Patents

Literature

85results about How to "Affect the grinding effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

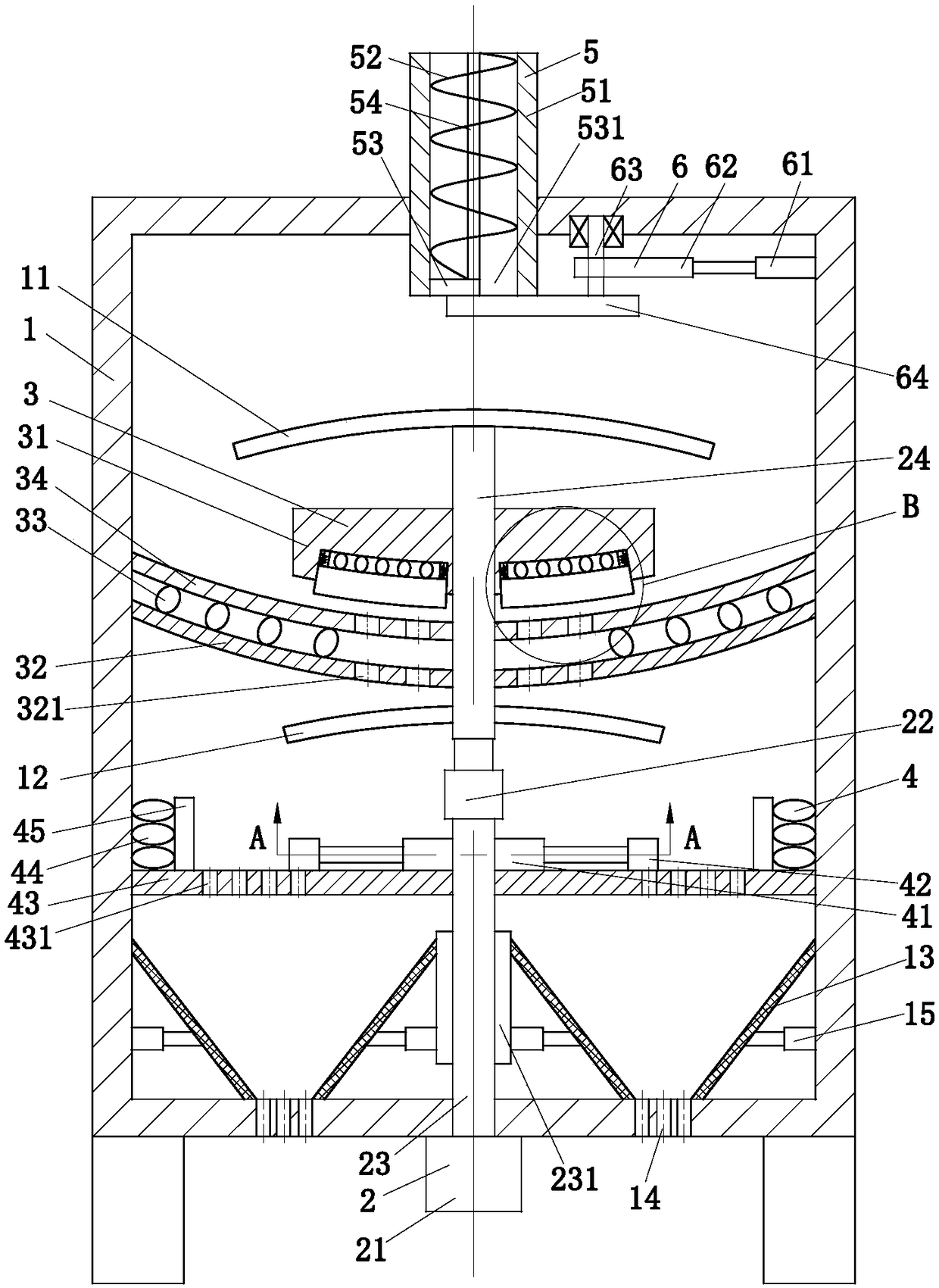

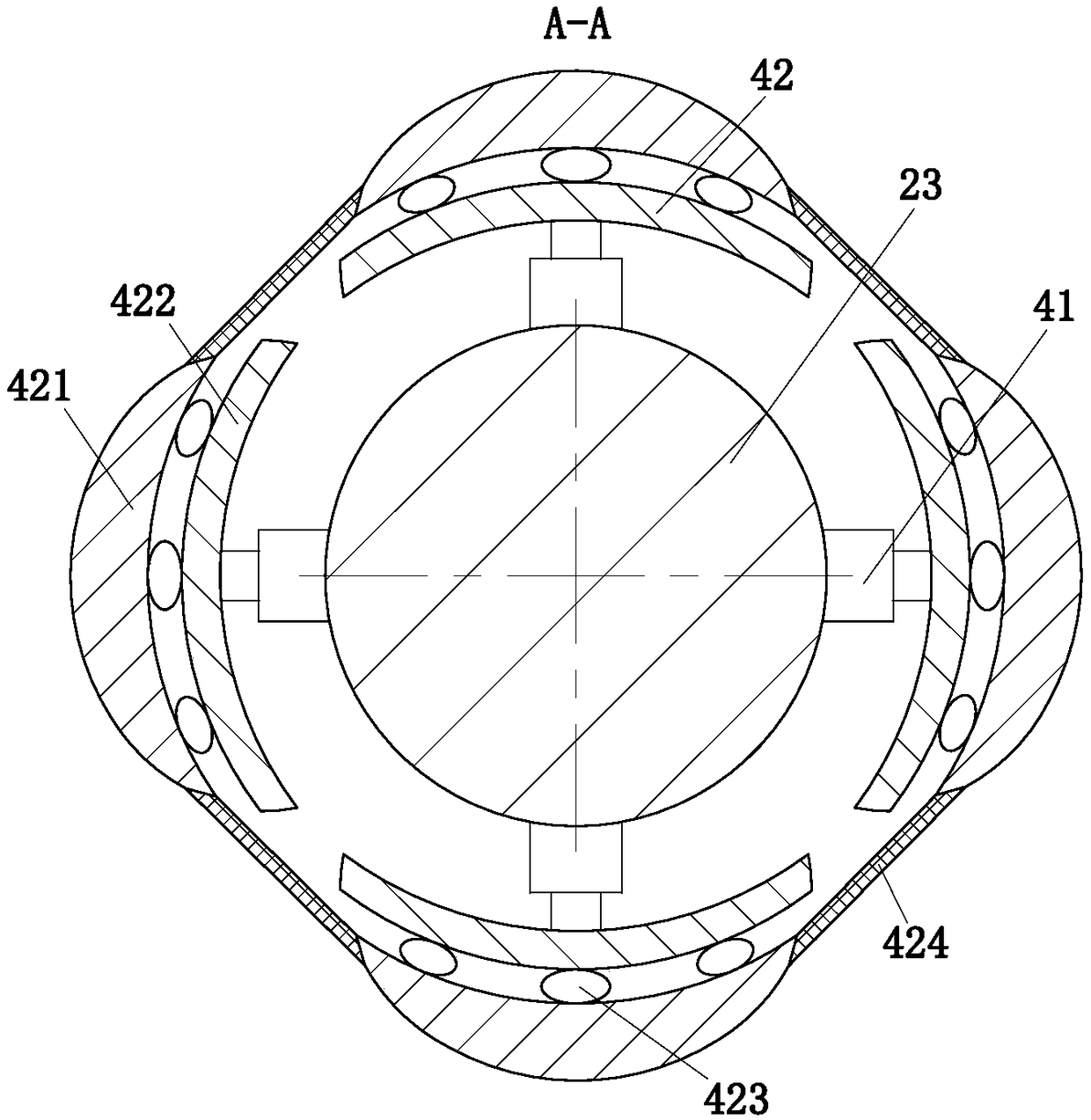

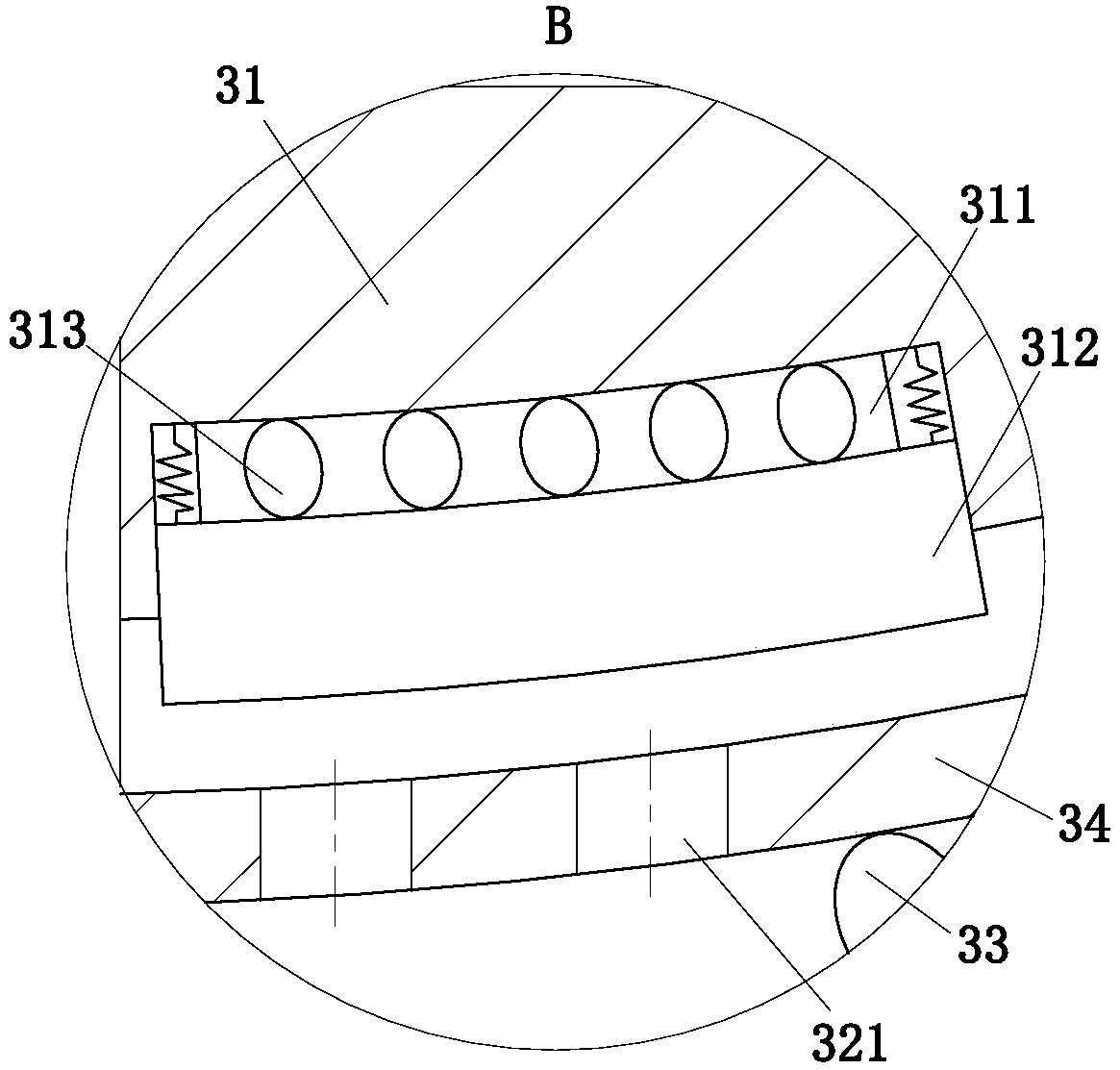

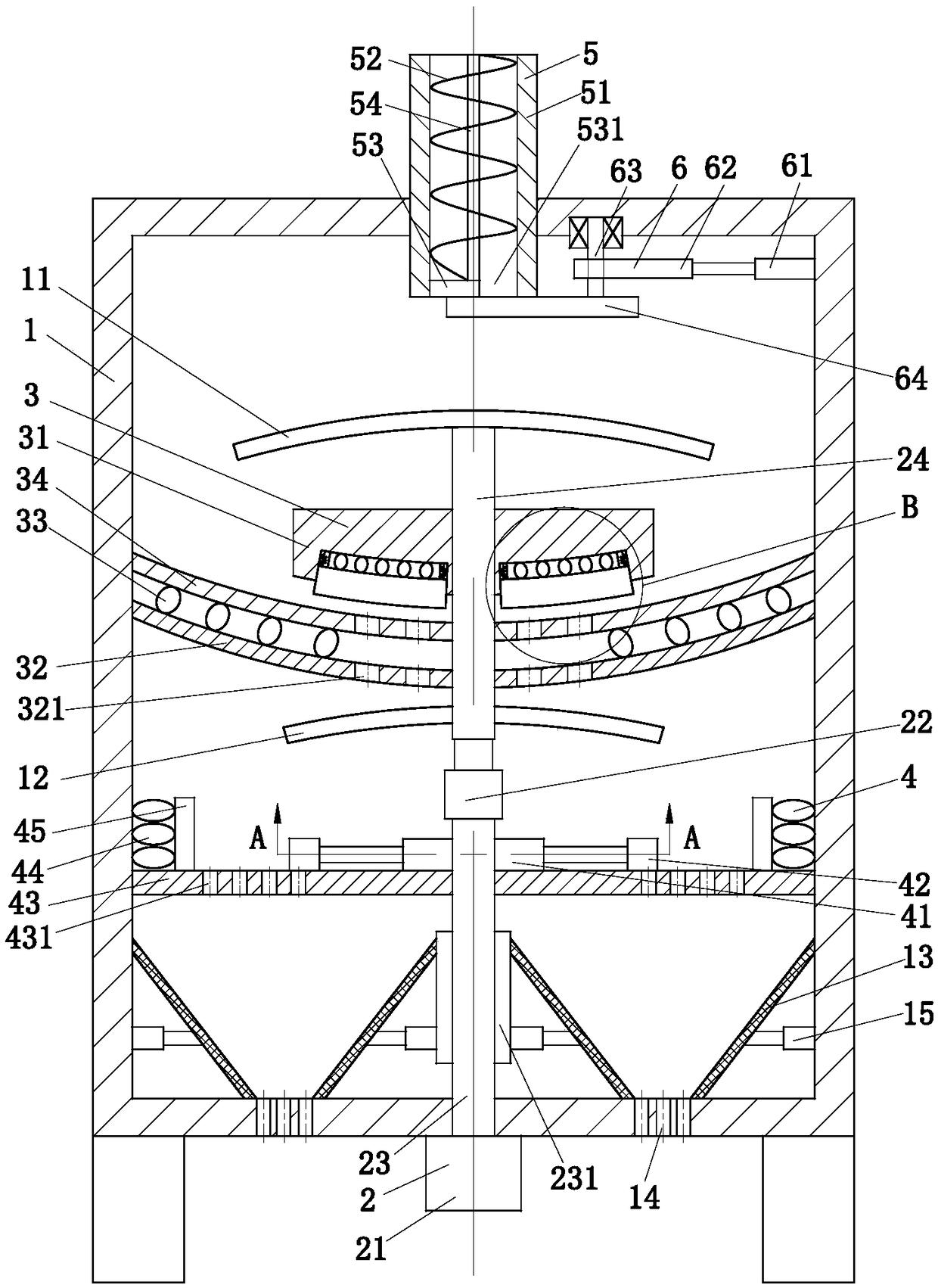

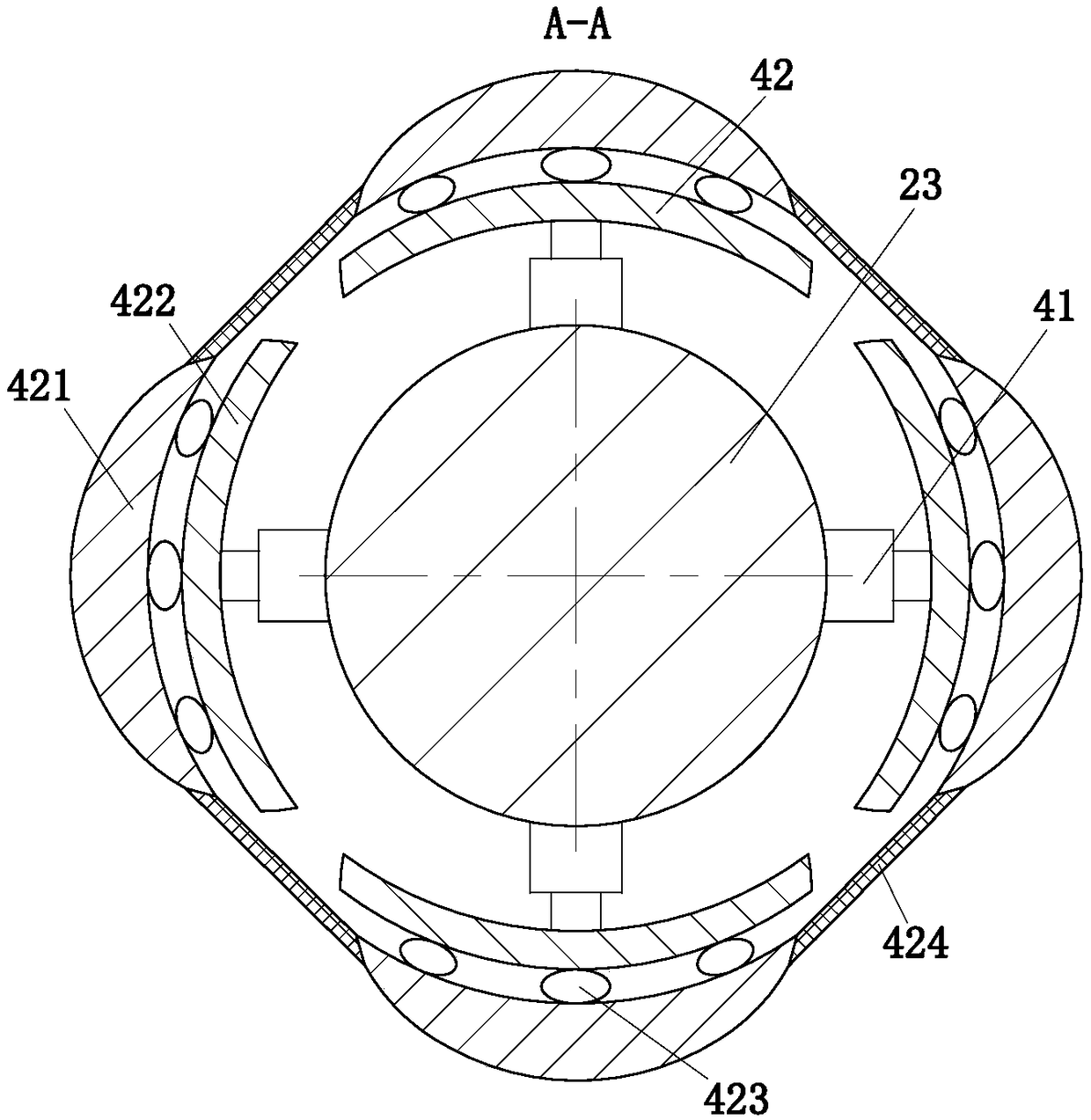

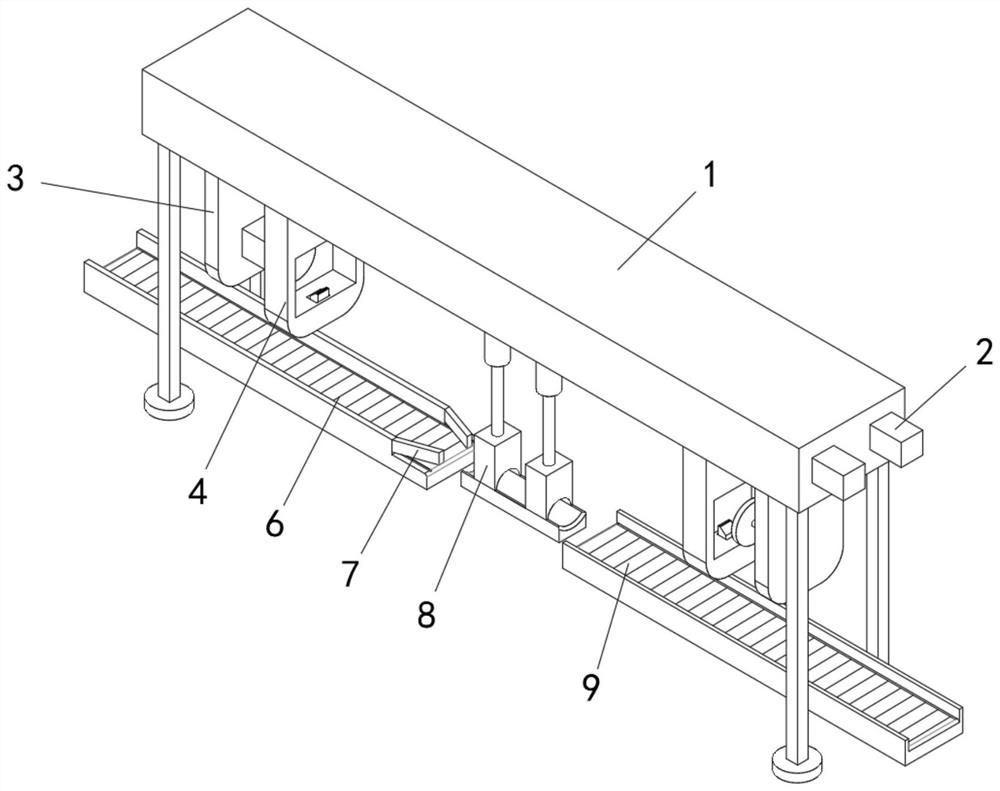

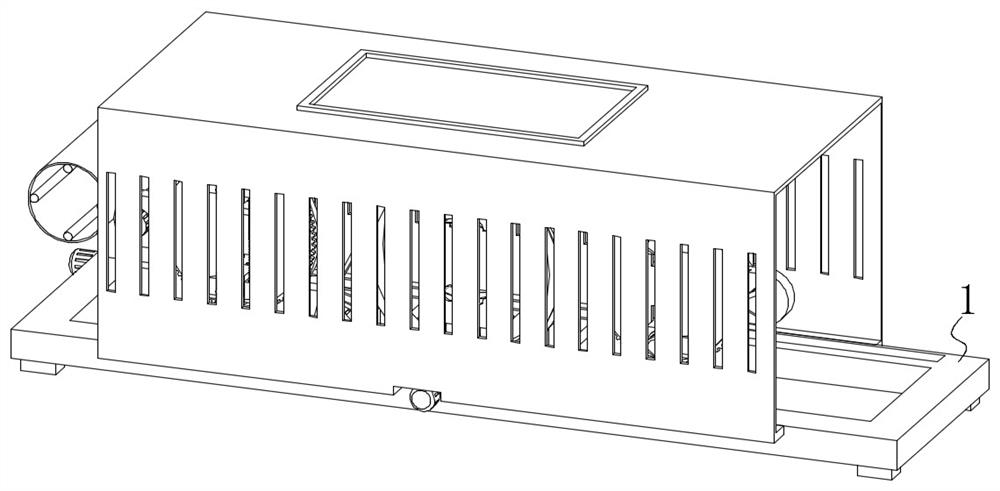

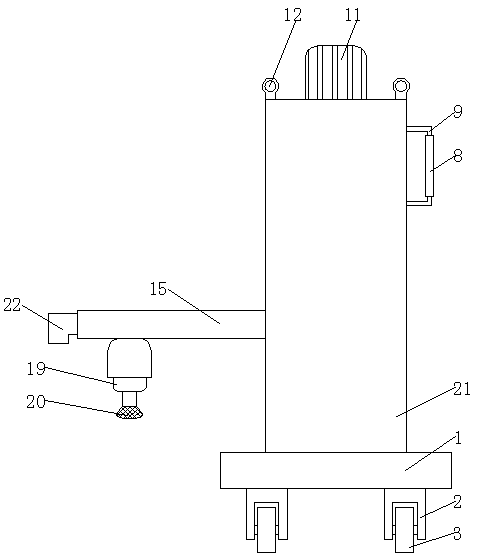

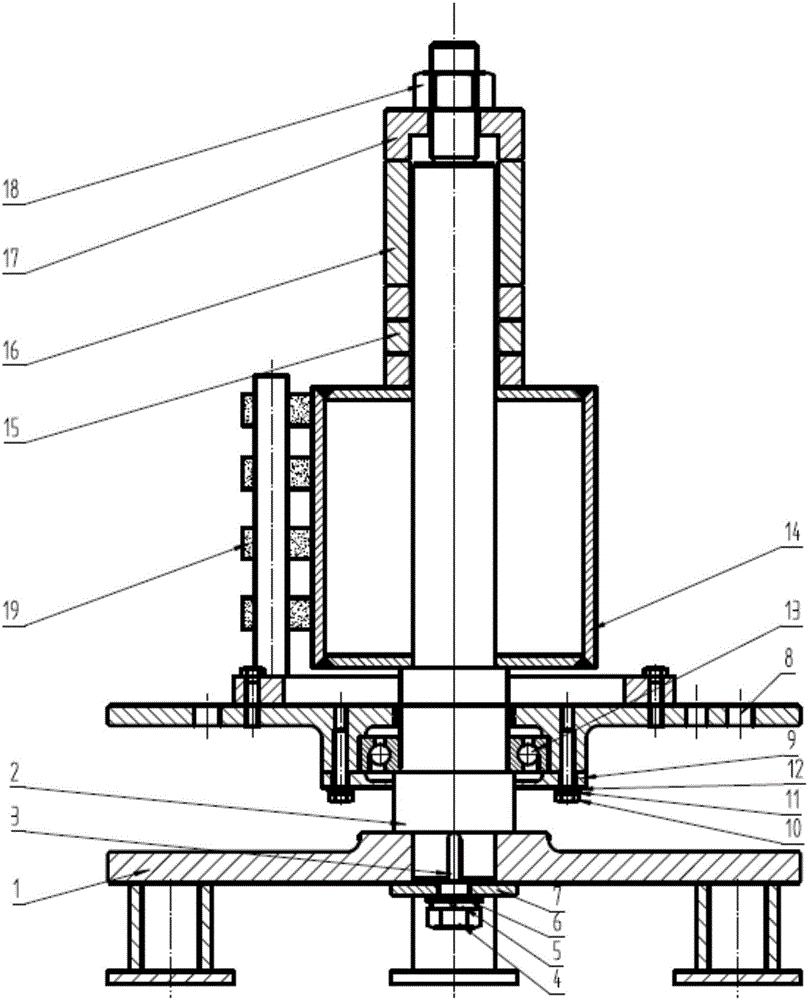

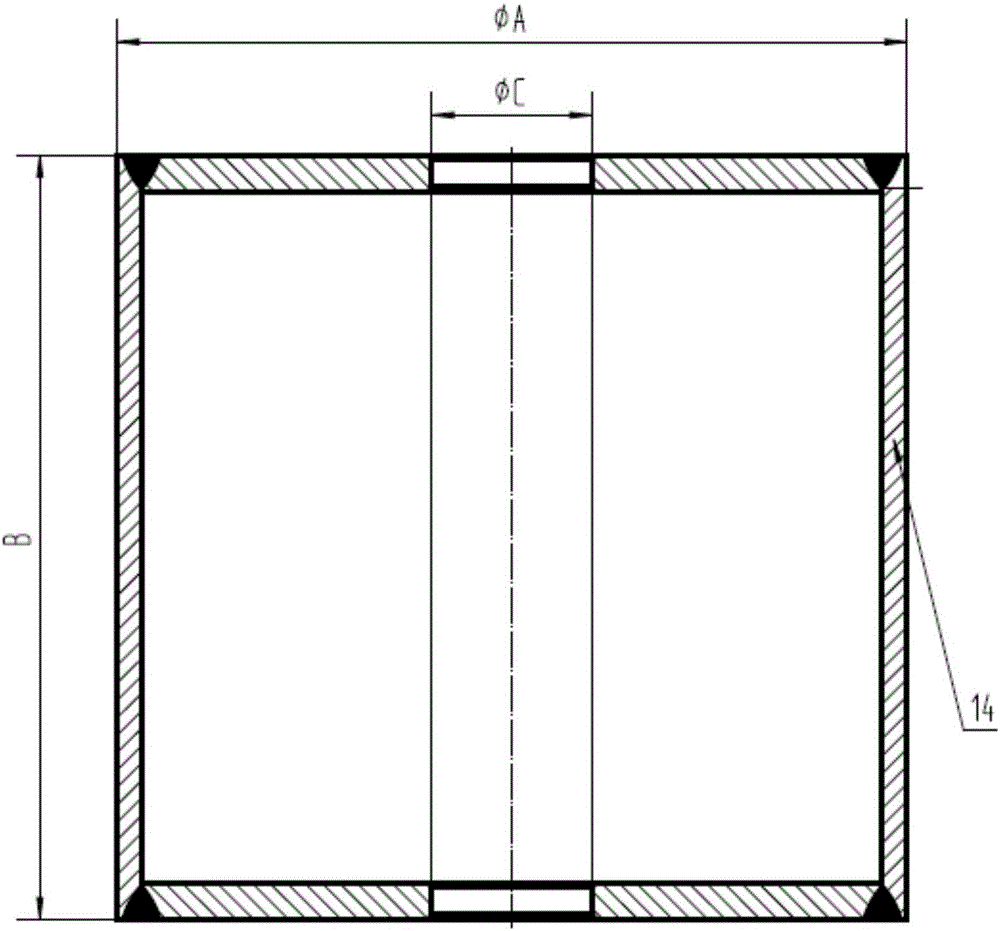

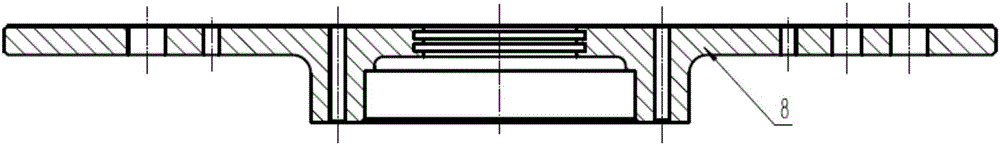

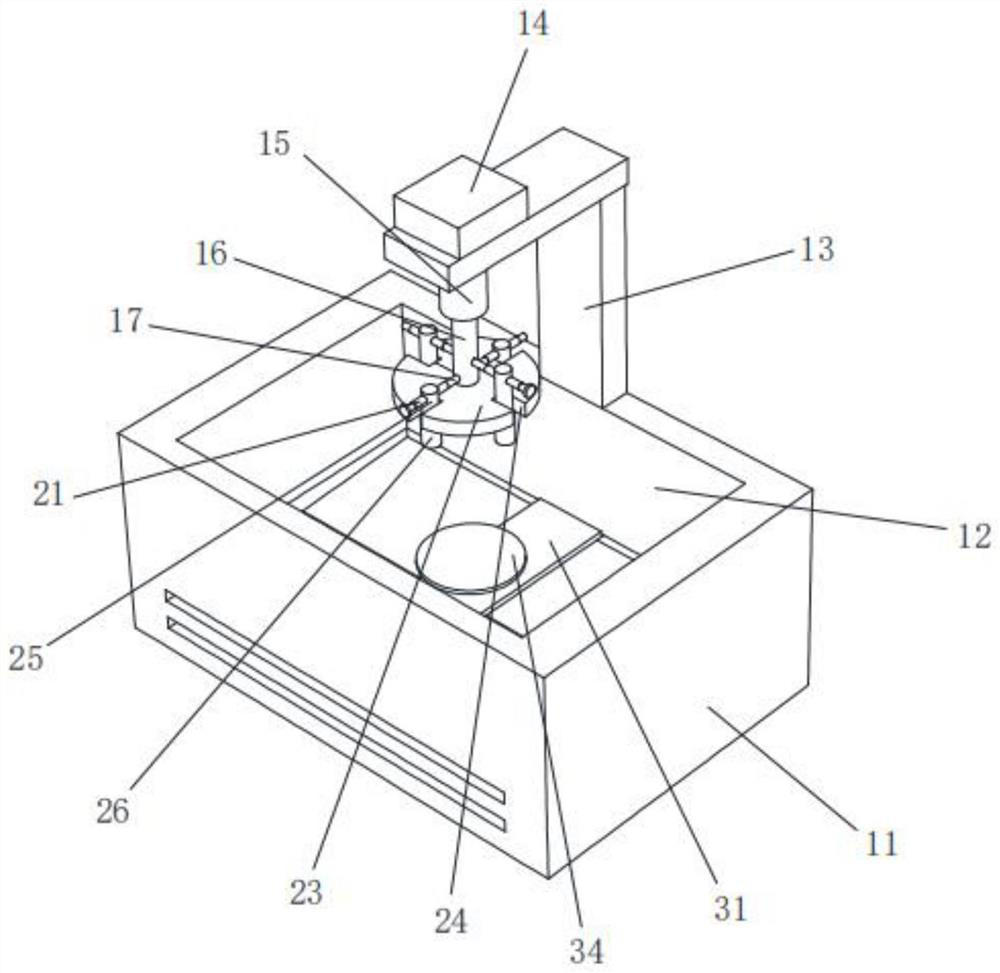

Refined table salt refined grinding processing system

ActiveCN109261277AImprove grinding effectImprove efficiencyGrain treatmentsFood scienceResource utilizationEngineering

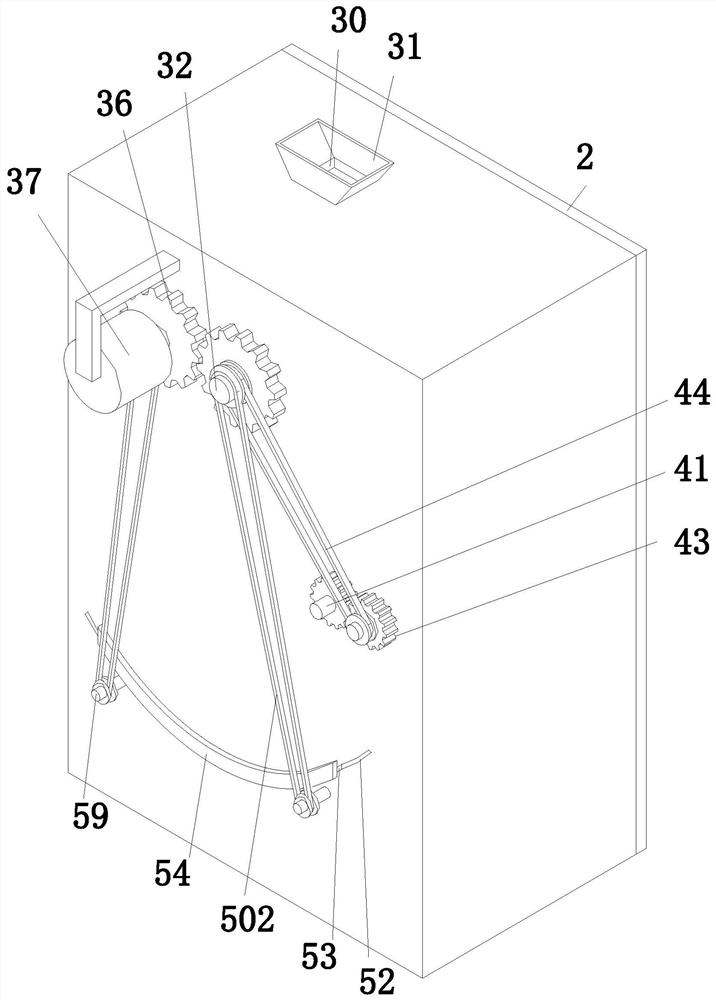

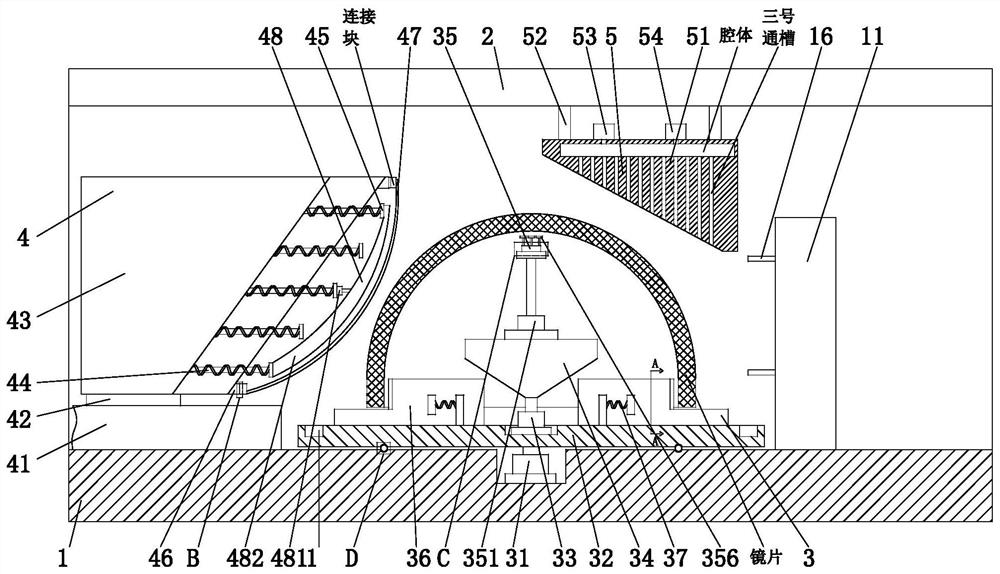

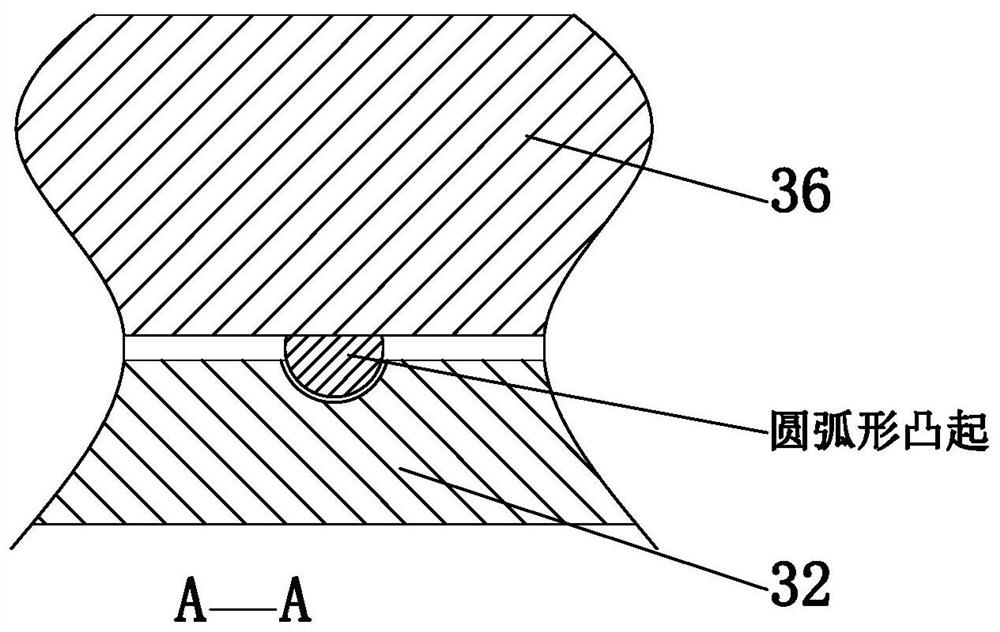

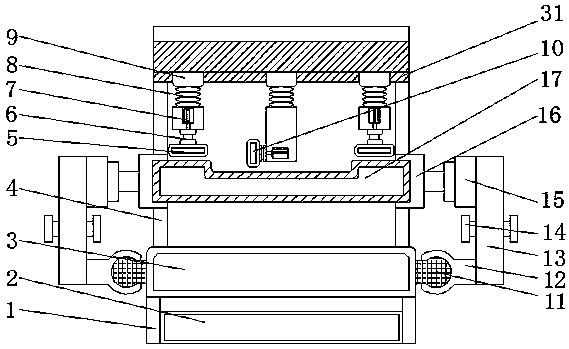

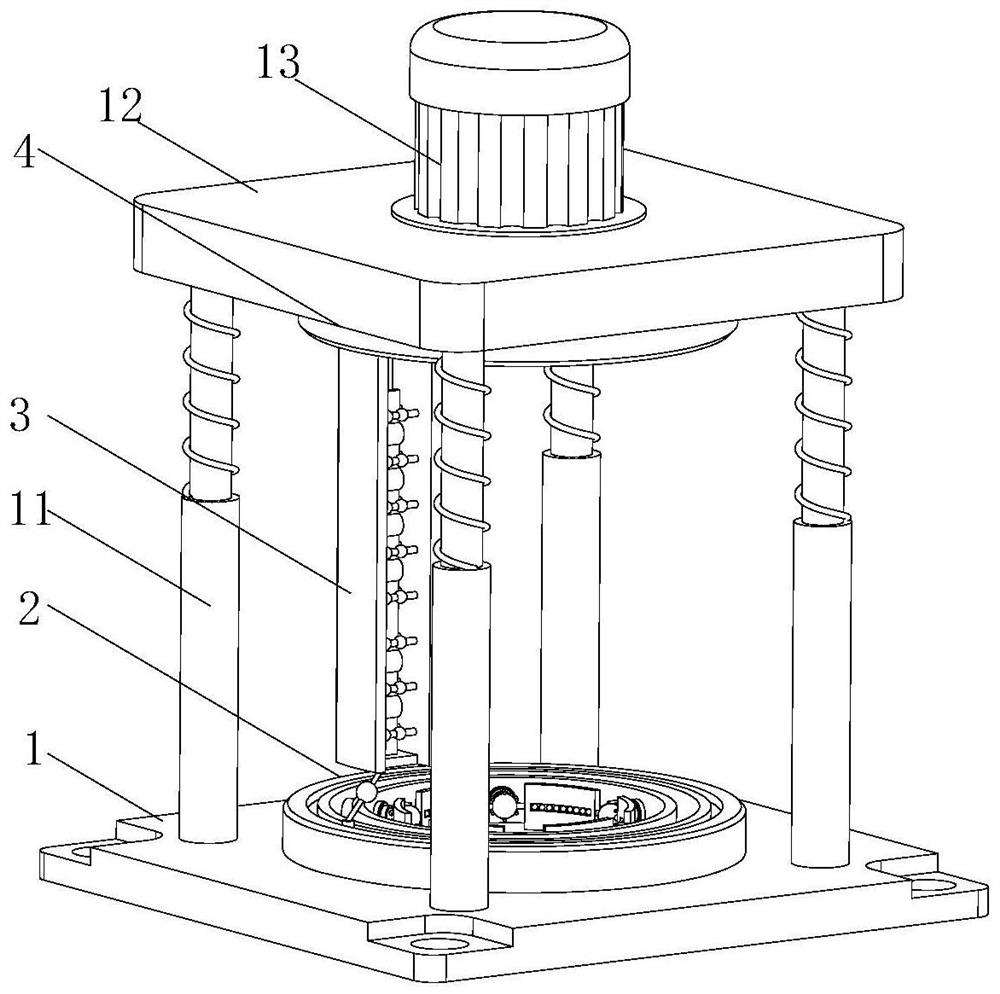

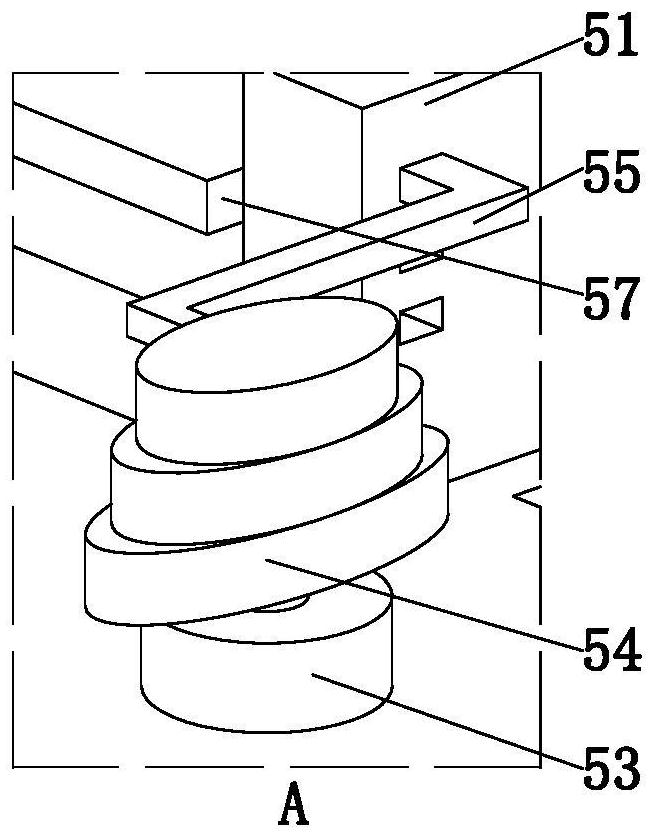

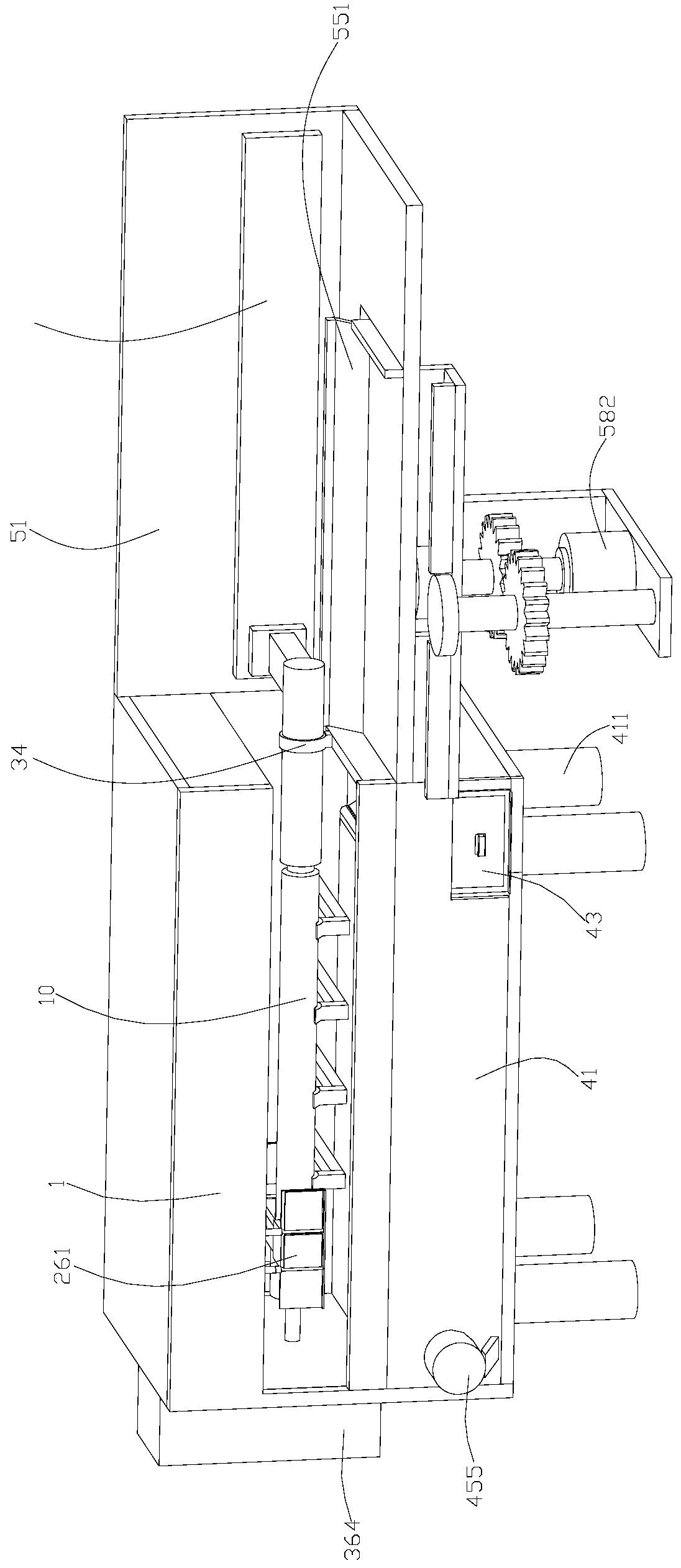

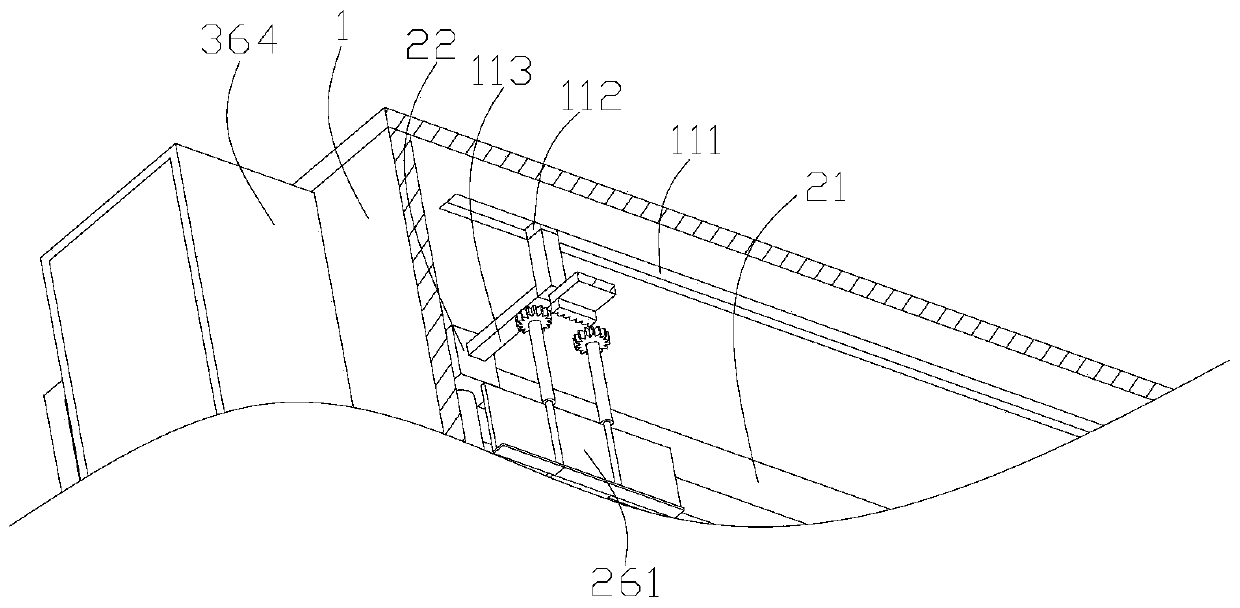

