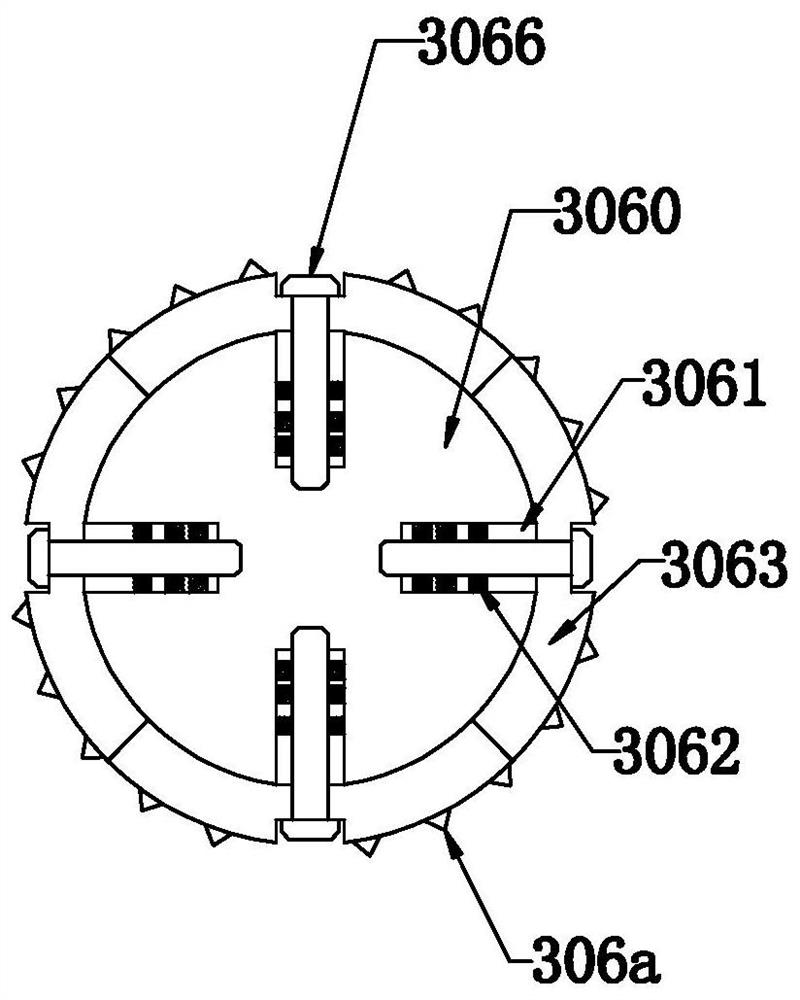

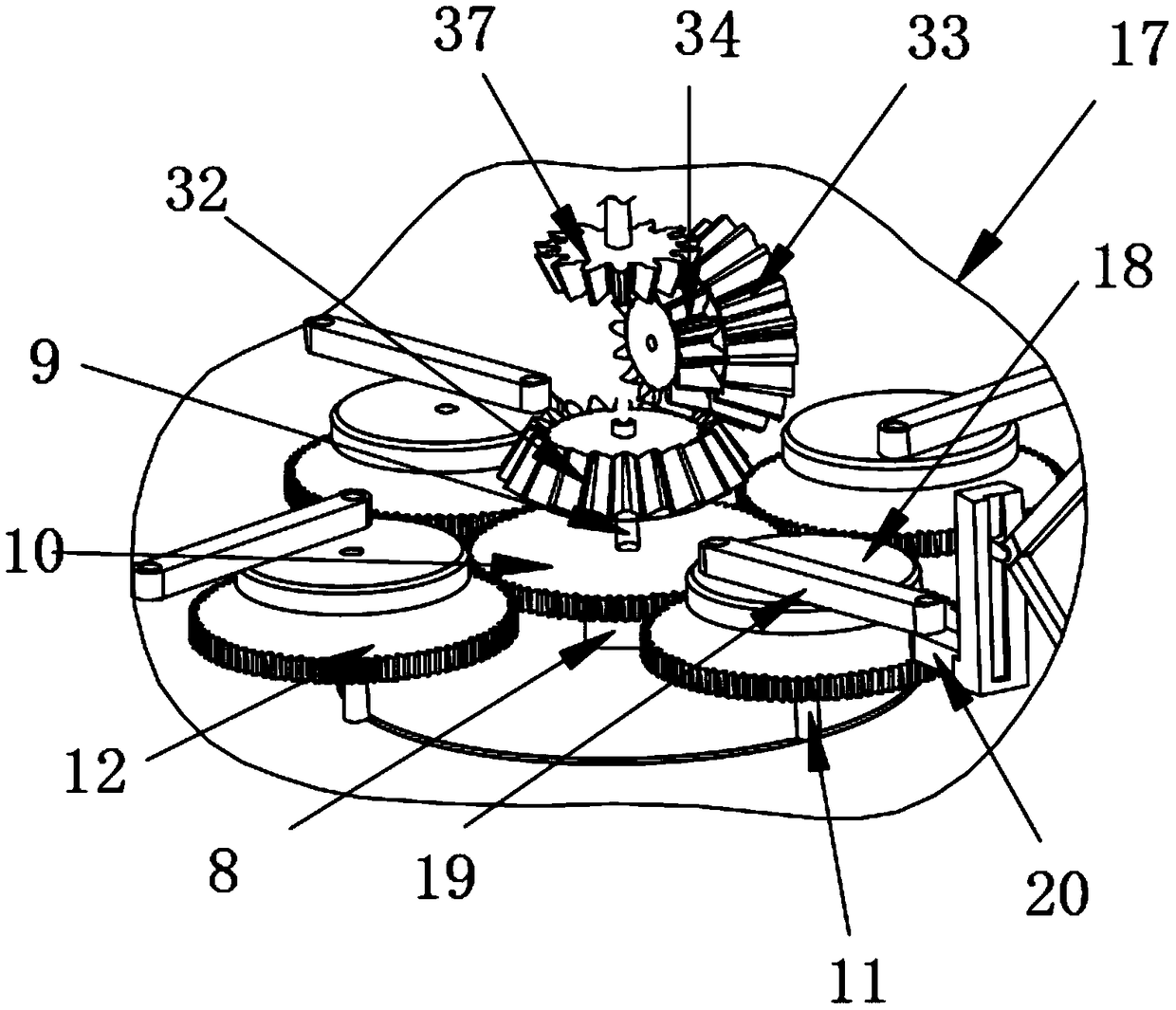

Cleaning and polishing mechanism and cleaning and polishing system

InactiveCN102716882AIncrease contact areaIncrease cleaning strengthFlexible article cleaningPlane surface grinding machinesEngineeringCoating

The invention discloses a cleaning and polishing mechanism which is installed on a delivery track and is used for cleaning and polishing film coated glass delivered by the delivery track The cleaning and polishing mechanism comprises a cleaning and polishing driver, an intermediate delivery component and a plurality of plate brushes; the plate brushes are arranged in a row shape along the crossed direction for the delivery track to deliver the film coated glass so as to form a plate brush row; the plate brush row stretches across the film coated glass delivered by the delivery track; also the plate brushes are rotatably pivoted on the delivery track along the vertical direction and are connected with one end of the intermediate delivery component; the intermediate delivery component is arranged on the delivery track, and the other end of the intermediate delivery component is connected with the cleaning and polishing driver; the cleaning and polishing driver is arranged on the delivery track; and the cleaning and polishing driver drives the plate brushes to rotate through the intermediate delivery component, and further enables the plate brushes to clean and polish the film coated glass delivered by the delivery track. The cleaning and polishing mechanism provided by the invention can improve the cleaning effect of the film coated glass and can polish the film coated glass, thus a favorable condition is created for the subsequent technology process of the film coated glass.

Owner:DONGGUAN ANWELL DIGITAL MASCH CO LTD

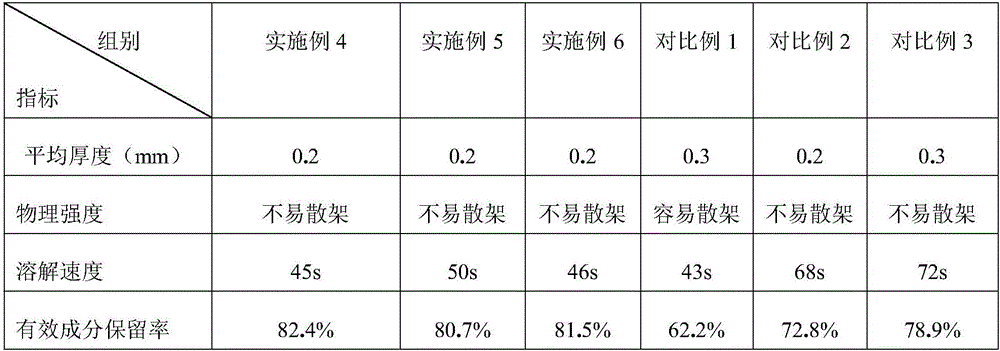

Soluble cleansing paper with deep cleaning effect and preparation method thereof

ActiveCN106667795AReduce volumeEasy to carryCosmetic preparationsToilet preparationsNatural materialClean water

The invention belongs to the field of cosmetics, and particularly relates to soluble cleansing paper with deep cleaning effect and a preparation method thereof. The invention adopts soluble anionic starch and cation nano microcrystalline cellulose as a carrier to prepare the soluble cleansing paper, and the soluble cleansing paper is prepared from natural materials and has the advantages of being small in volume, convenient to carry, rapid in dissolving speed, good in cleaning effect. The soluble cleansing paper has the thickness of only 0.2 to 0.3mm and a wide application prospect, the cleansing paper can be just dissolved with clean water when being used, and the face is not tight after cleaning.

Owner:广州同康生物科技有限公司

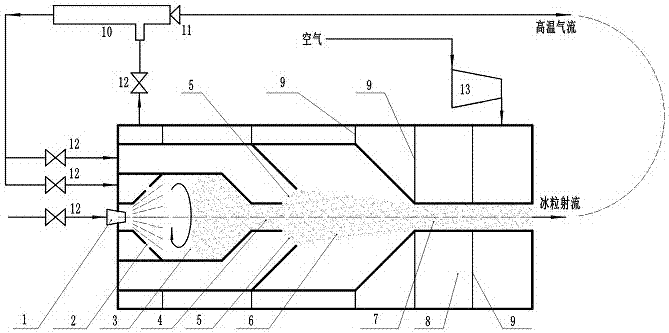

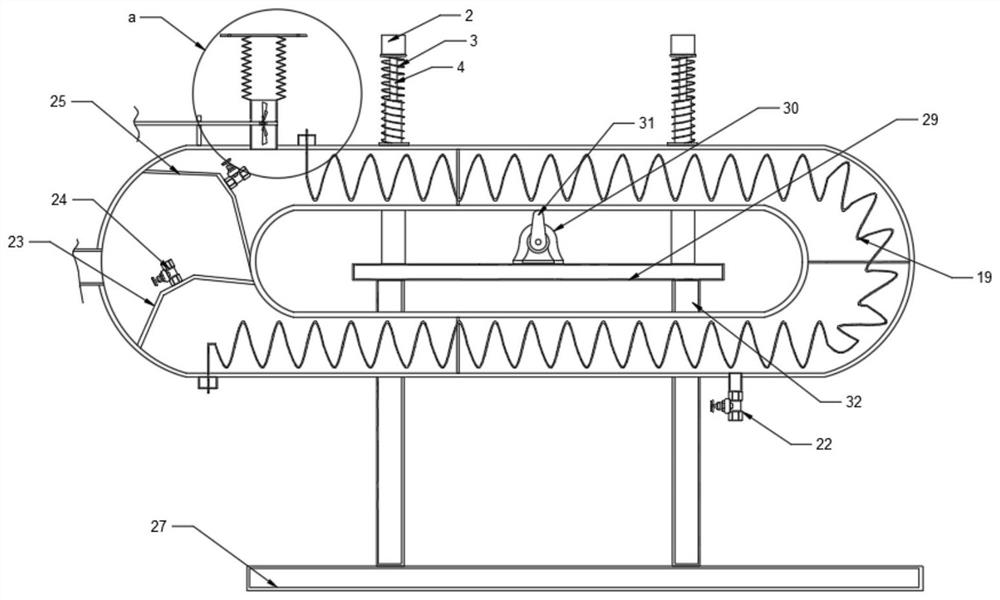

Continuous ice particle jet flow washing device based on vortex tube

InactiveCN107270767AGuaranteed generation speedGuaranteed setting strengthFood processingIce productionEngineeringCooling capacity

The invention provides a continuous ice particle jet flow washing device based on a vortex tube. The continuous ice particle jet flow washing device based on a vortex tube mainly comprises an atomizing nozzle, a swirl nozzle, an ice making chamber, a hollow tube, a hollow circulation nozzle, a mixing chamber, an ice particle jet flow nozzle, a pre-cooling cavity, the vortex tube and the like. The continuous ice particle jet flow washing device carries out refrigeration through the vortex tube and is simple in structure, small in volume, low in weight and convenient to use. Ice particle jet flow and high-temperature airflow alternately spray a heat dissipation surface, and online washing is completed. Water is atomized through the atomizing nozzle to form water drops, the swirl nozzle carries out swirl mixing in the ice making chamber to form ice particles in a freezing manner, through the jetting, entrainment and mixing effects of the hollow circulation nozzle, the ice particles are further frozen and shaped in the mixing chamber, the strength of the ice particles is high, and the ice particle jet flow is sprayed through the ice particle jet flow nozzle. The pre-cooling chamber carries out pre-cooling to reduce the temperature, recovers the cooling capacity and reduces and eliminates low-temperature air flow heat loss, and energy sources are saved. The system can be applied to various surface washing and treating occasions, especially to finned radiators.

Owner:QINGDAO UNIV

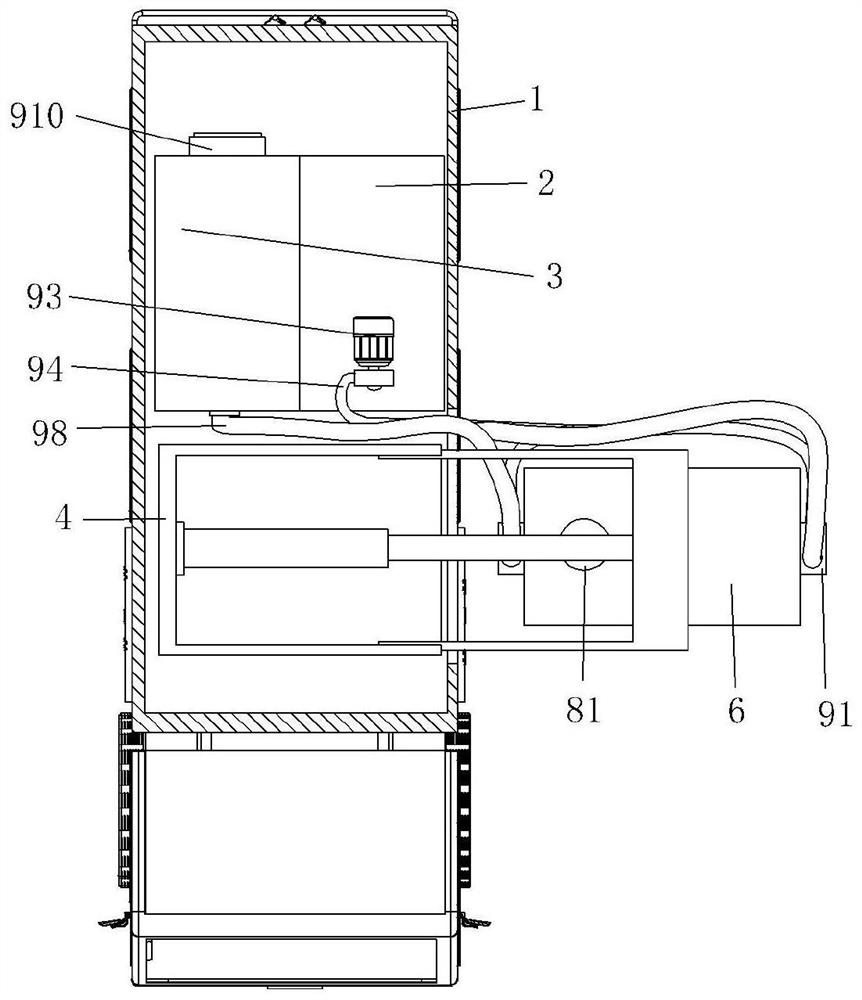

Automatic cleaning device for elevator drive part

InactiveCN102950125AReduce harmImprove carrying capacityCleaning using liquidsWater savingHydraulic cylinder

The invention relates to an automatic cleaning device for an elevator drive part. The automatic cleaning device comprises a bearing support component, a control module, a cleaning shell, a supporting base, a lifting door, a spray component and a hydraulic cylinder, the bearing support component and the cleaning shell are arranged on the supporting base, the elevator drive part is arranged on the bearing support component, the lifting door and the cleaning shell are in slide connection, the hydraulic cylinder and the lifting door are in transmission connection, the spray component is arranged in the cleaning shell, and a control module is connected with the bearing support component, the hydraulic cylinder and the spray component. Compared with the prior art, the automatic cleaning device for the elevator drive part has the advantages of high cleaning intensity, environmental protection, water saving and the like.

