Fast end trimming device for hardware stainless steel tube

A stainless steel tube, fast technology, used in grinding drives, metalworking equipment, grinding machines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

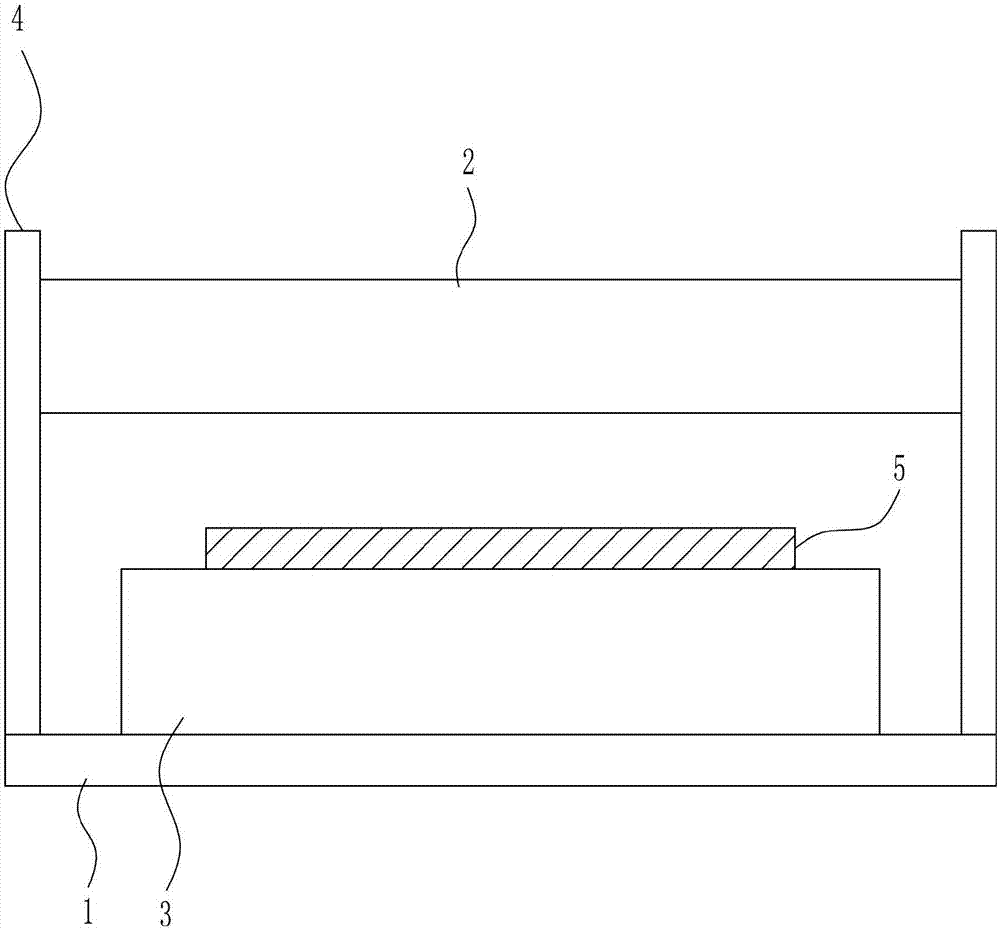

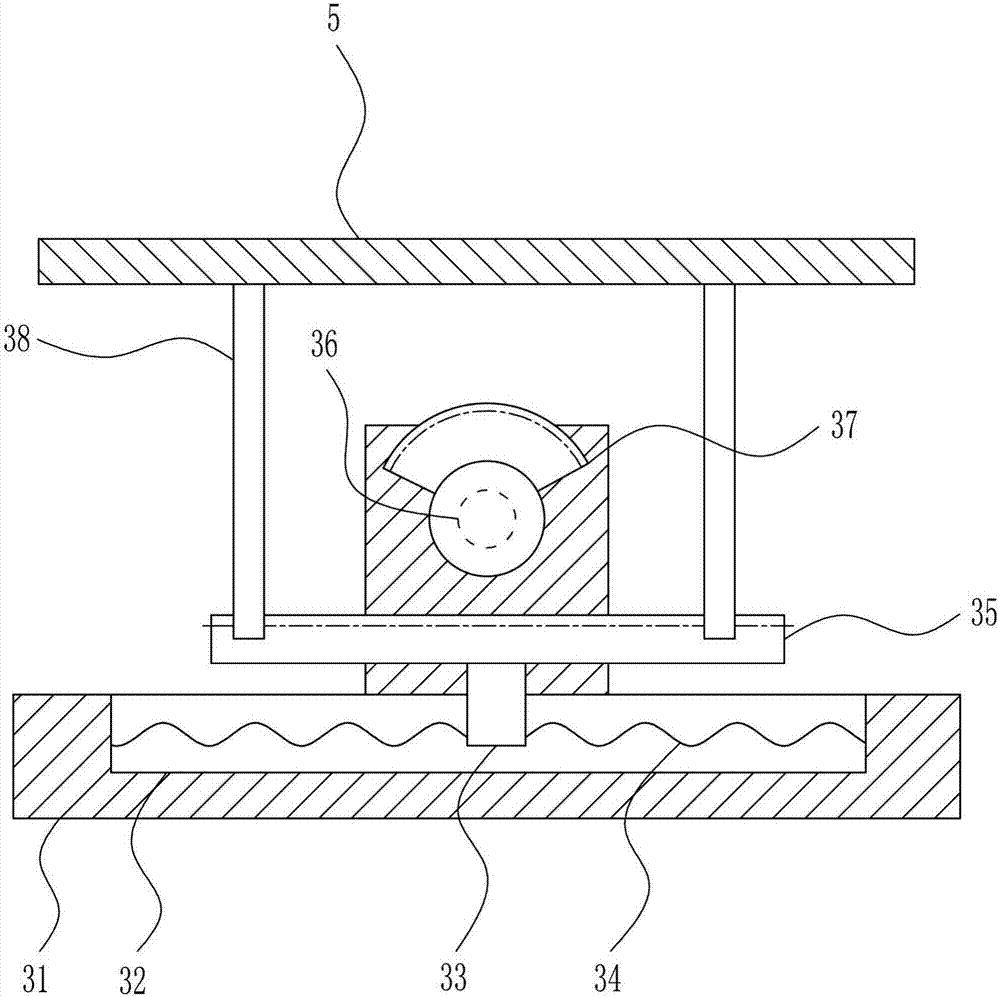

[0028] A hardware stainless steel pipe fast trimming device, such as Figure 1-3 As shown, it includes a base 1, a fixing mechanism 2, a moving mechanism 3, a mounting rod 4, and a grinding stone 5. The top of the base 1 is symmetrically connected to the left and right sides of the mounting rod 4, and the upper part of the inside of the mounting rod 4 is connected to a fixing mechanism. 2. A moving mechanism 3 is connected to the middle of the top of the base 1, and a grinding stone 5 is connected to the top of the moving mechanism 3.

Embodiment 2

[0030] A hardware stainless steel pipe fast trimming device, such as Figure 1-3 As shown, it includes a base 1, a fixing mechanism 2, a moving mechanism 3, a mounting rod 4, and a grinding stone 5. The top of the base 1 is symmetrically connected to the left and right sides of the mounting rod 4, and the upper part of the inside of the mounting rod 4 is connected to a fixing mechanism. 2. A moving mechanism 3 is connected to the middle of the top of the base 1, and a grinding stone 5 is connected to the top of the moving mechanism 3.

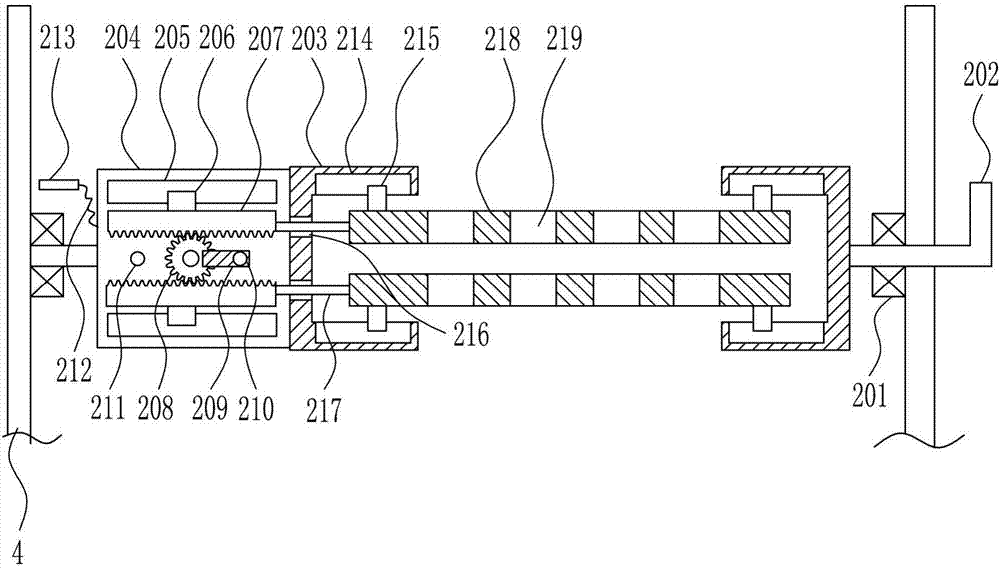

