Bevel gear polishing device

A polishing device and technology for helical gears, which are used in grinding drive devices, grinding/polishing equipment, and surface-polished machine tools, etc., can solve the problem that helical gears are not easy to be ground.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below by means of specific embodiments:

[0018] The reference signs in the accompanying drawings of the specification include:

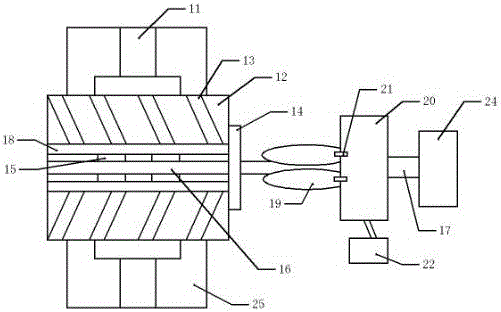

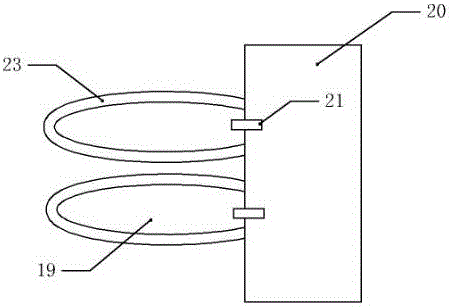

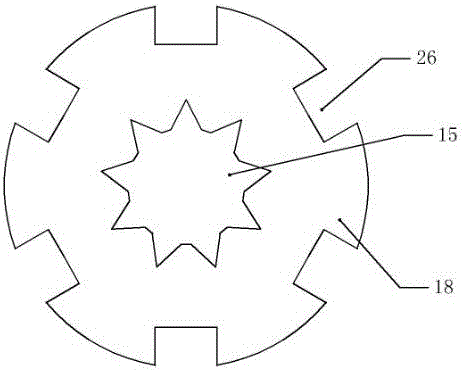

[0019] Rotary shaft 11, helical gear 12, tooth groove 13, baffle plate 14, saw gear 15, rack 16, telescopic rod 17, rotating disk 18, first airbag 19, second airbag 20, one-way air inlet 21, blower 22 , fine sandpaper 23, cylinder 24, collection tank 25, guide groove 26.

[0020] Such as figure 1 The helical gear grinding and polishing device shown includes a rotating shaft 11 and a collecting tank 25. A layer of magnetic filter screen is arranged inside the collecting tank 25, and the filter screen is stuck in the middle of the collecting tank 25 horizontally. The rotating shaft 11 is fixedly installed on the tank wall of the collection tank 25, and the rotating shaft 11 is sleeved with two hollow rotating discs 18 made of pure iron, and the rotating discs 18 are wound with electric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com