Owner:SHANGHAI LONGYU ELEVATOR ACCESSORIES

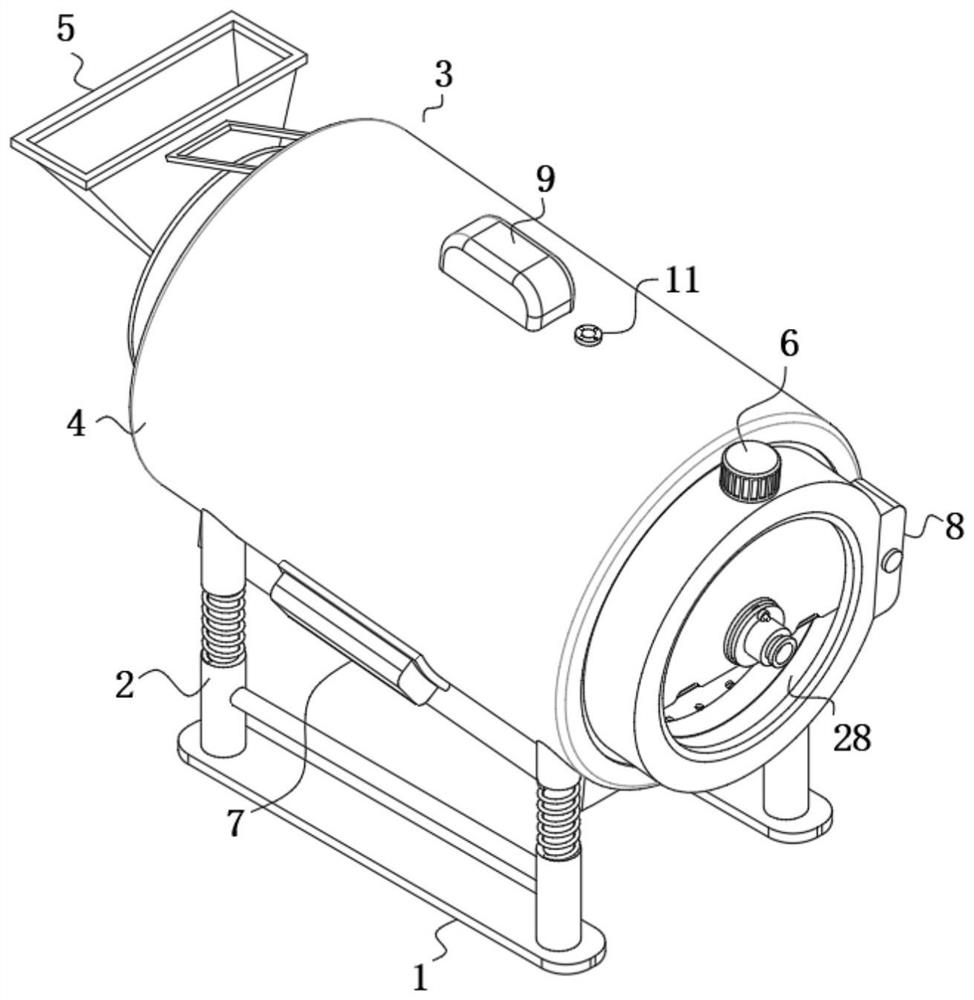

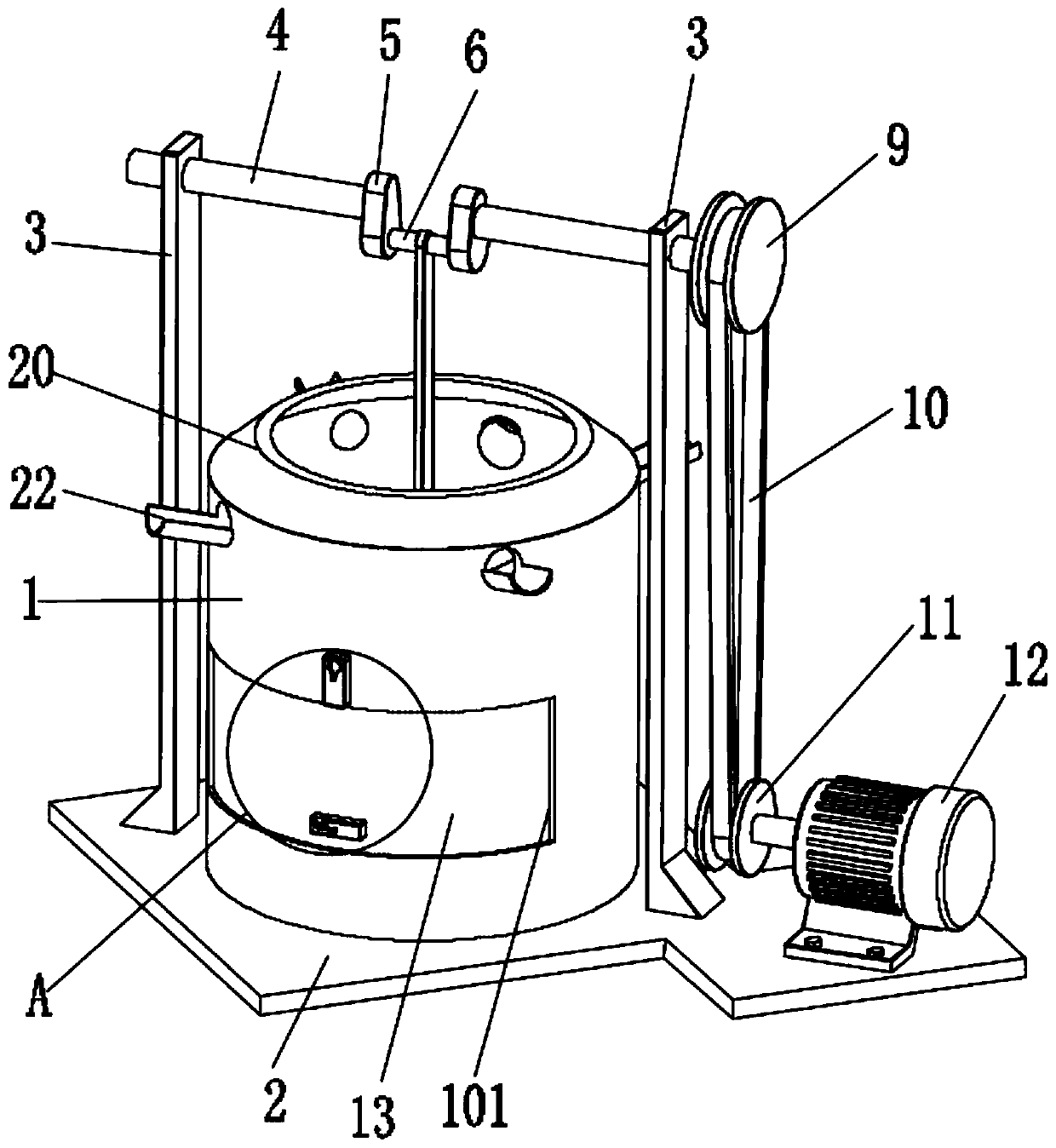

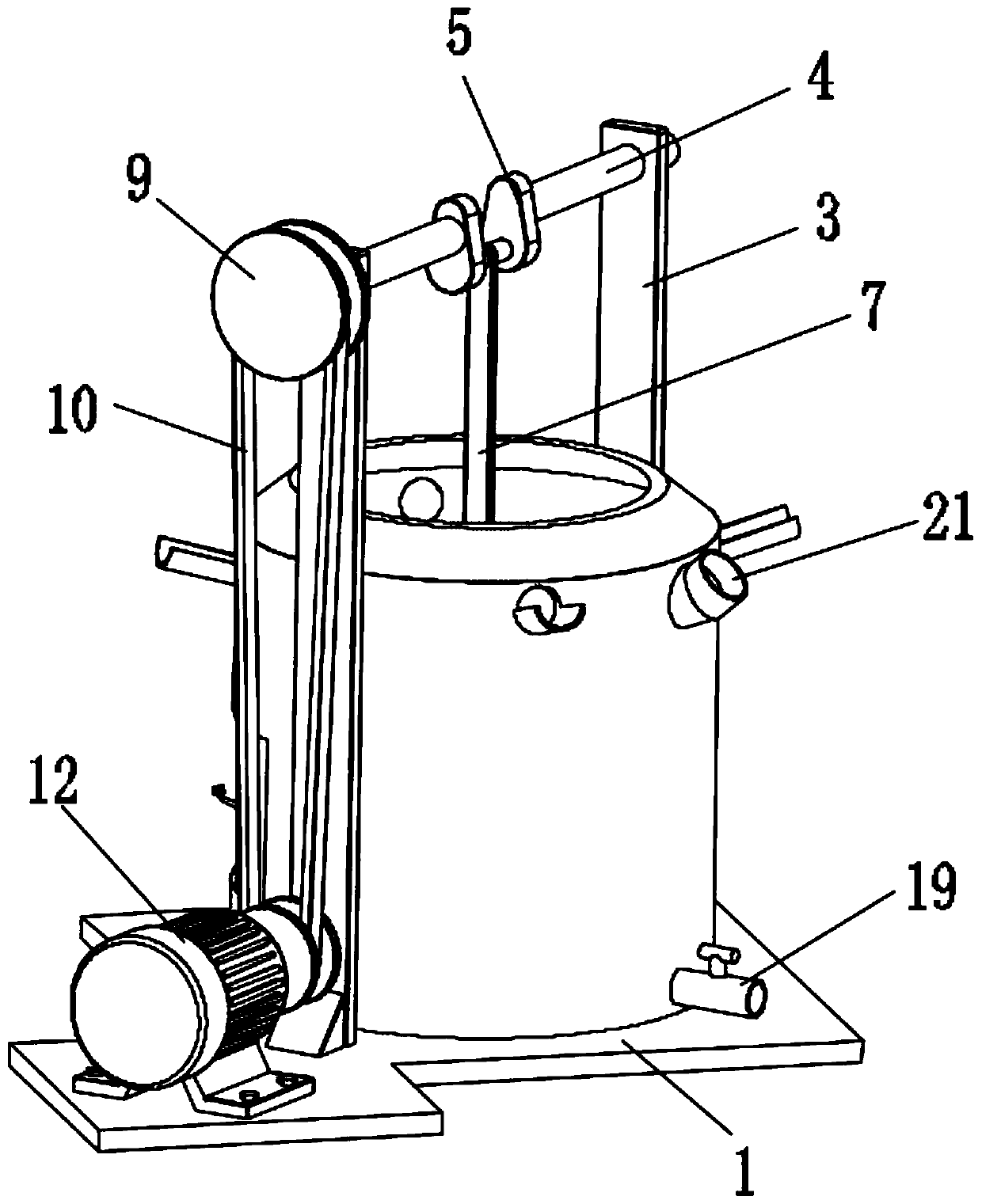

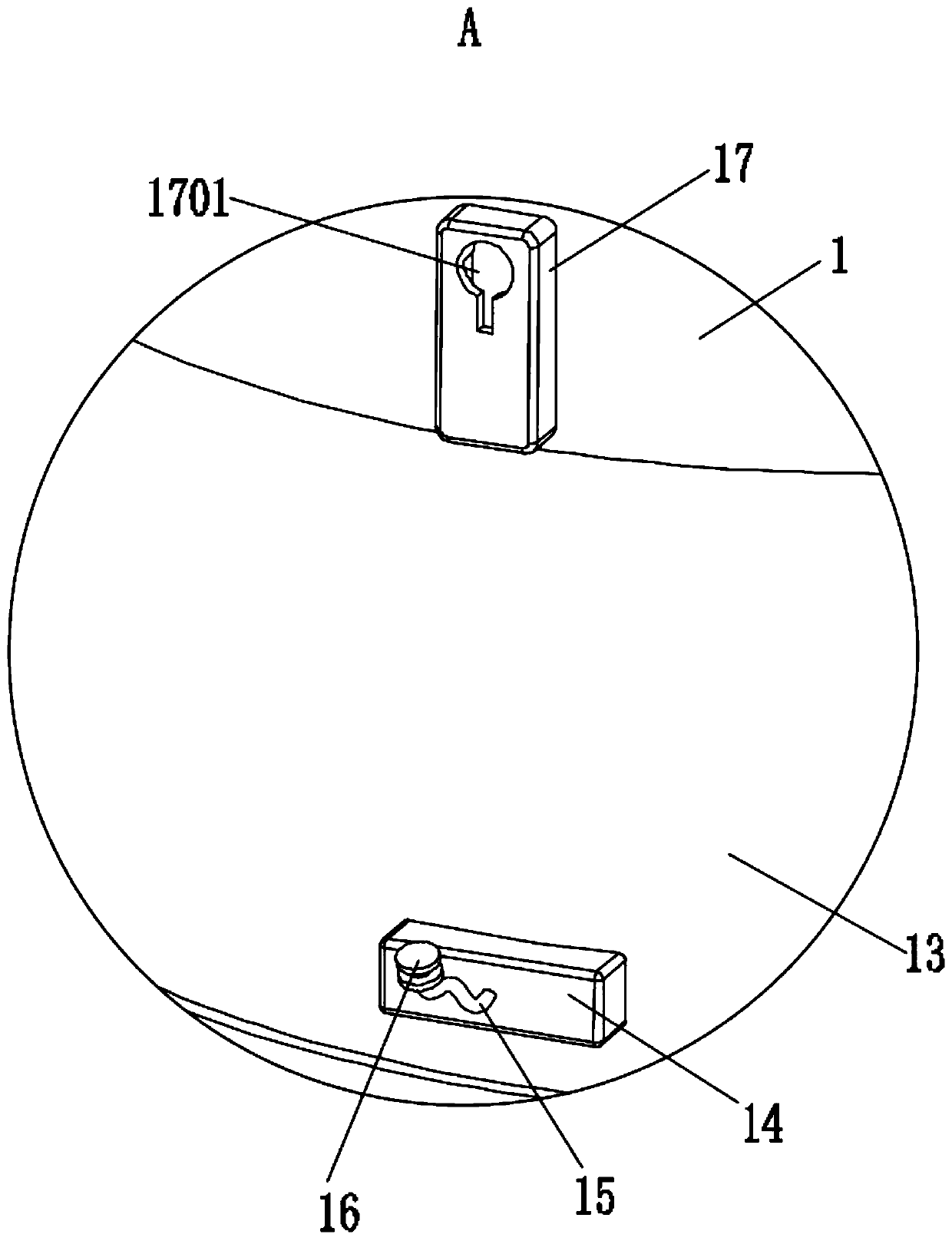

Novel washing water device for wig processing technology

The invention relates to the technical field of washing water devices in the wig production process, in particular to a novel washing water device for a wig processing technology. The device comprisesa base and a washing water barrel, vertical supports are leftwards and rightwards symmetrically and fixedly arranged on the washing water barrel, and a rotatable cooperation mechanism is connected tothe upper portion of the washing water barrel through a support; a first belt pulley is fixedly connected to the right end of a horizontal shaft of the right side, a second belt pulley is in transmission connection with the first belt pulley through a vertically-arranged belt, and a driving motor installed on the base is rotatably connected to the second belt pulley; a vertical arc opening is formed in one side of a washing water barrel body, a door plate which moves up and down is arranged in the arc opening, and a door handle is fixedly connected to the outer side face of the door plate; aclamping part is connected to the door handle through a pull rope, a clamping block cooperatively clamped to the clamping part is fixedly arranged on the outer wall of the washing water barrel body, and a blocking net is arranged at the inner bottom of the washing water barrel. According to the device, a hair extension is sufficiently and evenly soaked in the washing water barrel, and the wig quality is greatly improved.

Owner:安徽美源发制品有限公司

Multi-function intelligent cleaning robot

InactiveCN106691316AIncrease cleaning strengthReduce noiseAutomatic obstacle detectionTravelling automatic controlEngineeringOmni directional

The invention discloses a multi-function intelligent cleaning robot. The robot main comprises an infrared sensing module, a control module, a dust vacuuming module, a navigation module, a mopping device and a denoising module. The infrared sensing module receives signals, and sends the signals to the control module for processing. The navigation module sends route information to the control module for processing. The denoising module is controlled by the control module to control the noise decibel of the multi-function intelligent cleaning robot and clean the superfluous noise. The control module receives information to control the mopping device and the dust vacuuming device respectively. According to the multi-function intelligent cleaning robot, the infrared sensing module is used for sensing garbage in an omni-directional mode, the mopping device and the dust vacuuming device are arranged to enhance the cleaning intensity of the cleaning robot, the denoising module is arranged to minimize the noise of the intelligent cleaning robot, and enhance the service life of the robot.

