Cable sweeping robot

A technology of cleaning robots and cleaning motors, which is applied to overhead lines/cable equipment, grinding machines, metal processing equipment, etc., can solve the problems of inconvenient handling and installation, increase the weight of the whole machine, and robot jamming, etc., so as to facilitate handling and assembly , Reduce the weight of the whole machine and improve the effect of cleaning intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

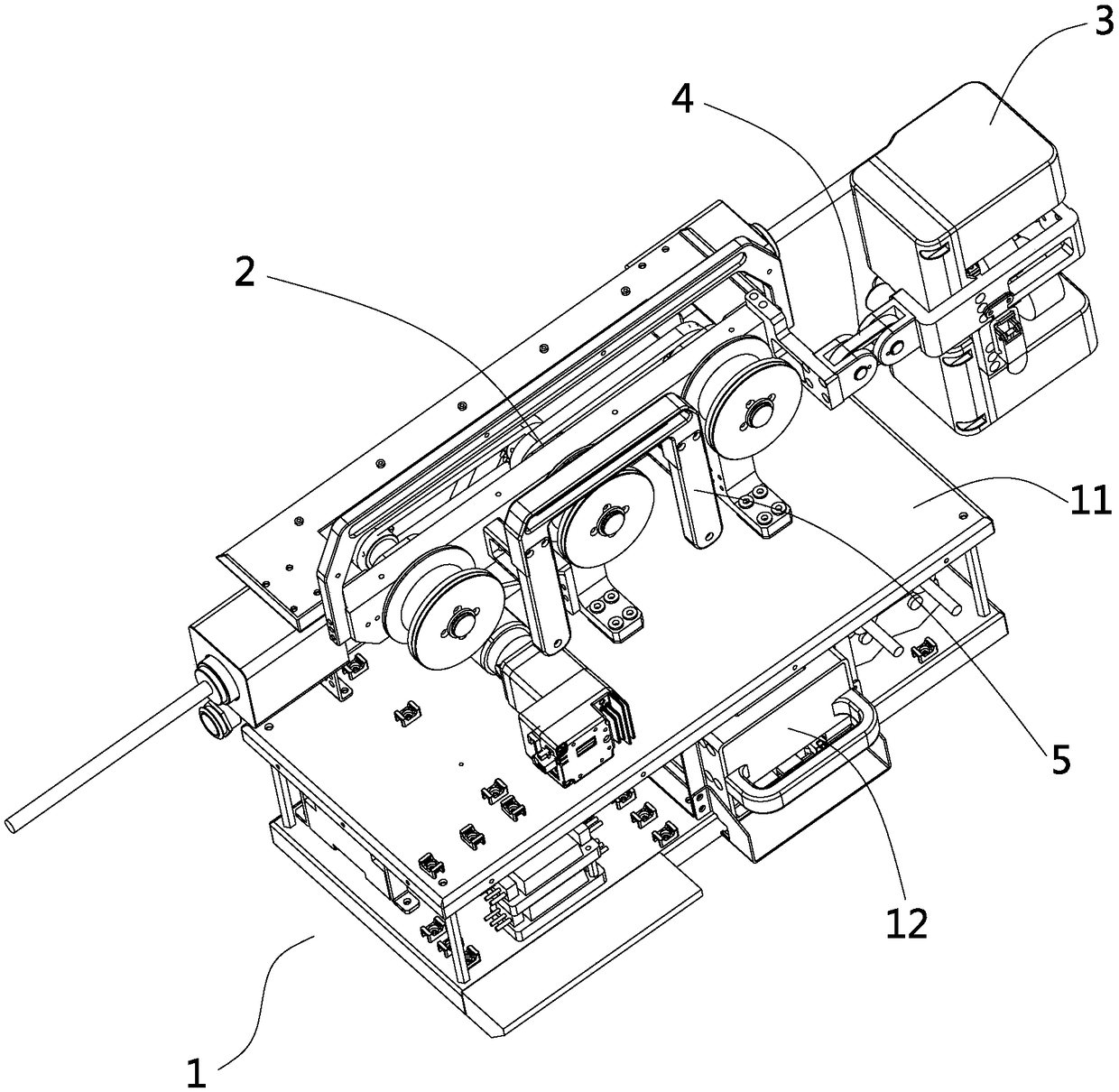

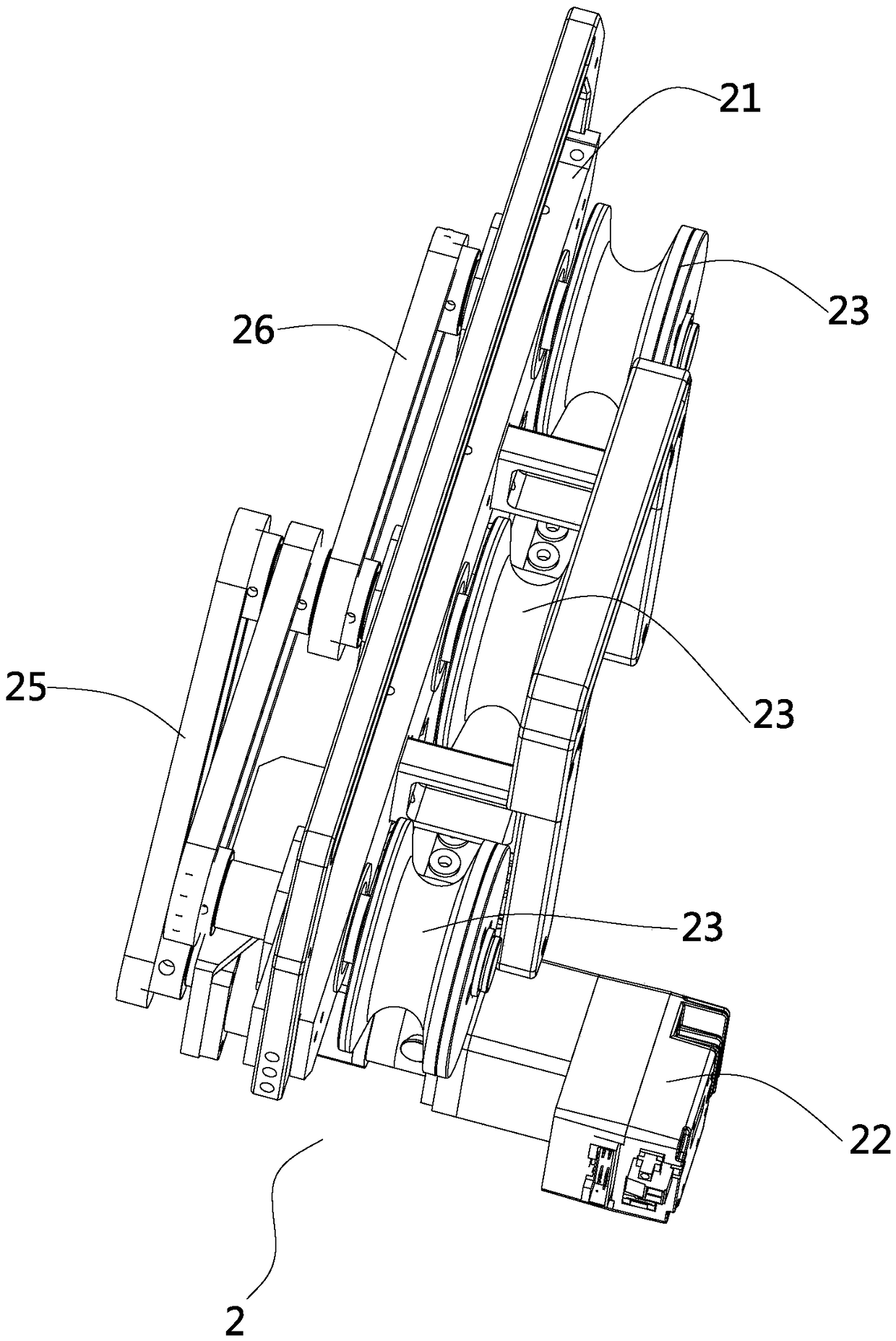