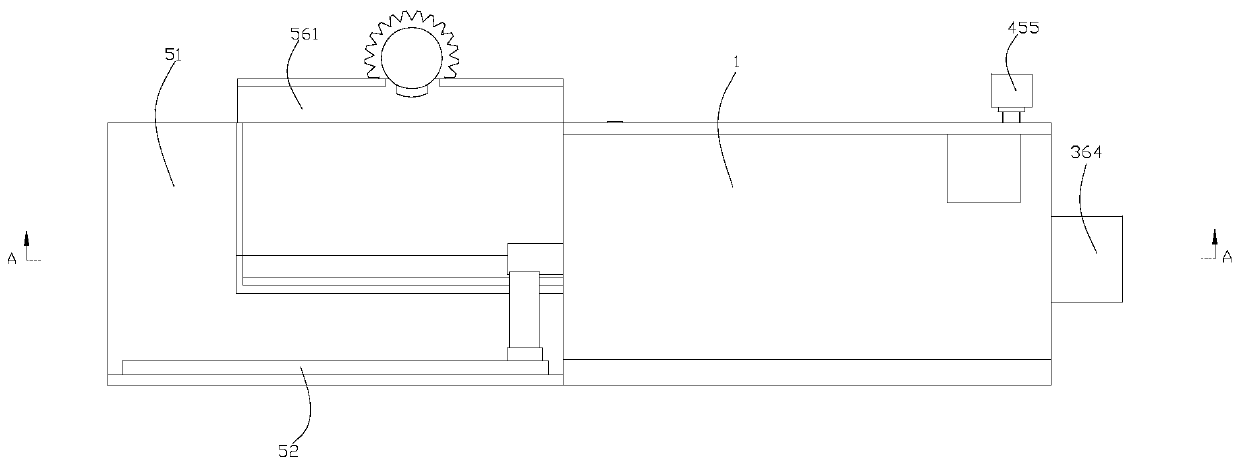

The invention belongs to the technical field of table salt processing, and particularly relates to a refined table salt refined grinding processing system. The refined table salt refined grinding processing system comprises a tube body, a driving unit, a first grinding unit, a second grinding unit, a blanking unit, a first material guide plate, a second material guide plate, a third material guideplate and a controller. Through the mutual matching of the driving unit, the first grinding unit, the second grinding unit, the blanking unit, the first material guide plate, the second material guide plate and the third material guide plate, on one hand, the driving unit drives the first grinding unit and the second grinding unit to grind the table salt grains; through the graded grading on thetable salt grains, the grinding effect and efficiency on the table salt grains can be improved; on the other hand, a power source generated in the table salt grinding process is utilized; the additional power source is reduced, so that the resource utilization rate is improved.

