Regenerated pouring material used for swinging runner and prepared from waste slide plates and preparation method of regenerated pouring material

A technology of castables and slide plates, which is applied in the field of refractory castables, can solve the problems of relatively expensive prices, achieve the effects of saving high-quality refractory raw material resources, improving product comprehensive benefits, and reducing material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

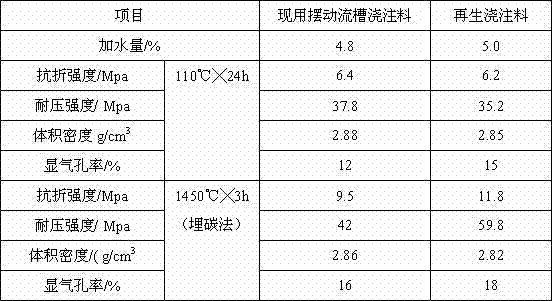

Examples

Embodiment 1

[0037] Embodiment 1: A regenerated castable for a swing launder prepared from waste slides, which includes the following materials in parts by weight: 40 parts of waste slide granular materials, 25 parts of high alumina bauxite, 20 parts of white corundum; 25 parts of silicon carbide 10 parts of α-Al2O3 micropowder, 5 parts of zircon sand, 3 parts of silicon micropowder, 4 parts of calcium aluminate cement, 3 parts of metal silicon, 0.12 part of explosion-proof fiber, and 0.15 part of admixture.

[0038] The particle size of the waste skateboard granular material is 0.1 mm to 3 mm and ≤0.074 mm; the particle size of the high alumina bauxite is 3 mm to 8 mm, and the quality index of the high alumina bauxite is: Al203≥88%.

[0039] The particle size of the white corundum is 0.1mm to 1mm and ≤0.088mm, and the quality index of the white corundum is: Al203≥99%.

[0040] The particle size of the silicon carbide is 0.1mm to 1mm and ≤0.088mm, and the quality index of the silicon carbi...

Embodiment 2

[0048] Embodiment 2: A regenerated castable for a swing launder prepared from waste slides, which includes the following materials in parts by weight: 30 parts of waste slide granular materials, 20 parts of high alumina bauxite, 15 parts of white corundum; 15 parts of silicon carbide 8 parts of α-Al2O3 micropowder, 3 parts of zircon sand, 1.5 parts of silicon micropowder, 2.5 parts of calcium aluminate cement, 1.5 parts of metal silicon, 0.1 part of explosion-proof fiber, and 0.1 part of admixture.

[0049] The particle size of the waste skateboard granular material is 0.1 mm to 3 mm and ≤0.074 mm; the particle size of the high alumina bauxite is 3 mm to 8 mm, and the quality index of the high alumina bauxite is: Al203≥88%.

[0050] The particle size of the white corundum is 0.1mm to 1mm and ≤0.088mm, and the quality index of the white corundum is: Al203≥99%.

[0051] The particle size of the silicon carbide is 0.1mm to 1mm and ≤0.088mm, and the quality index of the silicon c...

Embodiment 3

[0059] Embodiment 3: A regenerated castable for a swinging launder prepared from waste slides, which includes the following materials in parts by weight: 25 parts of waste slide granular materials, 15 parts of high alumina bauxite, 20 parts of white corundum; 10 parts of silicon carbide 5 parts of α-Al2O3 micropowder, 2 parts of zircon sand, 1 part of silicon micropowder, 2 parts of calcium aluminate cement, 1 part of metal silicon, 0.08 part of explosion-proof fiber, and 0.05 part of admixture.

[0060] The high alumina bauxite includes two particle sizes of 5mm to 8mm and 3mm to 5mm, and the quality index of the high alumina bauxite is: Al203≥88%.

[0061] The particle size of the waste skateboard granular material is 0.1 mm to 3 mm and ≤0.074 mm; the particle size of the high alumina bauxite is 3 mm to 8 mm, and the quality index of the high alumina bauxite is: Al203≥88%.

[0062] The particle size of the white corundum is 0.1mm to 1mm and ≤0.088mm, and the quality index of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com