Owner:HECHI UNIV

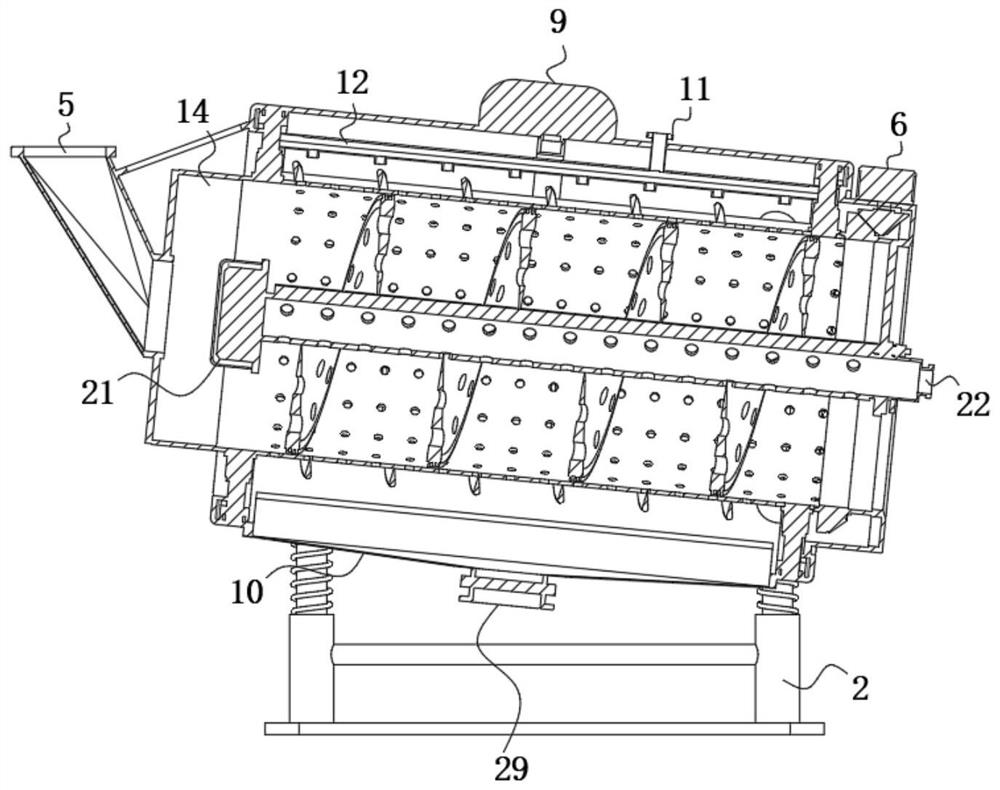

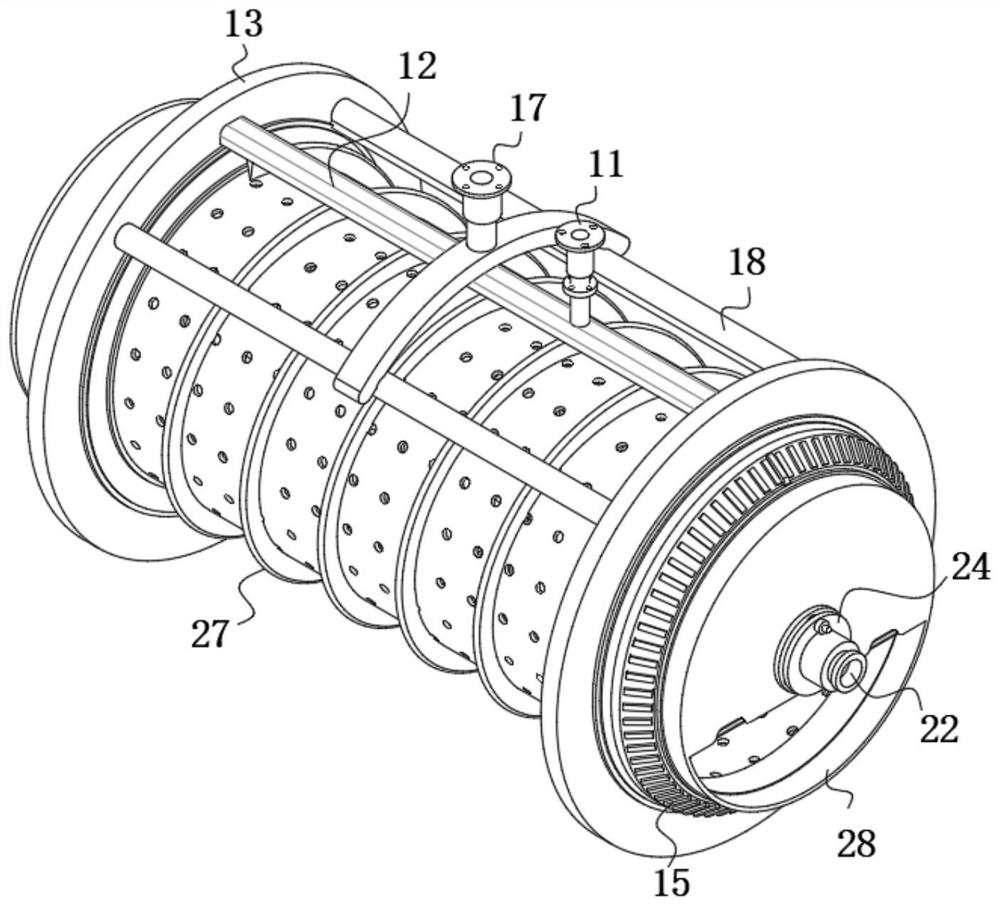

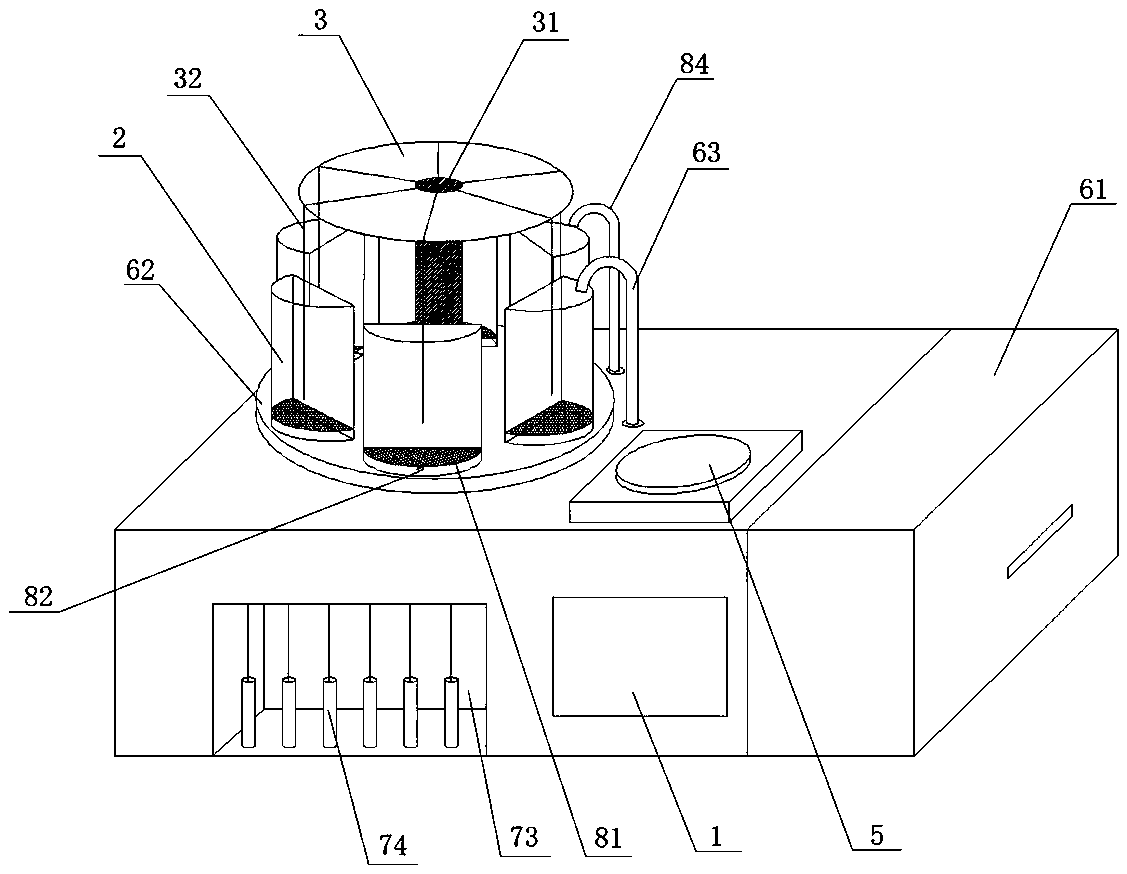

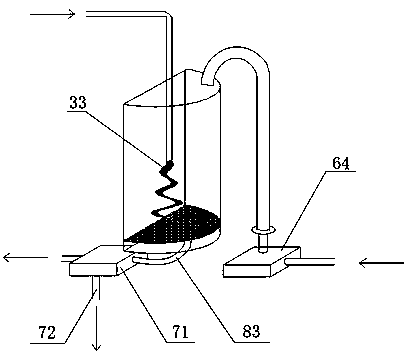

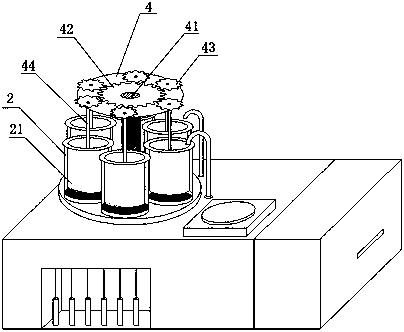

Raw material cleaning device for pectin processing

PendingCN111804651AEasy height adjustmentIncrease cleaning strengthClimate change adaptationDrying gas arrangementsElectric machineryProcess engineering

The invention discloses a raw material cleaning device for pectin processing. The raw material cleaning device comprises a first air pipe, a first air drying opening, a first motor, a fixed plate, a threaded rod, a second air drying opening, a baffle, a rubber seal block, a pull rod, a second air pipe, a connection rod, a recovery box, a strainer, a sleeve shaft, a fixed rod, a partition, a waterpump, a water injection opening, an outer frame, an inner frame, a brush plate, a connection plate, a cleaning box, a second motor, a fan, a support plate and a box door. The inner frame rotates alongwith the fixed rod, and raw materials can be washed. The threaded rod can adjust the height of the brush block, the surfaces of the raw materials are washed in a brushed mode, and cleaning strength and efficiency are improved. The connection rod can support the bottom of the outer frame, stable rotation of the inner frame is kept, the recovery box can filter and recover wastewater after primary cleaning, and water flow circulation between the recovery box and the cleaning box can be achieved. The first air drying opening and the second air drying opening can conduct air drying on the top andtwo sides of the inner frame, the contact area of the raw materials and air is increased, air drying speed is increased, and water can be prevented from entering the second air drying opening throughthe baffle and the rubber seal block.

Owner:DANGSHAN HAISHENG PECTIN

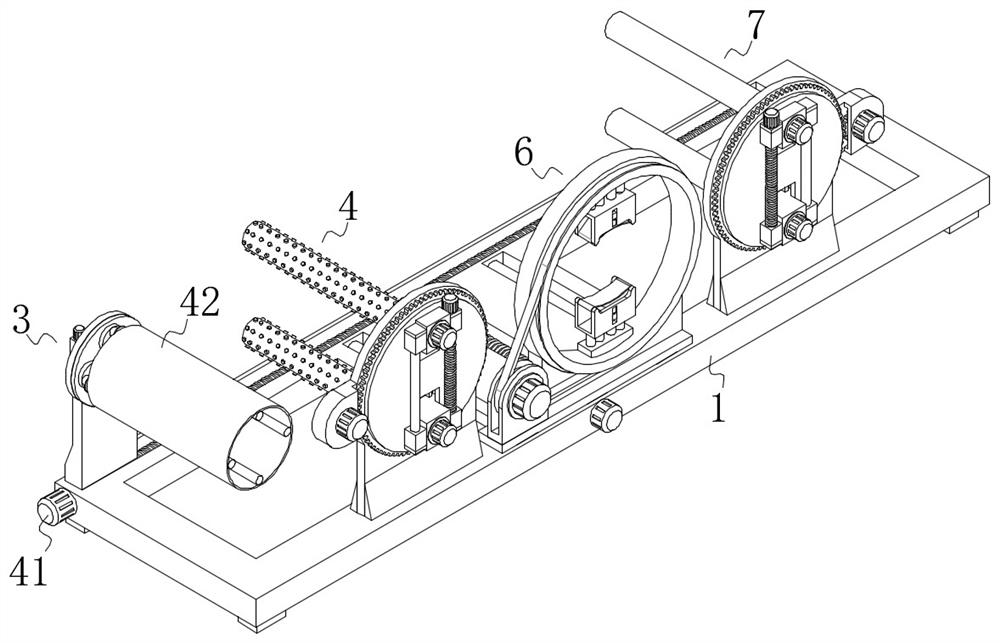

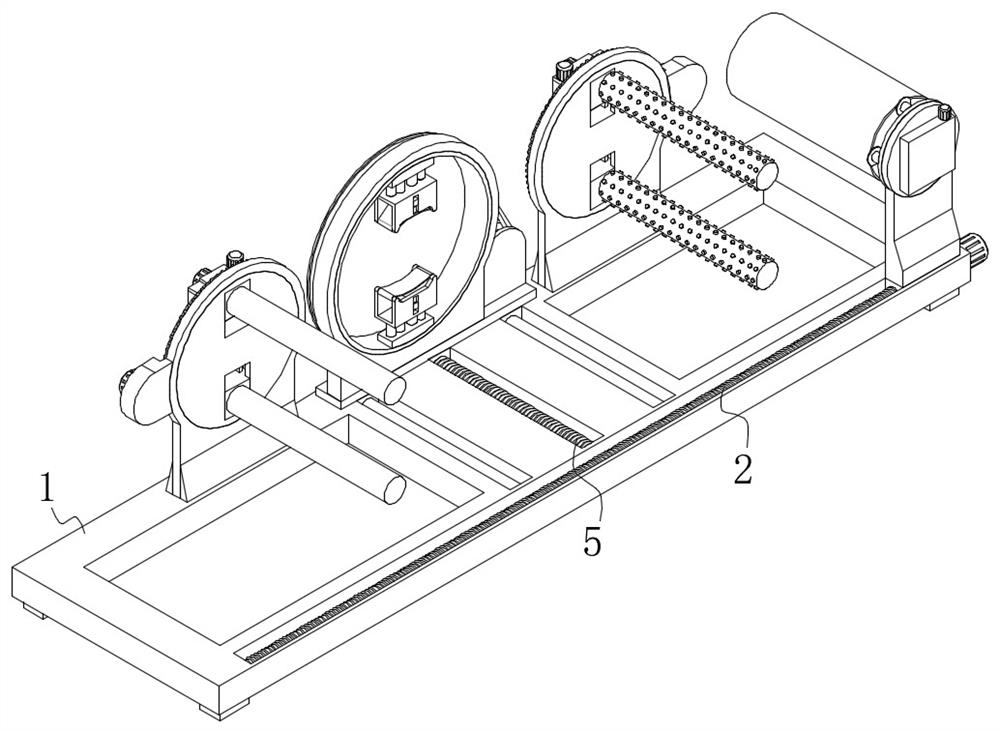

Multi-stage grinding and polishing device for metal pipe machining and grinding and polishing process

ActiveCN112518536AImprove sanding effectAffect the grinding effectRevolution surface grinding machinesGrinding drivesMetal machiningScrew thread

The invention discloses a multi-stage grinding and polishing device for metal pipe machining, and belongs to the technical field of metal machining. The multi-stage grinding and polishing device for metal pipe machining comprises a base, the inner wall of the base is rotationally connected with a threaded lead screw a, the peripheral side face of the threaded lead screw a is in threaded connectionwith a metal pipe fixing assembly, the upper surface of the base is fixedly connected with a pipe wall cleaning mechanism, the inner wall of the base is rotationally connected with a threaded lead screw b, a first-stage grinding mechanism is in threaded connection with the peripheral side face of the threaded lead screw b, the upper surface of the base is fixedly connected with a second-stage grinding mechanism, the metal pipe fixing assembly comprises a movable base, the inner wall of the movable base is in threaded connection with the threaded lead screw a, one surface of the movable base is fixedly connected with a support, and one surface of the support is fixedly connected with a fixed base. Through the design of the metal pipe fixing assembly, the pipe wall cleaning mechanism, the first-stage grinding mechanism and the second-stage grinding mechanism, the problem that an existing metal pipe grinding device is poor in practicability due to the fact that only one-time grinding isconducted on a metal pipe and the operation process is complex is solved.

