Packaging paperboard cutting and punching device and cutting method thereof

A technology for packaging cardboard and detection device, applied in packaging, transportation and packaging, paper/cardboard containers, etc., can solve the problems of increased production cost, damage, low production efficiency, etc., to save costs, improve friction, and improve efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

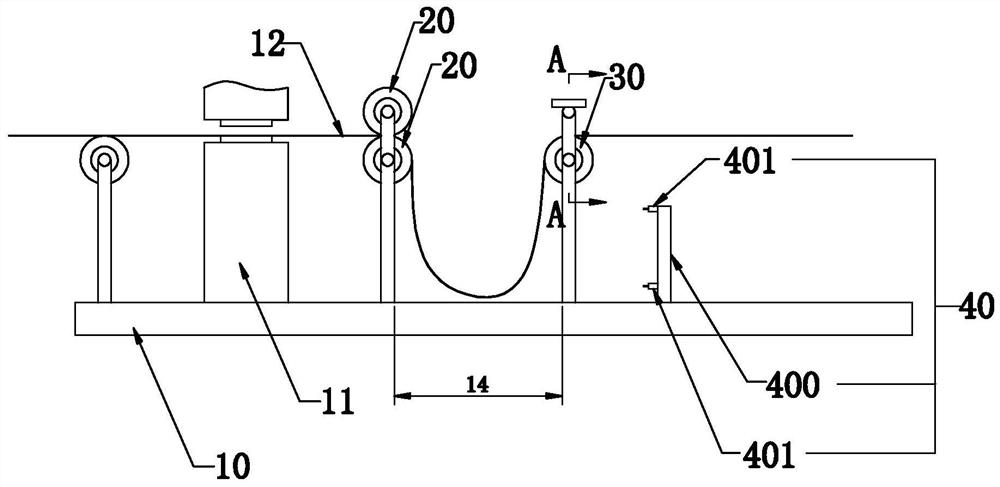

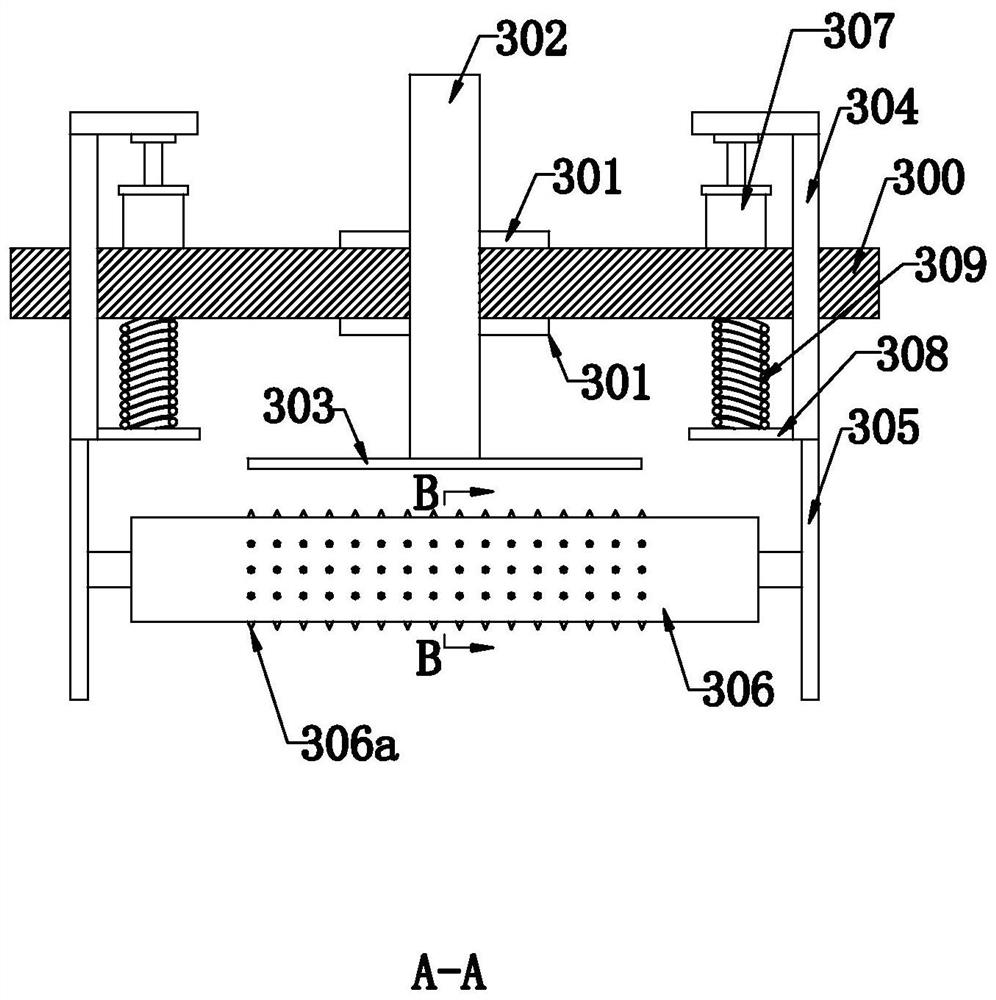

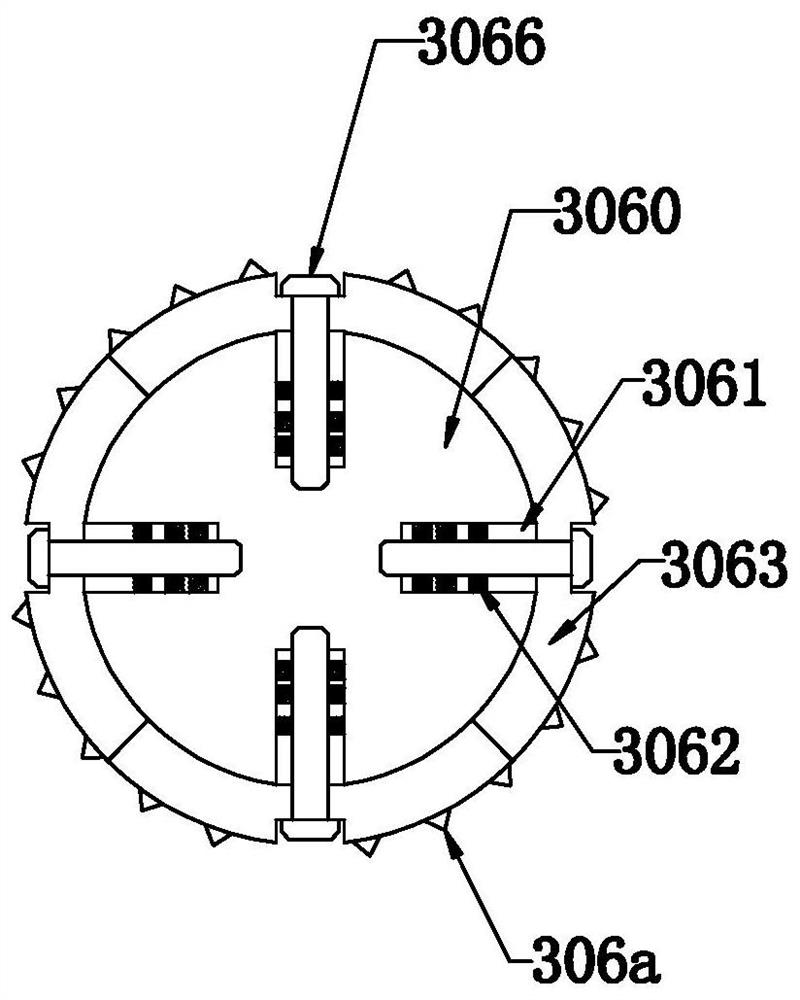

[0047] Such as Figure 1-4 As shown, the present invention discloses a packaging cardboard cutting and opening device, which includes a machine body 10 and a cutting part 11 arranged on the machine body 10. In a specific embodiment of the invention, at least one And it is used to convey the packing cardboard 12 and is controlled by the fixed speed roller 20 of the first plc motor, at least one is used for conveying the packaging cardboard 12 and is controlled by the second plc motor speed regulating punching assembly 30 and is used to control the first plc motor And the control unit of the second plc motor; wherein, between the fixed speed roller 20 and the speed regulating perforation assembly 30, a stacking area 14 for packing cardboard 12 is formed, and the body 10 is provided with a fixed speed roller 20 and a The detection device 40 between the speed-regulating punching assembly 30, the detection device 40 is used to detect the stacking depth of the packaging cardboard 12...

Embodiment 2

[0063] Embodiment 2, the difference with embodiment 1 is that

