Edge deburring device for rock plate machining

A technology for edge deburring and rock slabs, which is applied to machine tools, grinding drive devices, metal processing equipment, etc. suitable for grinding the edges of workpieces, and can solve rock slab wear, low grinding efficiency, and low grinding precision of rock slabs, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

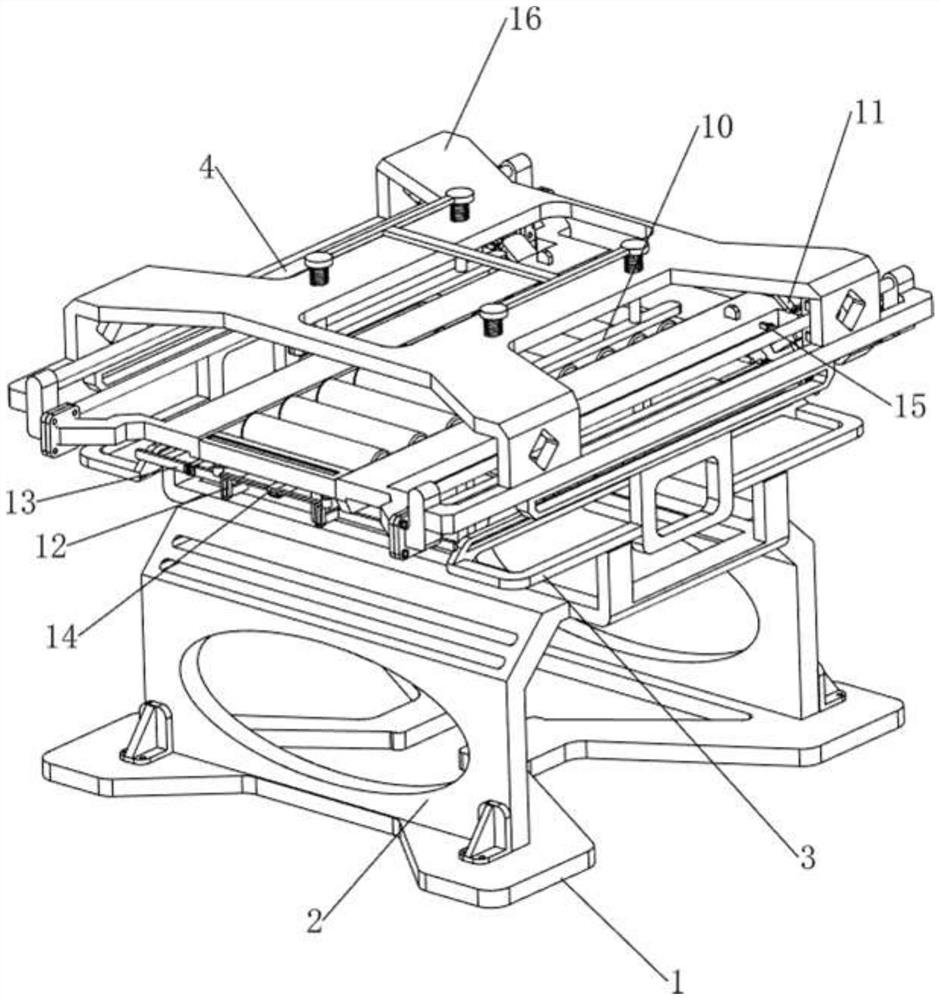

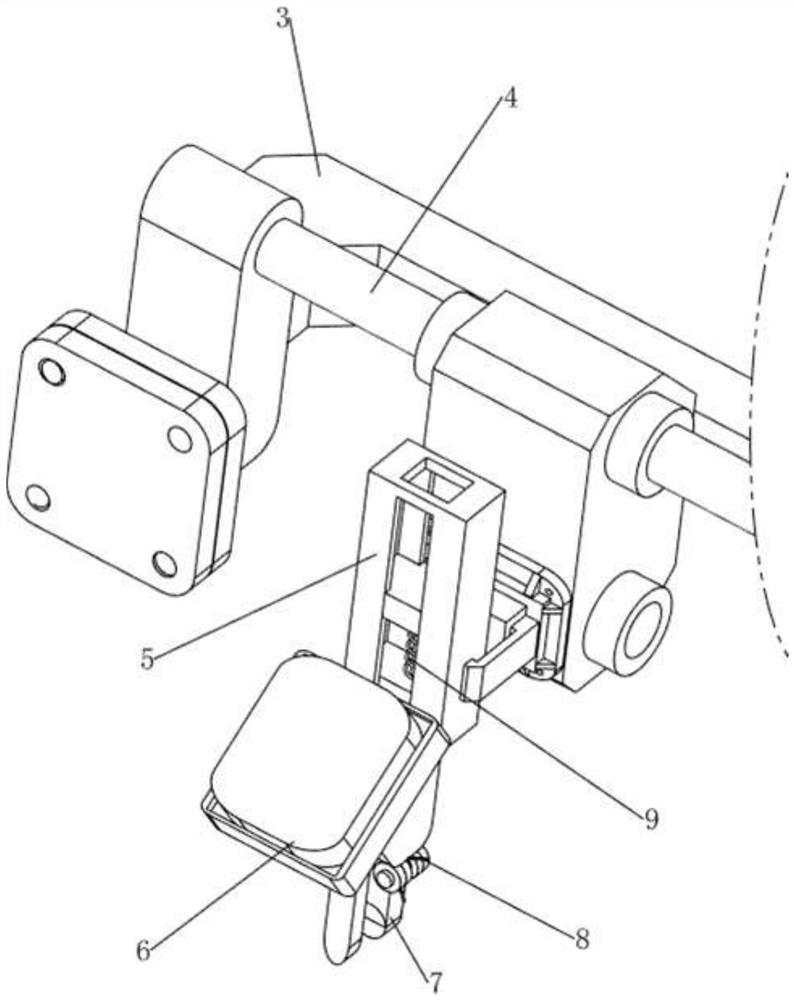

[0031] An edge deburring device for slate processing, such as Figure 1-4 As shown, it includes a base 1, a first support frame 2, a second support frame 3, a trackless cylinder 4, a fixed frame 5, a first grinding block 6, a sliding rod 7, a first torsion spring 8, a first compression spring 9, The loading mechanism 10 and the clamping mechanism 11 are connected with the first support frame 2 on the front and rear sides of the base 1, the second support frame 3 is connected between the first support frame 2, and the left and right sides of the second support frame 3 are connected with trackless The cylinder 4 and the trackless cylinder 4 are all slidably connected with a fixed frame 5, and the fixed frame 5 is slidably connected with a first grinding block 6, and the bottom of the first grinding block 6 is rotatably connected with a slide bar 7, and the slide bar 7 and First torsion springs 8 are arranged between the first grinding blocks 6, first compression springs 9 are ar...