Owner:无锡亚尔特金属制品有限公司

Non-woven fabric honeycomb curtain fabric processing method

InactiveCN112538741AIncrease cleaning strengthImprove processing qualityMechanical cleaningPressure cleaningHoneycombEngineering

The invention provides a non-woven fabric honeycomb curtain fabric processing method, and relates to the technical field of non-woven fabric processing. The non-woven fabric honeycomb curtain fabric processing method comprises a main body box, an ash removal mechanism and a cutting mechanism; a supporting frame is fixedly connected to the top of a supporting plate; a cloth winding roller is installed at the top of the supporting frame; a rotating roller is also installed at the top of the supporting plate through the supporting frame; a cam is rotatably connected between the side walls of themain body box through a rotating shaft; and one end of an air conveying pipe communicates with the output end of a draught fan assembly, and the other end of the air conveying pipe is obliquely arranged in an inner cavity of the main body box. By means of rotation of the cam, non-woven fabric between the cloth winding roller and the rotating roller is jacked up, and then a vibrator is adopted, sothat the dust in the non-woven fabric is vibrated out; the dust is blown away through the air conveying pipe; an arranged hair sticking roller can further clean the surface of the non-woven fabric, and the dust cleaning strength is improved; and flattening is conducted through a pressing roller, so that follow-up cutting is facilitated, and the processing quality is further improved.

Owner:连云港市汉普顿遮阳用品有限公司

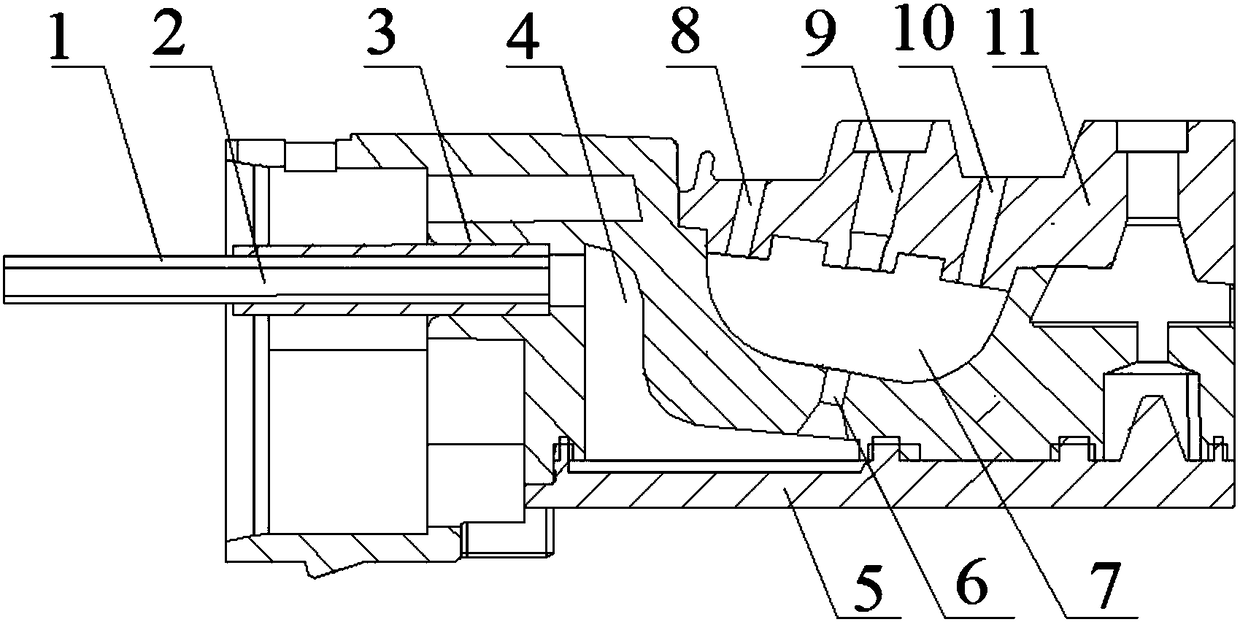

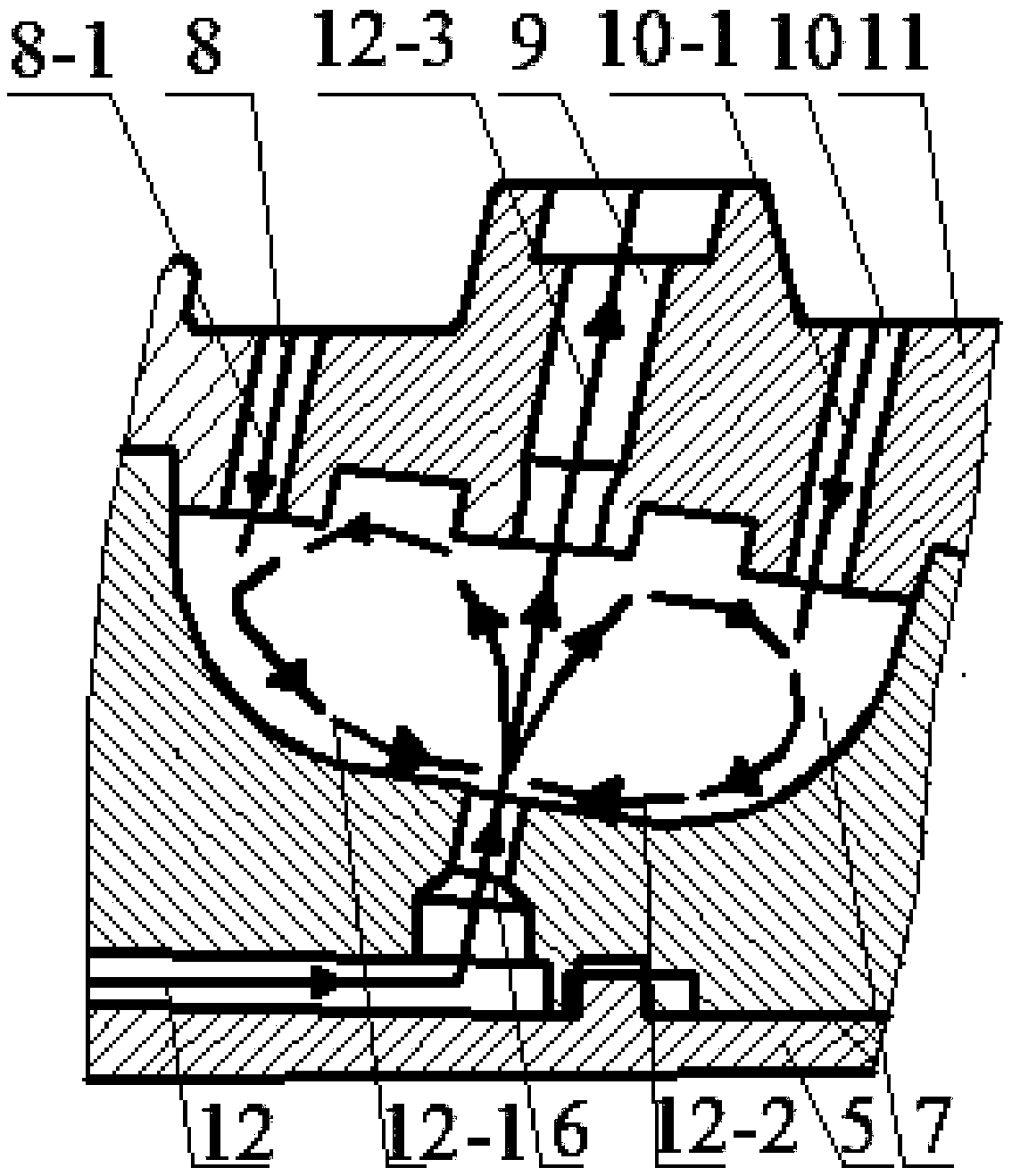

Water spouting device for toilet

InactiveCN108240023ASimple structurePromote productionFlushing devicesLavatory sanitoryGas mixingToilet

The invention provides a water spouting device for a toilet. The water spouting device comprises a spray head fixing device, a chassis and an upper cover, wherein the chassis is arranged on the lowerend surface of the spray head fixing device, and a cavity formed between the spray head fixing device and the chassis is a water supply room; the upper cover is arranged on the upper end surface of the spray head fixing device, and a cavity between the spray head fixing device and the upper cover is a gas mixing room; the gas mixing room and the water supply room are communicated through a throttle pipe; the upper cover is provided with a first gas suction pipe, a second gas suction pipe and a gas mixing pulse nozzle penetrating through the gas mixing room; the spray head fixing device is provided with a water inlet channel; and the water inlet channel is communicated with the water supply room. In the invention, a gas mixing pulse jet flow can be generated perfectly, the same aim of cleaning can be achieved by using little water, and the electric quantity for heating water is reduced.

Owner:JIANGSU UNIV

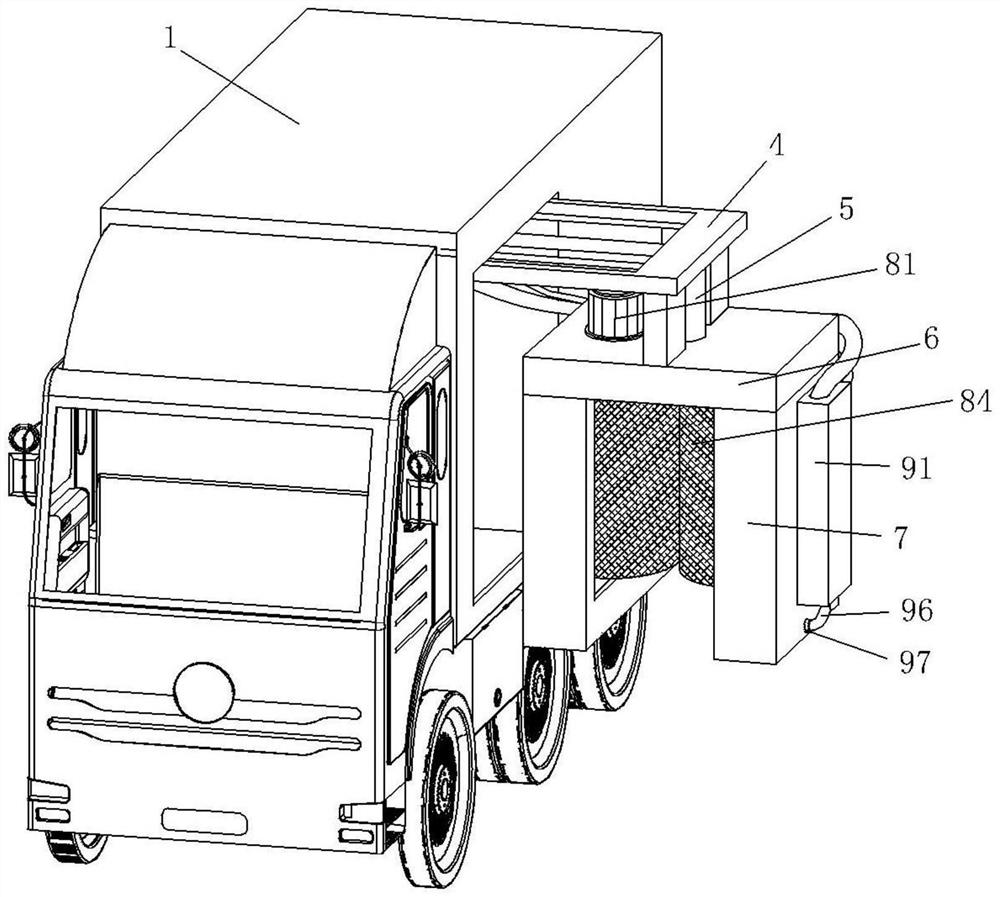

Automatic cleaning device of reflective guardrail for bridge warning

ActiveCN114273289AIncrease cleaning strengthEasy to operateGeneral water supply conservationDirt cleaningHydraulic cylinderStructural engineering

The invention discloses an automatic cleaning device of a reflective guardrail for bridge warning. The automatic cleaning device comprises a cleaning vehicle; the water tank is fixedly arranged on one side in a compartment of the cleaning vehicle; the collecting box is fixedly arranged on the other side in the compartment of the cleaning vehicle; the electric telescopic frame is fixedly arranged at the top end of an inner cavity of a compartment of the cleaning vehicle; the hydraulic cylinder is fixedly arranged on one side of the bottom end of the electric telescopic frame; the rectangular shell is fixedly arranged at the bottom end of the hydraulic cylinder; the cover bodies are fixedly arranged on the left side and the right side of the bottom end of the rectangular shell; the rolling brush cleaning mechanism is arranged on the inner side of the cover body; and the dust collection self-cleaning mechanism is arranged on the outer side of the cover body. According to the automatic cleaning device of the reflective guardrail for bridge warning, the cleaning brush can clean the rolling brush under continuous rotation of the rolling brush, self-cleaning of the rolling brush is completed by continuously spraying water to the rolling brush and sucking sewage, operation is easy, and long-term cleaning is facilitated.

Owner:LUSHAN COLLEGE OF GUANGXI UNIV OF SCI & TECH

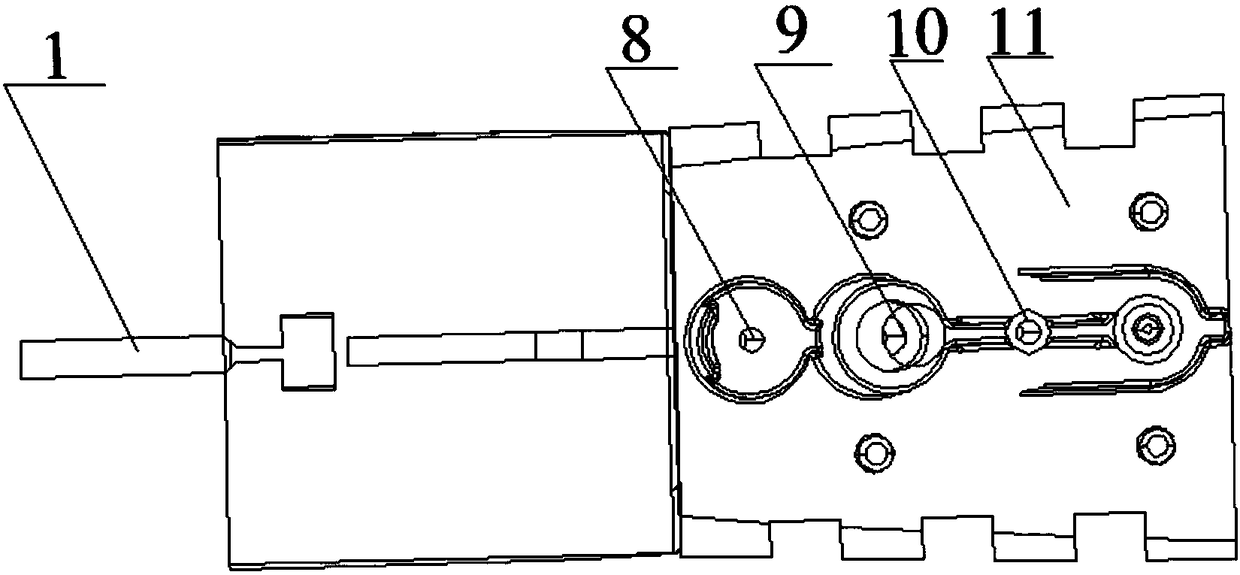

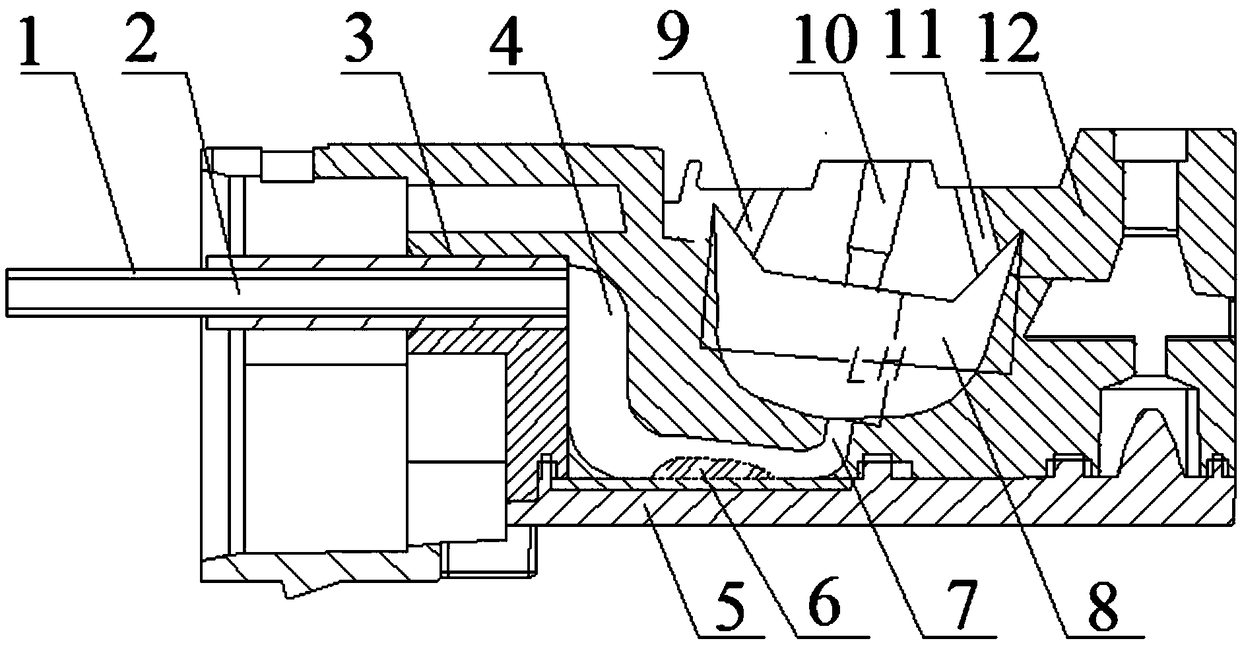

Spraying device for intelligent toilet

The invention belongs to the field of wet-jet cleaning device and provides a spraying device for an intelligent toilet. The spraying device comprises a spraying device body and a water inlet pipe, andthe spraying device body is internally provided with an elbow-shaped water supply pipe, a throttling pipe, an air mixing chamber, an air suction pipe A, an air mixing pulse nozzle and an air suctionpipe B. The water inlet pipe is communicated with one end of the elbow-shaped water supply pipe, and the other end of the elbow-shaped water supply pipe is communicated with the bottom end of the throttling pipe which is a straight pipe. The air mixing chamber is positioned above the throttling pipe, the top end of the throttling pipe is communicated with the bottom end of the air mixing chamber,and inclined jet flow can be generated and ejected into the air mixing chamber. The top end of the air mixing chamber is communicated with the air mixing pulse nozzle, and the air suction pipe A and the air suction pipe B are positioned on two sides of the air mixing pulse nozzle respectively. The elbow-shaped water supply pipe comprises a bent elbow section A, a bent elbow section B, a linear shrinkage section and a bent elbow shrinkage section in sequential communication arrangement. The spraying device has advantages that air mixing pulse jet flow can be well generated, and identical cleaning effects can be achieved under low water consumption.