[0064] Such as Figure 5-Figure 9 As shown, in the specific embodiment of the present invention, it includes a supporting module 5 arranged in the stacking area 14 and used to support the packaging cardboard 12. The supporting module 5 includes a frame 50 arranged on the machine body 10, a rotating The first support bar 51 and the second support bar 52 that are connected to the frame 50 and arranged at intervals, and the support platform 54 that is connected with the first support bar 51 and the second support bar 52 and is used to support the packaging cardboard 12 And the first cylinder 55 hinged on the frame 50 and used to control the movement of the first support rod 51 around the hinge point; wherein, the first support rod 51 includes a first rod body 510, and the first secondary rod 511 fixedly connected to the rod body 510; The second sub-rod 521 on the top, a coupling 53 is provided between the first sub...

Embodiment 3

[0075] Embodiment 3, the difference with embodiment 2 is that

[0076] Such as Figure 10-Figure 13As shown, in the specific embodiment of the present invention, it also includes an auxiliary device 6 arranged on the support table 54 and used to supply air to the packaging cardboard 12 and assist the lifting of the packaging cardboard 12. The auxiliary device 6 includes a row of spacers The first air outlet hole 61 distributed on the support platform 54 and located in the center, at least two rows of second air outlet holes 62 arranged at intervals on both sides of the first air outlet hole 61, are arranged on the support platform 54 and used for An air distribution device 65 for supplying air to the first air outlet 61 and the second air outlet 62, and an air pump 63 installed at the bottom of the support table 54 and used to supply air to the input end of the air distribution device 64; wherein the air distribution The device 65 includes a distributing body 651 arranged on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com