Immersed type anaerobic membrane bioreactor capable of effectively controlling membrane pollution and treatment method

An anaerobic membrane biology and reactor technology, applied in anaerobic digestion treatment and other directions, can solve the problems of serious membrane fouling, large floor space, difficult membrane cleaning, etc., to reduce membrane fouling, reduce pollution, and strengthen processing capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

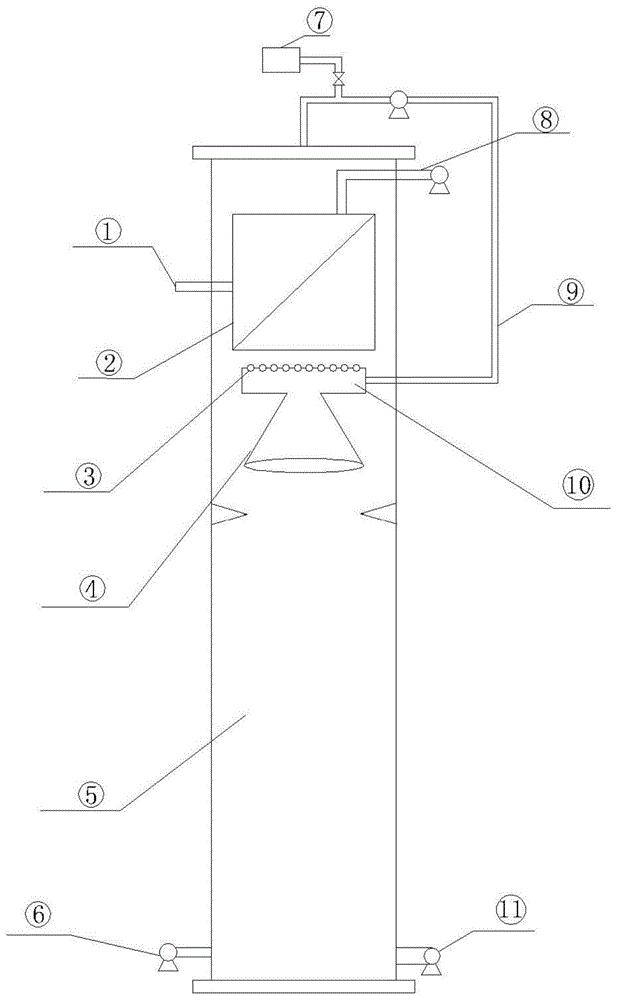

[0033] A submerged anaerobic membrane bioreactor for effectively controlling membrane fouling (see figure 1 ), the top of the bioreactor is provided with a biogas collection device 7, and the bottom is provided with a sludge discharge pipe 11. The interior of the reactor includes a membrane module 2, a three-phase separator 4 and a main reaction zone 5 from top to bottom; The bottom is provided with a water inlet pipe 6, the upper part of the three-phase separator 4 is connected to a gas distribution device 10, the upper part of the membrane module 2 is provided with a water outlet pipe 8, and the lower part is provided with a flushing pipe 1.

[0034] The membrane module is located on the upper part of the three-phase separator, after the purification of the main reaction zone and the separation of the three-phase separator, the waste water is relatively clear, so the pollution to the membrane module can be reduced.

[0035] The upper part of the three-phase separator is conn...

Embodiment 2

[0041] The main reaction zone of the submerged anaerobic membrane bioreactor that effectively controls membrane fouling is an upflow sludge bed reactor (UASB), which is cylindrical and has a height-to-diameter ratio of 3-8. The membrane module is a flat ultrafiltration membrane with a pore size of 0.03-0.06 μm.

[0042] The reactor is inoculated with anaerobic sludge and acclimatized, and the acclimatization period is 2-3 months; when the COD removal rate of the effluent reaches 85-95%, the acclimatization ends and is ready for use.

[0043] Wastewater treatment method:

[0044] The domestic sewage is pumped in through the water inlet pipe, transported to the main reaction area, and then passes through the three-phase separator together with the generated gas, and the separation of sludge, water and gas is realized in the three-phase separator; wherein, the generated gas undergoes three-phase separation After being separated by the filter, it is collected by the gas distribut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com