Owner:JIANGSU UNIV

Clothes washing device with drying function

InactiveCN108796959AWith drying functionEasy to useBrushing washing machinesOther washing machinesWater washingChemical engineering

The invention discloses a clothes washing device with a drying function. The device comprises a shell body, a heating shell is clamped to the surface of an L-shaped metal rod welded to the surface ofthe right side of the shell body, and a set of heating radiators are arranged in the heating shell; an air outlet transverse pipe is connected with the tail end of an air conveying pipeline arranged on the surface of the left side of the heating shell, an induced draft fan is fixed in the air outlet transverse pipe, and a metal shell is arranged in the shell body; a rotating platform is installedbelow the metal shell, a storage battery and a rotating motor are successively arranged on the upper surface of the base welded to the tail end of the shell body from left to right, and a metal opening and a groove are formed in the upper and lower ends of the metal shell, and a plurality of protruding blocks are arranged on the side surface of a metal rectangular rod clamped in the groove. Through the arrangement of the heating shell, the heating radiators, the air conveying pipeline, an air spraying opening, the induced draft fan, the metal shell, the groove, the metal opening and the metalrectangular rod, the problems that an existing washing device is short of the drying function and poor in clothes cleanliness are solved.

Owner:芜湖清柏白露智能信息科技有限公司

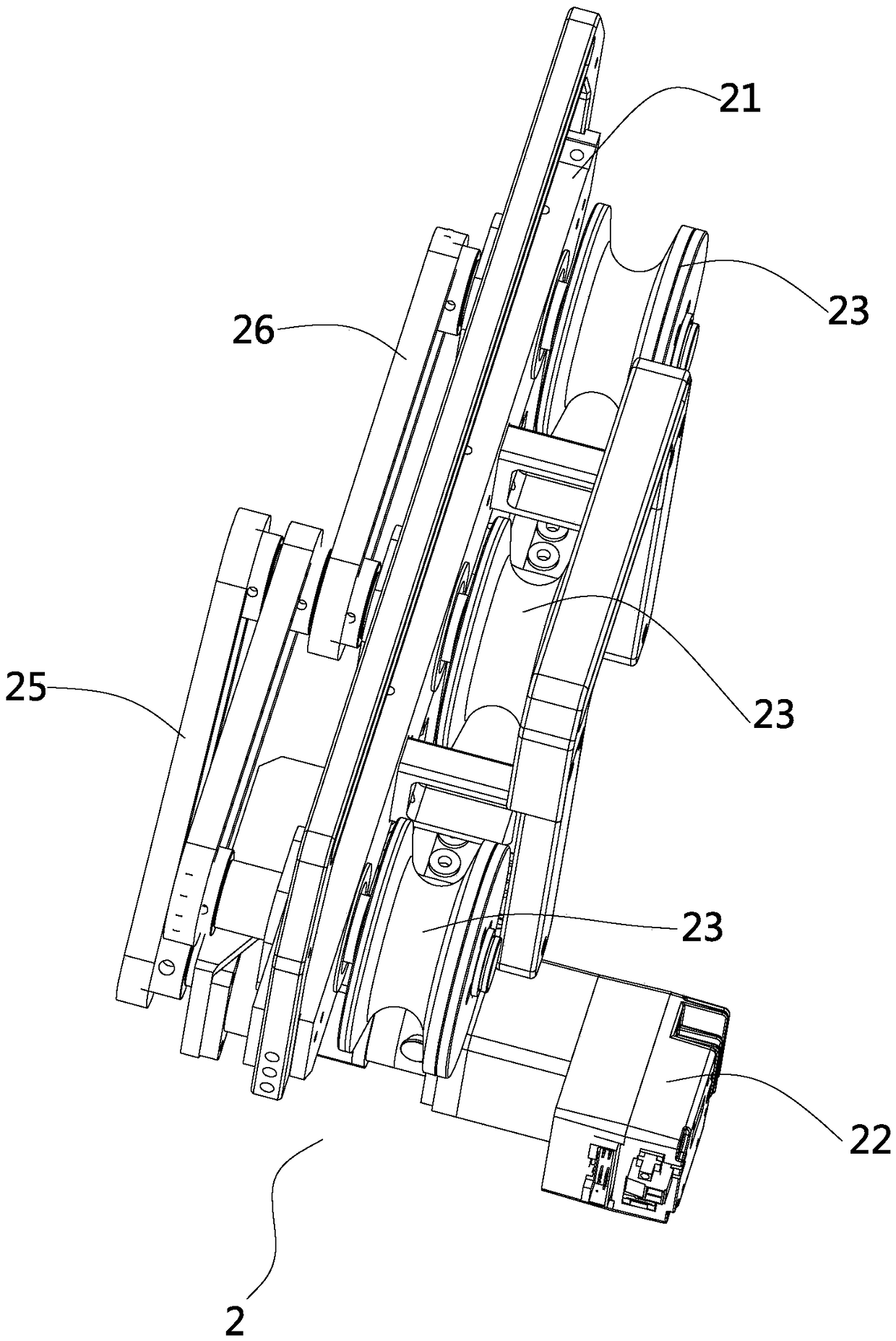

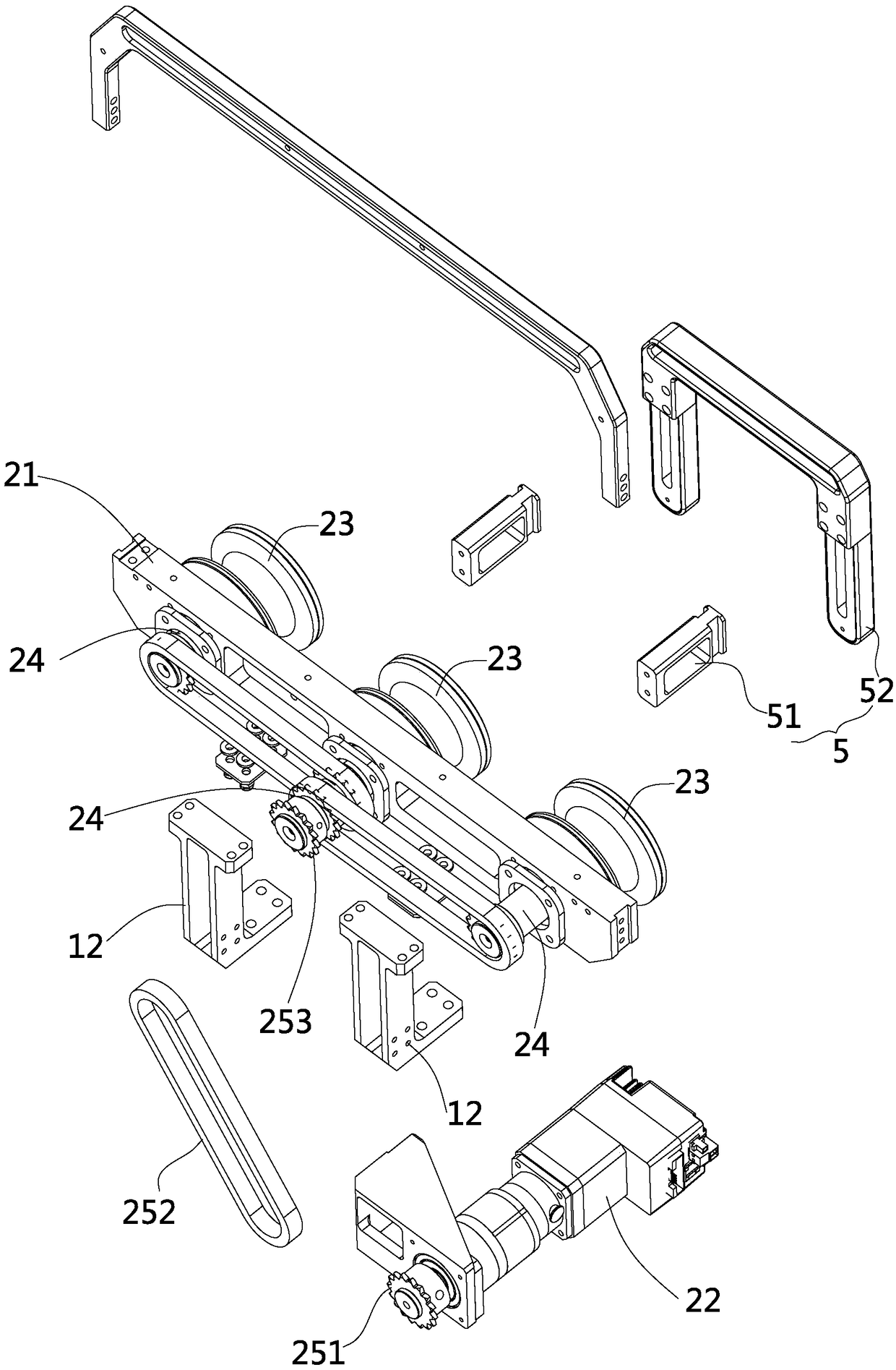

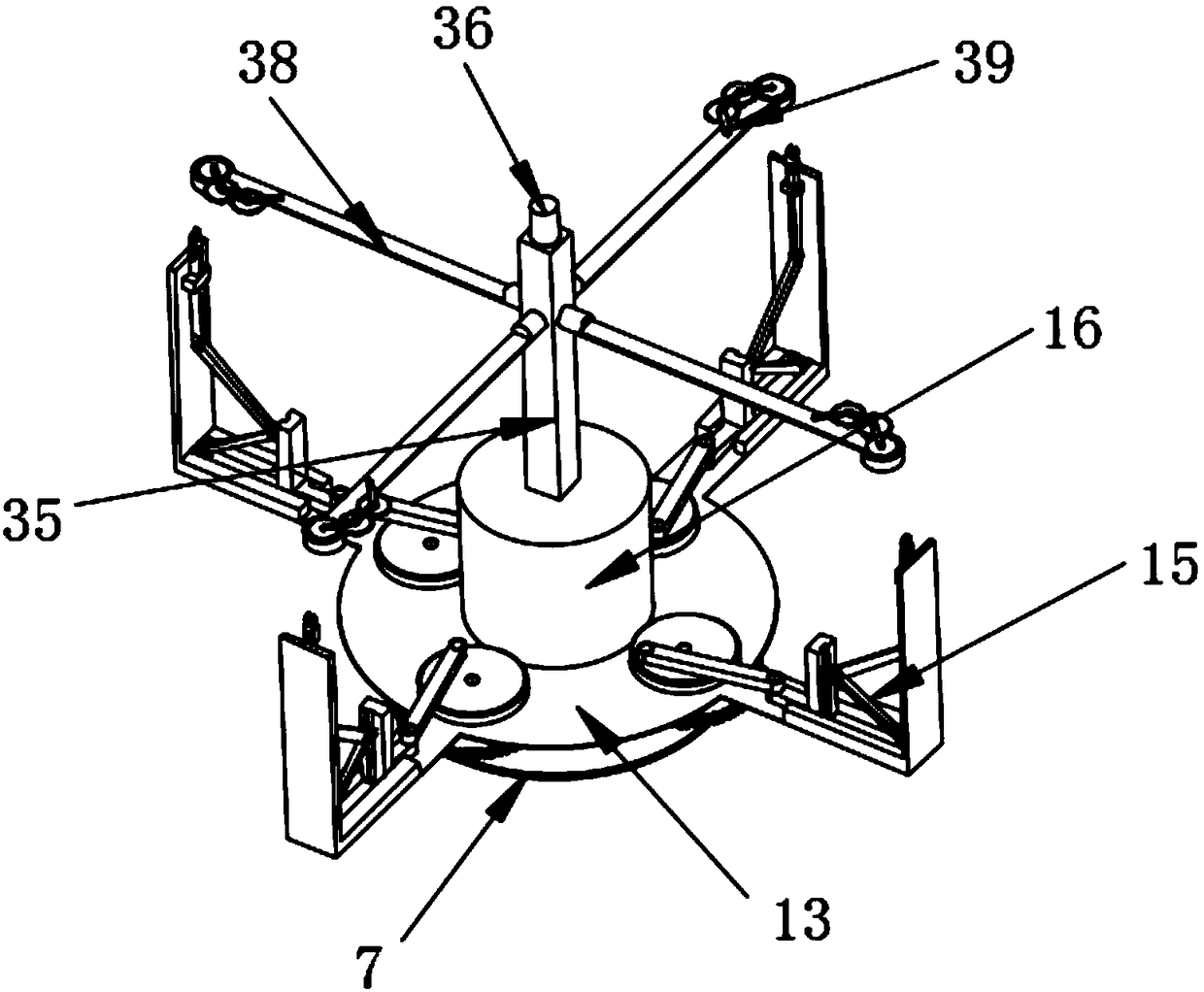

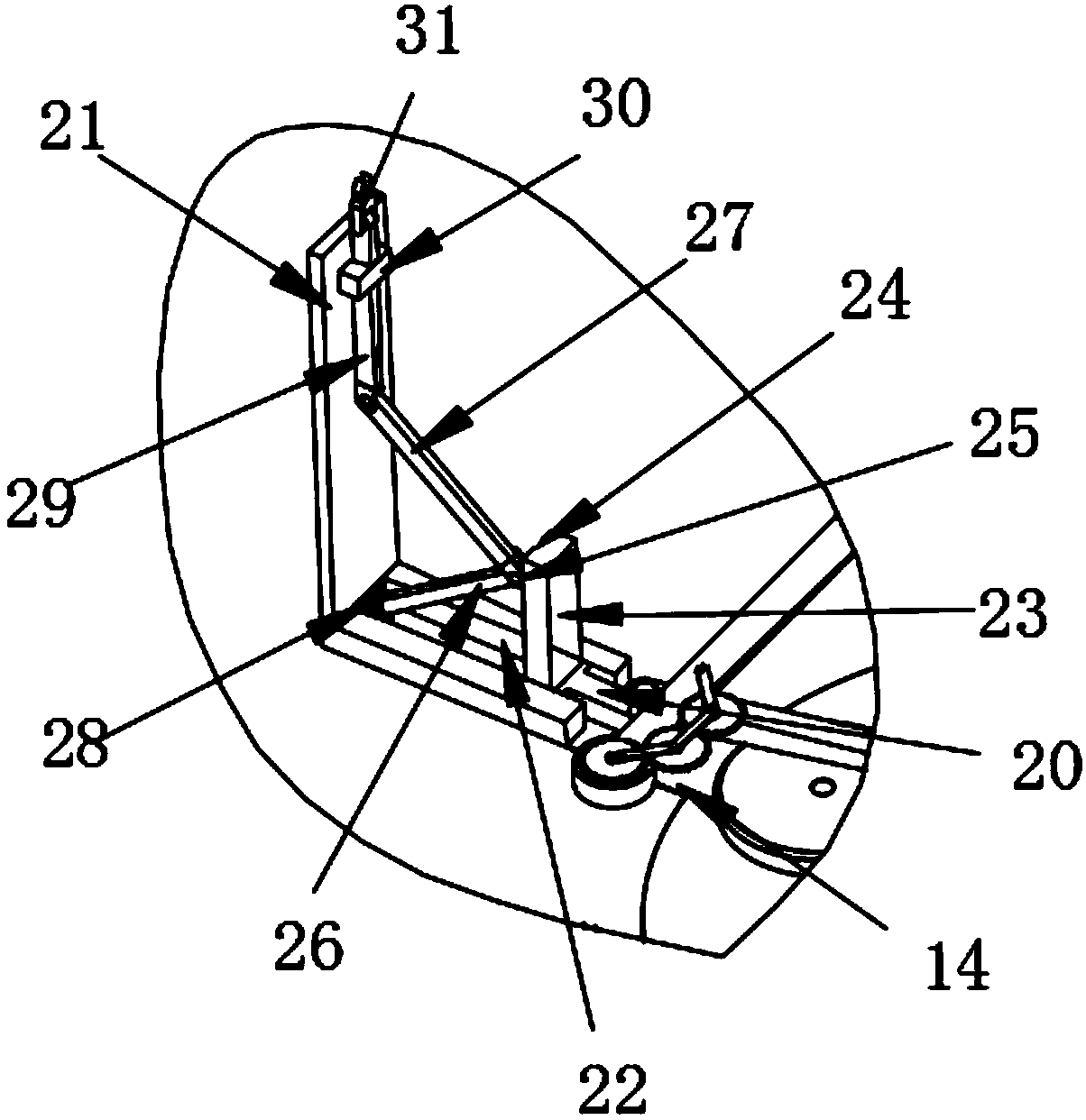

Cable sweeping robot

PendingCN109318104ASimple structureEasy to placeGrinding machinesApparatus for overhead lines/cablesMotor driveFixed frame

The invention discloses a cable sweeping robot. The cable sweeping robot comprises a walking device, a sweeping device and a self-adaptive adjusting device, wherein the sweeping device comprises at least two sweeping heads, every two adjacent sweeping heads are detachably connected, and at least two sweeping heads are assembled to form a channel for allowing a cable to penetrate through; the sweeping heads comprise mounting plates, grinding wheels and sweeping motors, wherein the grinding wheels and the sweeping motors are fixed on the mounting plates, and the sweeping motors drive the grinding wheels to rotate so as to remove dirt on the cable; and the self-adaptive adjusting device comprises a fixed frame and a swing rod, one end of the fixed frame is fixed on the walking device, the other end of the fixed frame is rotationally connected with one end of the swing rod, and the other end of the swing rod is fixedly installed on the sweeping device so that the sweeping device can swingup and down relative to the fixed frame. By simplifying the structure of the sweeping device, the weight of the sweeping robot is reduced, and meanwhile, the sweeping device can float up and down along with the trend of the cable so that the sweeping robot can walk on the cable smoothly.