Owner:宜宾丰源盐业有限公司

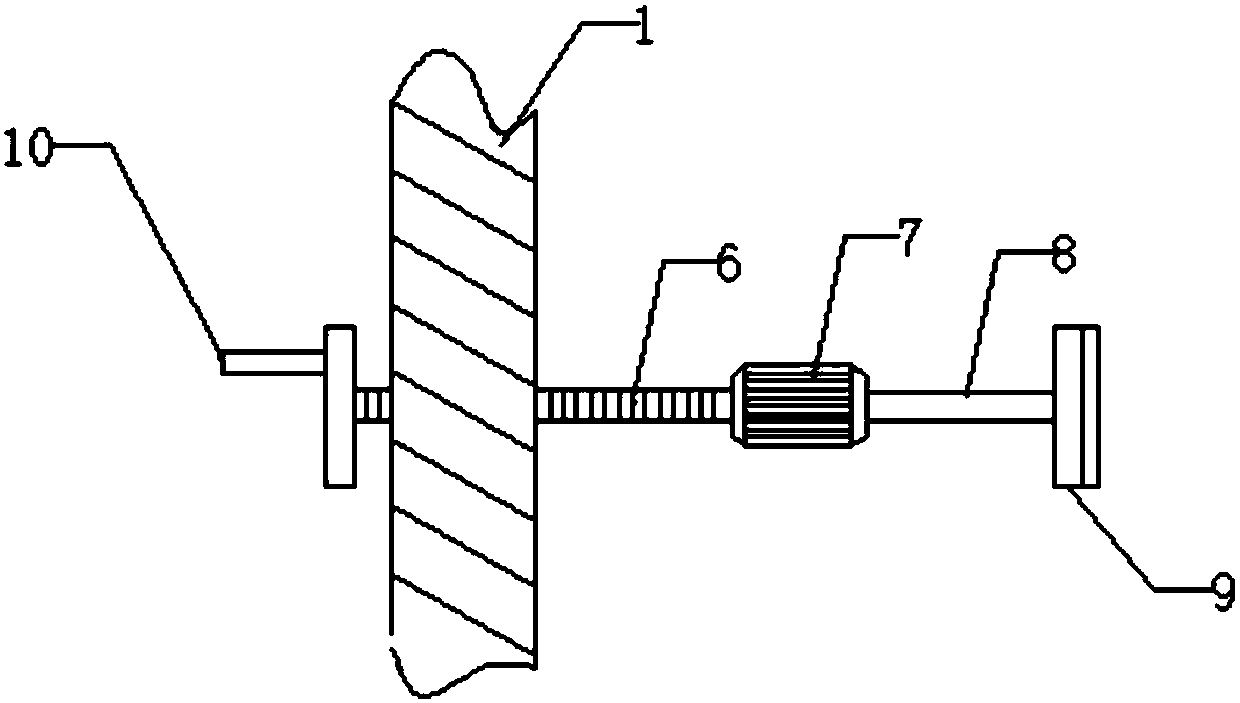

Bevel gear polishing device

InactiveCN106826515AAchieve grindingSqueeze fullyGrinding carriagesPolishing machinesGear wheelEngineering

The invention relates to the technical field of gear machining, in particular to a bevel gear polishing device. The bevel gear polishing device comprises a rotating shaft and a collecting tank; the rotating shaft is fixedly mounted on the collecting tank, and is sleeved with two rotating discs; a saw gear is arranged between the rotating discs; bevel gears are respectively arranged on the outer sides, far from the saw gear, of the two rotating discs; tooth grooves of the two bevel gears are distributed in a herringbone manner; the rotating discs are provided with guide grooves communicated with the tooth grooves of the bevel gears; a rack engaged with the saw gear is arranged on the outer side of the saw gear; one end, far from the rotating discs, of the rack is fixedly connected with an extension rod; one end, far from the bevel gears, of the extension rod is connected with a second airbag and a cylinder in sequence; the second airbag is inserted in the extension rod; one side, far from the cylinder, of the second airbag is connected with two first airbags; the first airbags are coated with elastic fine abrasive papers; and one-way intake holes are formed in the connecting places of the second airbag and the first airbags. The bevel gear polishing device solves the problem that the tooth roots of the bevel gears are not liable to polish.

Owner:滁州伏特威电气技术有限公司

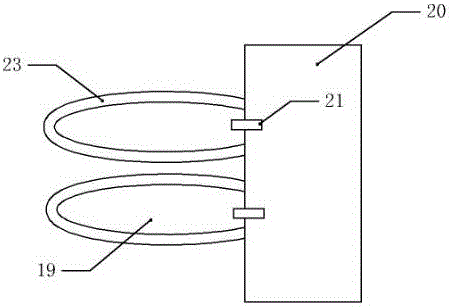

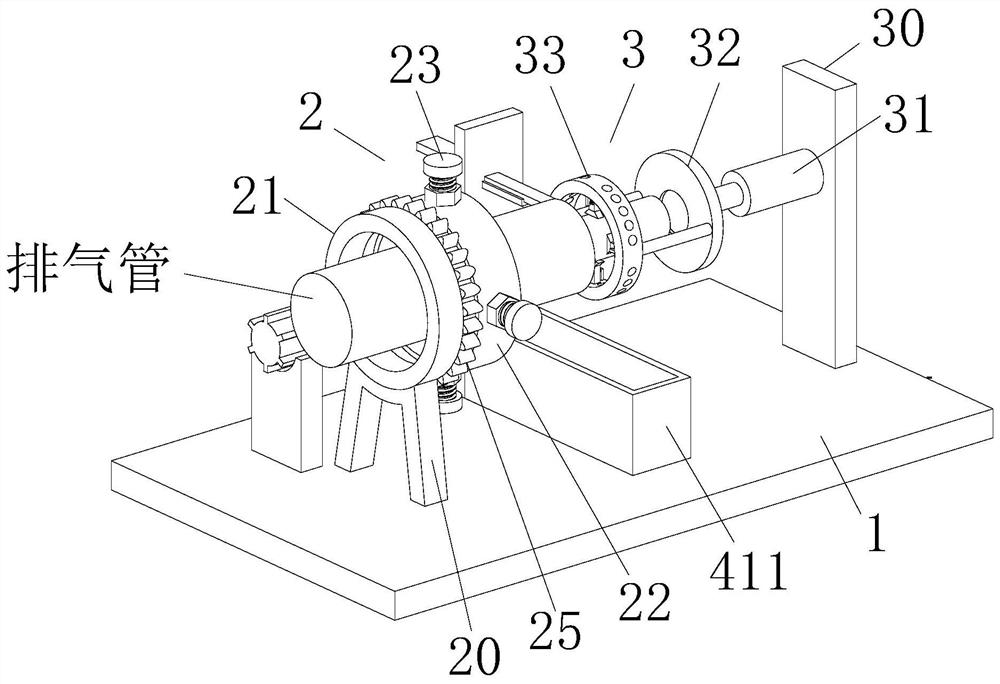

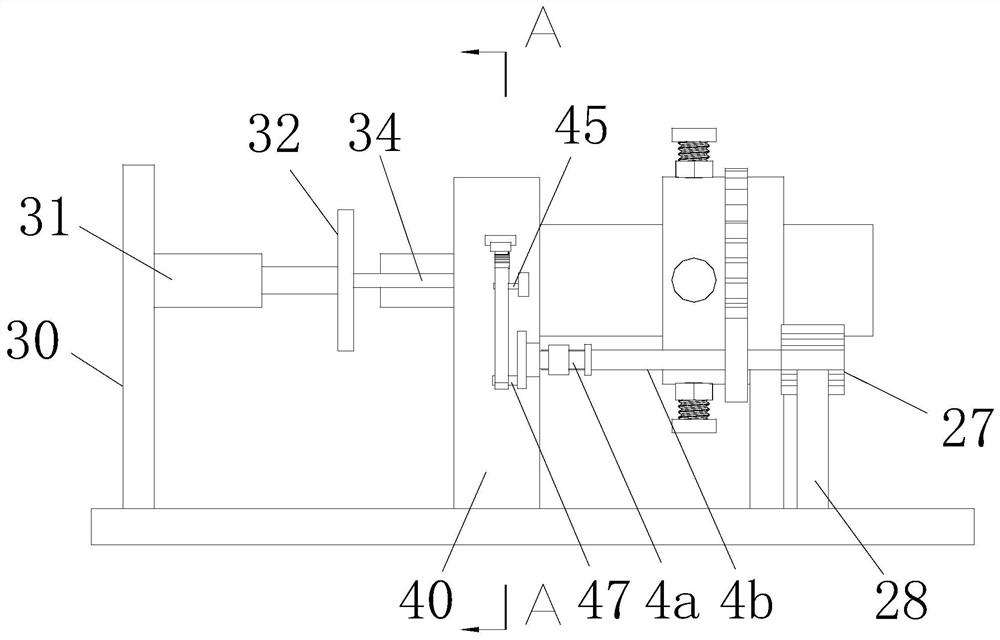

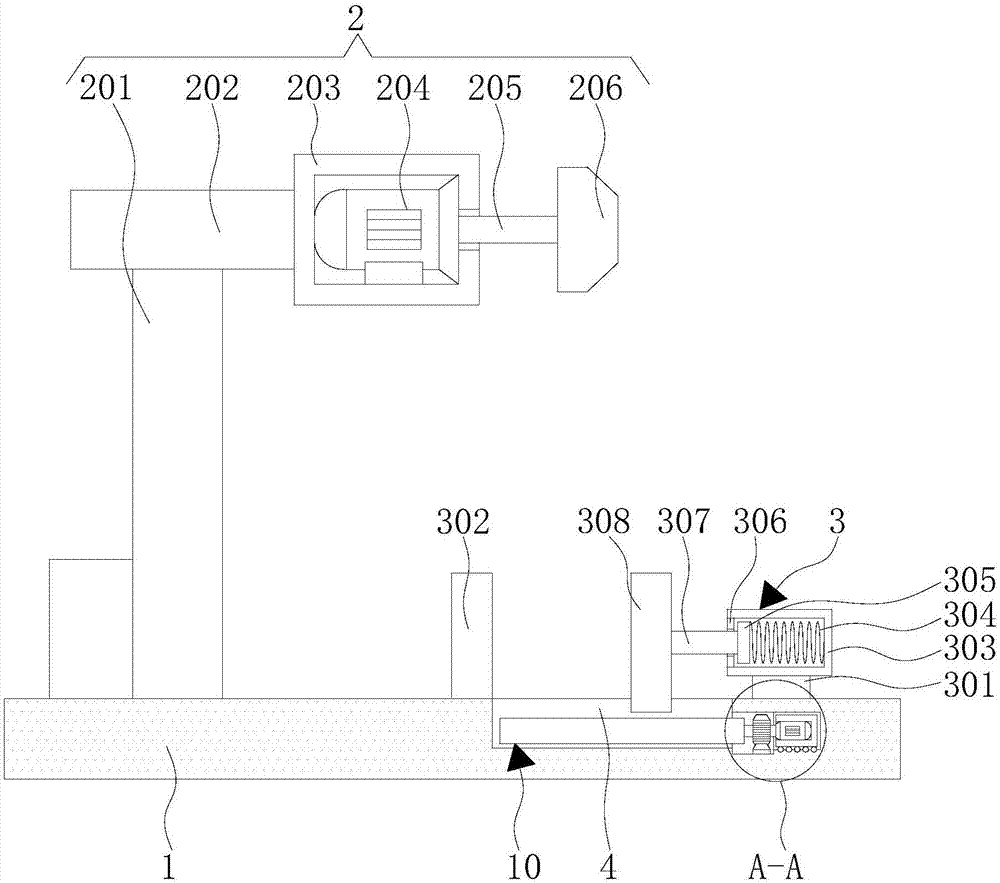

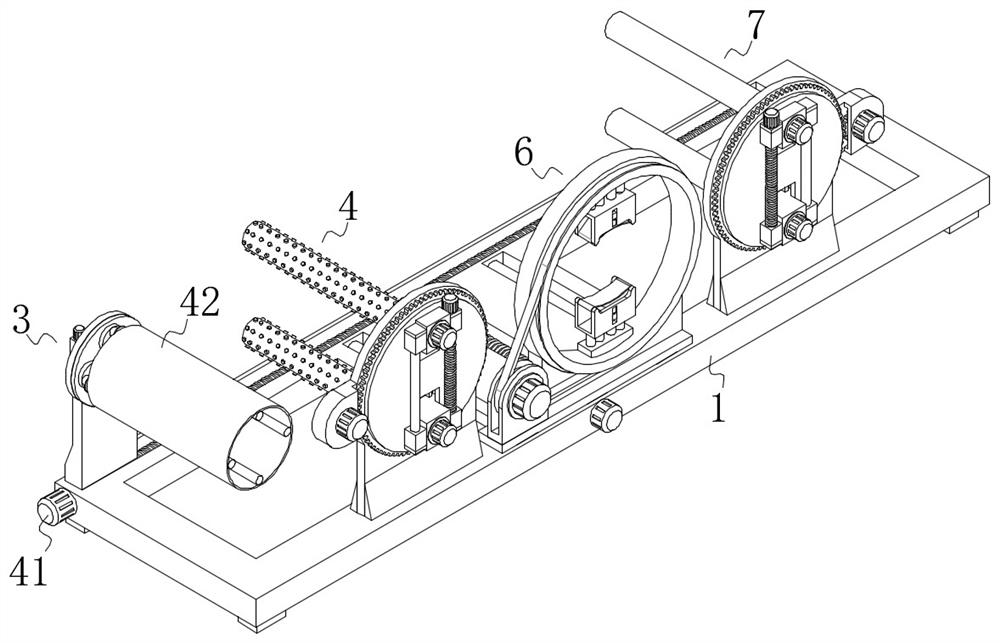

Automobile exhaust pipe welding forming post-processing equipment and post-processing method

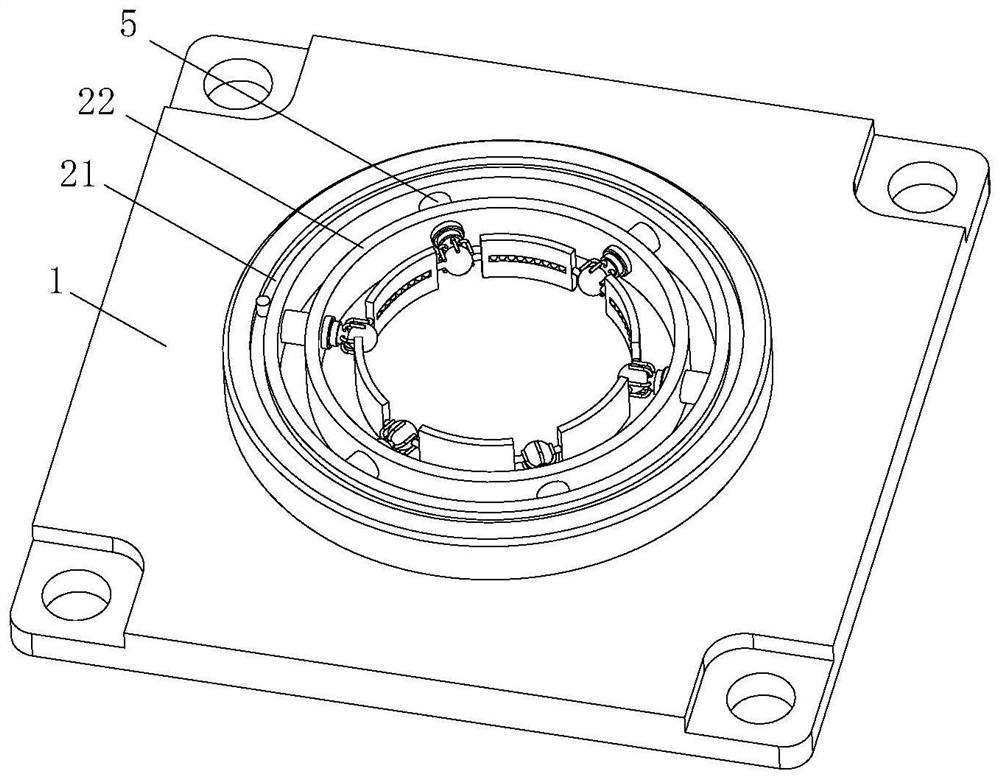

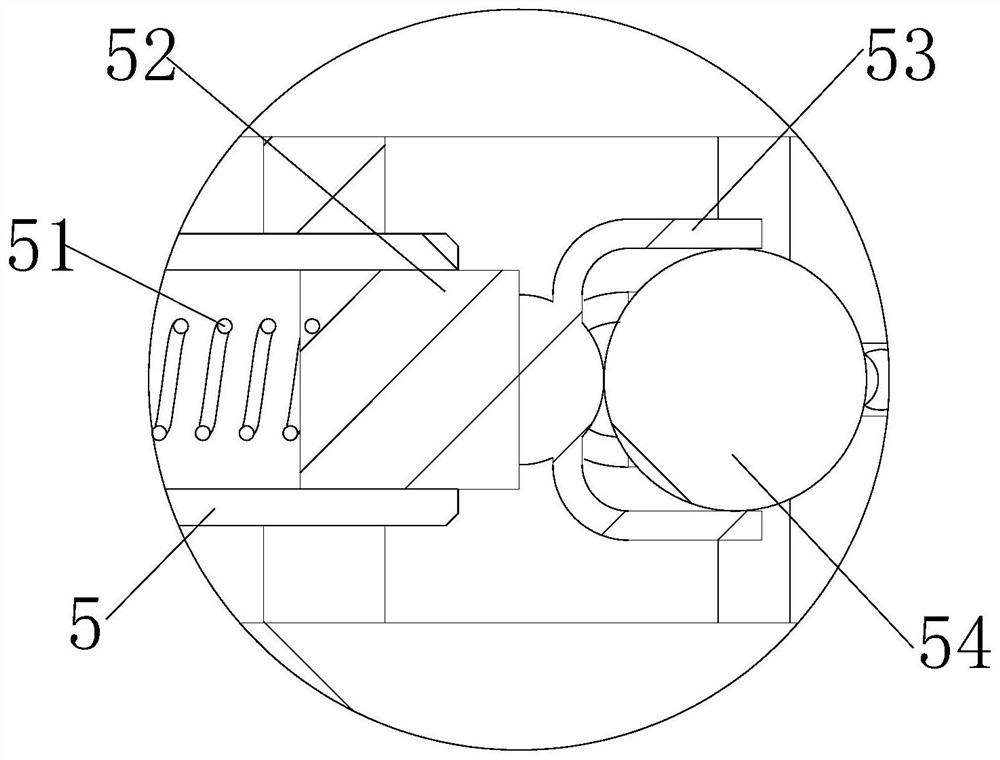

InactiveCN113103082ARealize the function of secondary fine grindingRealize the function of preliminary grindingPolishing machinesRevolution surface grinding machinesMechanical engineeringExhaust pipe

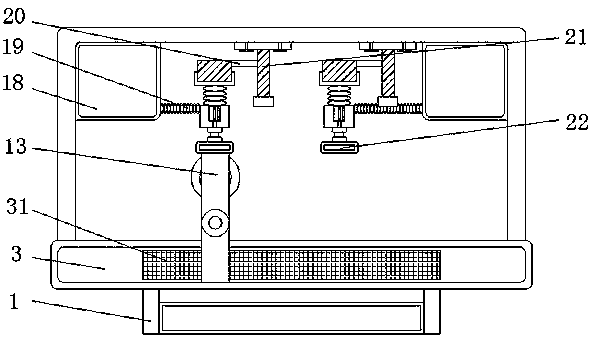

The invention relates to automobile exhaust pipe welding forming post-processing equipment and a post-processing method. The automobile exhaust pipe welding forming post-processing equipment comprises a base, a fixing device and a polishing device, the lower end of the base is connected with the existing ground, and the fixing device and the polishing device are sequentially installed at the upper end of the base from front to back. Through cooperation of fixing rings, limiting bolts and arc-shaped blocks, automobile exhaust pipes can be fixed, the situation that the welded and formed automobile exhaust pipes deviate and shake in the polishing process is avoided, and the distance between the arc-shaped blocks can be adjusted by adjusting the limiting bolts, so that the equipment can fix the exhaust pipes with different diameters, and then the exhaust pipes with different diameters can be polished.

Owner:王小前

Super-hydrophobic anti-clogging sandpaper composite adhesive and preparation method thereof

The invention discloses super-hydrophobic anti-clogging sandpaper composite adhesive, which comprises a component I, a component II, a component III and a component IV, wherein the component I consists of adhesive and solvent; the component II consists of filler and solvent; the component III consists of slipping agent and solvent; the component IV consists of pigment and hydrophobic accelerant. The invention also relates to a preparation method of the super-hydrophobic anti-clogging sandpaper composite adhesive. The method comprises the steps of respectively preparing the adhesive and the filler according to the ingredients of the adhesive in the component I and the ingredients of the filler in the component II, respectively mixing the adhesive of the component I, the filler of the component II, the slipping agent of the component III and the solvent according to a weight ratio, respectively mixing the pigment and the hydrophobic accelerant of the component IV according to the weight ratio, and finally mixing the four components according to the ratio, and uniformly stirring the mixture. By adopting the super-hydrophobic anti-clogging sandpaper composite adhesive and the preparation method thereof, the hydrophobic property of the sandpaper can be improved, and the sandpaper has the characteristics of electrostatic resistance, clogging resistance and long service life.

Owner:JIANGSU FENGMANG COMPOUND MATERIAL SCI&TECH GRP CO LTD

Metal machining polisher working platform with automatic cleaning function

InactiveCN106976019AThe sanding effect will not be affected by debrisRealize the effect of automatic cleaningGrinding/polishing safety devicesMetal workingDissection

The invention discloses a metal machining polisher working platform with an automatic cleaning function. The metal machining polisher working platform comprises a platform body. A polishing device is fixedly connected to one side of the top of the platform body. A clamping device is arranged on the other side of the top of the platform body. A placing groove is formed in the position, corresponding to the clamping device, of the top of the platform body. A moving groove communicating with the platform body is formed in the side surface, corresponding to the placing groove, of the platform body. A sliding groove communicating with the platform body is formed in the side surface, corresponding to the moving groove, of the platform body. A cleaning motor shell is arranged in the sliding groove. The moving groove, the sliding groove, the cleaning motor shell, a cleaning motor, a cleaning rotating shaft, a cleaning electromagnet, a moving gear and a rack plate are matched with each other, thus, an automatic cleaning effect is achieved, and metal waste chips produced through polishing can be cleaned, so that the situation that the polishing effect of a polisher is affected due to the waste chips is avoided, manual cleaning is not needed, the time and effort are saved, the working efficiency is improved, and using is more convenient.