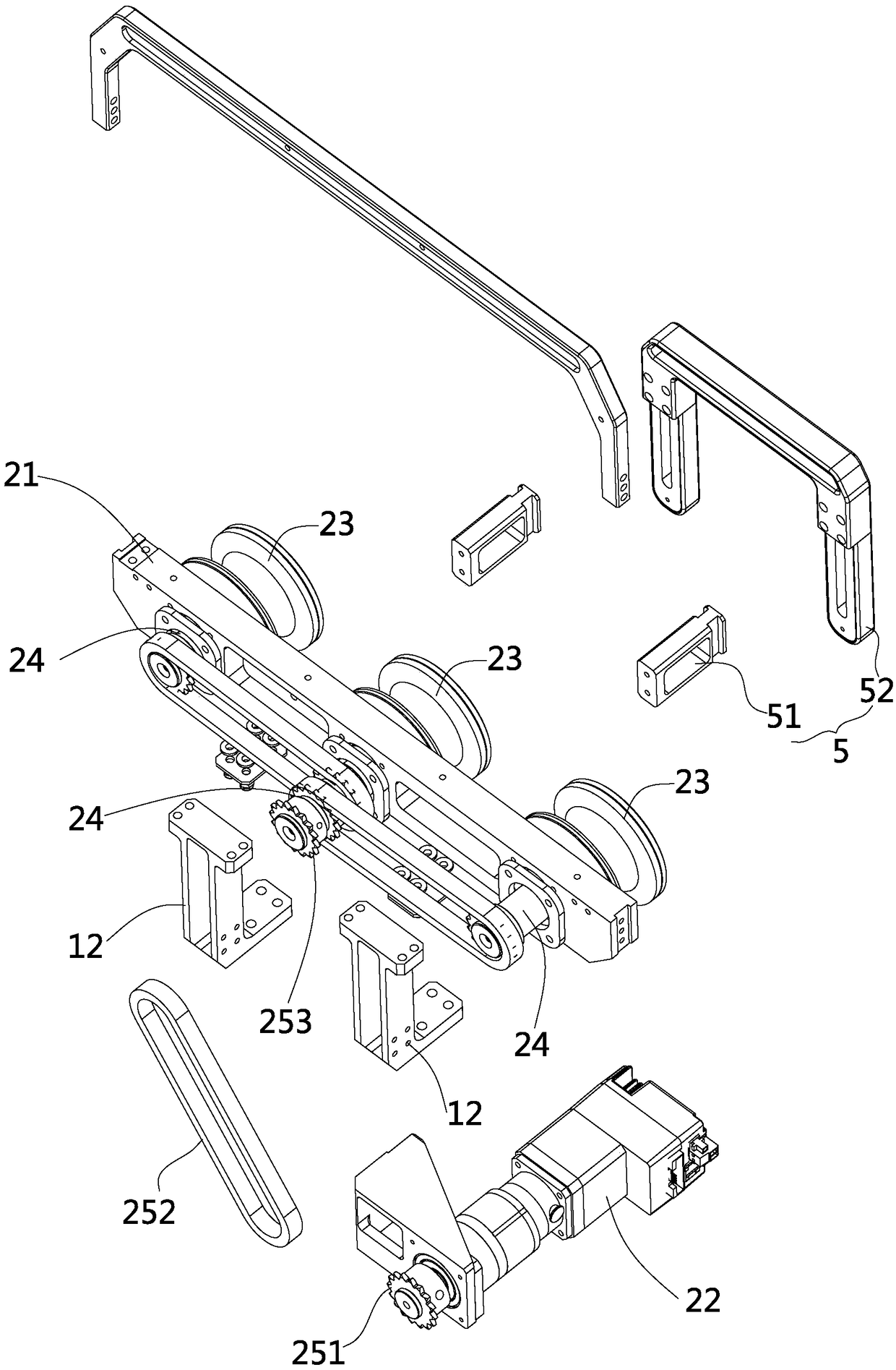

[0037] refer to Figures 1 to 3 As shown, the cable cleaning robot in this embodiment includes a control device 1, a walking device 2, a cleaning device 3 and an adaptive adjustment device 4, and the control device 1 includes a housing 11, and a control unit and a power supply installed in the housing 11 The battery pack 12, the power supply battery pack 12 is detachably inserted in the casing 11 and realizes plugging and power supply with the control unit, the running device 2 is fixedly installed on the top wall of the casing 11, and the cleaning device 3 passes through the self-adaptive adjustment device 4 Installed on the running gear 2.

[0038]Specifically, the traveling device 2 in this embodiment includes a bracket 21, a drive motor 22 and a plurality of traveling wheels 23, and the traveling wheels 23 are provided with wire grooves matched with cables. is a positive integer, the support 21 is provided with a plurality of rotating shafts 24 corresponding to the travel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com