[0031] The fixing mechanism 2 includes a bearing seat 201, a rotating rod 202, a mounting plate 203, a fixing plate 204, a first slide rail 205, a first slider 206, a first rack 207, a first gear 208, a handle 209, a first Spring 212, inserting rod 213, the second slide rail 214, the second slide block 215, moving bar 217 and clamping plate 218, are connected with bearing seat 201 symmetrically between the upper part of mounting rod 4 inner sid...

Embodiment 3

[0033] A hardware stainless steel pipe fast trimming device, such as Figure 1-3 As shown, it includes a base 1, a fixing mechanism 2, a moving mechanism 3, a mounting rod 4, and a grinding stone 5. The top of the base 1 is symmetrically connected to the left and right sides of the mounting rod 4, and the upper part of the inside of the mounting rod 4 is connected to a fixing mechanism. 2. A moving mechanism 3 is connected to the middle of the top of the base 1, and a grinding stone 5 is connected to the top of the moving mechanism 3.

[0034] The fixing mechanism 2 includes a bearing seat 201, a rotating rod 202, a mounting plate 203, a fixing plate 204, a first slide rail 205, a first slider 206, a first rack 207, a first gear 208, a handle 209, a first Spring 212, inserting rod 213, the second slide rail 214, the second slide block 215, moving bar 217 and clamping plate 218, are connected with bearing seat 201 symmetrically between the upper part of mounting rod 4 inner sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com