Embodiment 2

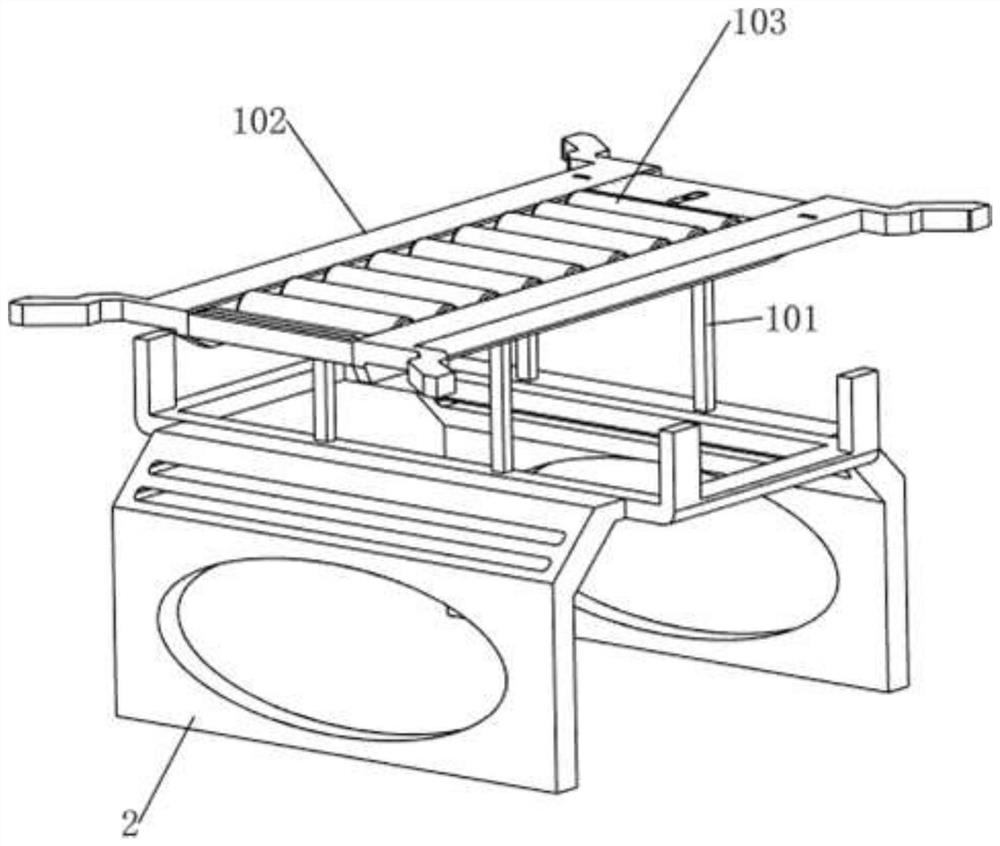

[0036] On the basis of Example 1, such as Figure 5-12 As shown, it also includes a blocking mechanism 12. The blocking mechanism 12 includes a clamping rod 121, a baffle 122 and a second compression spring 123. The front side of the support plate 102 is slidably connected to the baffle 122. A second compression spring 123 is provided between the side and the support plate 102 , and a locking rod 121 is provided at the bottom of the baffle plate 122 .

[0037] The original state of the baffle plate 122 is the state of moving upwards. When people discharge the material, the baffle plate 122 and the clamping rod 121 are moved downward, so that the second compression spring 123 is compressed, and when the material is pushed backward and separated from the baffle plate 122 , under the action of the second compression spring 123, the baffle plate 122 and the clamping rod 121 are driven to move upward and reset, so that the position of the material can be limited.

[0038] Also inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com