Owner:ZHEJIANG GUOZI ROBOT TECH

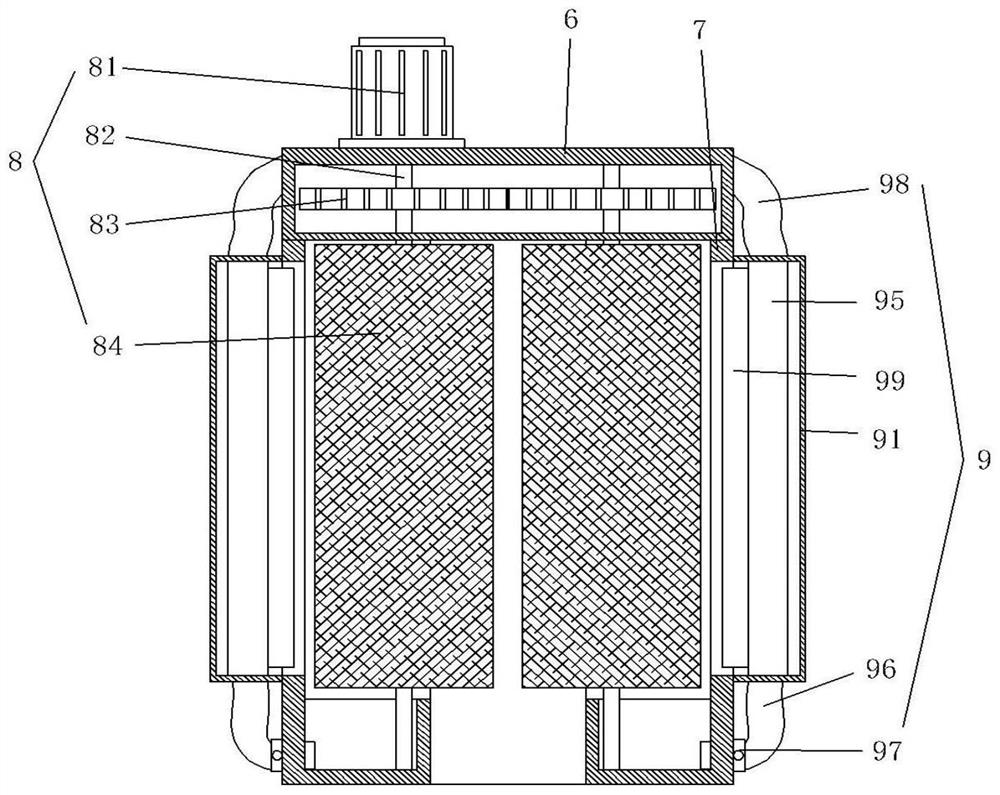

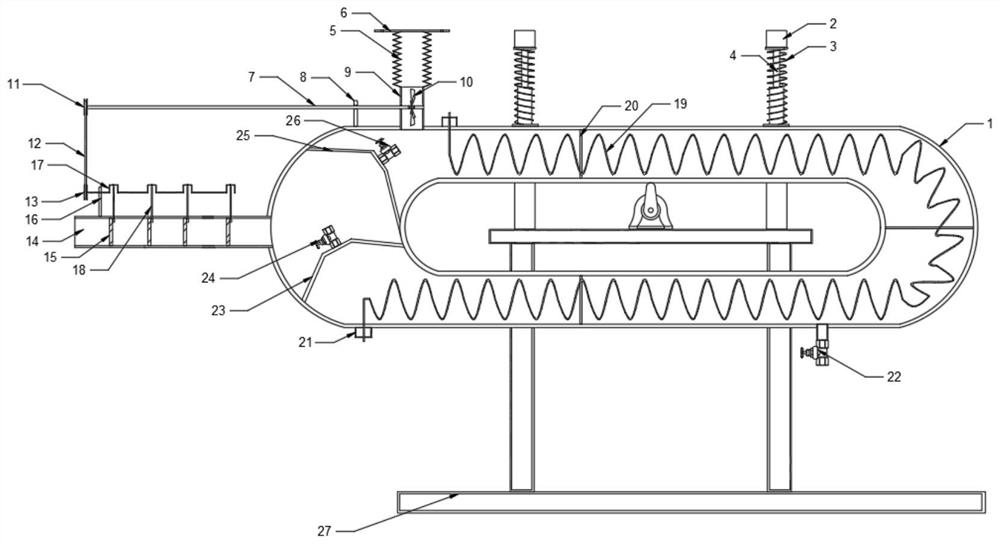

Combined high-efficiency air preheater and preheating method thereof

ActiveCN114508765AIncrease cleaning strengthRecuperative heat exchangersCombustion processAir preheaterProcess engineering

The invention discloses a combined type high-efficiency air preheater and a preheating method thereof, and belongs to the technical field of air preheaters. Gas or liquid needing to be preheated is guided into a spiral preheating guide-in pipe and sealed through a valve, and high-temperature smoke exhausted by a boiler is connected through a connecting disc; high-temperature smoke enters a hollow oval heat exchange bin through a telescopic pipe and an air guide pipe, flows in the hollow oval heat exchange bin after entering the hollow oval heat exchange bin and reaches a first trapezoid plate; and if the temperature detected by a first temperature sensor mounted on the first trapezoidal plate is higher than the temperature detected by a second temperature sensor mounted at the tail part of the spiral preheating ingress pipe, the first valve and the second valve are opened, and the valve leading to the filter bin is closed.

Owner:YANGZHOU JINTAO CHEM IND EQUIP

Cleaning method, cleaning device, water purification system and readable storage medium

ActiveCN112624372AImprove flushing effectEasy to peelSpecific water treatment objectivesTreatment involving filtrationFiltrationMembrane surface

The invention relates to the technical field of water purification, in particular to a cleaning method, a cleaning device, a water purification system and a readable storage medium. The cleaning method is used for cleaning a fine filtration unit in the water purification system. The water purification system comprises a pretreatment unit, a fine filtration unit and a supercharging device arranged between the pretreatment unit and the fine filtration unit, wherein a concentrated water port of the filtering unit communicates with a waste water pipeline, and a flushing valve is arranged on the waste water pipeline. The cleaning method comprises the following steps: a first cleaning step: adjusting the output flow of the supercharging device to a first flow and conducting operation for a first preset time; and a second cleaning step: adjusting the output flow of the supercharging device to a second flow and conducting operation for a second preset time. When the first cleaning step is switched to the second cleaning step, the speed of water flow on a membrane surface of the fine filtering unit is disturbed, so the fine filtering unit can obtain a better washing effect, salt ions and scales deposited on the membrane surface can be stripped more easily, and washing effect is enhanced.