Owner:湖州多玛智能科技股份有限公司

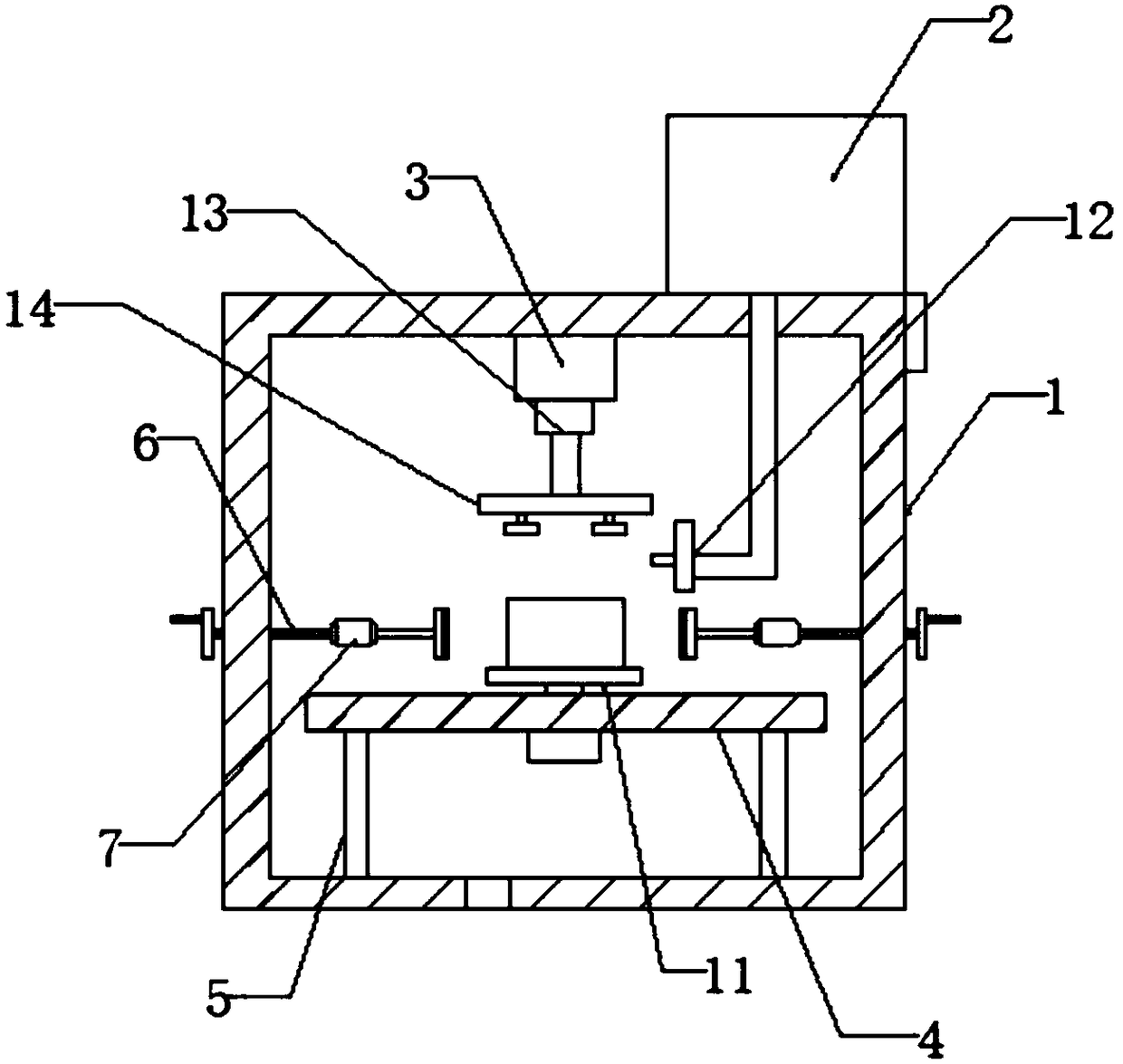

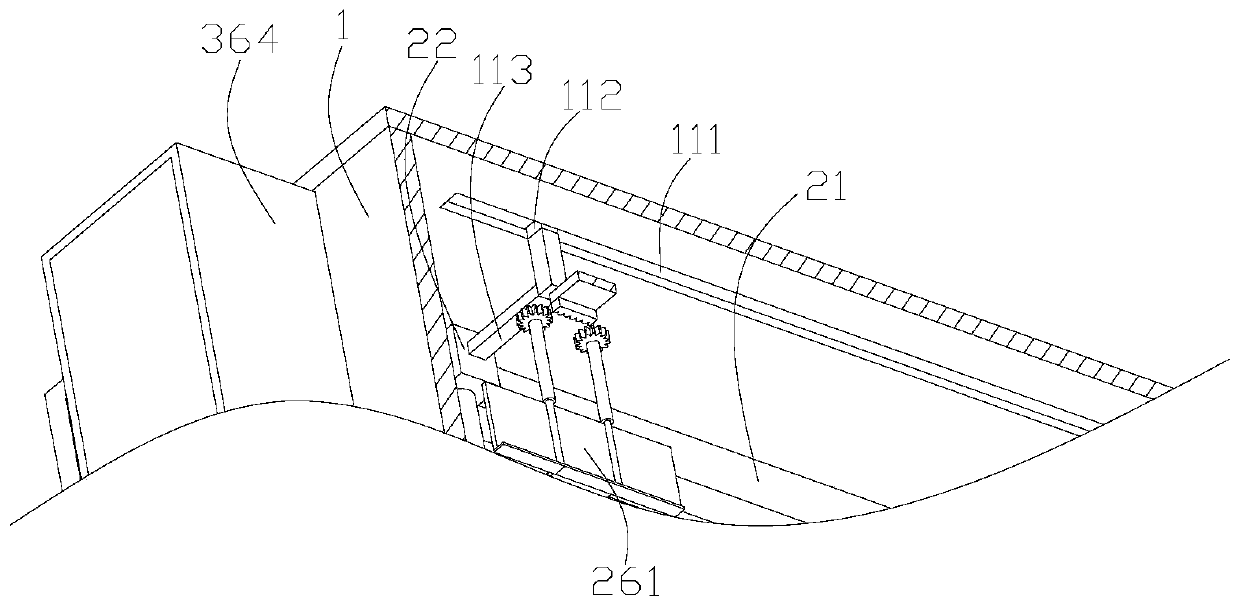

Mirror surface grinding device suitable for stainless steel square pipes of multiple sizes

ActiveCN113770896AGuaranteed smoothnessAffect the grinding effectEdge grinding machinesPolishing machinesSS - Stainless steelSurface grinding

The invention discloses a mirror grinding device suitable for stainless steel square pipes of multiple sizes, and belongs to the field of stainless steel square pipe grinding. The mirror surface grinding device suitable for the stainless steel square pipes of multiple sizes comprises a grinding mechanism, a locking mechanism, a clamping mechanism, a triggering mechanism, a dust suction pipe and a deburring mechanism. A locking mechanism is installed at the upper end of a supporting frame to limit descending of a grinding disc, a triggering mechanism is arranged on one side of one of clamping plates to achieve actual control over descending movement of the grinding disc, and therefore only when the square pipes are clamped, the locking mechanism can release the descending movement of the grinding disc, safety accidents caused by insufficient grinding precision of the square pipes and even flying-out of the square pipes due to collision when the square pipes are ground before being clamped are avoided, the dust suction pipe is installed on the supporting frame, so that dust generated by grinding is sucked, and the deburring mechanism is installed on one side of a second rack, so that the two sides of the ground mirror surface are ground.

Owner:中山德立洁具有限公司

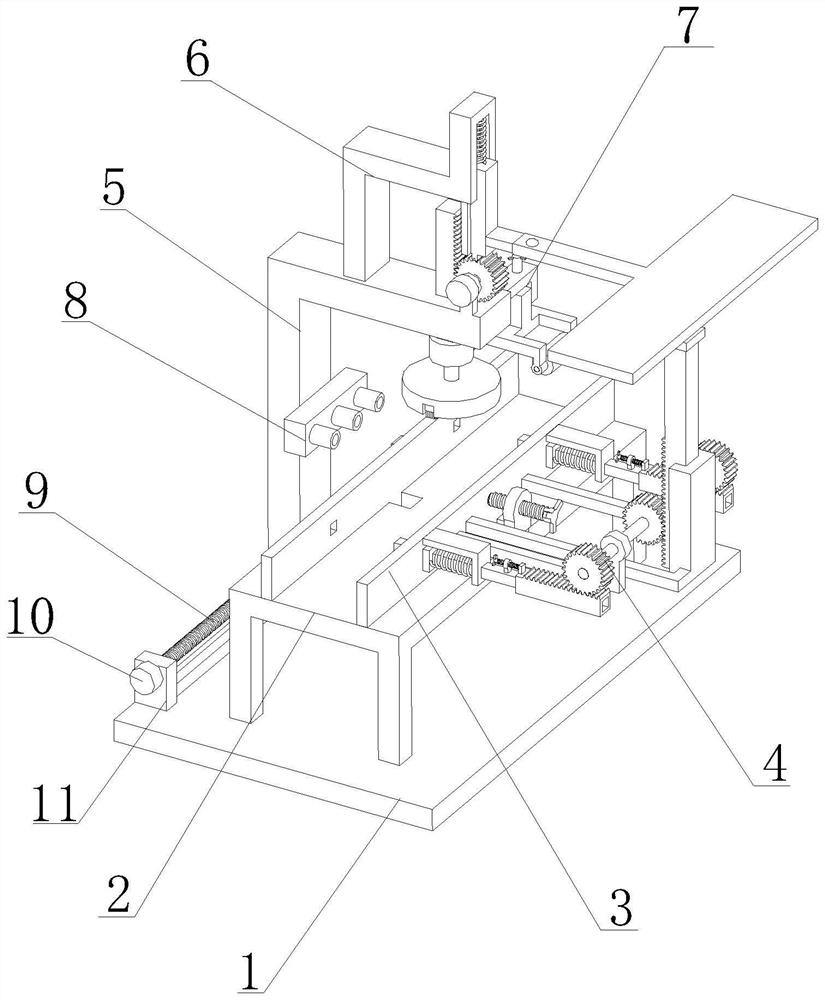

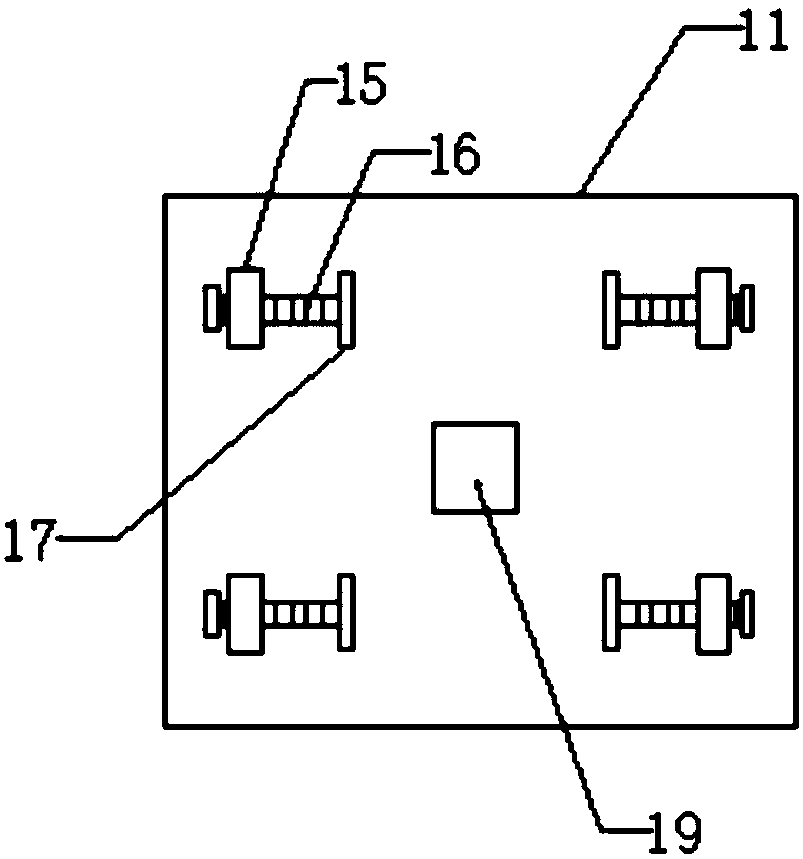

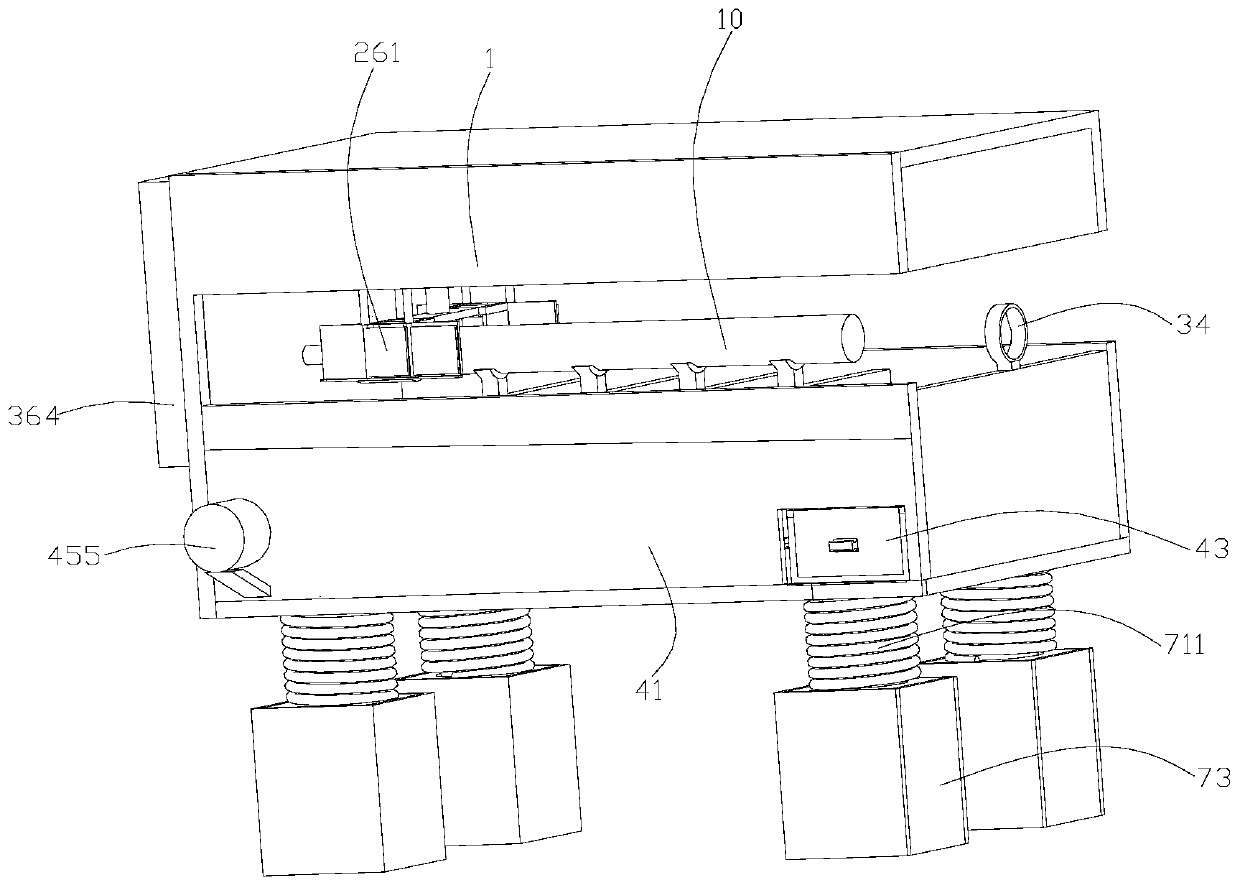

Polishing equipment for robot part plate

PendingCN108311977AImprove work efficiencyEasy to fixGrinding drivesGrinding feed controlHigh pressureOperating table

The invention discloses polishing equipment for a robot part plate. The polishing equipment comprises a box body; the bottom of the interior of the box body is fixedly connected with the two sides ofthe bottom of an operating table through supporting legs; the middle part of the top of the operating table is rotationally connected with a fixture table through a rotating shaft; and connecting tables are arranged at four corners of the top of the fixture table. The rotating shaft rotates to drive the fixture table, so that repeated clamping is not required after multi-surface parts are polished, and the polishing equipment can continue to polish after the fixture table is rotated directly and then is fixed again; the bottoms of the polished parts can be fixed with the adoption of clamping devices arranged on the fixture table; with the adoption of a telescopic rod to drive first clamping plates, the fixing of the parts can be improved, so that the situation that the polishing effect ofthe parts is affected due to loosening in the polishing process is avoided; and the temperatures of the surfaces of the parts can be detected with the adoption of a temperature sensor, so that the surfaces of the parts are cooled with a high-pressure water pump when the temperatures reach a preset value.

