Iron rod polishing equipment

An iron rod and equipment technology, which is applied in the field of hardware and building materials processing equipment, can solve the problems of low cleaning efficiency, large vibration, and impact on production efficiency, so as to ensure the polishing accuracy, improve the grinding effect, and improve the processing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

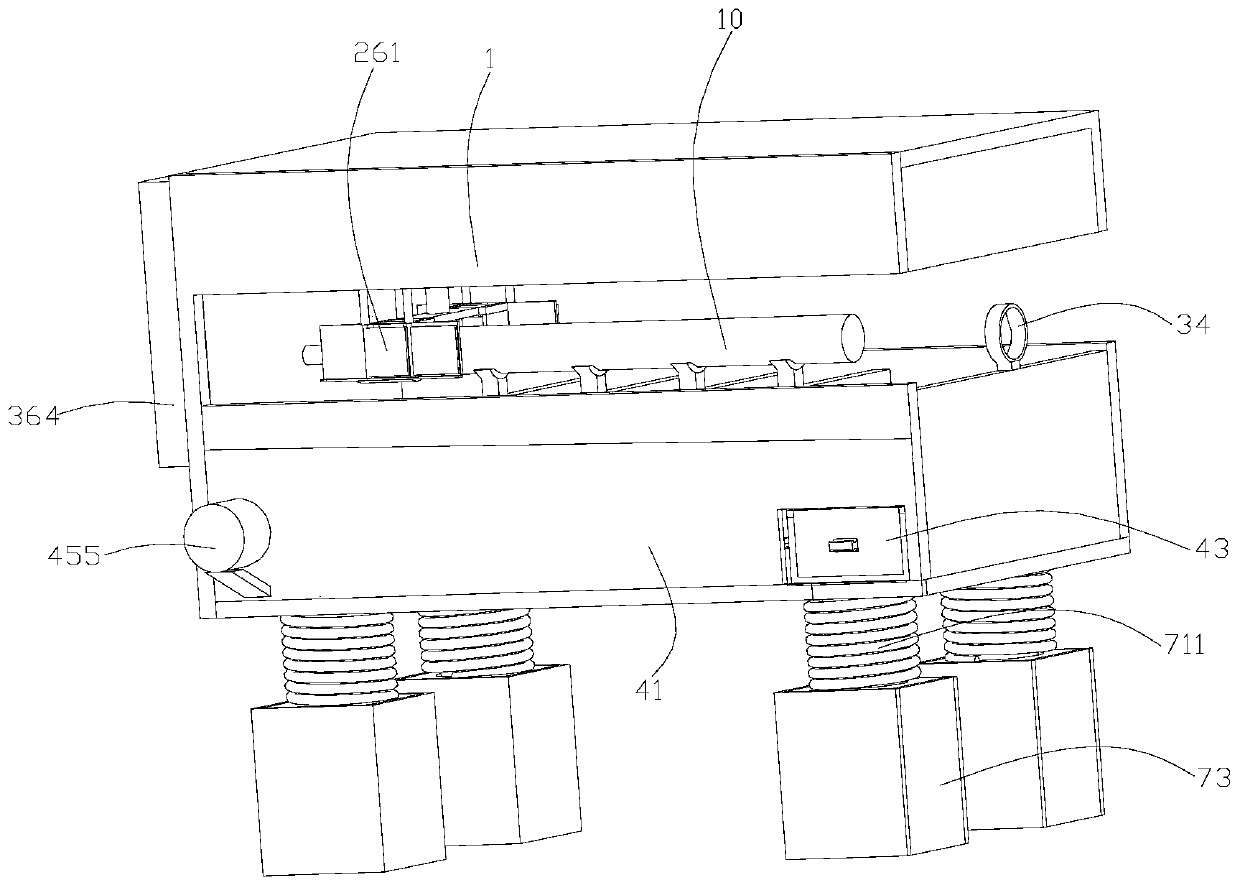

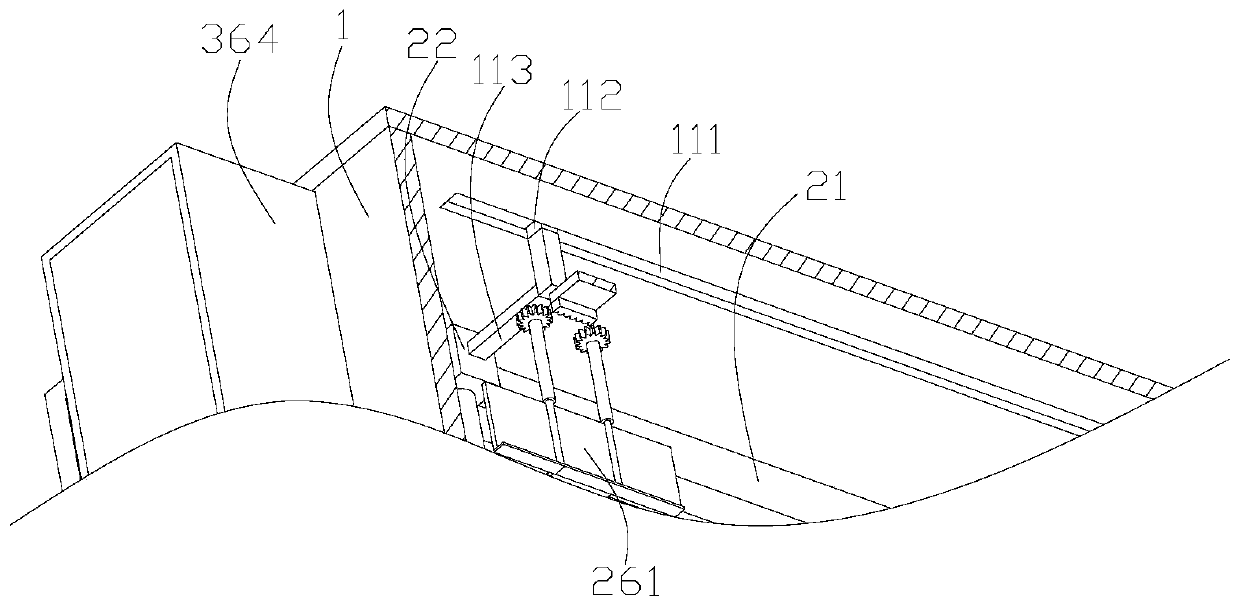

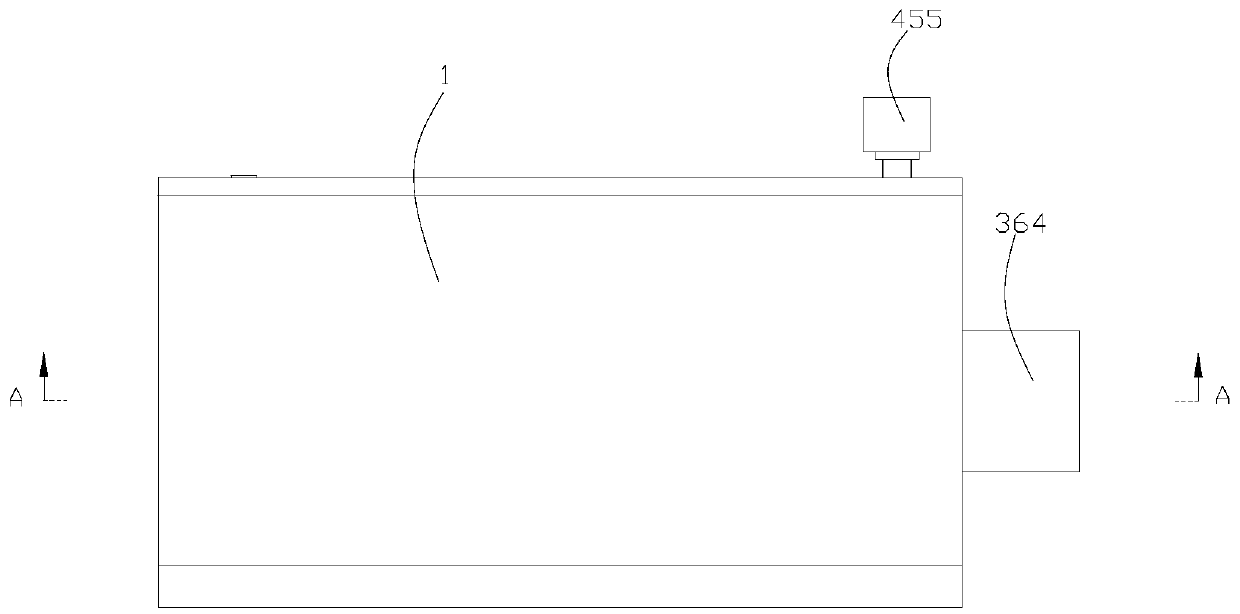

[0035] like Figure 1-18The shown iron rod polishing equipment includes a box body 1, a grinding device, a clamping device, a waste collection device and a shock absorption device. The box body 1 is a metal box, and the bottom of the box body 1 is a plastic Bottom, preferably, the bottom of the box body 1 is inclined, so that the discharge of waste can be facilitated. The grinding device includes a lead screw 21, a lead screw nut 22, a connecting rod 23, a grinding component and a shielding component. The lead screw 21 is a two-way lead screw that can be directly purchased on the market. The specific structure and principle will not be repeated here. One end of the rod 21 is matched with one side wall of the box through a bearing, the other end of the screw 21 is matched with the other side wall of the box through a bearing, and the screw nut 22 is sleeved on the On the screw rod 21, the connecting rod 23 is a metal rod, one end of the connecting rod 23 is connected with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com