Novel washing water device for wig processing technology

A processing technology and wig technology, which is applied in the field of washing devices for new wig processing technology, can solve the problems of inability to absorb nutrients by hair strands, affect the quality of wigs, uneven quality of hair strands, etc. The effect of increasing the cleaning intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

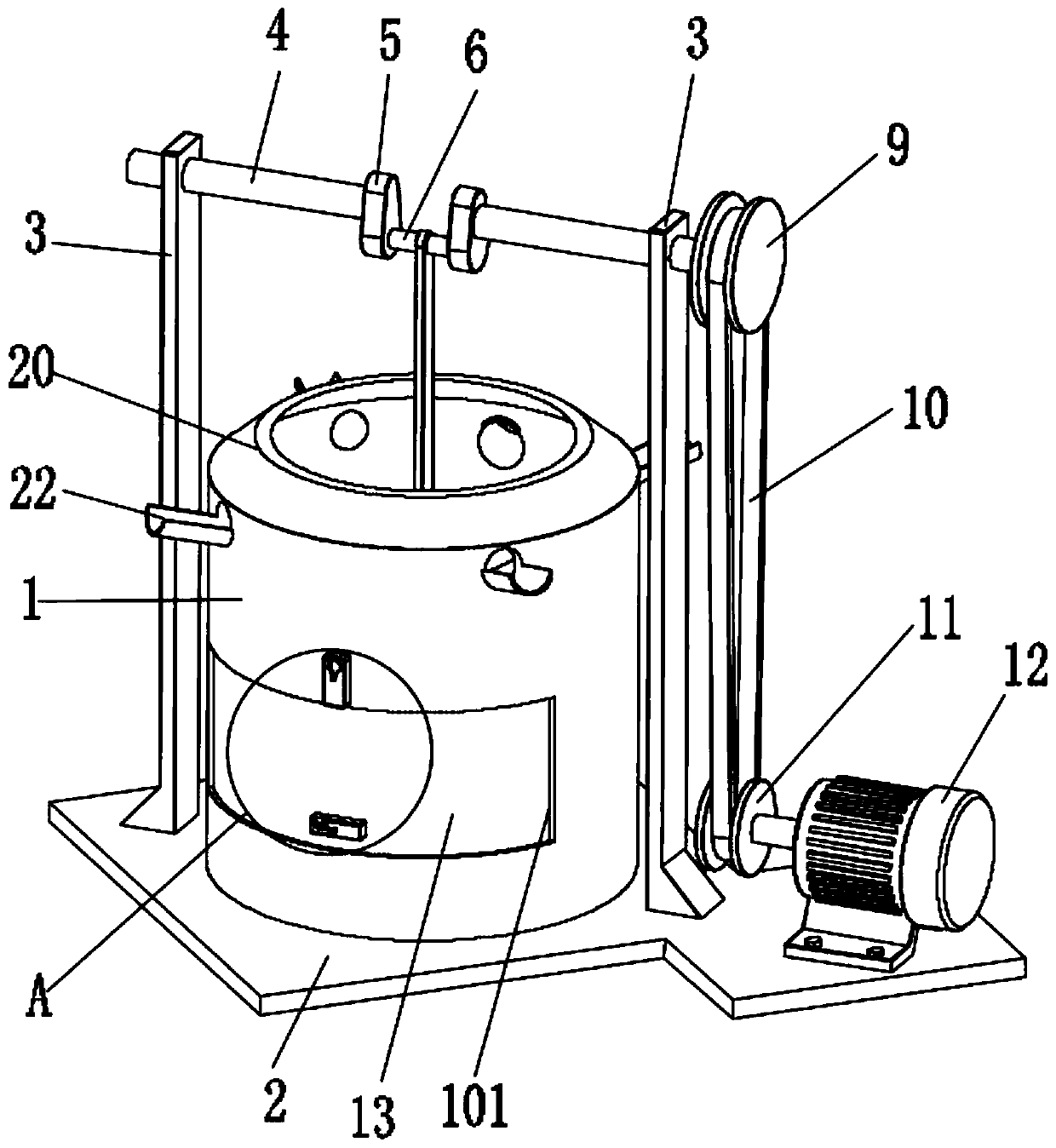

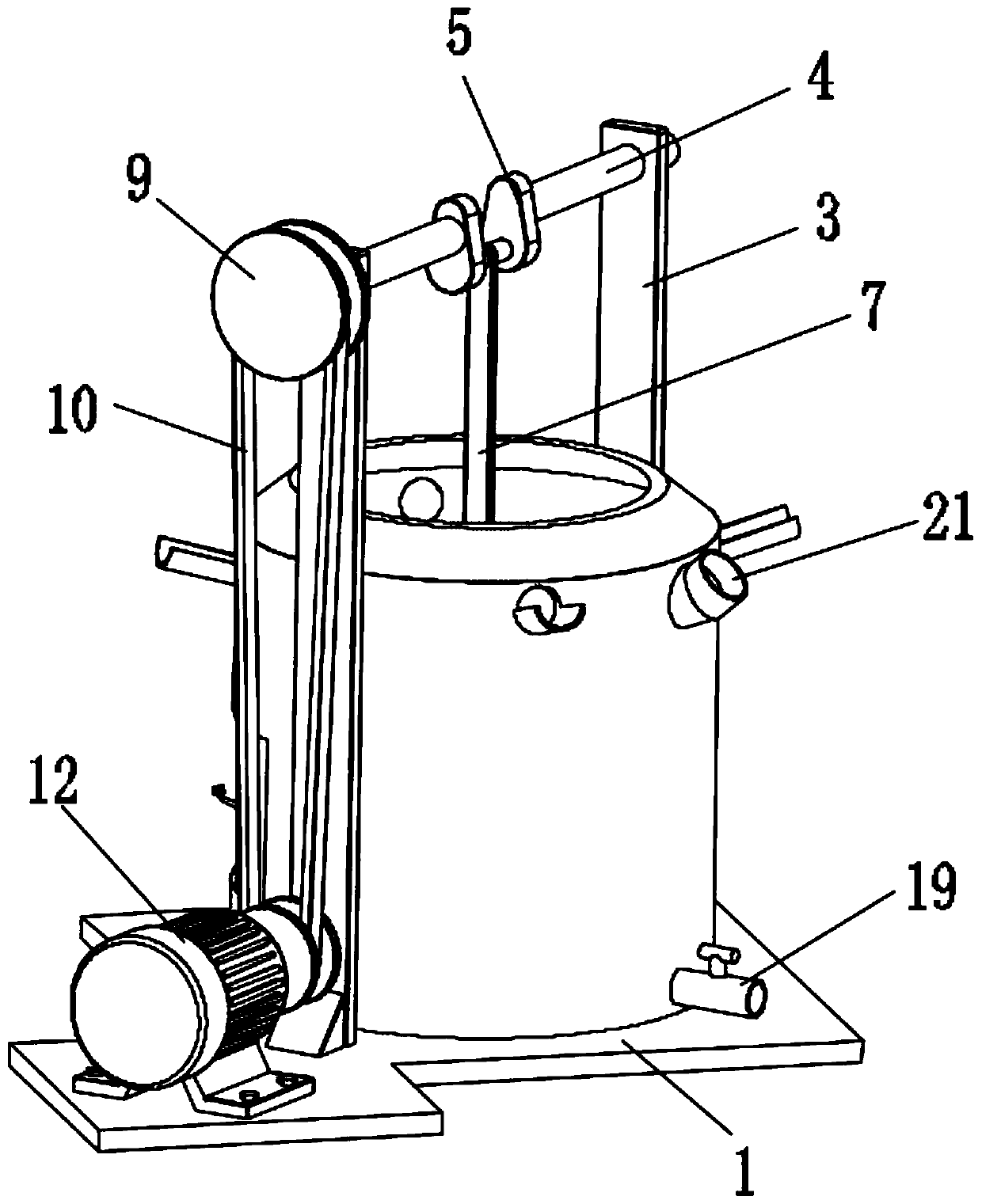

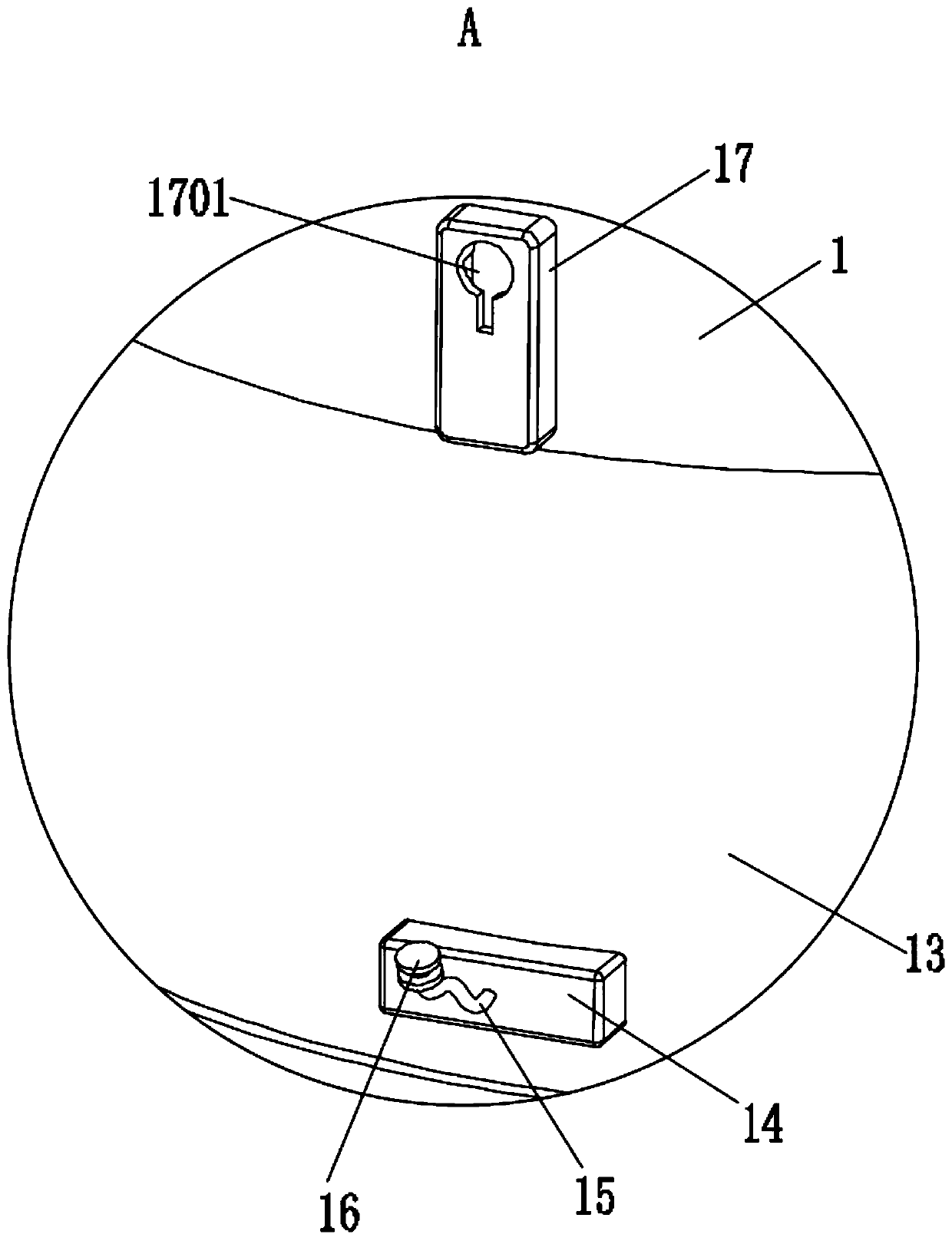

[0030] A new type of washing device for wig processing technology in this embodiment includes a washing bucket 1 and a base 2, the washing bucket 1 is fixedly installed on the base 2, and the washing bucket 1 is fixedly arranged with longitudinal brackets 3 left and right symmetrically. The top is rotatably connected with a horizontal shaft 4 that is symmetrically arranged relative to each other, and the horizontal shaft 4 is located above the washing bucket 1, and the opposite surfaces of the horizontal shaft 4 are fixedly connected with a cam 5, and the long-end opposite surfaces of the cam 5 are jointly fixedly connected with a fixed Shaft 6, the central position of the fixed shaft 6 is movably connected with a longitudinal connecting rod 7, the bottom end of the connecting rod 7 is fixedly connected with a pressure plate 8, and the right end of the horizontal shaft 4 on the right side is fixedly connected with a first pulley 9, the first Belt pulley 9 is connected with seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com