Stainless steel dinner plate polishing equipment

A stainless steel, dinner plate technology, applied in grinding/polishing equipment, metal processing equipment, surface polishing machine tools, etc., can solve the problems of high labor intensity, easy grinding, uneven grinding efficiency, etc., and achieve efficient grinding and polishing, uniform grinding polished effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

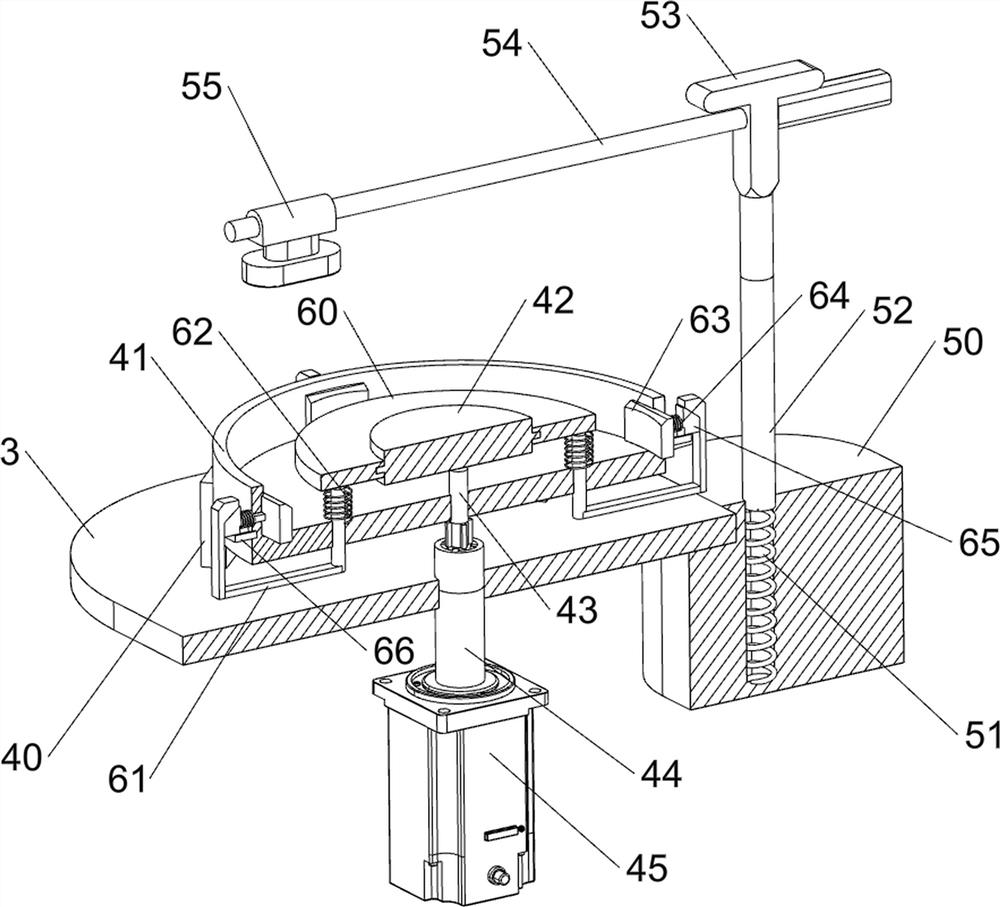

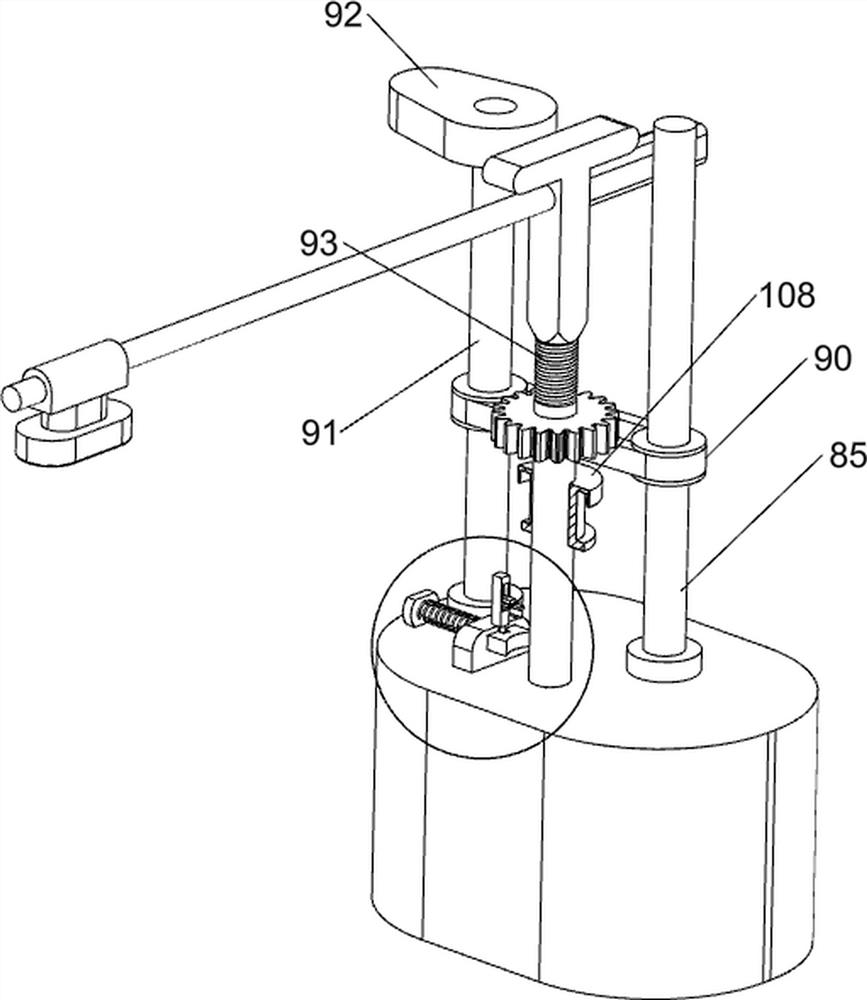

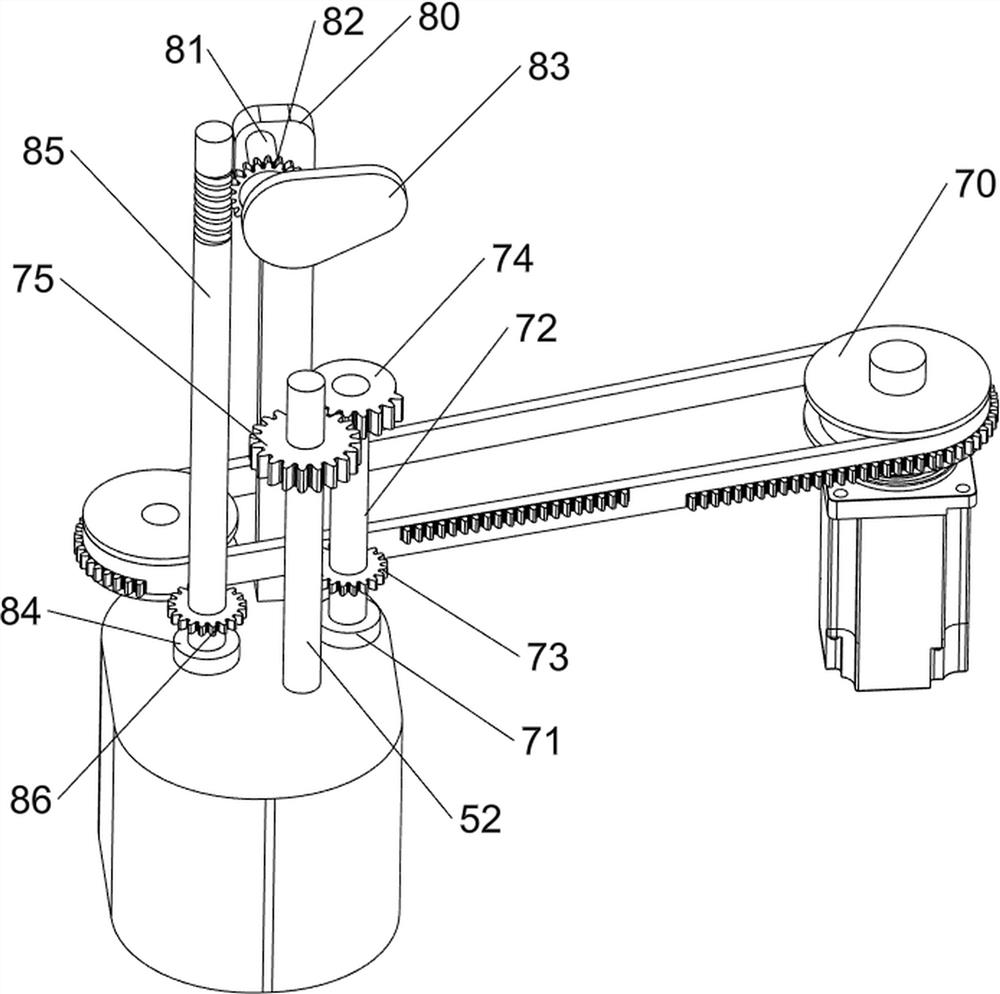

[0027] A stainless steel dinner plate polishing equipment, such as figure 1 and figure 2 As shown, it includes a base 1, a first support 2, a workbench 3, a rotating mechanism 4 and a grinding mechanism 5. The base 1 is provided with a plurality of first supports 2, and a workbench 3 is arranged between the first supports 2. The platform 3 is provided with a rotating mechanism 4, and the base 1 is provided with a grinding mechanism 5.

[0028] When people need to use this equipment, first people place the stainless steel dining basin on the rotating mechanism 4, then manually rotate the grinding mechanism 5, so that the polishing mechanism 5 moves to the top of the stainless steel dining basin, and then people start the rotating mechanism 4 again, so that the rotating mechanism 4 drives the stainless steel dining basin to rotate, and simultaneously people extrude the polishing mechanism 5 so that the polishing mechanism 5 contacts the stainless steel dining basin, and then t...

Embodiment 2

[0033] On the basis of Example 1, such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 Shown, also comprise positioning mechanism 6, positioning mechanism 6 comprises top plate 60, ejector rod 61, second spring 62, positioning block 63, the 3rd spring 64, wedge-shaped block 65 and guide block 66, and the rotation type on the rotating disk 42 is provided with Top plate 60, the bottom of top plate 60 is evenly provided with a plurality of push rods 61, and the push rods 61 slide on the placement plate 41, and the second springs 62 are sleeved on the push rods 61, and the second springs 62 are connected with the top plate 60 and the placement plate 41, Placement plate 41 is provided with a plurality of positioning blocks 63 slidingly, and the positioning block 63 is equipped with a third spring 64. The positioning block 63 is equipped with a wedge block 65. The wedge block 65 cooperates with the push rod 61, and the third spring 64 It is connected with the wedge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com