Refined table salt refined grinding processing system

A refined edible salt and processing system technology, which is applied in the field of fine grinding and processing system for refined edible salt, can solve problems such as poor grinding effect of coarse salt, impact on resource utilization, and limitations, so as to reduce additional power sources and improve grinding effect and efficiency, the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

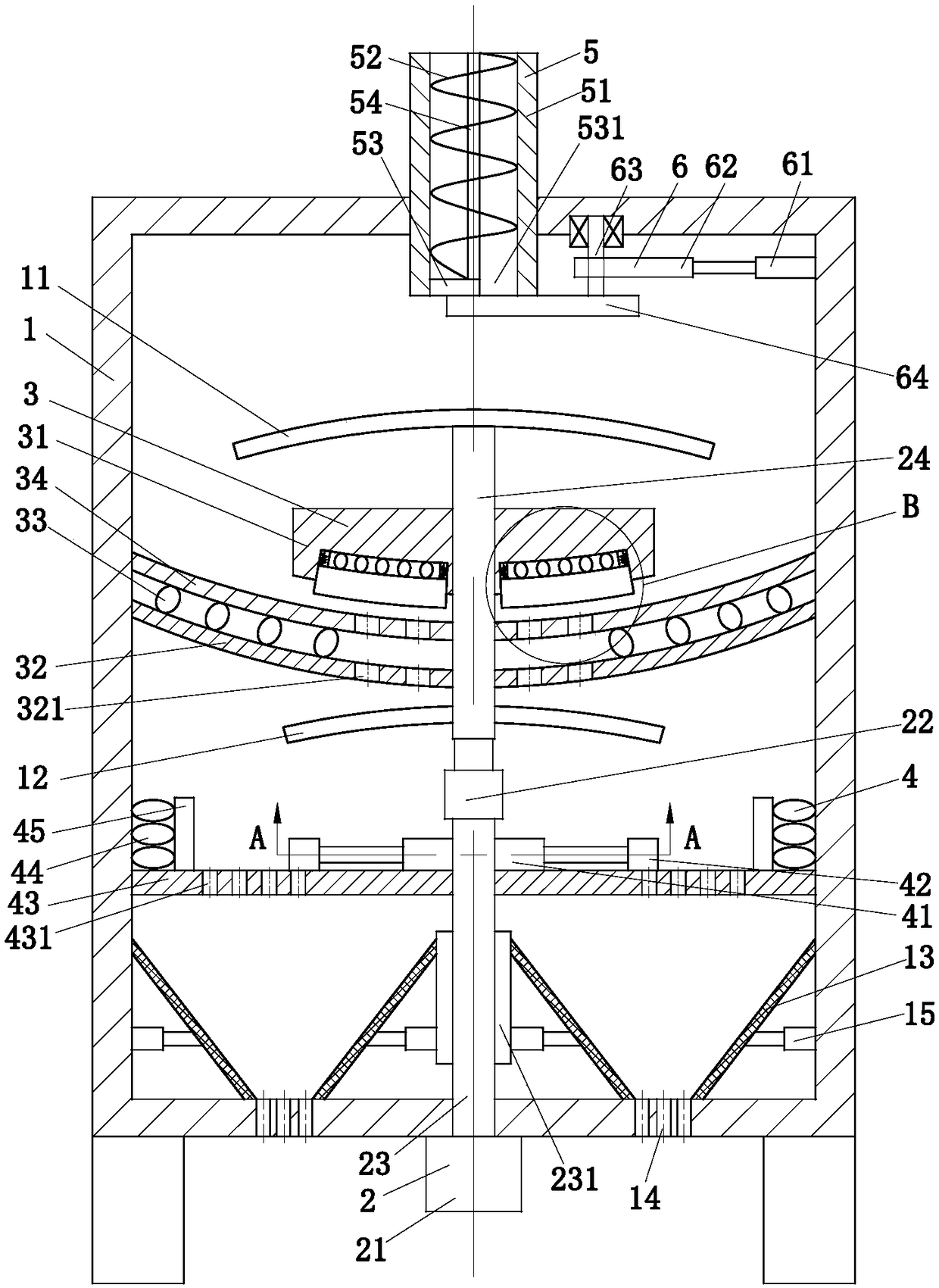

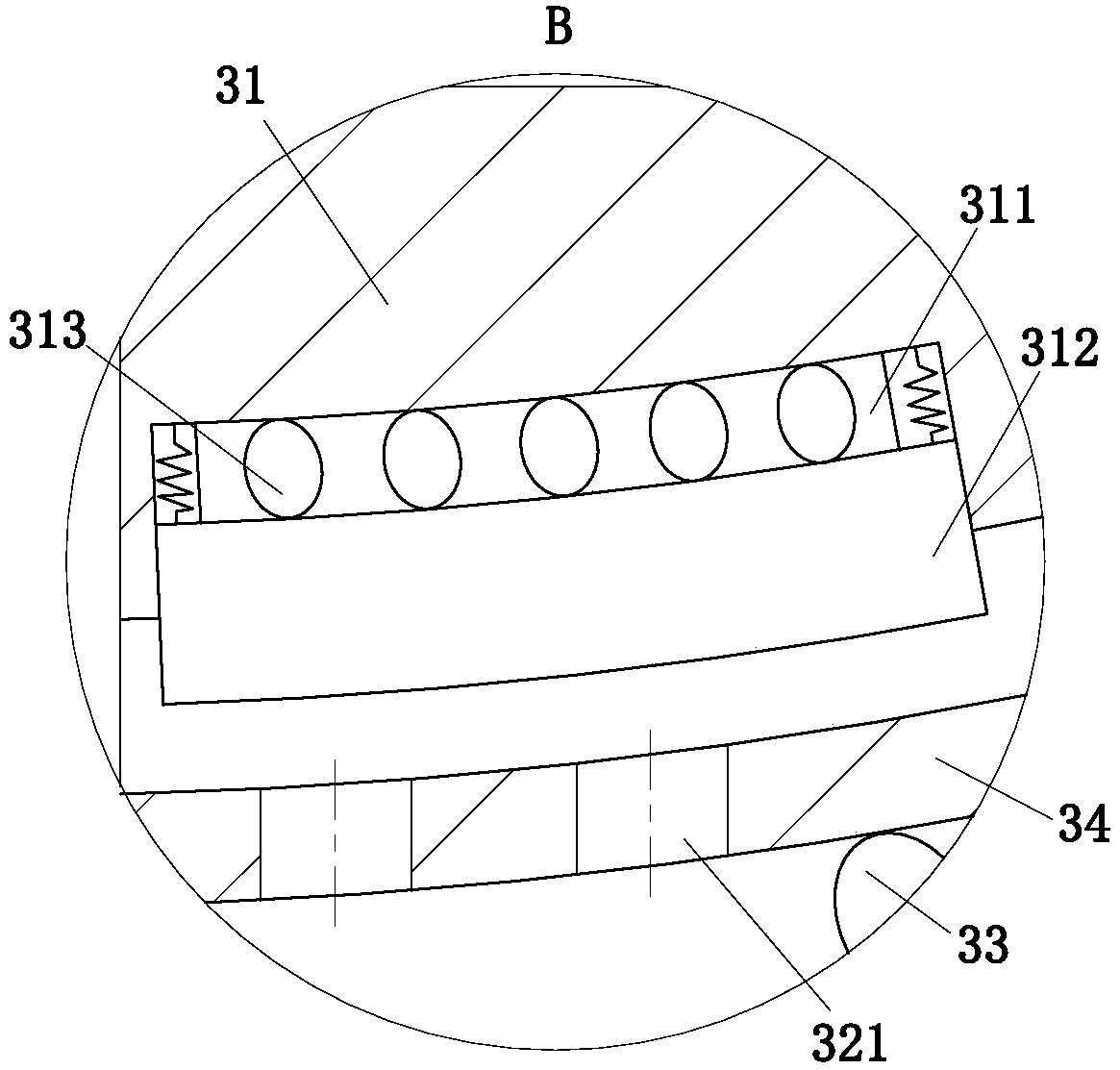

[0038] As an embodiment of the present invention, the No. 1 grinding disc 31 is provided with a No. 1 groove 311; the No. 1 groove 311 is provided with a grinding roller 312 and a No. 3 air bag 313; No. air bag 313 is fixedly connected on No. 1 groove 311. In the prior art, when the No. 1 cylinder 22 drives the No. 1 grinding disc 31 to move downward, the No. 1 grinding disc 31 and the No. 1 grinding plate 34 undergo rigid collision, thereby easily causing damage to the No. 1 grinding disc 31; The No. 3 air bag 313 is set, on the one hand, the No. 3 air bag 313 buffers the collision force between the grinding roller 312 and the No. 1 grinding plate 34, avoiding the damage of the grinding roller 312, thereby improving the service life of the grinding roller 312; On the one hand, when the No. 3 airbag 313 is squeezed, it inflates outwards, and the bulging gas is used as a power source, thereby improving the utilization rate of resources.

[0039] The No. 1 cylinder 22 drives th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com