Owner:SUZHOU PULINGDA AUTOMATION TECH CO LTD

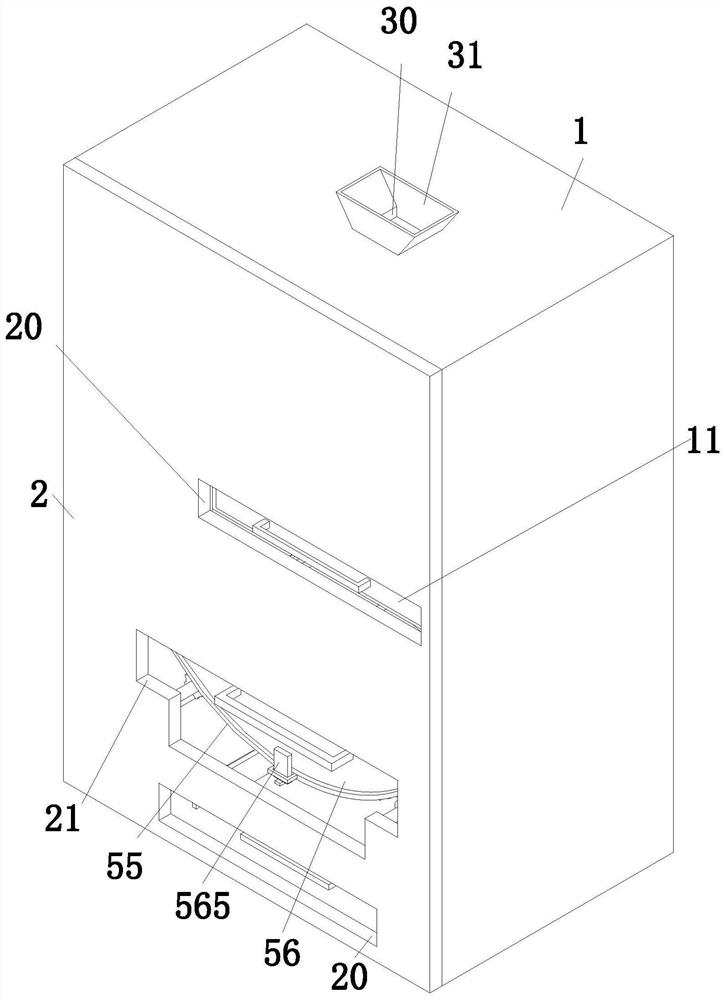

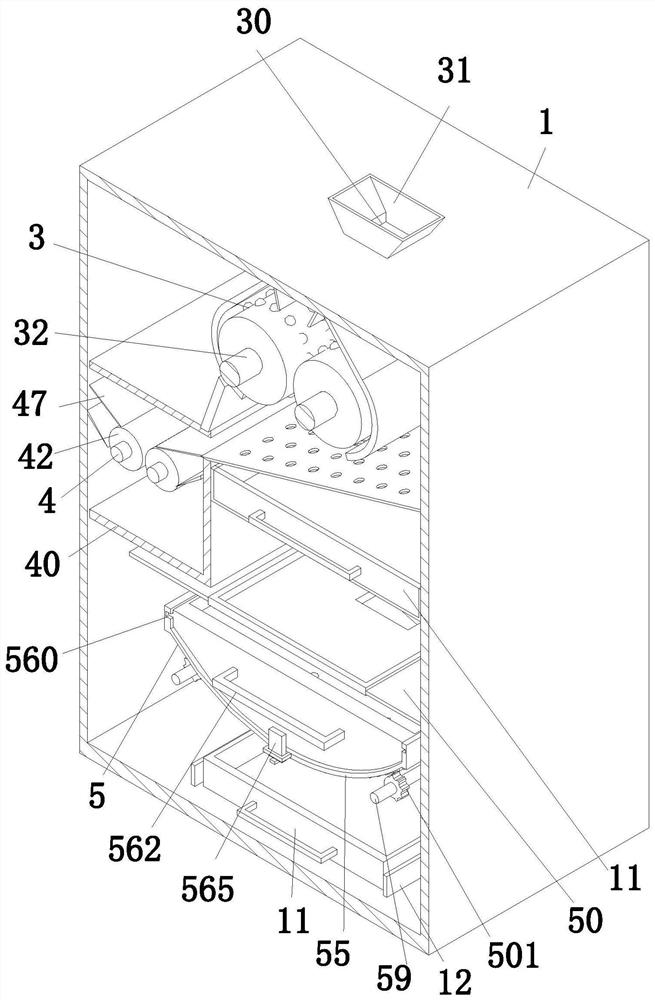

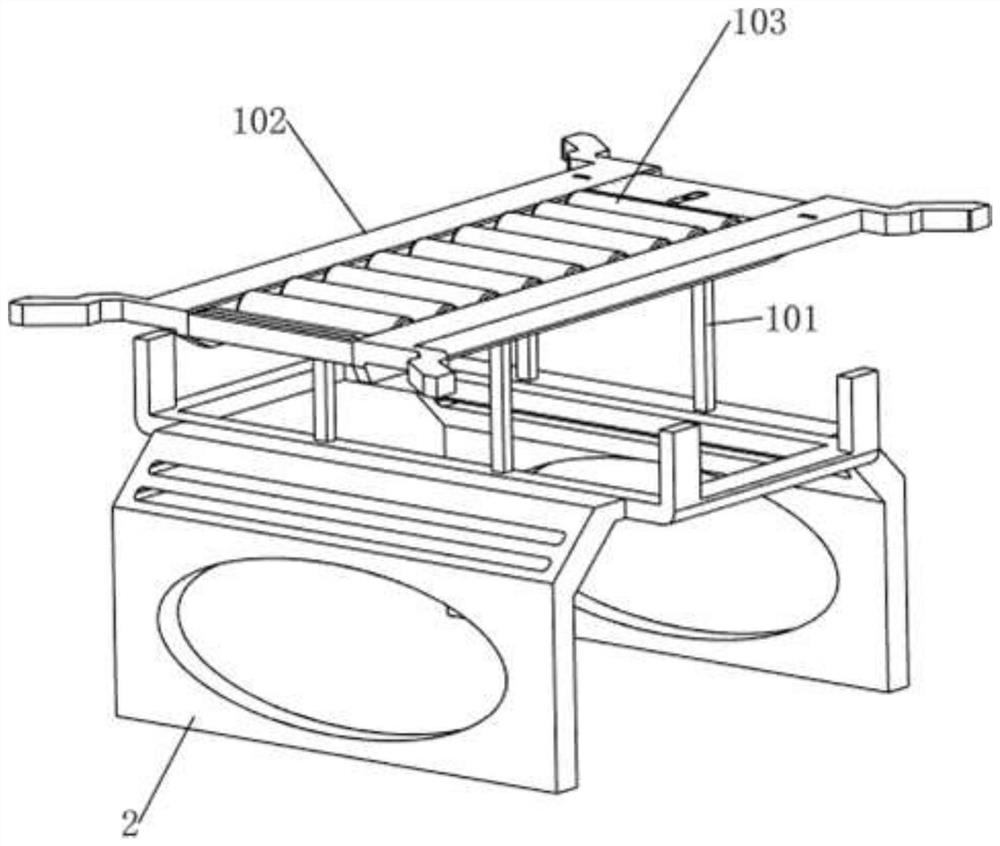

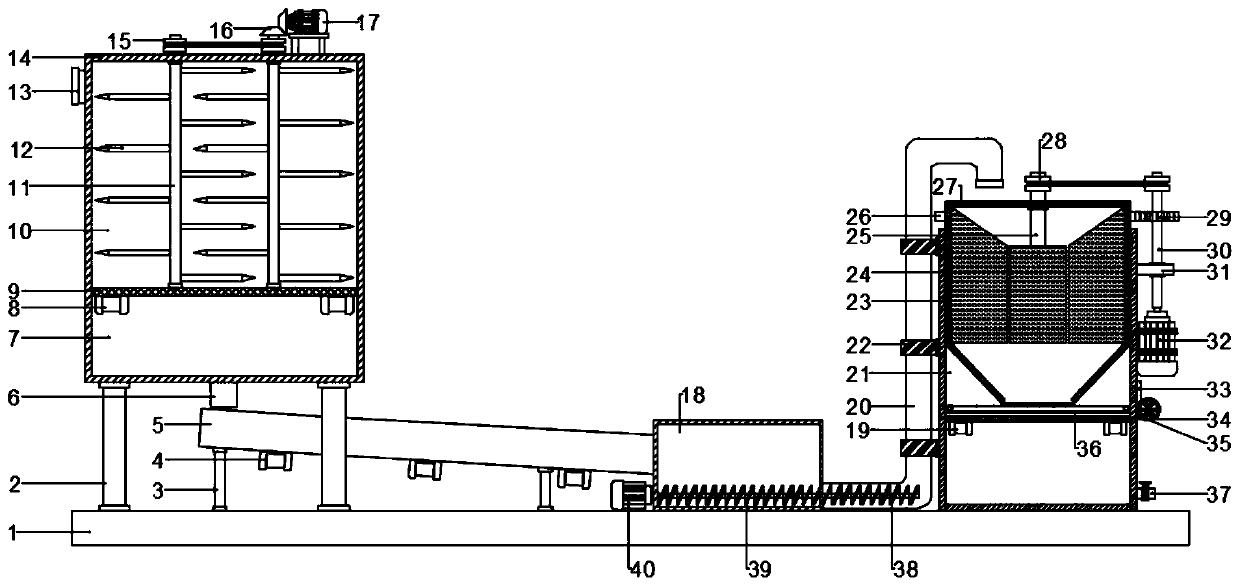

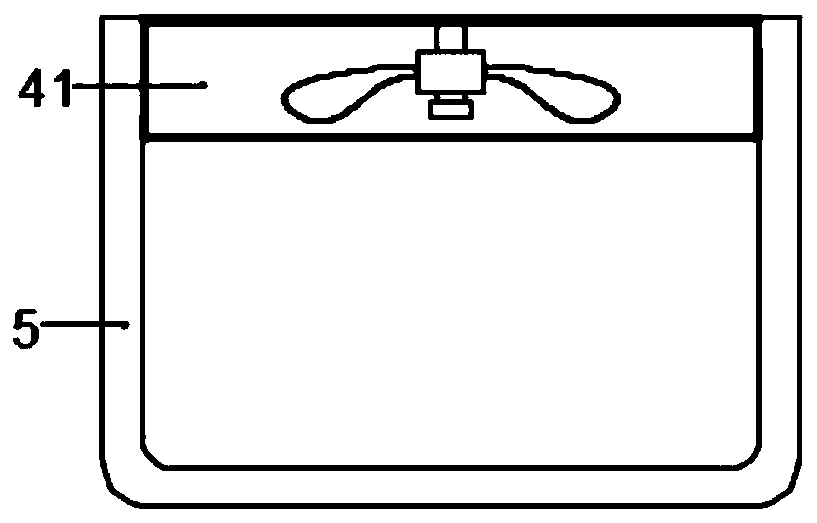

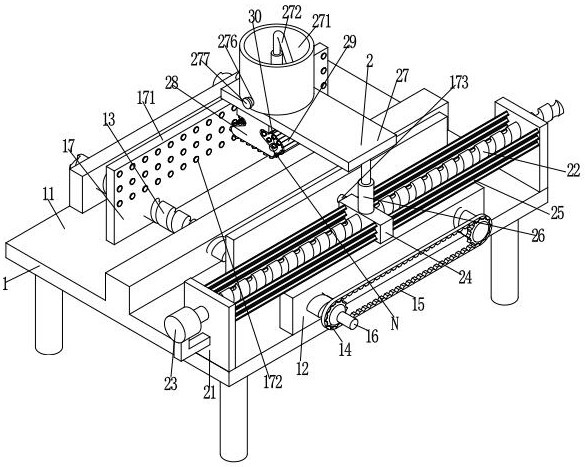

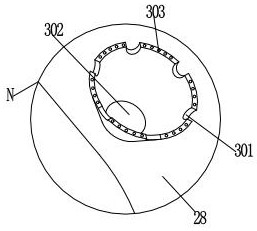

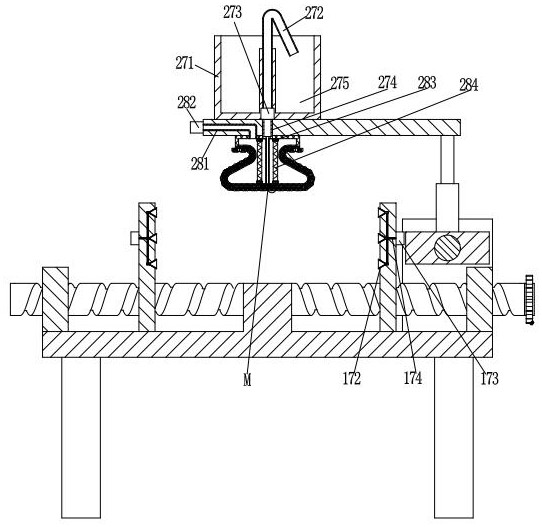

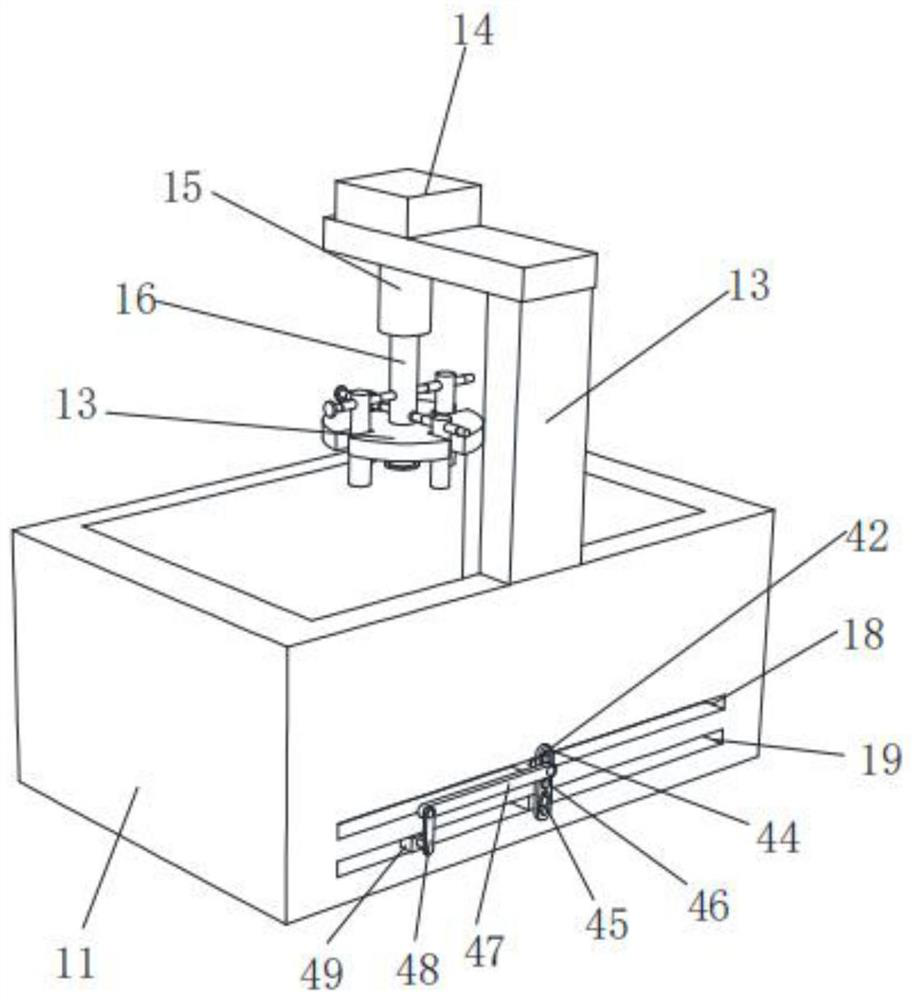

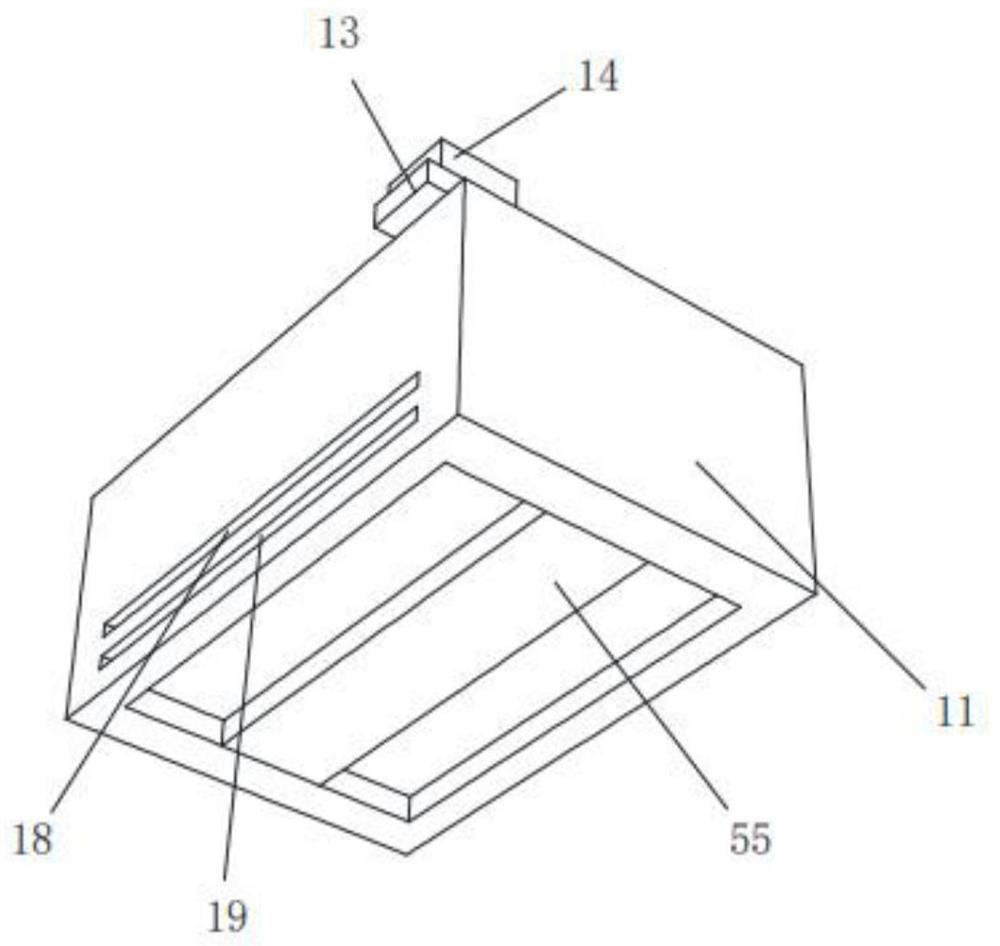

Recycled fine aggregate self-compacting concrete preparation system and preparation method

InactiveCN113413958AAvoid Poor Mixing EffectsEffective crushing and grindingGrain treatmentsConstruction engineeringStructural engineering

The invention relates to a recycled fine aggregate self-compacting concrete preparation system and method. The recycled fine aggregate self-compacting concrete preparation system comprises a preparation box, an end cover, a first-stage crushing mechanism, a second-stage crushing mechanism and a screening mechanism, and a filter plate is arranged between the first-stage crushing mechanism and the second-stage crushing mechanism; according to the secondary crushing mechanism, fine aggregate generated in the building aggregate after primary crushing can be screened out in the falling process, so that the workload of the secondary crushing mechanism is reduced, the secondary crushing mechanism can effectively crush and grind the building aggregate, and the situation that large particles exist in the fine aggregate is avoided; and meanwhile, the adopted screening frame and the screening box are in a drawing type, so that the screening box after screening is convenient to take out.

Owner:武汉汉祥亿源建材有限公司

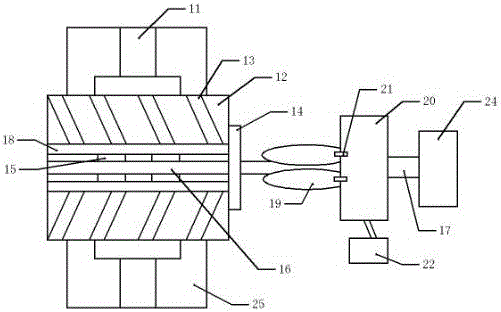

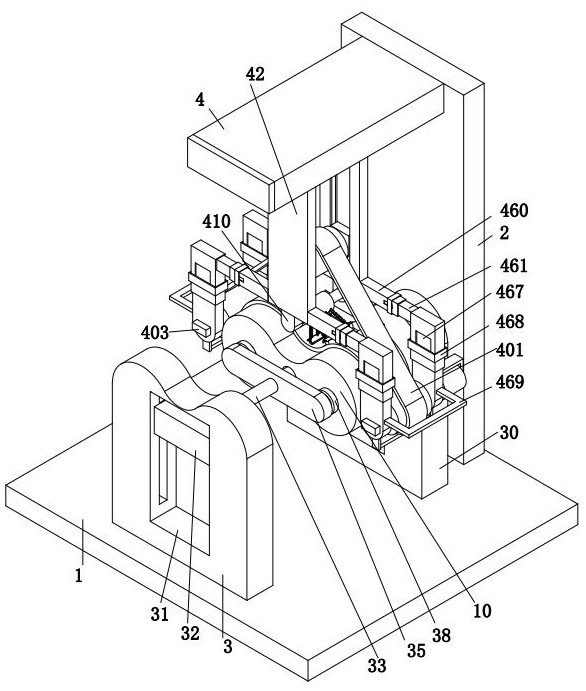

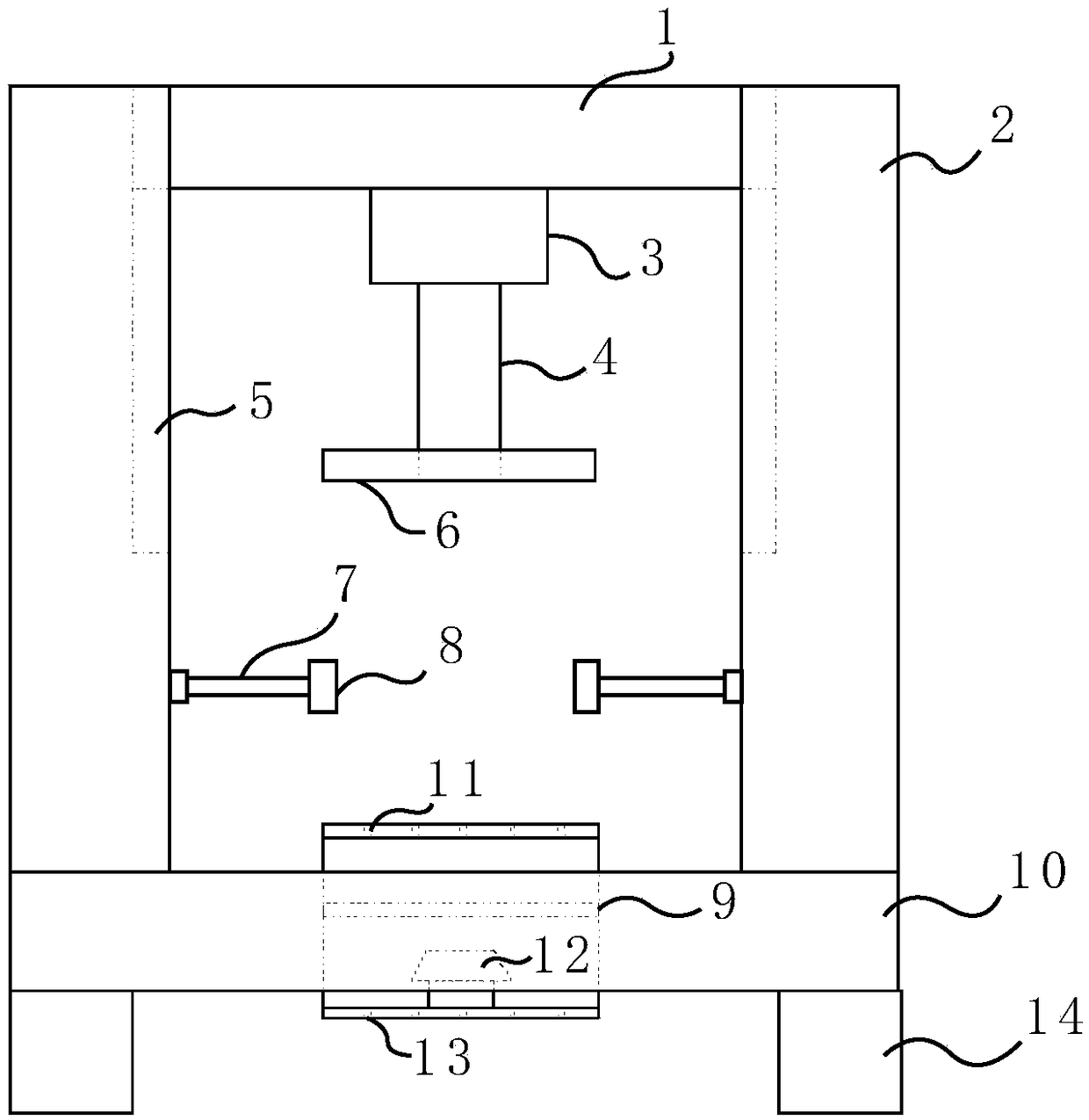

High-definition camera lens manufacturing process

ActiveCN112496950AEasy to disperseAffect the grinding effectOptical surface grinding machinesGlass shaping apparatusCamera lensMedicine

The invention relates to a high-definition camera lens manufacturing process, which adopts a camera lens manufacturing device. The camera lens manufacturing device comprises a bottom rack, a verticalrack, an inner clamping mechanism, a polishing mechanism and a spraying mechanism. The high-definition camera lens manufacturing process provided by the invention can solve the following problems in the manufacturing process of the high-definition camera lens: a, in the traditional high-definition camera lens forming and manufacturing process, a non-uniform porous structure is generated on the surface of the cooled and formed lens due to the action of air, and if the non-uniform porous structure is not removed in time, the later coating effect is influenced, meanwhile, the image acquisition effect of the camera lens in the later period is also caused, and the use effect of the camera is further influenced; and b, in the polishing process of a traditional high-definition camera lens, dust is generated in the polishing process, aerosol is possibly formed in air after the dust is generated, and the aerosol is not prone to being scattered in the air, so that the environment is polluted, workers can inhale the aerosol, and the body health of the workers is affected.

Owner:深圳森云智能科技有限公司

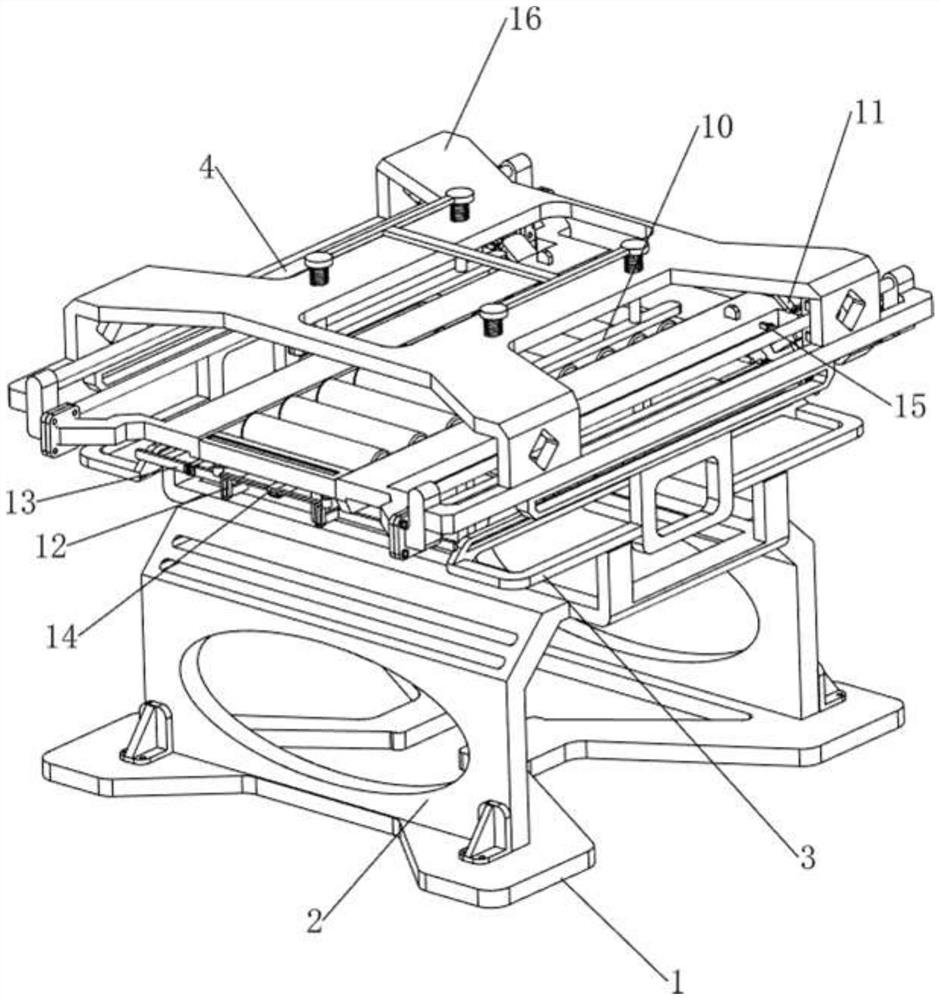

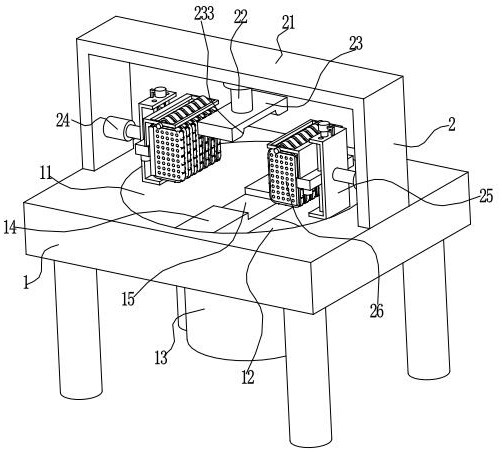

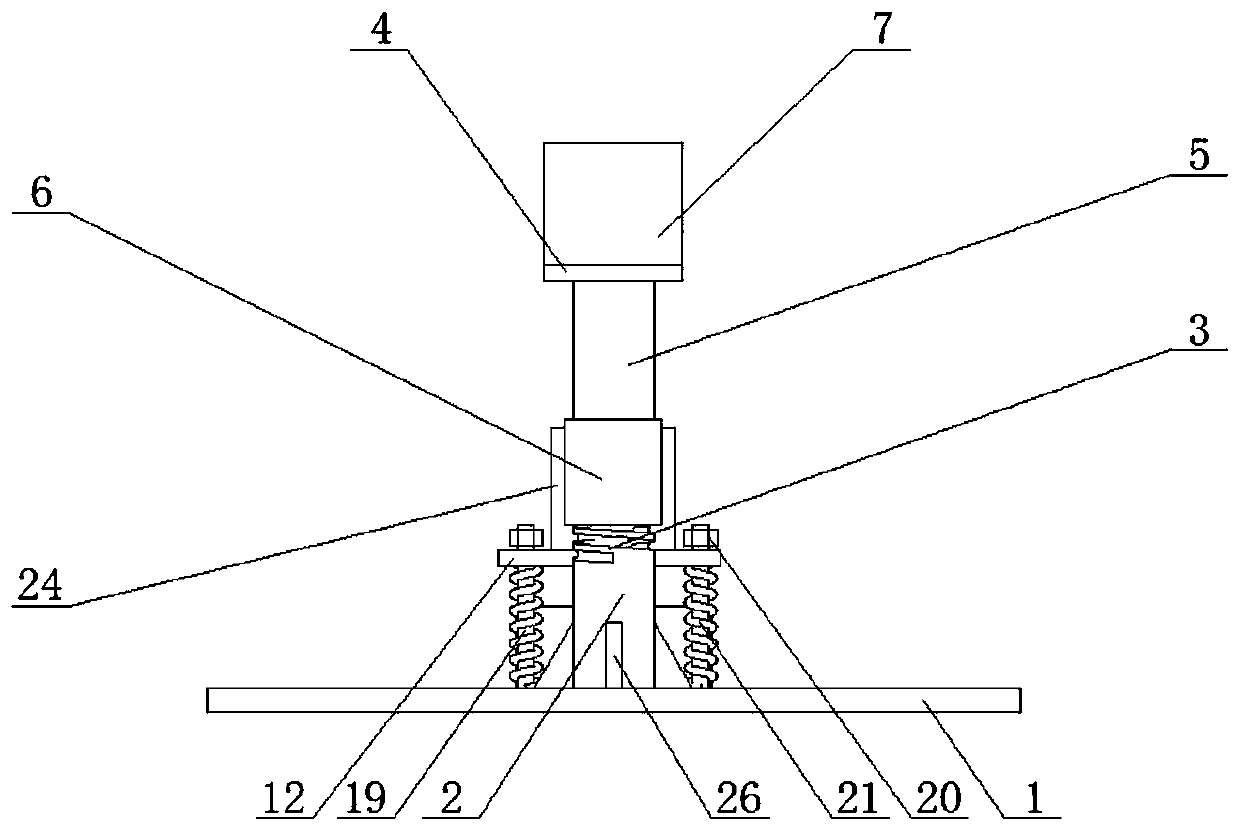

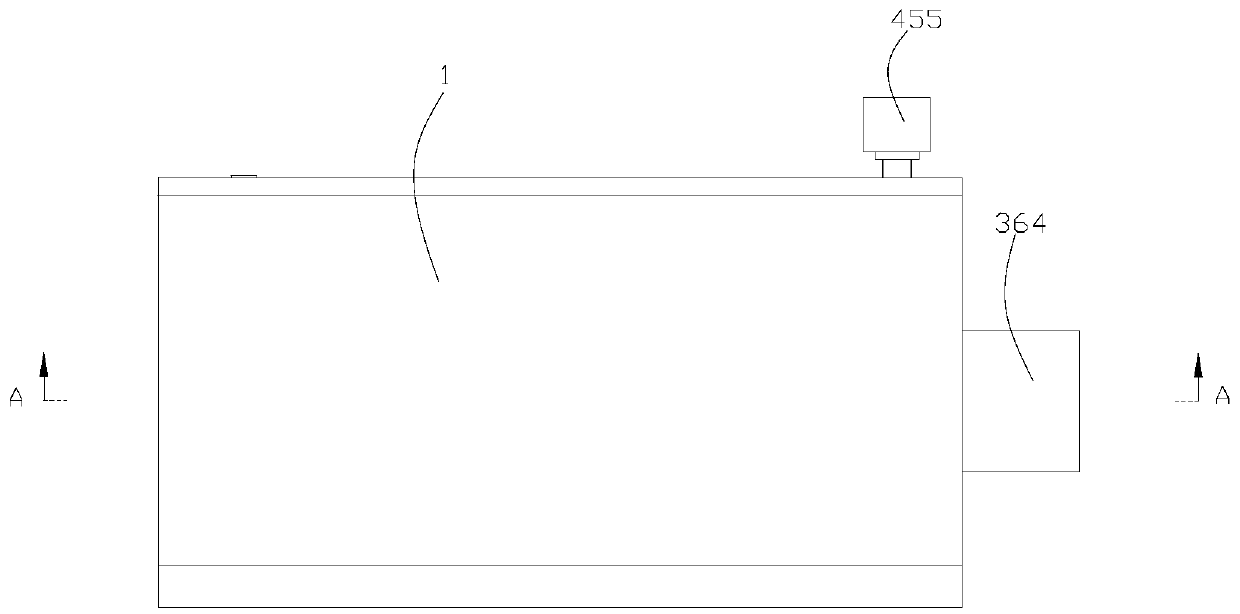

Automatic grinding and polishing device for high speed rail sleeper production

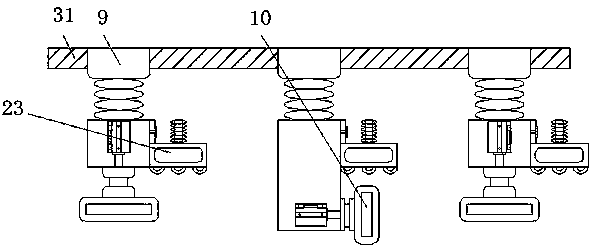

InactiveCN108406516ASave human effortGrinding speed is fastGrinding carriagesGrinding machinesEngineeringWater spray

The invention relates to an automatic grinding and polishing device for high speed rail sleeper production. The device comprises a supporting foot and a second transverse grinding stone; a waste box is arranged on the right side of the supporting foot, a containing table is arranged at the upper end of the supporting foot, a supporting frame is fixed to the two sides of the upper end of the containing table, water tanks are arranged on the two sides of the upper end of the interior of the supporting frame, telescopic water pipes are connected to the lower ends of the right sides of the water tanks, water spraying heads are embedded on the lower ends of the telescopic water pipes, and the second transverse grinding stone is arranged on the right sides of first transverse grinding stones. Transverse sliding blocks slide on a second transverse sliding rail, three first transverse grinding stones and a longitudinal grinding stone are driven to slide on the second transverse sliding rail left and right, the first transverse grinding stones and the longitudinal grinding stone can carry out sliding grinding on a sleeper on the second transverse sliding rail, sliding of the first transverse grinding stones and the longitudinal grinding stone does not need to be manually controlled, manpower is saved, the grinding speed is increased, and grinding is more uniform.

