Cleaning method, cleaning device, water purification system and readable storage medium

A technology of water purification system and cleaning device, applied in the field of water purification, can solve the problem of poor cleaning effect of reverse osmosis membrane, and achieve the effects of easy peeling, prolonging service life and strengthening washing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

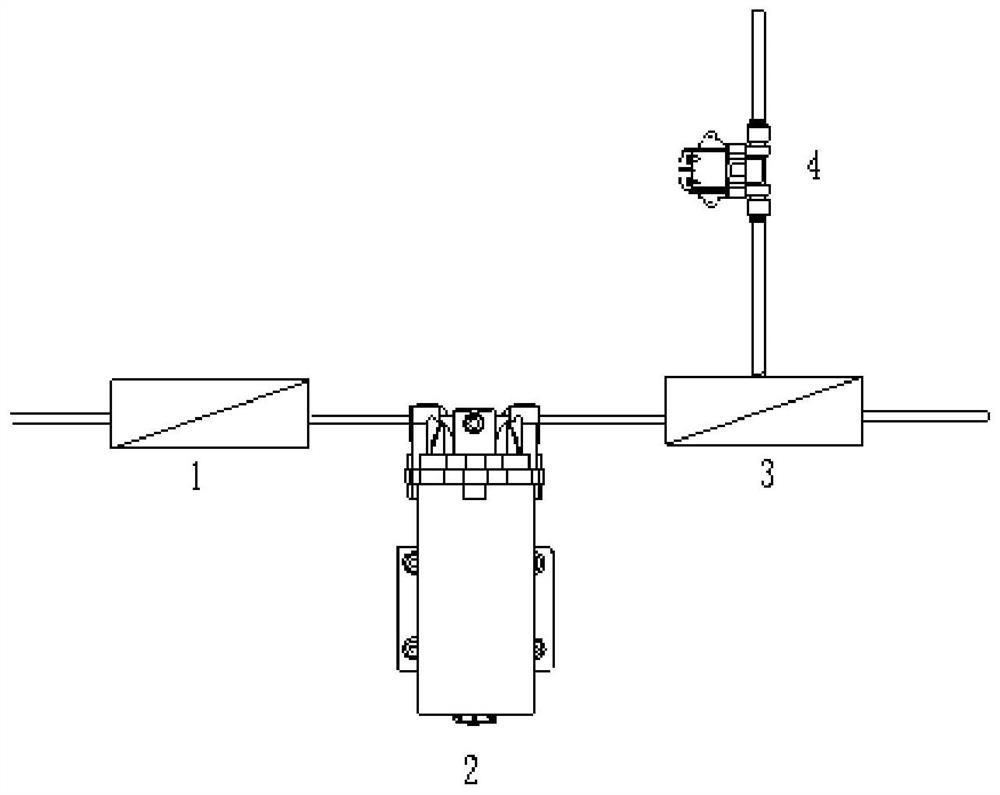

[0048] This embodiment provides a cleaning method for cleaning the fine filter unit 3 in the water purification system. In one embodiment, such as figure 1 As shown, the water purification system includes a pretreatment unit 1, a fine filtration unit 3, a pressurization device 2 arranged between the pretreatment unit 1 and the filtered unit, the concentrated water outlet of the filtered unit is connected with a waste water pipeline, and the waste water pipeline A flush valve 4 is provided. The pretreatment unit 1 can be a combination of single-stage or multi-stage pretreatment filter elements, the booster device 2 can be a booster pump, a pressure regulator pump, a self-priming pump, etc., and the fine filtration unit 3 can be a reverse osmosis membrane, nanofiltration, etc.

[0049] In one embodiment, the cleaning method comprises the steps of:

[0050] The first cleaning step includes adjusting the output flow of the pressurizing device 2 to a first flow and running for a fir...

Embodiment 2

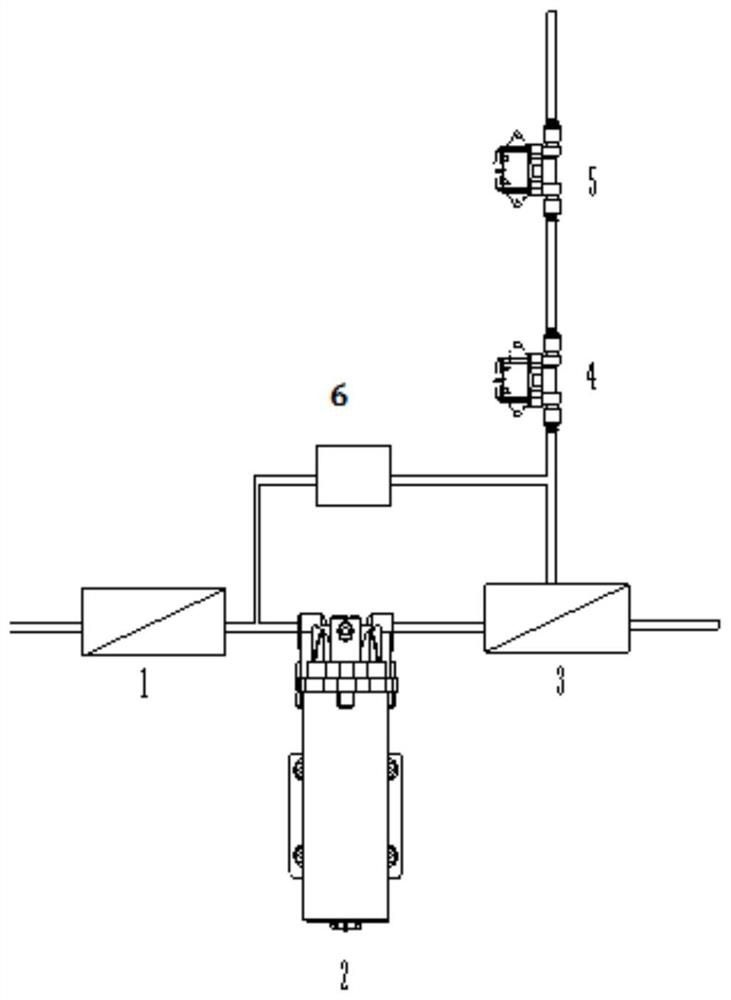

[0067] This embodiment provides a cleaning device for cleaning the fine filter unit 3 in the water purification system. The pressurizing device 2 is connected to a waste water pipeline through the concentrated water port of the filter unit, and a flushing valve 4 is arranged on the waste water pipeline. The pretreatment unit 1 can be a combination of single-stage or multi-stage pretreatment filter elements, the booster device 2 can be a booster pump, a pressure regulator pump, a self-priming pump, etc., and the fine filtration unit 3 can be a reverse osmosis membrane, nanofiltration, etc.

[0068] In one embodiment, the cleaning device includes a first cleaning module and a second cleaning module. The first cleaning module includes a first regulating module, which is used to adjust the output flow of the supercharging device 2 to be the first flow and run for the first preset time; the second cleaning module includes a second regulating module, which is used to adjust the outp...

Embodiment 3

[0077] This embodiment provides a water purification system, including a memory and a processor, the memory and the processor are connected to each other in communication, and computer instructions are stored in the memory, and the processor executes the cleaning method provided in Embodiment 1 by executing the computer instructions .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com