Owner:GREE ELECTRIC APPLIANCES INC

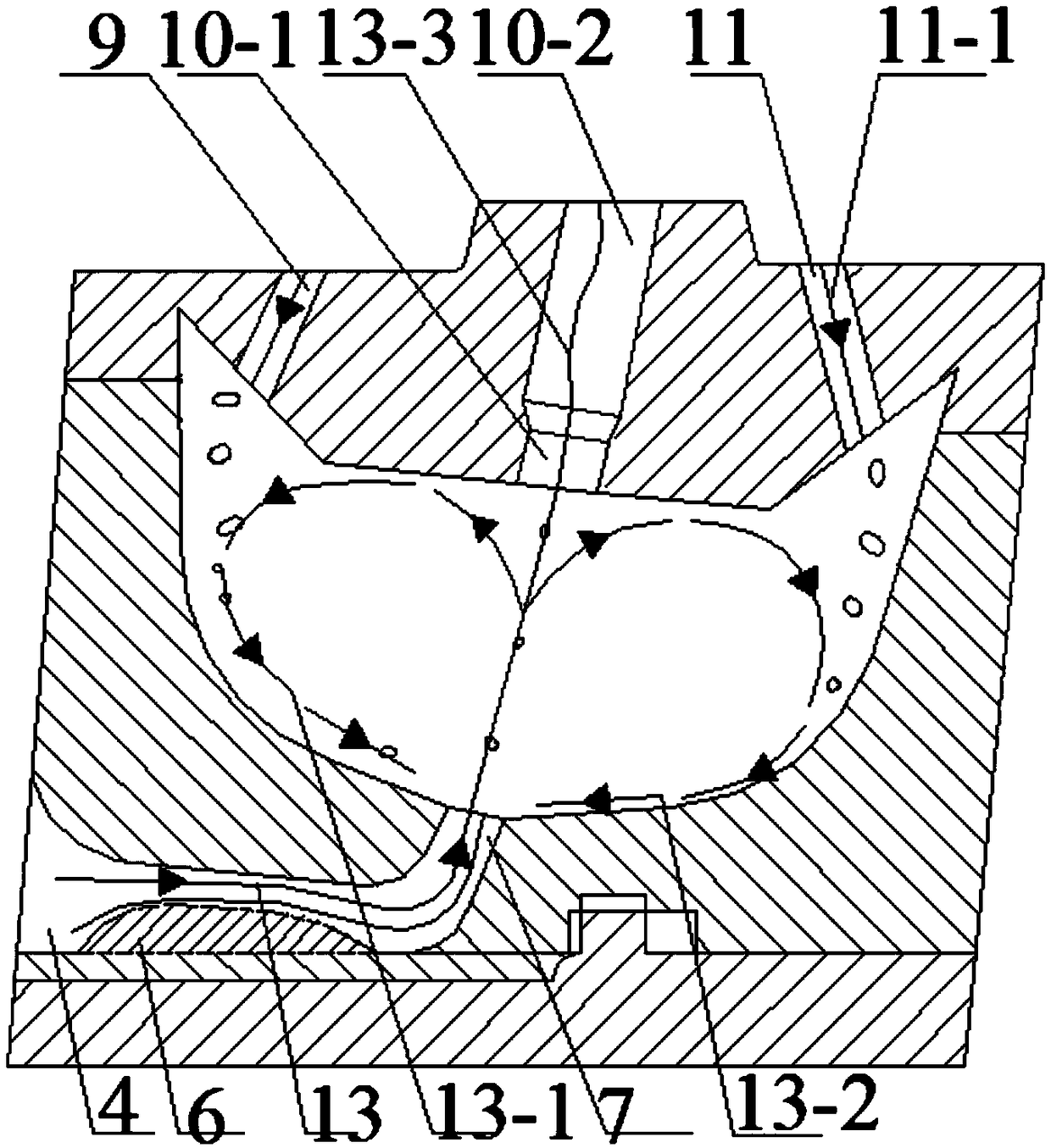

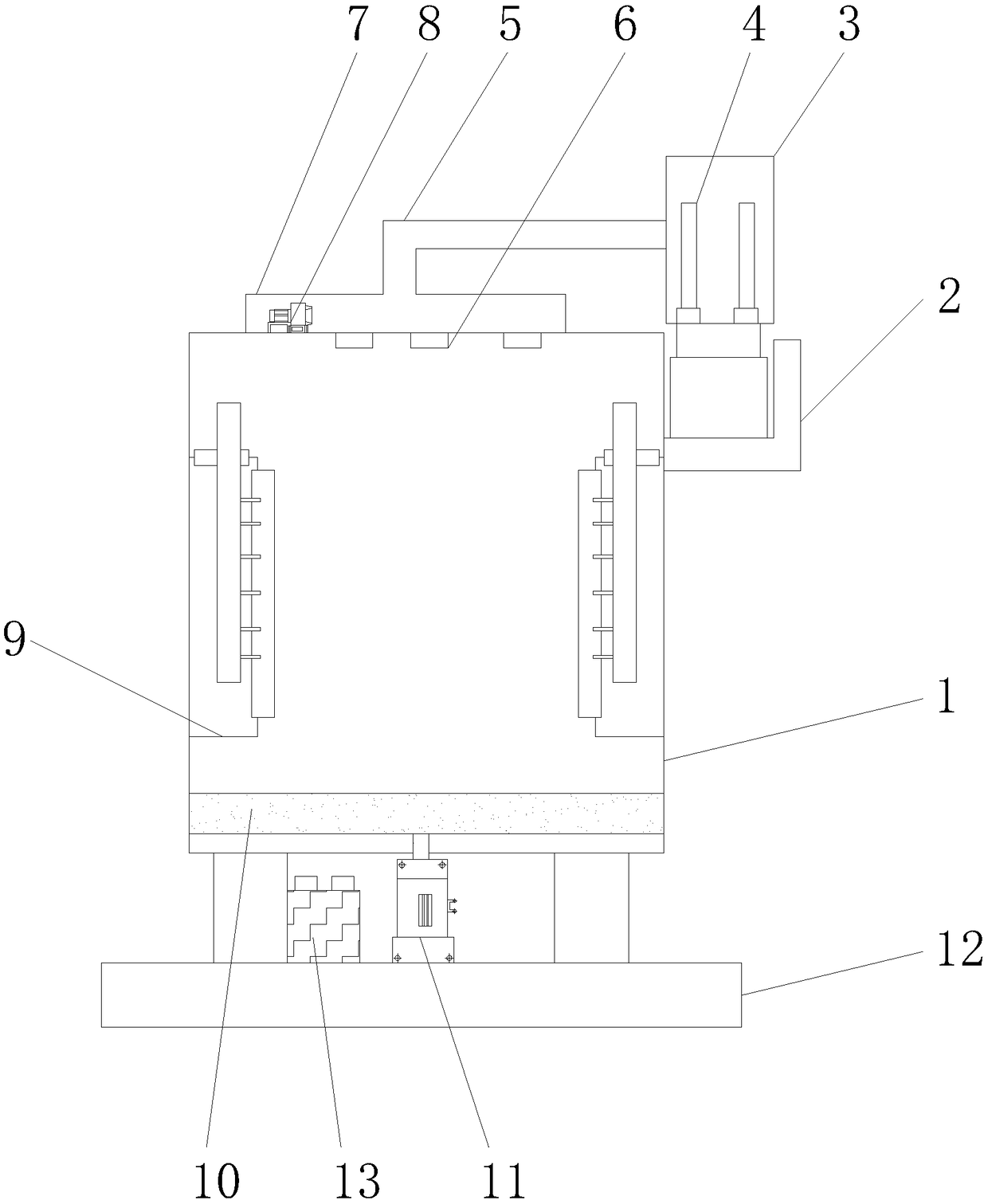

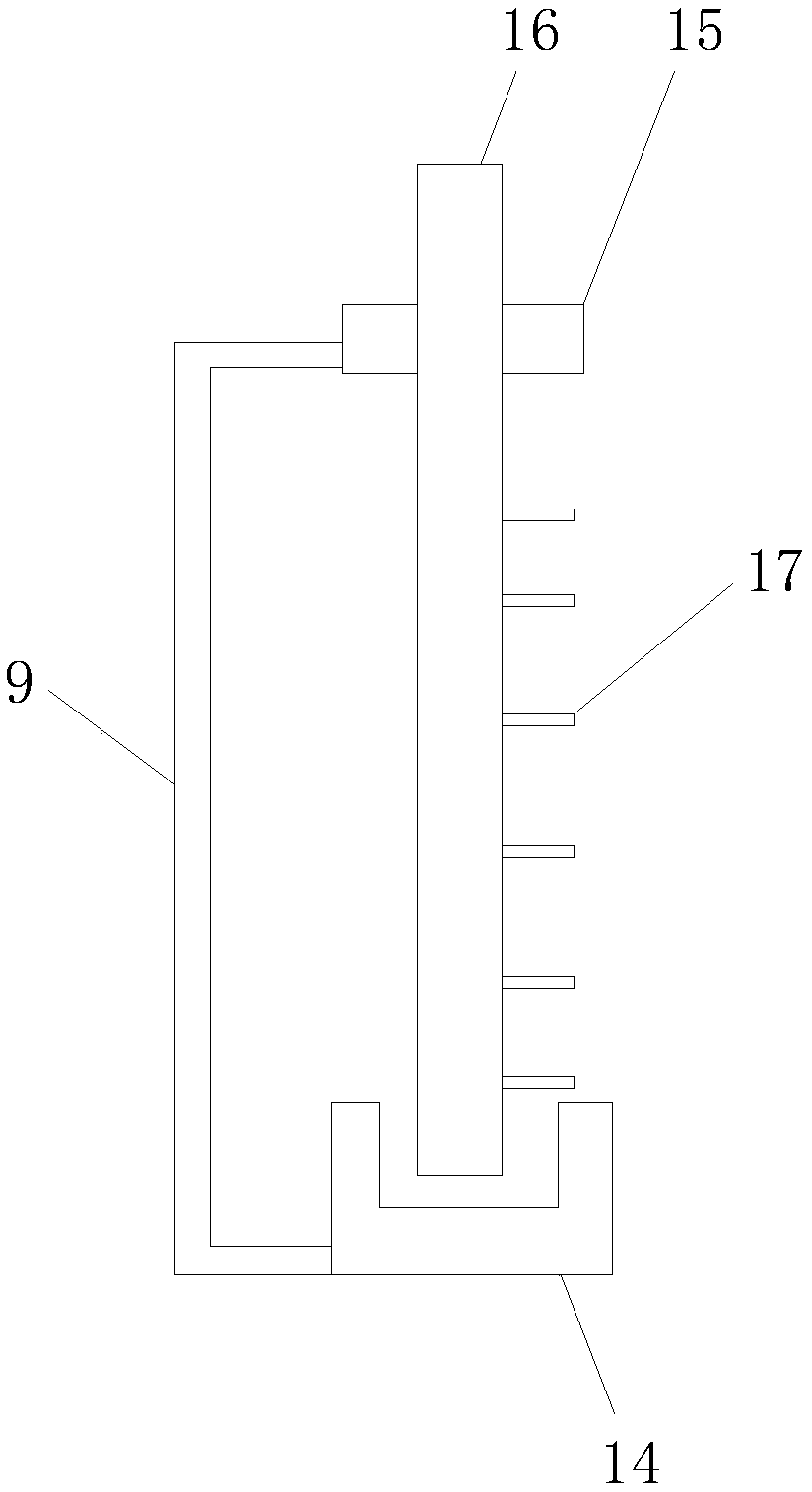

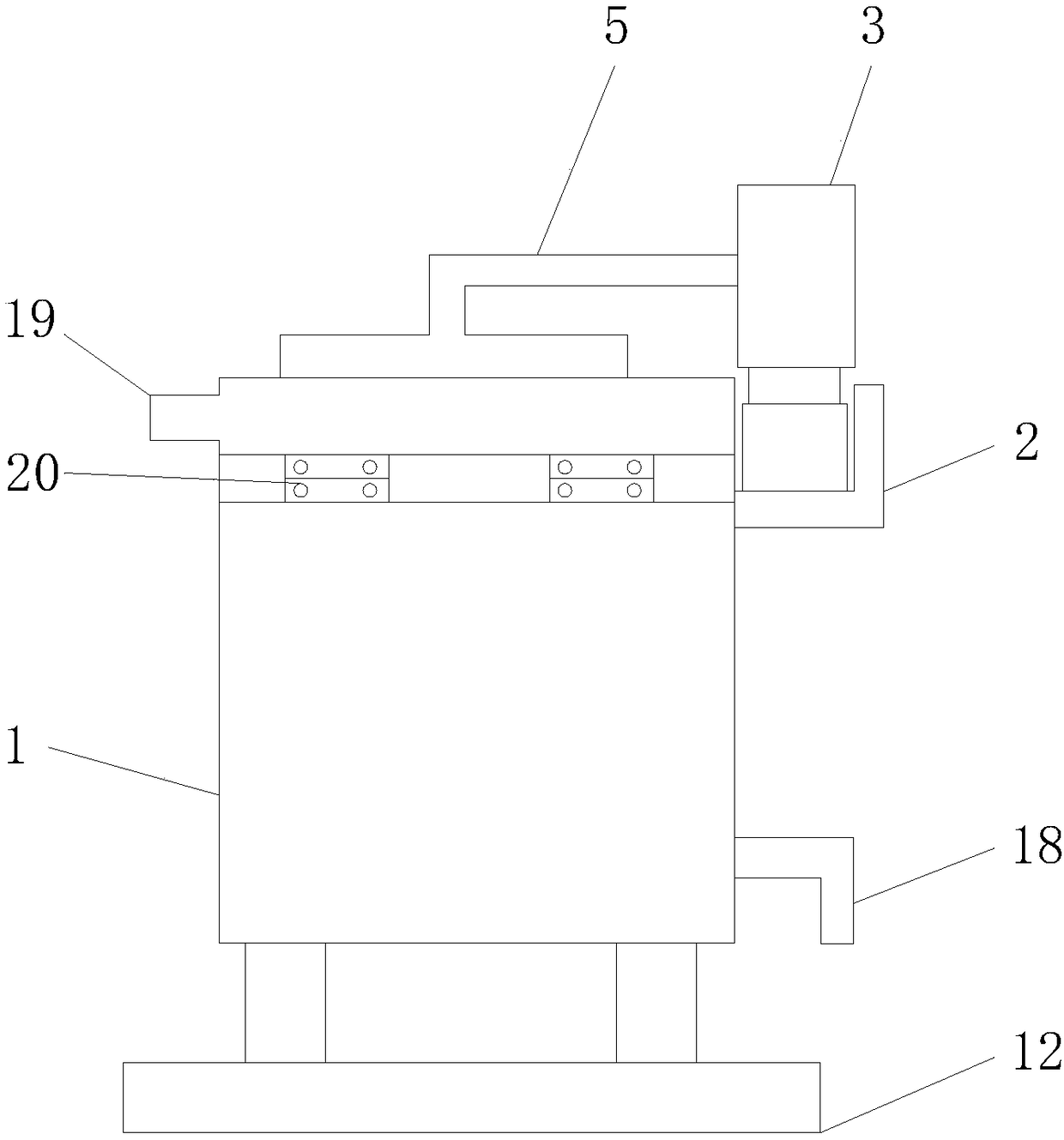

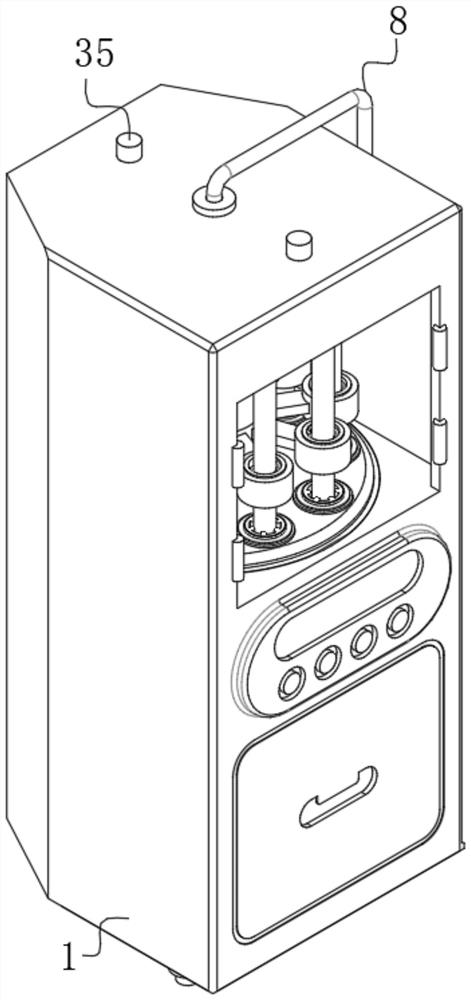

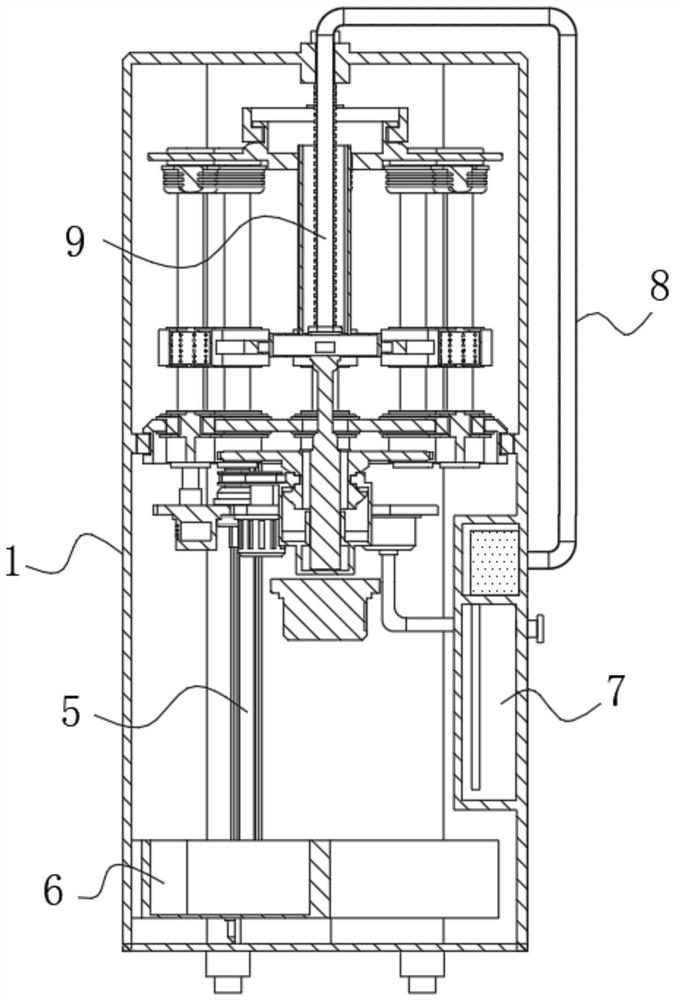

Multi-mode internal cleaning range hood

ActiveCN112413696AKeep clean and tidyFull power removalDomestic stoves or rangesLighting and heating apparatusHydraulic cylinderFan blade

The invention discloses a multi-mode internal cleaning range hood which comprises a rack. A main cavity is formed at the middle position of the rack, and hydraulic cylinders are symmetrically and fixedly connected to the upper and lower positions of the front side wall face of the middle of the main cavity. According to the multi-mode internal cleaning range hood, negative pressure is generated inthe main cavity through rotation of suction fan blades, and therefore oily fumes generated in a kitchen are sucked away, and it is guaranteed that the kitchen is clean and tidy; after equipment is used for a period of time, oil stains attached to the interior of the main cavity can be softened through a heating pipe, the oil stains on the main cavity are thrown away through rotation of an isolation ring, water absorbing cleaning liquid can completely make contact with the inner wall face of the main cavity, and therefore the internal cleaning effect is enhanced, and the oil stains on the inner wall can be removed completely and powerfully through shoveling of an oil removal shovel; and the multi-mode internal cleaning range hood is high in cleaning strength and is provided with a hard oilstain cleaning device, the problems that in the past, a range hood is high in cleaning difficulty and poor in cleaning effect are changed, and the multi-mode internal cleaning range hood is worthy ofvigorous popularization and production and putting into use.