Owner:DONGGUAN UNIV OF TECH

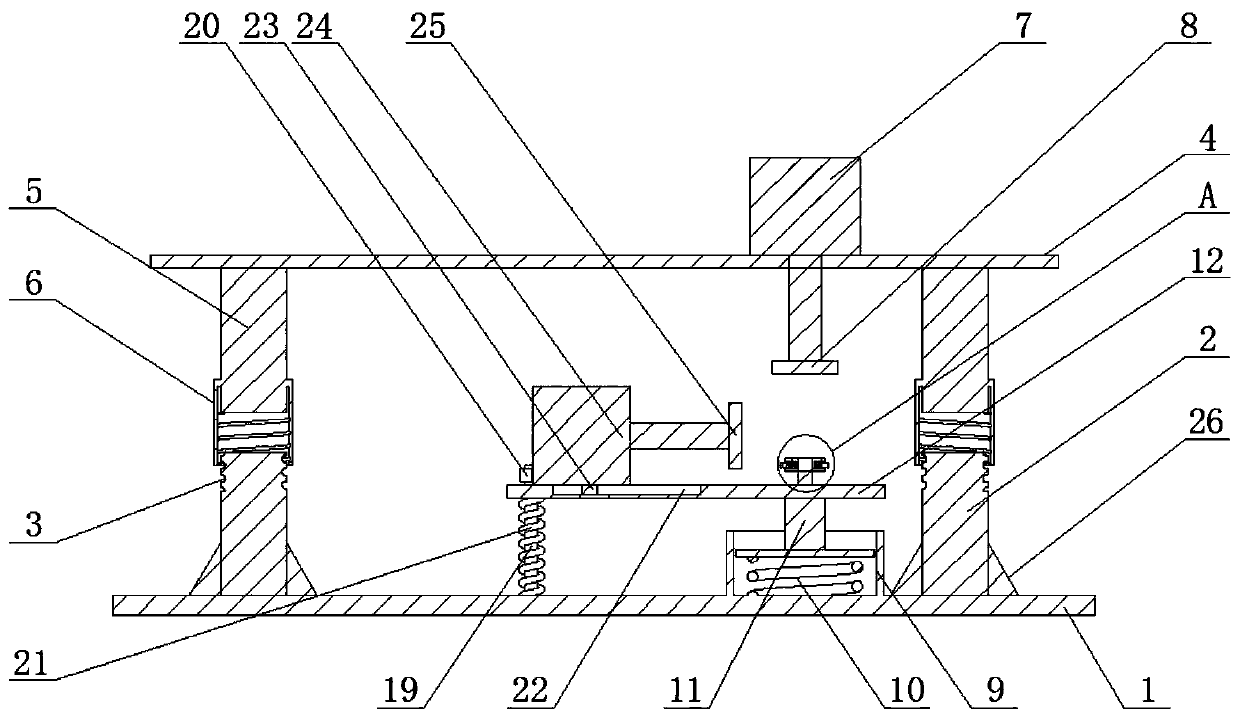

Ceramic product surface grinding machine

InactiveCN114012558AImprove sanding effectEasy dischargeGrinding machinesGrinding work supportsDrive shaftEconomic benefits

The invention discloses a ceramic product surface grinding machine. The ceramic product surface grinding machine comprises a bottom plate, a plurality of mounting holes are formed in the surface of the bottom plate, a plurality of telescopic rods are fixedly connected to the surface of the bottom plate, vibration springs sleeve the telescopic rods, a connecting plate is fixedly connected to the surfaces of the telescopic rods, a driving motor is fixedly mounted on the surface of the connecting plate, a fixing frame is fixedly connected to the bottom of the connecting plate, a movable groove is formed in the bottom of the fixing frame, a transmission shaft is slidably arranged in the movable groove, and a limiting disc is fixedly connected to the surface of the bottom plate and located between the telescopic rods. According to the ceramic product surface grinding machine, when a transmission shaft does circular motion, a friction plate can polish the surface of a ceramic product, a compression plate can lift the surface of the ceramic product under the action of interaction force and a connecting shaft, and thus, compared with the prior art, the ceramic product surface grinding machine has a large application range, can polish ceramics in different shapes, can improve the processing efficiency of ceramic products, and achieves good economic benefits.

Owner:新昌县宏满机械科技有限公司

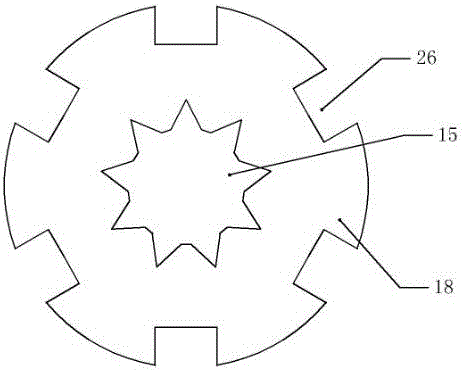

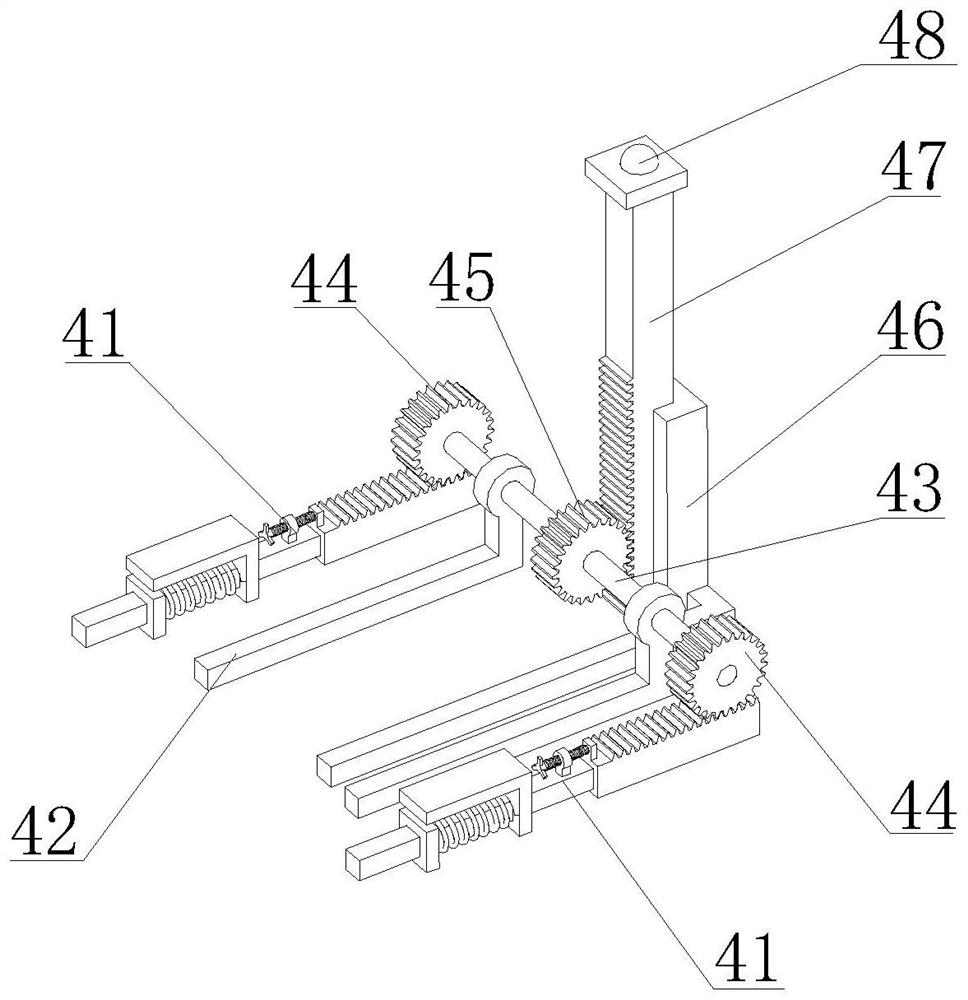

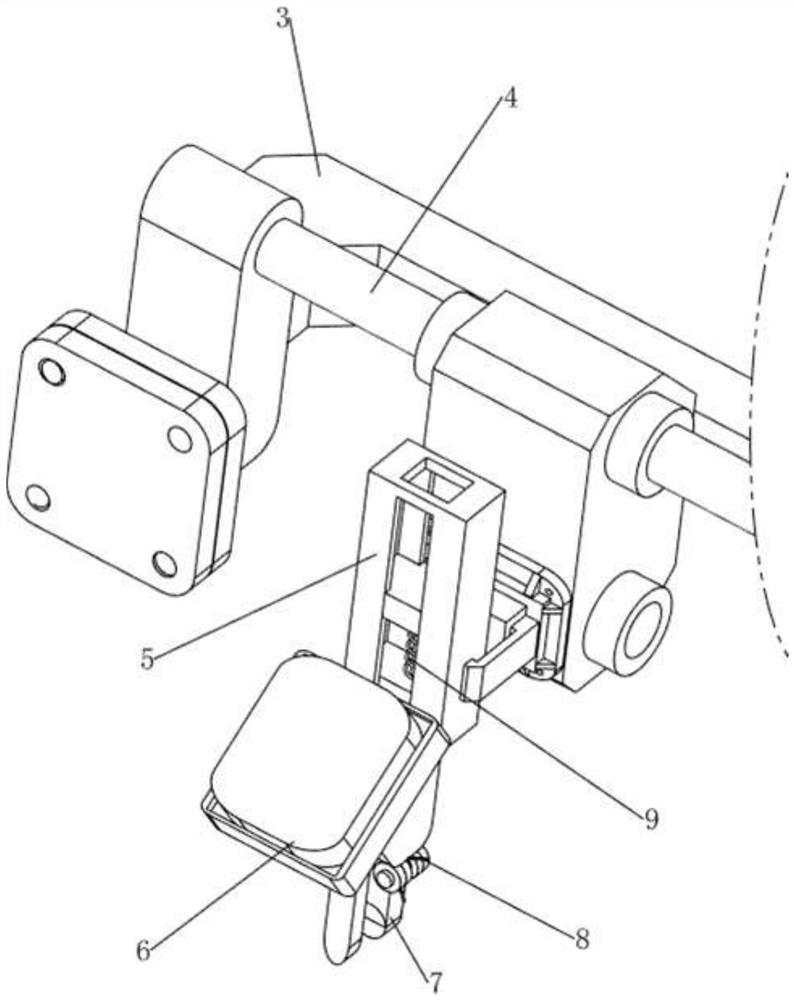

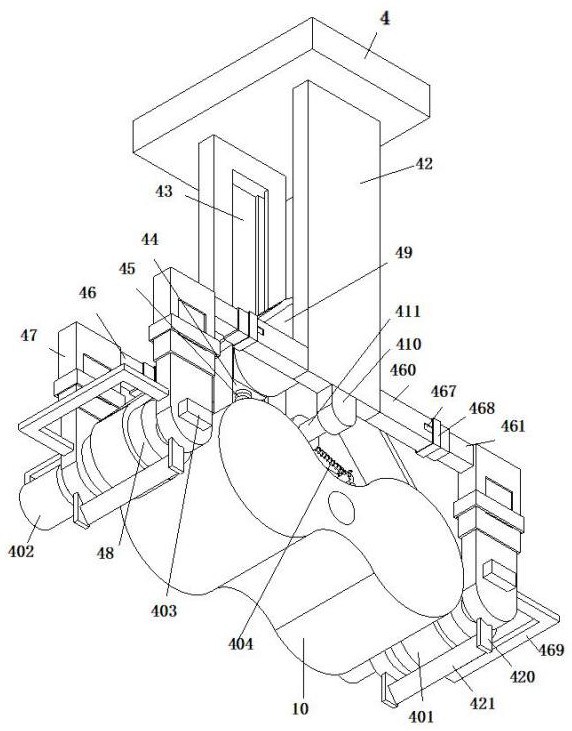

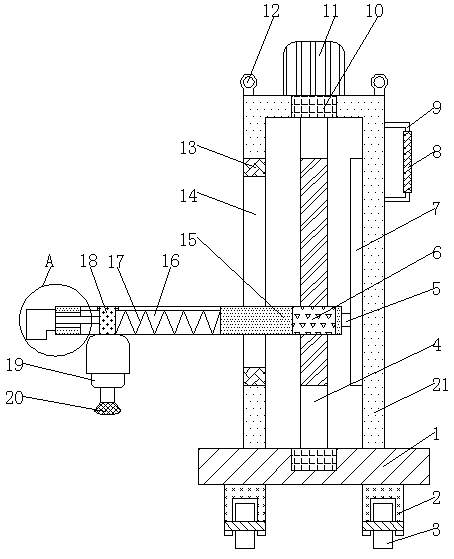

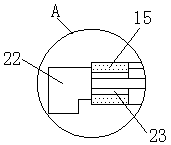

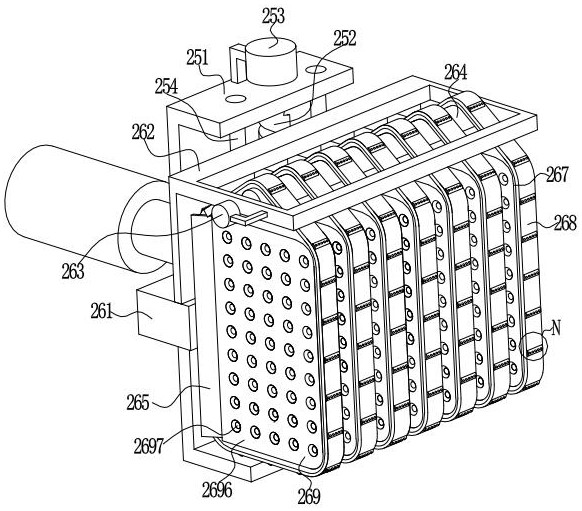

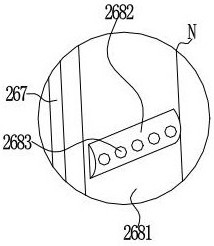

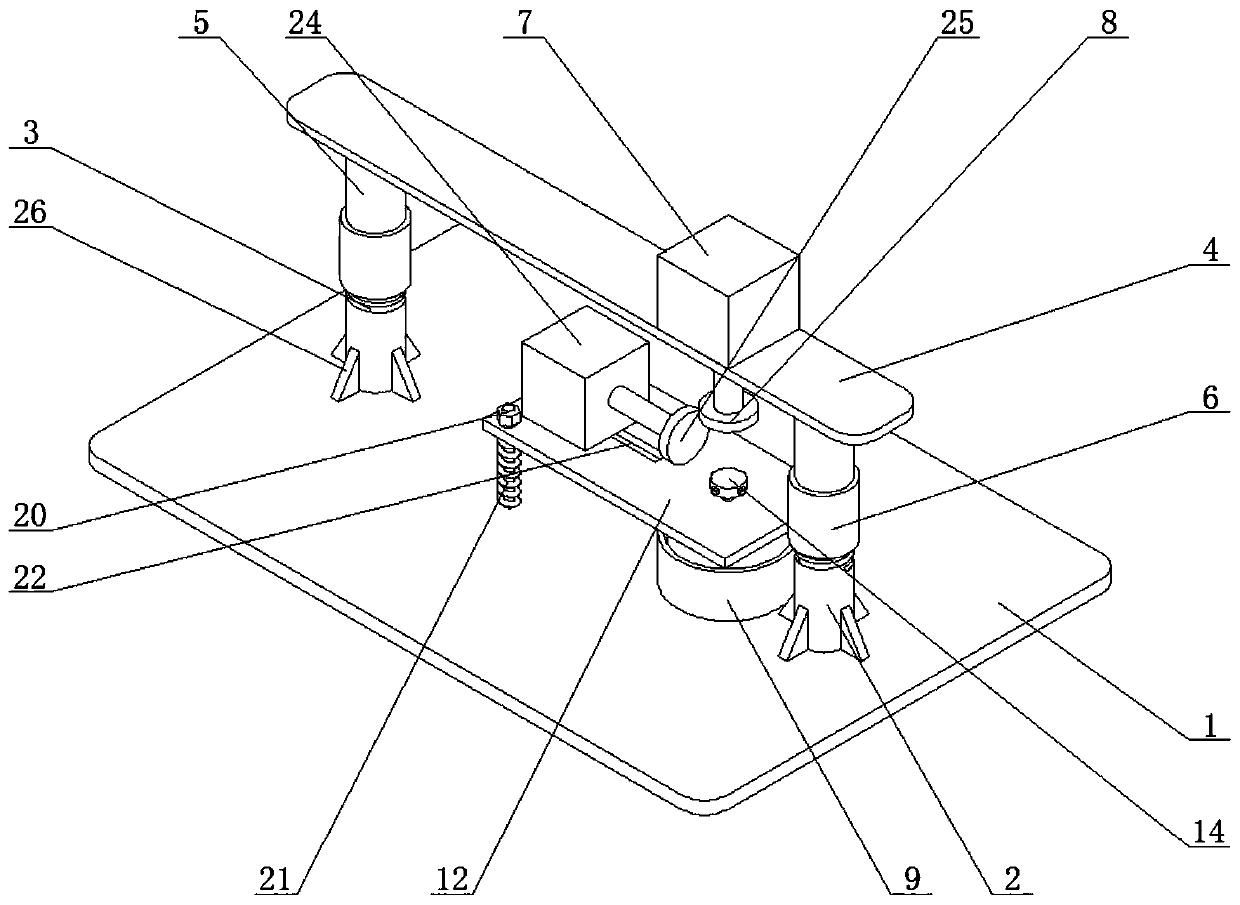

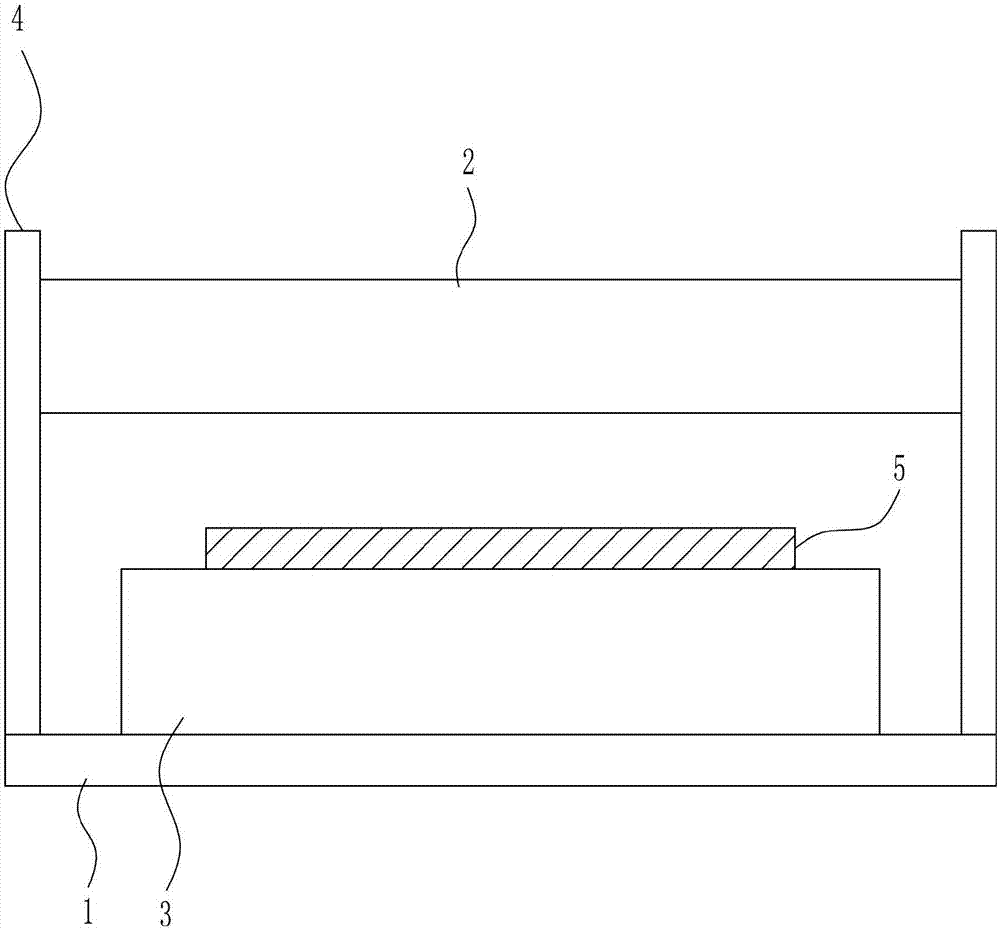

Planet gear machining system and machining process

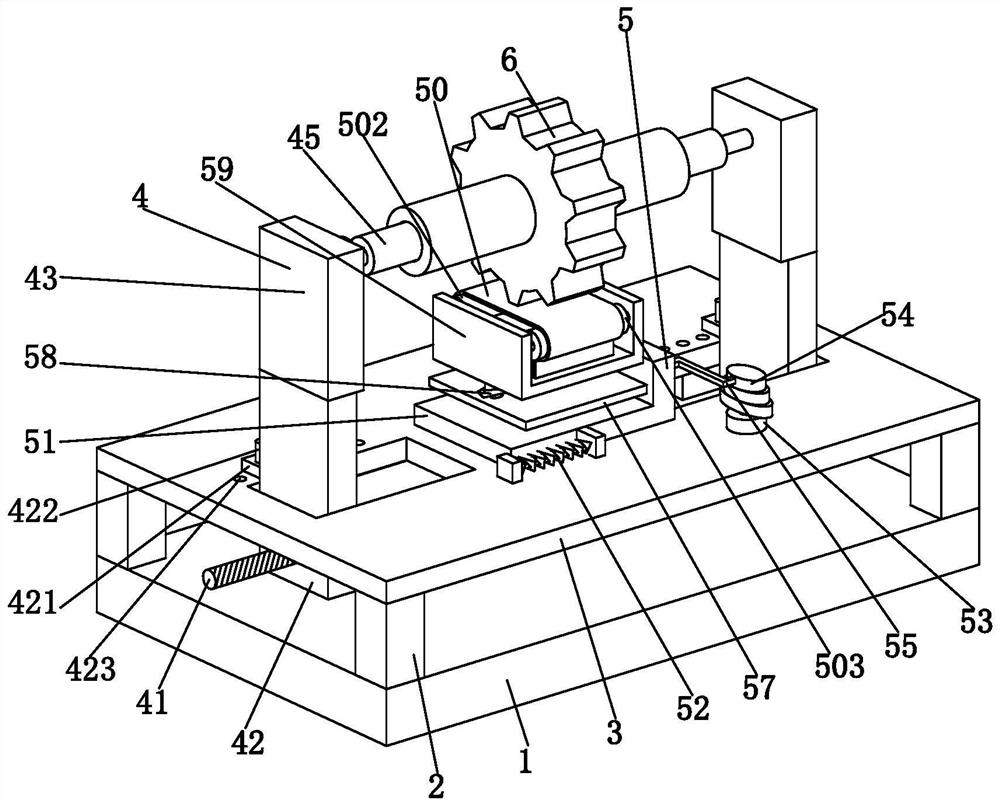

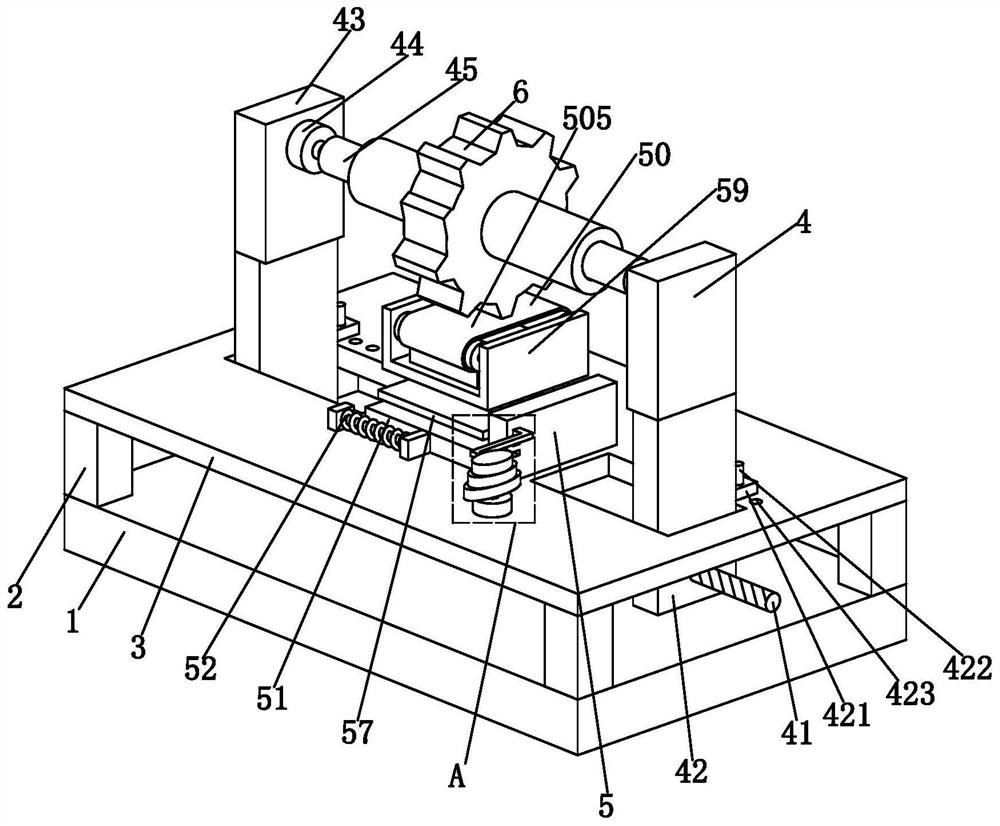

ActiveCN113829196AAffect the transmission effectPrevent rotationGrinding drivesBelt grinding machinesMachining systemMachining process

The invention relates to the technical field of planet gear machining, in particular to a planet gear machining system and a machining process. The planet gear machining system comprises a bottom rack, supporting columns, a supporting plate, a limiting clamping mechanism and a grinding mechanism. According to the planet gear machining system and the machining process, in a designed grinding belt, an air bag can drive grinding abrasive paper to be tightly attached to planet gear teeth through the good deformation capacity of an air bag in the expansion process, so that the grinding abrasive paper grinds the planet gear teeth more thoroughly, and the situation that burrs left on the planet gear teeth affect the transmission effect of a planet gear in the follow-up using process is avoided. According to the planet gear machining system and the machining process, arc-shaped plates are formed by hinging a plurality of sets of arc-shaped strips through hinges, so that the contact area between inner supporting frames and the planet gear is increased when the planet gear is internally supported by the inner supporting frame, the planet gear is prevented from relatively rotating in the rotating process, and it is ensured that the planet gear more stably clamped by the supporting plate.

Owner:泰州市东方传动技术有限公司

Iron rod polishing equipment with convenient discharge function

ActiveCN109909861AImprove grinding efficiencyAvoid harmGrinding carriagesPolishing machinesScrapElectromagnet

The invention discloses iron rod polishing equipment with a convenient discharge function. The iron rod polishing equipment comprises a box body, a grinding device arranged in the box body, a clampingdevice used for clamping an iron rod, a waste chip collecting device arranged at the outer bottom of the box body, and a discharging device used for discharging the iron rod; and the discharging device comprises a frame body arranged on one side of the box body, a third driving piece arranged on the frame body, a fixing rod with one end connected with the third driving piece, a dragging rod connected with the other end of the fixing rod, a material receiving assembly arranged on the frame body and a transmission assembly matched with the material receiving assembly, wherein a second electromagnet is arranged at one end of the dragging rod. According to the equipment, the iron rod can be comprehensively and efficiently polished, in the polishing process, scrap iron fallen from the iron rodcan be removed in time, polished iron rod can be discharged automatically, the polishing efficiency is improved, in addition, operation is simple in the whole process, discharging is rapid and stable, and the safety is high.

Owner:安徽伟迈信息技术有限公司

Edge deburring device for rock plate machining

ActiveCN112894531AAchieve positioningAffect the grinding effectEdge grinding machinesGrinding drivesEngineeringMachining

The invention relates to a deburring device, in particular to an edge deburring device for rock plate machining. According to the edge deburring device for rock plate machining, automatic grinding can be achieved, manual operation is not needed, and operation is easy. According to the technical scheme, the edge deburring device for rock plate machining comprises a base, first supporting frames, a second supporting frame, trackless air cylinders and fixing frames, the first supporting frames are connected to the two sides of the base, the second supporting frame is connected between the first supporting frames, the trackless air cylinders are connected to the two sides of the second supporting frame, and the fixing frames are slidably connected to the trackless air cylinders. Through cooperation of a loading mechanism and a clamping mechanism, automatic deburring can be conducted on the edge of a rock plate, manual grinding is not needed, and time and labor are saved.

Owner:高安常莹新型材料有限公司

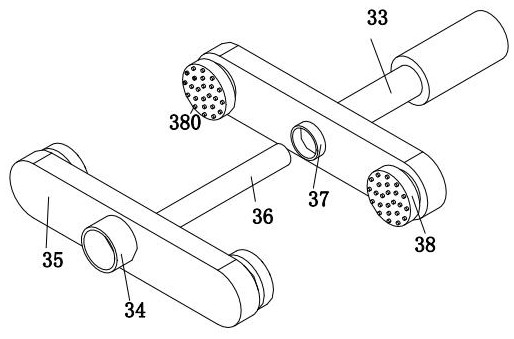

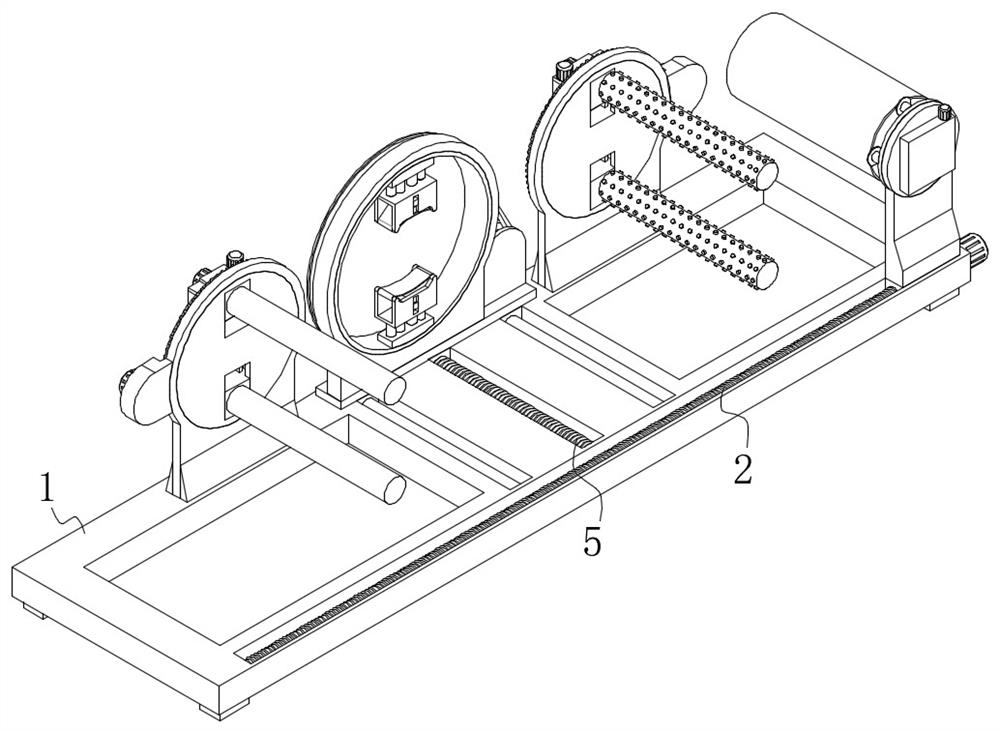

Rotor grinding equipment for waist wheel type flow meter

ActiveCN114147592AEasy to polishImprove grinding efficiencyGrinding drivesBelt grinding machinesRotor (electric)Control theory

The invention relates to the technical field of grinding machining, in particular to waist wheel type flowmeter rotor grinding machining equipment which comprises a machining table, a vertical plate, a clamping mechanism and a grinding mechanism. The grinding mechanism comprises a T-shaped sliding groove, a grinding electric sliding block, a supporting plate, a rectangular groove, a moving block, a supporting spring, a first adjusting frame, a second adjusting frame, a rotating roller, a tensioning shaft, a grinding belt, a motor, a balance block and an abutting forming set. By utilizing the characteristic that the grinding belt is easy to deform, the grinding belt wraps the outer wall of the rotor, and the rotor is ground through rotation of the grinding belt, so that the rotor is comprehensively ground, and the problem that the rotor is not comprehensively ground and finished or needs to be ground for multiple times due to the special structure of the rotor is solved; and meanwhile, the grinding belt can be adjusted according to the size of the rotor, so that the grinding belt and the rotor can be tightly attached, the contact area between the grinding belt and the rotor is increased, and the grinding efficiency of the rotor is improved.

Owner:XUZHOU DESHENG PETROLEUM MACHINERY CO LTD

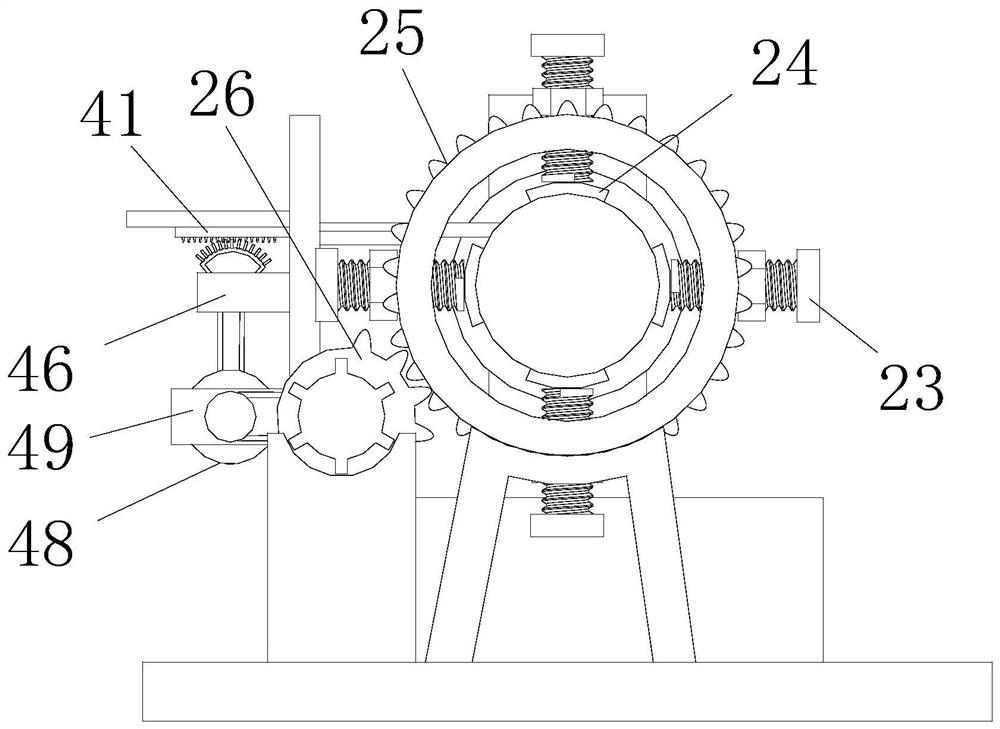

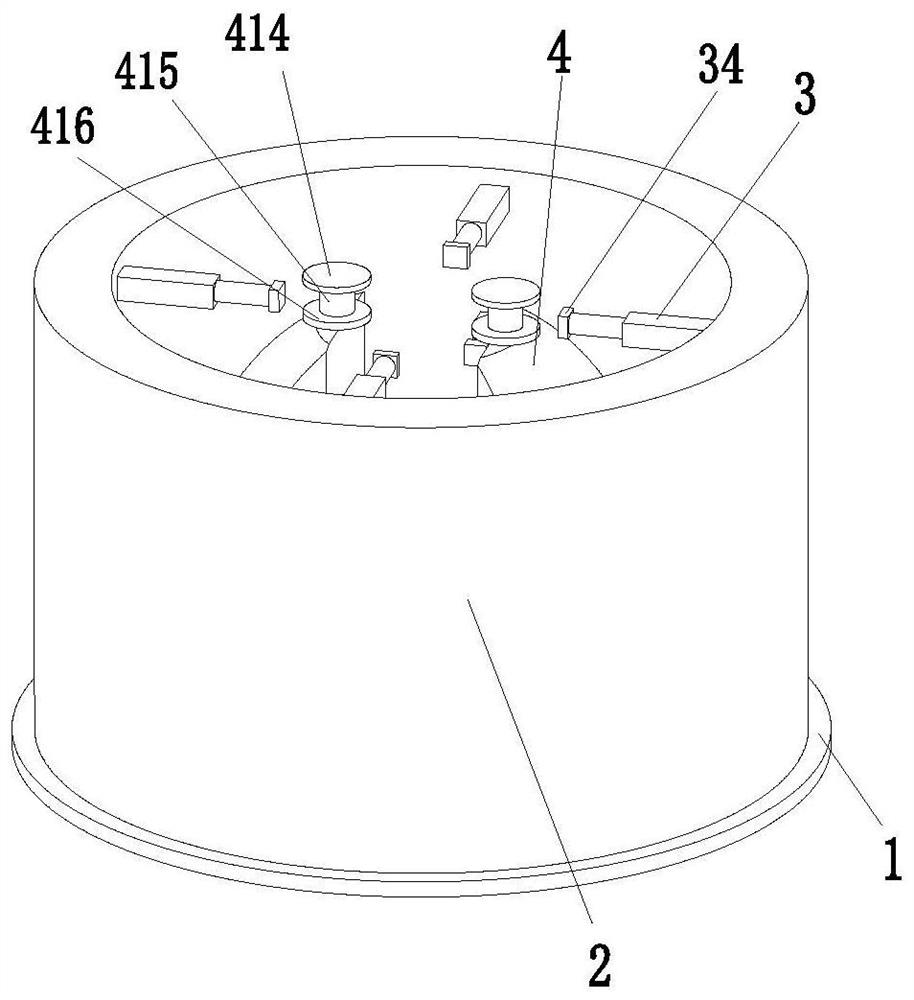

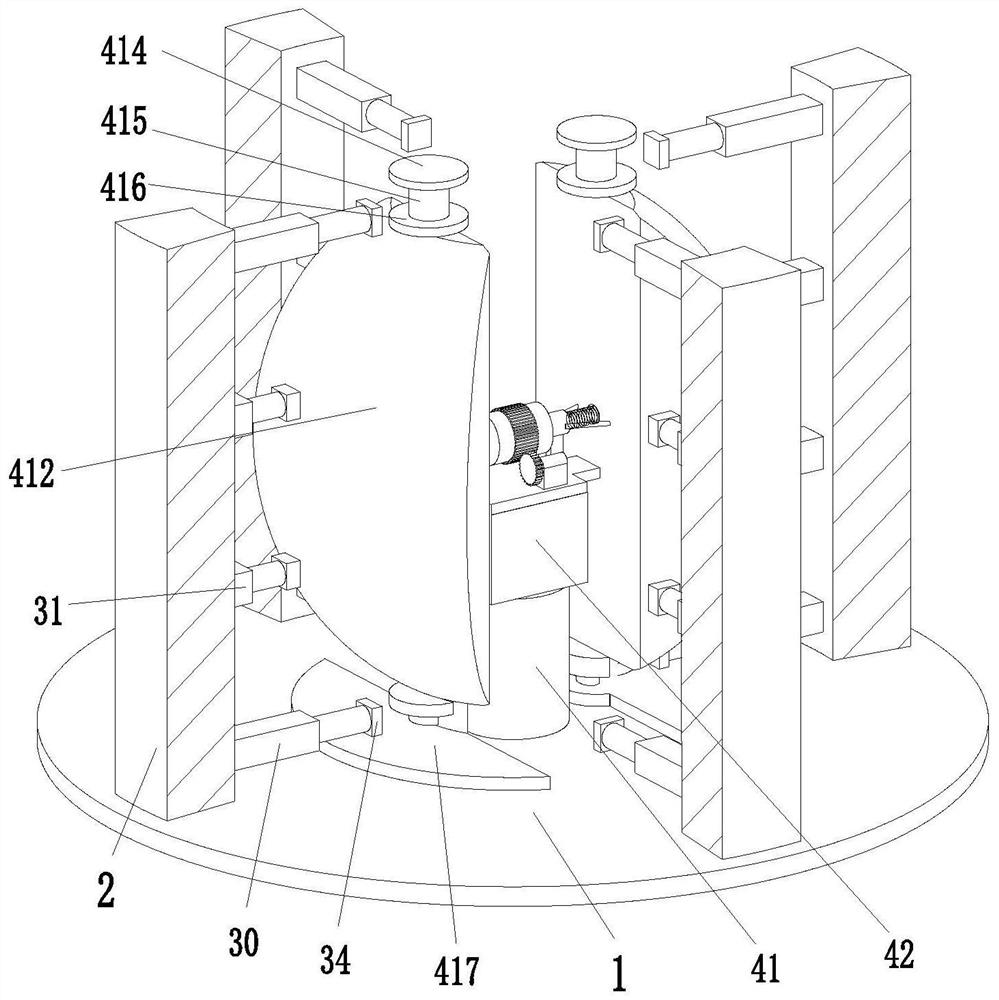

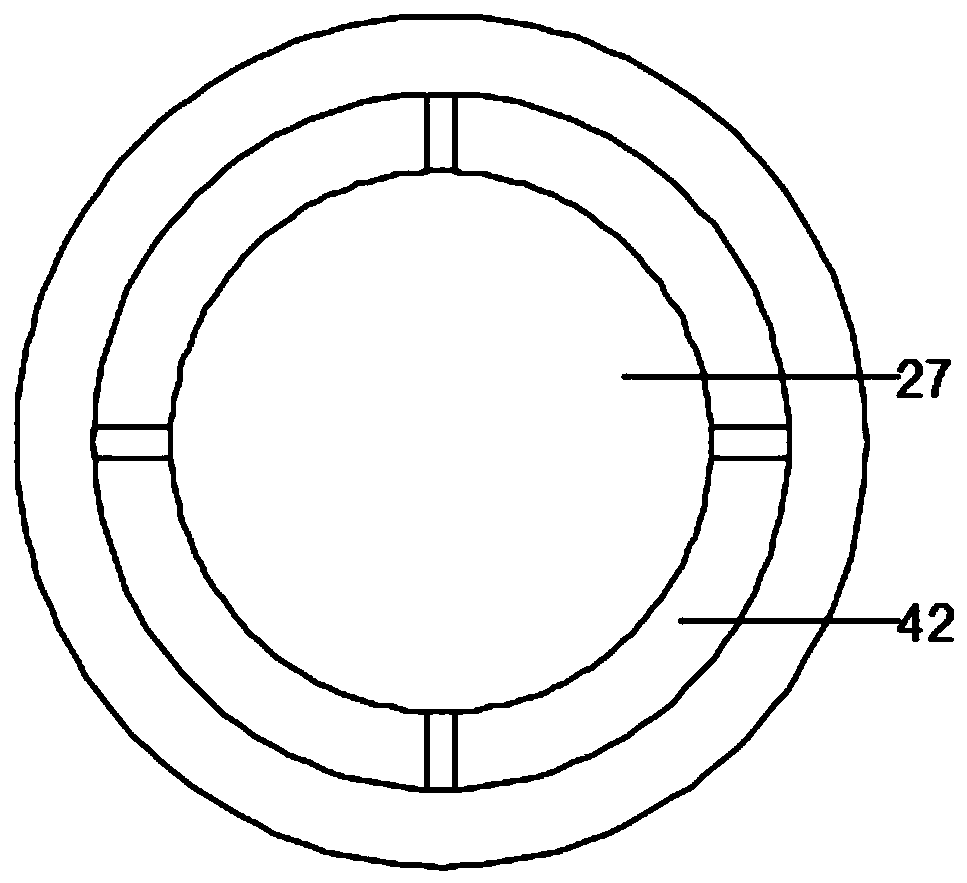

Explosion-proof rubber tire forming finish machining system

ActiveCN112975650AReduced service lifeReduce sanding effectEdge grinding machinesGrinding drivesMachining systemMechanical engineering

The invention relates to an explosion-proof rubber tire forming finish machining system. The system comprises a base, an annular cylinder, outer clamping mechanisms and an inner grinding mechanism; the annular cylinder is arranged on the upper end surface of the base, the outer clamping mechanisms are arranged on the inner side wall of the annular cylinder in the circumferential direction, and the inner grinding mechanism is arranged in the middle of the upper end surface of the base. The problems can be solved by the system. An inner clamping mechanism is used for supporting a rubber tire, and polishing abrasive paper is used for removing burrs and rim charge corners of the rubber tire; a rectangular plate is guided and limited through a dovetail block, the rectangular plate is prevented from rotating and deviating when a rotating lead screw rotates, and an outer ring of the rubber tire is clamped and fixed through the outer clamping mechanisms, so that the rubber tire is polished; a polishing block can be replaced, the cylindrical polishing block is prevented from being abraded, the safety of the rubber tire is improved, and the service life of the rubber tire is prolonged.

Owner:咸阳黄河轮胎橡胶有限公司

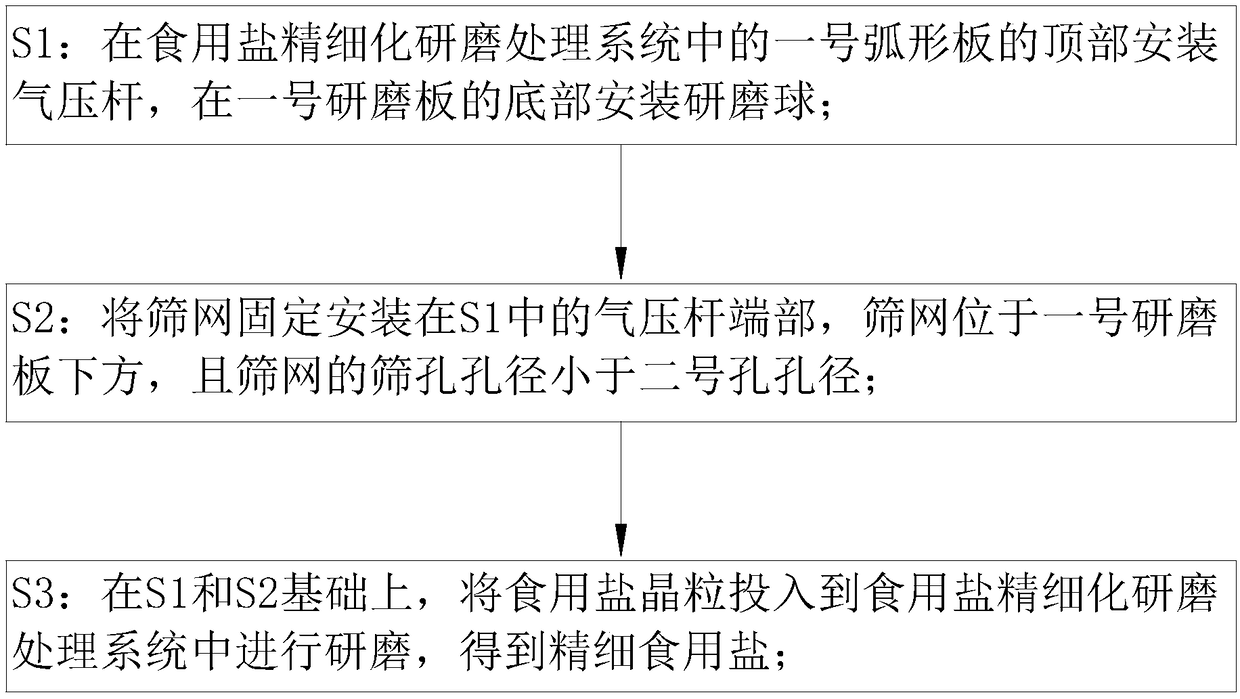

Preparation method of refined table salt

ActiveCN109261278AImprove grinding effectImprove efficiencyGrain treatmentsResource utilizationEngineering

The invention belongs to the technical field of table salt production, and particularly relates to a preparation method of refined table salt. The method is characterized in that a table salt refinedgrinding processing system is used and comprises a tube body, a driving unit, a first grinding unit, a second grinding unit, a blanking unit, a first material guide plate, a second material guide plate, a third material guide plate and a controller. Through the mutual matching of the driving unit, the first grinding unit, the second grinding unit, the blanking unit, the first material guide plate,the second material guide plate and the third material guide plate, on one hand, the driving unit drives the first grinding unit and the second grinding unit to grind table salt grains; through the grading grinding on the table salt grains, the grinding effect and efficiency of the table salt grains are improved; on the other hand, a power source generated by the table salt grinding process is utilized; the additional power source is reduced, so that the resource utilization rate is improved.

Owner:阜阳市艺凯农业科技有限公司

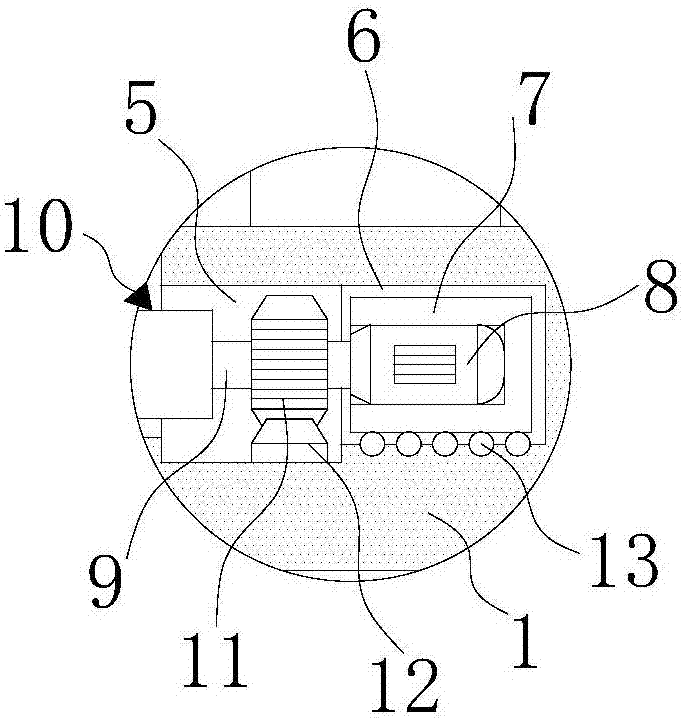

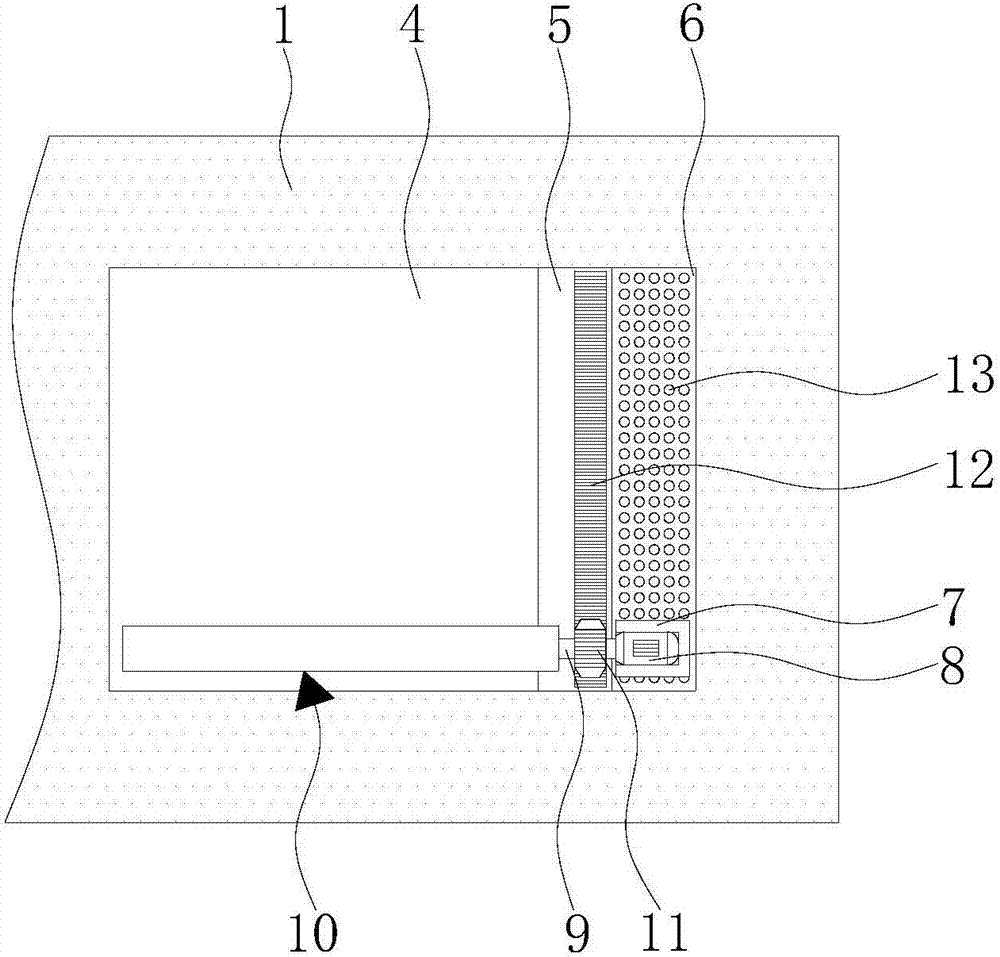

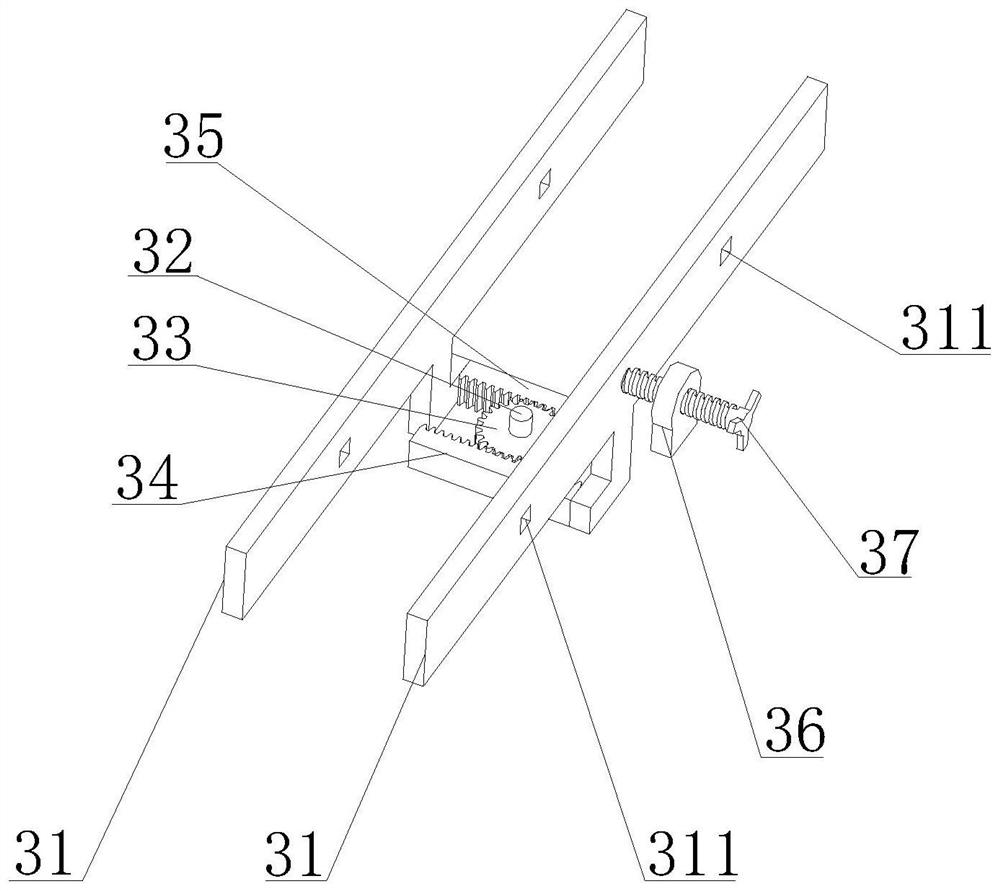

Grinding device for pipe incision

ActiveCN113118903BImprove the efficiency of deburringReduce the difficulty of operationEdge grinding machinesGrinding carriagesTransmission beltElectric machinery