Owner:ZHEJIANG TAOSHI GROUP HUANGYAN MOLD SECOND FACTORY

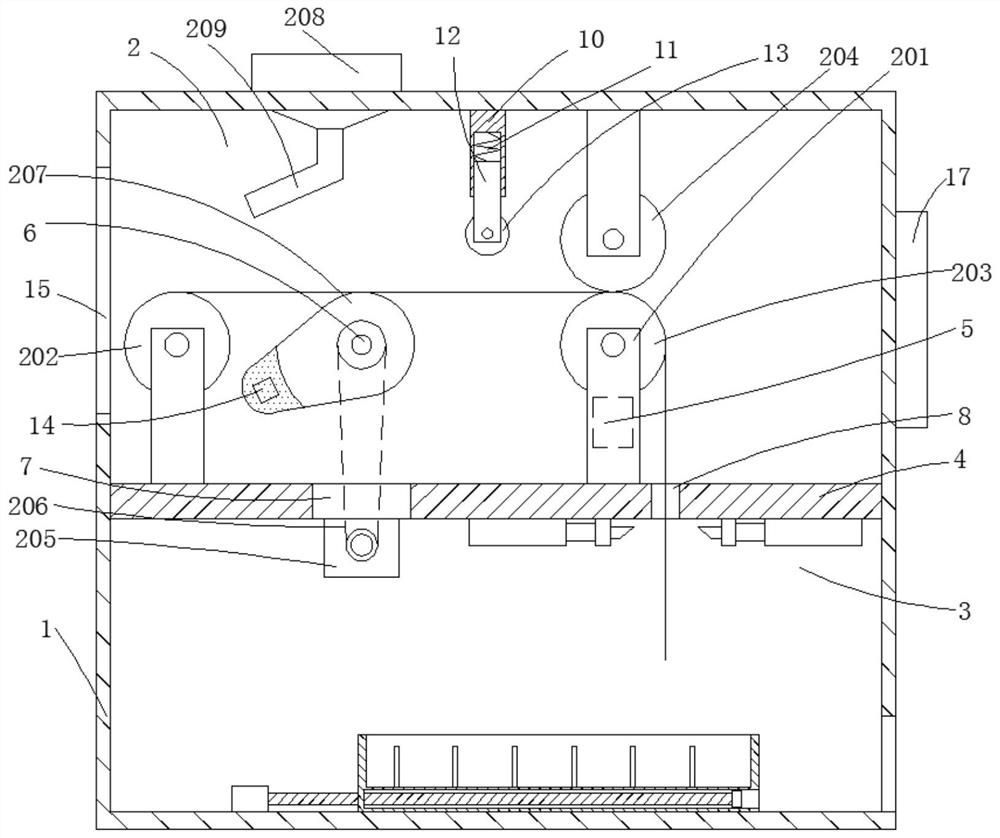

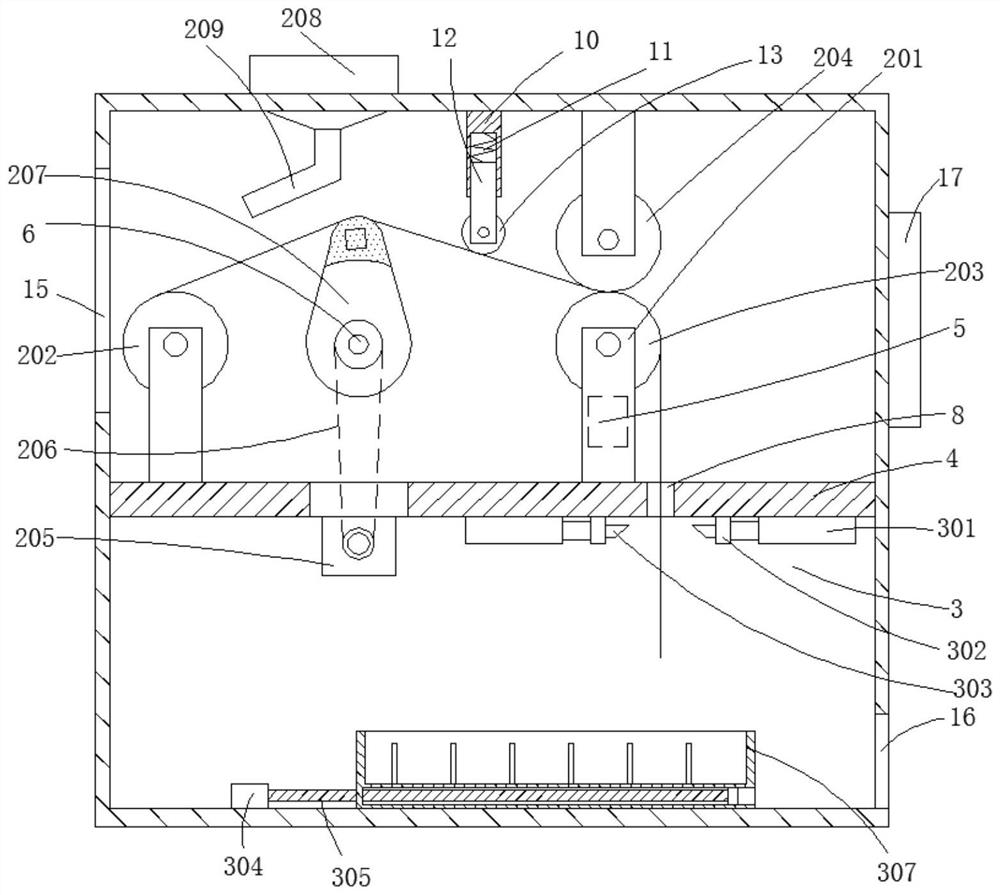

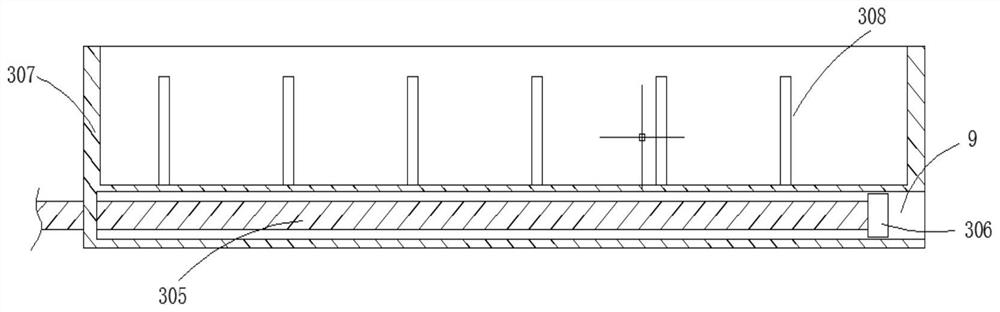

Packaging paperboard cutting and punching device and cutting method thereof

The invention relates to a packaging paperboard cutting and punching device and a cutting method thereof. The packaging paperboard cutting and punching device comprises a machine body and a cutting part arranged on the machine body; the packaging paperboard cutting and punching device is characterized by comprising at least one constant-speed roller which is arranged on any side of the cutting part, used for conveying a packaging paperboard and controlled by a first plc motor, at least one speed-regulating punching assembly which is used for conveying the packaging paperboard and controlled by a second plc motor, and a control unit which is used for controlling the first plc motor and the second plc motor, wherein an accumulation area for accumulation of the packaging paperboards is formed between the constant-speed roller and the speed-regulating punching assembly; a detection device located between the constant-speed roller and the speed-regulating punching assembly is arranged on the machine body, and the detection device is used for detecting the accumulation depth of the packaging paperboards in the accumulation area and feeding the accumulation depth back to the control unit; and the control unit controls the second plc motor to drive the speed-regulating punching assembly to rotate on the basis of a detection result of the detection device. The packaging paperboard cutting and punching device has the beneficial effects that the efficiency is high, and the packaging paperboard can be punched before being cut.

Owner:毛振高

Sock washing machine with high cleaning intensity

ActiveCN108978102AIncrease cleaning strengthClean upOther washing machinesTextiles and paperWater pipeSOCKS

The invention discloses a sock washing machine with high cleaning intensity, the sock washing machine includes a housing, a sleeve, friction blocks, a cover plate, a water inlet pipe, water guide pipes, a bottom plate, a first servo motor, a driving shaft, a driving horizontal gear, a first driven shaft, a driven horizontal gear, a fixed rotating plate, a fixed plate, an intermittent reciprocatingmechanism, a fixed cover and a coaxial speed change mechanism, the sleeve is rotatably connected to a side wall of the interior of the housing, an inner wall of sleeve is symmetrically provided withthe friction blocks, one end of the sleeve, which is away from the bottom of the housing, is fixedly provided with the cover plate, the water inlet pipe is fixed in a middle part of a surface of the cover plate, an upper surface of the cover plate is equidistantly fixedly provided with the water guide pipes, one ends of the water guide pipes, which are close to the water inlet pipe, communicate with the water inlet pipe, one ends of the water guide pipes, which are away from the water inlet pipe, communicate with the cover plate, the bottom of an inner wall of the housing is fixedly provided with the bottom plate, and the first servo motor is fixed in the center of an upper surface of the bottom plate. Through the intermittent reciprocating mechanism and an intermittent swing mechanism, the sock washing machine continuously twists and stretches socks in the cleaning process, so that the socks are more thoroughly cleaned.

Owner:XUZHOU YUNCHUANG PROPERTY SERVICE CO LTD

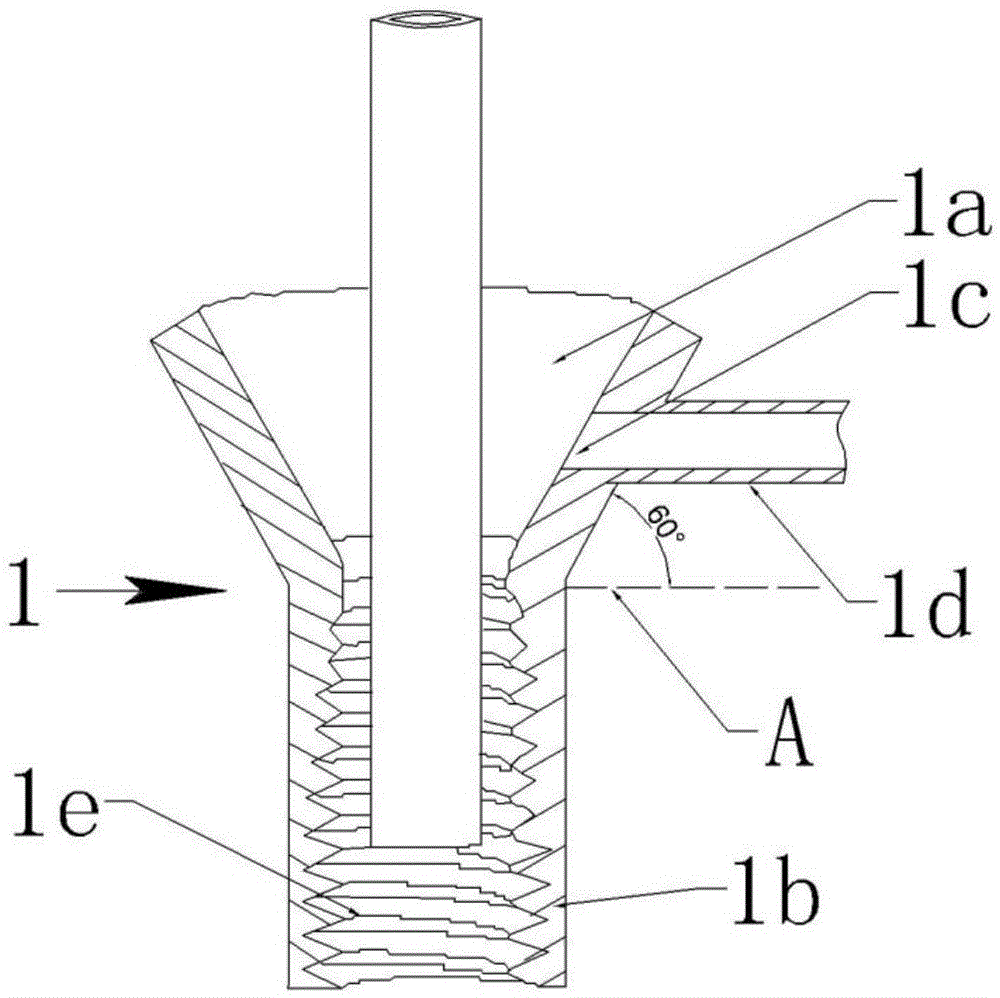

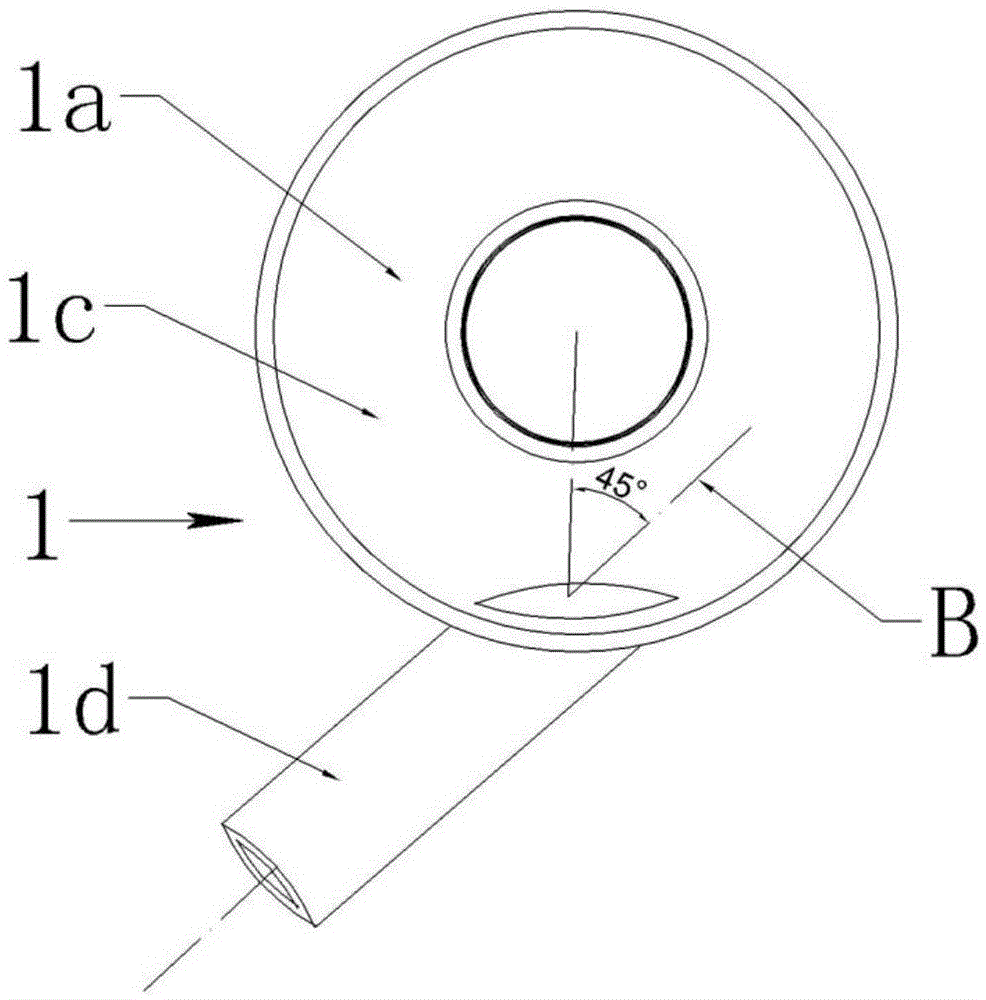

Vortex type sampling needle washing device

The invention discloses a vortex type sampling needle washing device which comprises a needle washing unit. The needle washing unit comprises a small-end-down conical cavity and a liquid outlet pipe, wherein the conical cavity is located on the upper portion, and the liquid outlet pipe is vertical and located on the lower portion. The upper end of the conical cavity is open, the inner surface of the conical cavity is a polished surface, and a liquid inlet for washing liquid penetrates through the side wall of the conical cavity; a horizontally-titling liquid inlet pipe is arranged outside the washing liquid inlet, and the tilting angle of the liquid inlet pipe is 30-60 degrees; the lower end of the conical cavity communicates with the liquid outlet pipe, and the axis of the conical cavity and the axis of the liquid outlet pipe are located on the same straight line. A spiral groove is formed in the inner wall of the liquid outlet pipe, and the depth of the groove is gradually increased from top to bottom in the spiral direction. The vortex type sampling needle washing device has the beneficial effects that when sampling needles are washed, washing force is large, the washing speed is high, the washing effect is good, and pollution is avoided; the effects can be further enhanced by changing parameters of the needle washing unit.

Owner:CHONGQING NANFANG NUMERICAL CONTROL EQUIP

Drainage pipeline with decontamination and purification functions for industrial drainage

InactiveCN113304519AImprove cleaning efficiencyIncrease cleaning strengthSewer cleaningSewer pipelinesOutfallMechanical engineering

The invention discloses a drainage pipeline with decontamination and purification functions for industrial drainage. The drainage pipeline comprises a main water pipe, a connecting pipe is fixedly connected to the outer wall of the end, close to the main water pipe, of the main water pipe, a water outlet is fixedly connected to the end, away from the main water pipe, of the connecting pipe, and discontinuous sliding grooves are formed in the outer wall of the connecting pipe; a rotating wheel is slidably connected into the discontinuous sliding groove, the connecting pipe can keep the sealing performance when the rotating wheel slides in the sliding groove, an opening and closing device which can be opened or closed when the rotating wheel rotates is arranged on the inner wall of the rotating wheel, and a filter screen is fixedly installed on the inner wall, away from the water outlet, of the main water pipe. And a cleaning device capable of cleaning the filter screen when the rotating wheel rotates is arranged on the inner wall of the main water pipe. By arranging the opening and closing device and the cleaning device, under the cooperation of the filter screen, the effects that solid waste can be treated, the cleaning efficiency of the interior of the pipeline is high, and the cleaning strength is high are achieved, and the device is superior to an existing product.

Owner:赵卫东

Cleaning instrument for high school chemical experiment glass tubes and use method of cleaning instrument

ActiveCN113680719AEasy to cleanFunction increaseHollow article cleaningCleaning using toolsElectric machineryTest tube

The invention discloses a cleaning instrument for high school chemical experiment glass tubes and a use method of the cleaning instrument, and relates to the technical field of cleaning instruments. The cleaning instrument comprises a shell, wherein a clamping mechanism is rotationally connected between the inner surfaces of the shell, a servo main motor is fixedly installed at the position, under the clamping mechanism, of the inner wall of the shell, one end of an output shaft of the servo main motor is fixedly connected with the clamping mechanism, a cleaning mechanism is slidably connected to the inner wall of the shell, a driving module is fixedly installed between the inner surfaces of the shell, the peripheral side face of the driving module is connected with the cleaning mechanism, a dirt collecting hopper is fixedly installed on the bottom face of the shell, and a liquid feeding module is fixedly installed on the inner wall of the shell. Through the design of the clamping mechanism and the cleaning mechanism, the cleaning instrument can automatically complete the cleaning operation of the glass test tubes in batches; and during the cleaning operation, the single inner wall cleaning mode of a traditional cleaning instrument is changed into an inner and outer wall synchronous cleaning mode.

Owner:南京多昇智能科技有限公司

Artificial intelligence production system for sheet metal part

ActiveCN112643519AImprove processing efficiencyPlay a role in cycle cleaningPolishing machinesGrinding drivesPolishingElectric machinery

The invention discloses an artificial intelligence production system for a sheet metal part, and relates to the technical field of sheet metal part machining. The artificial intelligence production system involves an outer shell body, wherein a material conveying mechanism is fixedly installed inside the outer shell body, a material pressing mechanism and a polishing mechanism are fixedly installed in the positions, corresponding to the positions right above the material conveying mechanism, inside the outer shell body, a feeding port is fixedly formed in the position, adjacent to one side of the material pressing mechanism, of the end of the outer shell body, and a discharging port is fixedly formed in the end, away from the feeding port, of the outer shell body; and an electromagnetic attraction seat matched with the material conveying mechanism is fixedly connected to the inner wall of the outer shell body, a main driving motor is fixedly connected to the end surface of the outer shell body, and one end of an output shaft of the main driving motor is fixedly connected with the material conveying mechanism. According to the artificial intelligence production system, through the design of the material pressing mechanism, the material conveying mechanism and the polishing mechanism, the system can automatically complete the polishing work of the surface of the sheet metal part through an assembly line mode, and the machining efficiency of the system on the sheet metal part is effectively improved through the implementation of the assembly line type operation mode.

Owner:安徽卡尔制冷科技有限公司

Equipment for rapidly determining floated color of surface of textile and method thereof

InactiveCN108226451AIncrease cleaning strengthReduce in quantityTextile testingFiltrationProcess engineering

The invention provides detection equipment and a detection method thereof, and concretely relates to the equipment for rapidly determining floated color of a surface of textile and a method thereof. The equipment comprises a control module, a control panel, a test container, a stirring device, an electronic balance, an automatic liquid feeding apparatus, a pumping filtration liquid-collection apparatus, and a liquid-discharge cleaning device. The current floated color testing methods are characterized in that a container filled with a sample and a solution is subjected to artificial stirring or shaking, so that time and labor are consumed, sample quantity with one-time test is less, artificial testing is carried out, and the detection result error between samples is large. The equipment has the advantage of high automation degree, and integrates automatic weighing, automatic liquid feeding, automatic stirring, automatic pumping filtration, liquid discharge, and cleaning, the floated color testing method can be better adapted, the automation requirement of each step can be satisfied, and the equipment provides the convenient, rapid, and standard test method for the tests.

Owner:LILANG CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com