Owner:喜有沃不锈钢(肇庆)有限公司

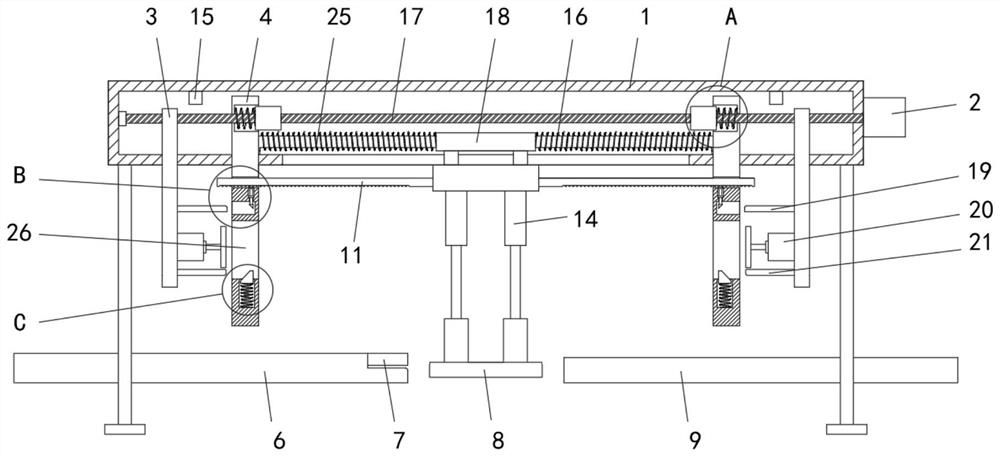

Circular pipe polishing machine with dust collection device

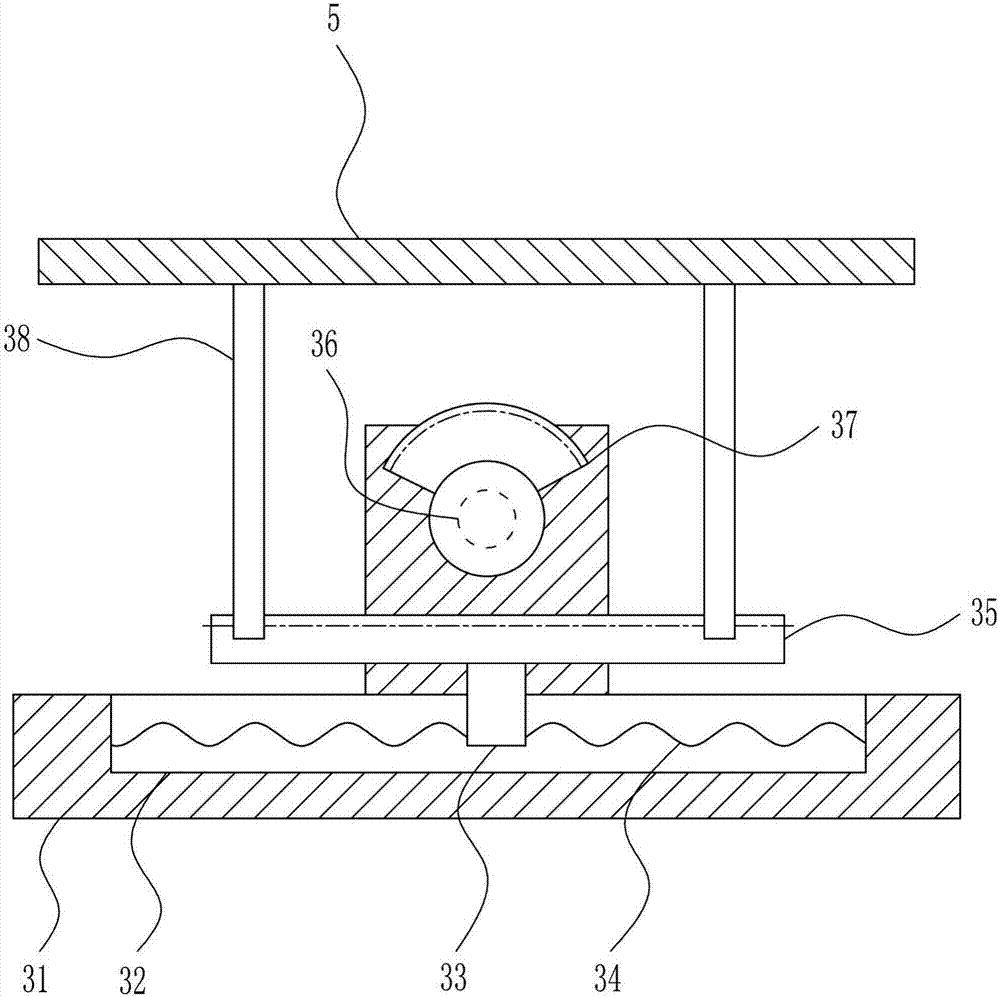

PendingCN108637828AAffect the grinding effectImprove work efficiencyEdge grinding machinesGrinding/polishing safety devicesEngineeringLinear actuator

The invention relates to a circular pipe polishing machine with a dust collection device. The circular pipe polishing machine with the dust collection device comprises a drive platform, a polishing device and a supporting platform. The two sides of the upper surface of the supporting platform are symmetrically and fixedly provided with fixing platforms. The upper middle parts of the fixing platforms are provided with sliding grooves. The sliding grooves are internally provided with sliding blocks. The drive platform is fixedly connected between the sliding blocks in the two fixing platforms. The lower surface of the drive platform is fixedly connected with the polishing device. The lower middle parts of the fixing platforms are symmetrically provided with linear actuators perpendicular tothe inner side faces of the fixing platforms. The middle of the upper surface of the supporting platform is downwards provided with a dust collection channel. The dust collection channel is internallyand fixedly connected with the dust collection device. A circular pipe is put above the dust collection device when polished, the dust collection device adsorbs scrap metal, the scrap metal generatedby polishing can be swept, the polishing effect of the polishing machine cannot be affected by the scraps, manual sweeping is not needed, time and labor are saved, the working efficiency is improved,and using is more convenient.

Owner:天津市永友工贸有限公司

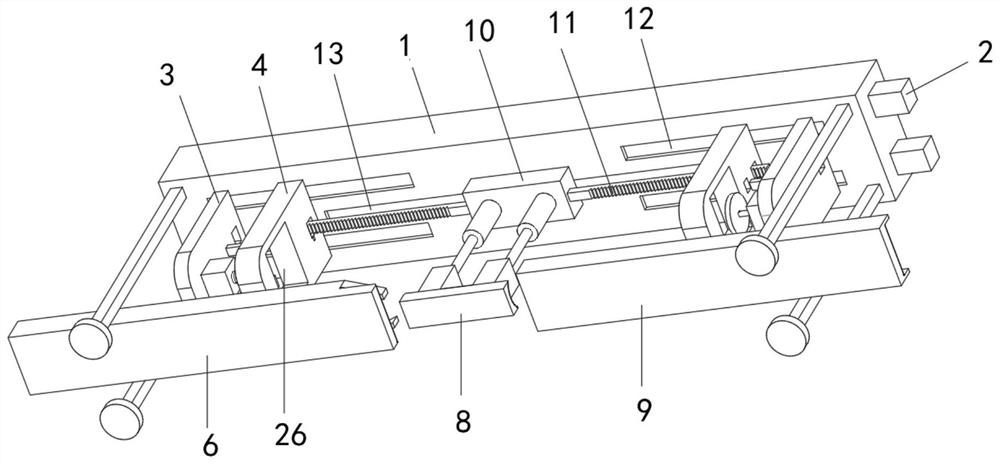

Multi-stage grinding and polishing device for metal pipe machining and grinding and polishing process

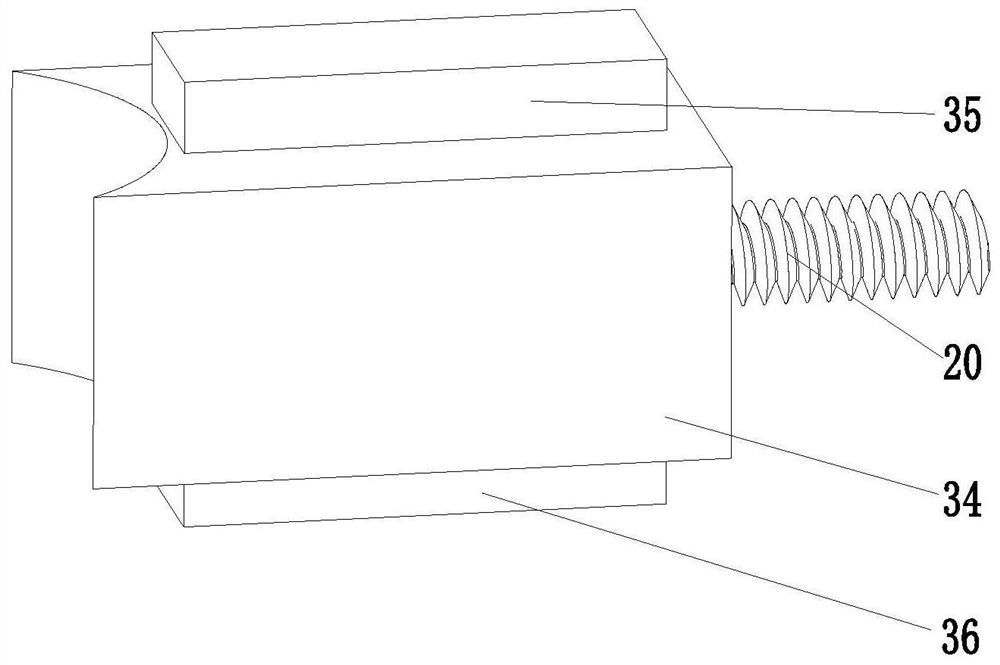

ActiveCN112518536AImprove sanding effectAffect the grinding effectRevolution surface grinding machinesGrinding drivesMetal machiningScrew thread

The invention discloses a multi-stage grinding and polishing device for metal pipe machining, and belongs to the technical field of metal machining. The multi-stage grinding and polishing device for metal pipe machining comprises a base, the inner wall of the base is rotationally connected with a threaded lead screw a, the peripheral side face of the threaded lead screw a is in threaded connectionwith a metal pipe fixing assembly, the upper surface of the base is fixedly connected with a pipe wall cleaning mechanism, the inner wall of the base is rotationally connected with a threaded lead screw b, a first-stage grinding mechanism is in threaded connection with the peripheral side face of the threaded lead screw b, the upper surface of the base is fixedly connected with a second-stage grinding mechanism, the metal pipe fixing assembly comprises a movable base, the inner wall of the movable base is in threaded connection with the threaded lead screw a, one surface of the movable base is fixedly connected with a support, and one surface of the support is fixedly connected with a fixed base. Through the design of the metal pipe fixing assembly, the pipe wall cleaning mechanism, the first-stage grinding mechanism and the second-stage grinding mechanism, the problem that an existing metal pipe grinding device is poor in practicability due to the fact that only one-time grinding isconducted on a metal pipe and the operation process is complex is solved.

Owner:无锡亚尔特金属制品有限公司

Grinding device for traditional Chinese herb processing

InactiveCN111495521AAffect the grinding effectGrind evenlyPharmaceutical product form changeGrain treatmentsAir blowerHerb

The invention discloses a grinding device for traditional Chinese herb processing. The grinding device comprises a base, a pretreatment tank and a grinding tank. The pretreatment tank is fixedly arranged above the base through a plurality of first supporting rods. The interior of the pretreatment tank is divided into a cutting chamber and a discharge chamber through a first screen plate. A U-shaped guide plate arranged obliquely is arranged above the base through a plurality of second supporting rods with the different lengths. A material collection tank is fixedly arranged on the base. The lower end of the U-shaped guide plate extends into the material collection tank. A plurality of hot air blowers are equidistantly arranged on the U-shaped guide plate. The grinding tank is fixedly arranged on the base. The grinding tank is internally and rotatably provided with a working chamber. A grinding ring is fixedly mounted on the inner wall of the working chamber. A second rotary rod is rotatably inserted at the top of the working chamber through a bearing. The lower end of the second rotary rod is fixedly provided with a grinding column. The grinding device adopts the integrated structure design, is easy to operate and convenient to use and has high practicality.

Owner:张海燕

Car roof rust removal device for automobile manufacturing

InactiveCN111571400ARealize the purpose of horizontal grinding and derustingAffect the grinding effectGrinding carriagesGrinding drivesElectric machineSlide plate

The invention discloses a car roof rust removal device for automobile manufacturing. The car roof rust removal device comprises a base, two symmetrical supporting columns are fixedly connected to thebottom face of the base, a roller is fixedly hinged to the bottom end of each supporting column through a pin, a power box is fixedly connected to the middle portion of the upper surface of the base,a channel is formed in the middle of the right side face of the power box, a sliding plate matched with the channel is placed in the power box, and the left end of the sliding plate penetrates throughthe channel and extends to the left side of the power box. According to the car roof rust removal device for automobile manufacturing, a screw rod is arranged, under the action of a screw ring and the channel, the sliding plate and an angle grinding piece can be driven to ascend and descend, the purposes of grinding and rust removal at different automobile body heights are achieved, and car roofdeformation is effectively avoided; by arranging an electric push rod, a rotating motor and the angle grinding piece can move left and right under the action of a spring, and a whole car roof is subjected to transverse grinding and rust removal; and by arranging the rollers, the device can be driven to move front and back, and longitudinal grinding and rust removal are conducted on the whole car roof.

Owner:余祥红

Rectifier heat dissipation shell manufacturing and forming machining equipment

ActiveCN114310580AImprove processing efficiencyUniform surface qualityEdge grinding machinesBelt grinding machinesElectric machineryEngineering

The invention relates to the technical field of rectifier heat dissipation shell machining, in particular to rectifier heat dissipation shell manufacturing and forming machining equipment which comprises a machining table and a positioning device, the positioning device is fixedly installed on the upper end face of the machining table, and the positioning device comprises an inverted-U-shaped plate, a positioning air cylinder, an extrusion plate, an electric telescopic rod, a moving frame, a grinding frame and a cleaning frame. The grinding frame comprises a moving plate, an L-shaped frame, a first motor, a first chain wheel, a support, a second chain wheel, a toothed chain belt, a grinding belt and a grinding plate, the machining table is matched with the positioning device to position a heat dissipation shell, the heat dissipation shell is ground through the positioning device, chippings on the surface of a part can be removed in time in the grinding process, and in the whole process, the machining efficiency is improved. Workers do not need to carry out machining operation, the machining efficiency of the equipment for machining the heat dissipation shell is improved, and meanwhile it is guaranteed that the surface quality of the heat dissipation shell is uniform.

Owner:江苏凯西电气设备科技有限公司

Dust-free grinding machine for sliding rail of solid wood furniture

ActiveCN114378659AImprove processing efficiencyPrevent floatingGrinding drivesGrinding feedersSolid woodPolishing

The invention relates to the technical field of solid wood furniture sliding rail machining, in particular to a solid wood furniture sliding rail dust-free polishing machine which comprises a fixing unit and a polishing unit, and the polishing unit is fixedly installed at the upper end of the fixing unit. Meanwhile, chippings generated on the surface of the solid wood furniture sliding rail in the polishing process are cleaned, chippings and dust are sucked and collected through wind power, and the situation that the machining environment of the solid wood furniture sliding rail becomes poor, more dust is absorbed by operators, the bodies of the operators are extremely prone to being damaged due to the fact that the chippings and dust float in air in the polishing process is prevented; the grinding unit is rapidly attached to the groove in the solid wood furniture sliding rail, grinding is conducted, manual adjustment is not needed, and the machining efficiency of the machine is improved.

Owner:徐州博枫木业有限公司

Micro-bearing grinding tool

InactiveCN110695777AEasy to holdImprove grinding efficiencyRevolution surface grinding machinesGrinding work supportsEngineeringScrew thread

The invention discloses a micro-bearing grinding tool, and relates to the technical field of bearing production. The micro-bearing grinding tool comprises a base, two symmetrical first vertical rods are fixedly connected to the upper surface of the base, threads are formed on the upper portions of the outer surfaces of the two first vertical rods respectively, a transverse plate is arranged abovethe two first vertical rods, two symmetrical second vertical rods are rotationally connected to the two ends of the bottom surface of the transverse plate, the ends, away from the transverse plate, ofthe two second vertical rods are fixedly connected with threaded cylinders, and the threaded cylinders are matched with the threads and are in threaded connection. According to the micro-bearing grinding tool, a piston and a first telescopic spring are arranged, so that the device plays a buffering role when the upper surface of a bearing is ground, meanwhile, the first telescopic spring changesfrom a natural state to a compressed state and then changes from the compressed state to the natural state, repeated floating grinding on the upper surface of the bearing is achieved, and a second telescopic spring realizes fixing of an inner ring of the bearing.

Owner:HUNAN MEIBEIDA TECH CO LTD

Operation method for separating crust from seeds of tomato paste by disk huller

InactiveCN101579104AGuaranteed moisture contentSmooth feedingVegetable peelingFood preparationCircular discEngineering

The invention discloses an operation method for separating a crust from seeds of tomato paste by a disk huller. The operation method comprises the following steps: the water content of the fed tomato paste is about 10-20 percent, an inclined packing auger provides 2.2 KW power input with the diameter of 650 mm and the power of 17 KW to grind the disk huller at a rated speed; and a manual handle is used for firstly adjusting a grinding disc distance to be 5 mm and a feeding amount to be about 0.8 ton per hour, and then adjusting the grinding disc distance to be 3 mm to feed the ground materials by 0.4-0.6 ton per hour for once or twice so as to fully separate the crust form the seeds of the tomato paste. The invention overcomes the defect that the prior art can not finish separating the tomato crust form the tomato seeds in a device, adjusts the grinding disc distance of the disk huller by controlling the feeding amount of the tomato paste and grinds the tomato paste twice so that the separation effect of the crust from the seeds of the tomato paste can reach over 96 percent.

Owner:NORTHWEST NORMAL UNIVERSITY

Fast end trimming device for hardware stainless steel tube

InactiveCN106944893AAffect the grinding effectImpact rateEdge grinding machinesGrinding drivesMaterials science

The invention relates to an end trimming device, in particular to a quick end trimming device for hardware stainless steel pipes. The technical problem to be solved by the present invention is to provide a hardware stainless steel pipe quick end trimming device specially for grinding the end of the stainless steel pipe. In order to solve the above-mentioned technical problems, the present invention provides such a hardware stainless steel pipe quick trimming device, including a base, a fixing mechanism, a moving mechanism, a mounting rod and a grinding stone, etc.; the left and right sides of the top of the base are symmetrically connected with mounting rods A fixing mechanism is connected between the upper parts of the inside of the installation rods, a moving mechanism is connected in the middle of the top of the base, and a millstone is connected at the top of the moving mechanism. In the present invention, the fourth through holes on the upper and lower sides are staggered to a certain position by turning the handle, and then the first gear is fixed by the inserting rod, so that the metal stainless steel pipe can be fixed for grinding.

Owner:梁培燕

Iron rod polishing equipment

InactiveCN111496663AEfficient grinding and polishingAffect the grinding effectGrinding carriagesPolishing machinesPolishingEngineering

The invention discloses iron rod polishing equipment. The iron rod polishing equipment comprises a box, a grinding device arranged in the box, a clamping device used for clamping iron rods, a waste scrap collection device arranged at the outer bottom of the box and vibration reduction devices. The vibration reduction devices comprise supporting columns arranged at the bottom of the box, press parts connected with the supporting columns, vibration reduction seats cooperating with the press parts, vibration reduction assemblies arranged in the vibration reduction seats and fourth elastic parts arranged on the supporting columns in a sleeving manner. One end of each fourth elastic part is connected with the bottom of the box, and the other ends of the fourth elastic parts are connected with the vibration reduction seats. According to the iron rod polishing equipment, iron rods can be ground and polished comprehensively and efficiently; iron scraps ground down from iron rods can be removedin time by the waste scrap collection device in the grinding process, and the situation that waste scraps are accumulated on the box to influence the iron rod grinding effect is avoided; and stability of the whole equipment is high, the polishing precision to iron rods can be guaranteed, and the grinding effect to iron rods is good.

Owner:浙江安尚电气有限公司

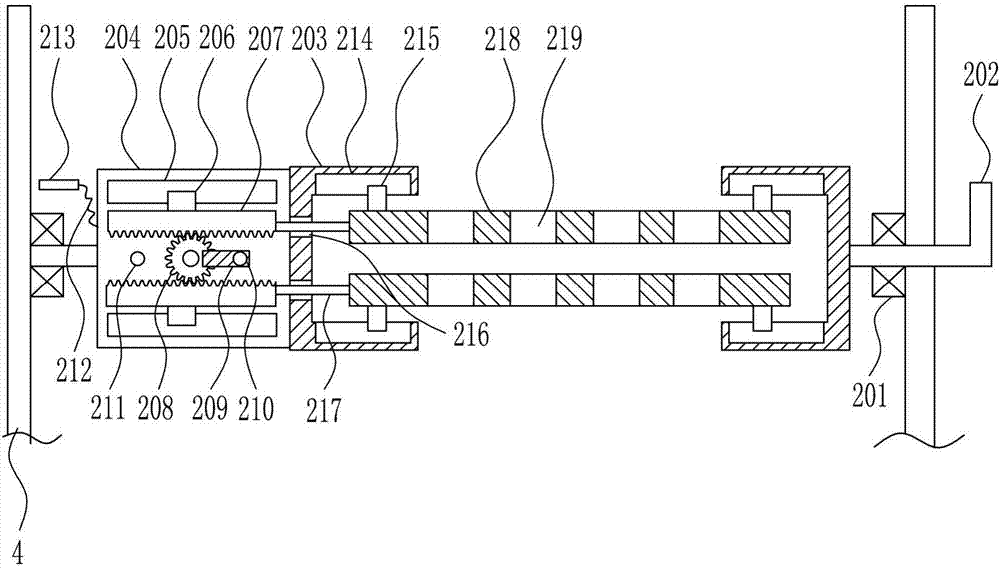

Grinding device for alternating-current motor carbon brushes

InactiveCN105856059AEasy to observe the grinding situationImprove grinding effectGrinding machine componentsLapping machinesBall bearingElectric machine

The invention relates to a grinding device for alternating-current motor carbon brushes. The grinding device is characterized in that a spindle (2) is fixed on a base (1) through a C-shaped flat key and a bolt (4), a bearing cap (9) and an angular contact ball bearing (13) are mounted on the spindle (2), the bearing chamber of a large rotary cover (8) is mounted on the outer ring of the angular contact ball bearing (13), the angular contact ball bearing (13) is connected with the spindle (2) through a bolt (10), a grinding cylinder (14) is mounted on the spindle (2), a first support sleeve (15) and a second support sleeve (16) sequentially sleeve the spindle (2), and a pressing cap (17) is mounted on the upper portion of the spindle (2) and connected to the spindle (2) through a nut (18). The grinding device has the advantages that the grinding device can replace a collecting ring; the cylindrical grinding cylinder can facilitate the fixing of an abrasive belt, carbon powder generated during grinding falls freely instead of remaining on the surface of the grinding cylinder, cleaning is facilitated, multiple groups of carbon brushes can be ground at the same time, the grinding condition of the carbon brushes can be observed conveniently, new carbon brushes can be replaced at any time, a good carbon brush grinding effect is achieved, and oxidization films can be favorably built between the carbon brushes and collecting rings during the operations of motors.

Owner:HARBIN ELECTRIC POWER EQUIP

Wafer grinding equipment for research and development of high-side NMOSFET driver chip

ActiveCN113263435AAdjustable distanceImprove stabilityLapping machinesLapping toolsWaferElectric machinery

The invention discloses wafer grinding equipment for research and development of a high-side NMOSFET driver chip. The wafer grinding equipment comprises a workbench, a rectangular groove is formed in the center of the end part of the workbench, a connecting rod is fixedly mounted on the side wall of the workbench, a first motor is fixedly mounted at the end part of the connecting rod, and a column sleeve is fixedly mounted at the end part of the first motor; a hydraulic rod is fixedly mounted on the side, away from the first motor, of the column sleeve, an adjusting column penetrates through the interior of the hydraulic rod, a first strip-shaped groove and a second strip-shaped groove are formed in the side wall of the workbench, an adjusting mechanism sleeves the surface of the adjusting column and comprises threaded sleeves, and the two threaded sleeves are symmetrically arranged with the midpoint of the adjusting column as the center point; and the surfaces of the two threaded sleeves are opposite in thread direction, the threaded sleeves are arranged on the surface of the adjusting column in a sleeving mode, a rotating cap is fixedly installed at the end of the adjusting column, and a rotating disc is fixedly installed on the side, away from the column sleeves, of the hydraulic rod, so that when the equipment is used, the distance of grinding sleeves can be adjusted at will, the equipment is suitable for wafers of any size, and the application range is wider.

Owner:深圳国融智能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com