Equipment for rapidly determining floated color of surface of textile and method thereof

A technology for rapid determination of textiles, applied in the field of equipment for rapid determination of floating color on the surface of textiles, can solve problems such as staining, absence of textile fabrics, floating color on the surface of garments, fabric color brightness, and uniformity. High degree of automation and the effect of increasing cleaning intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

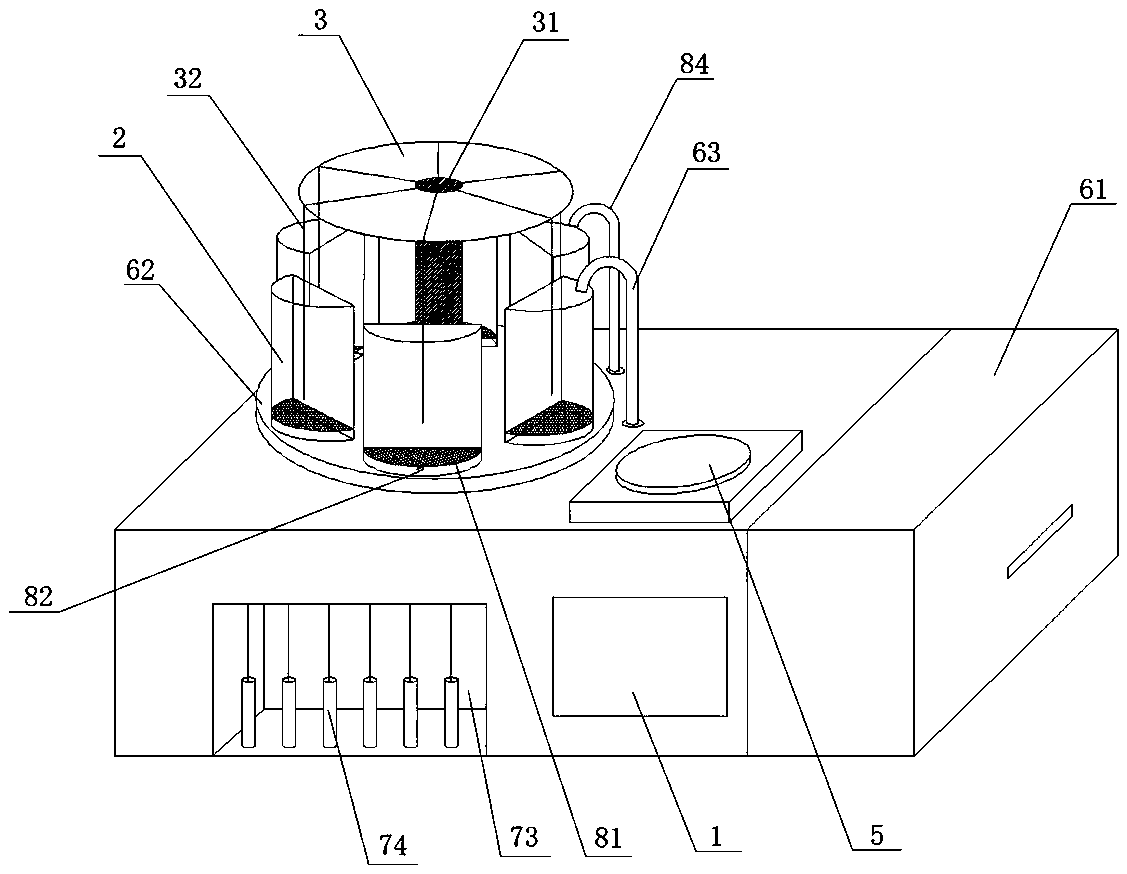

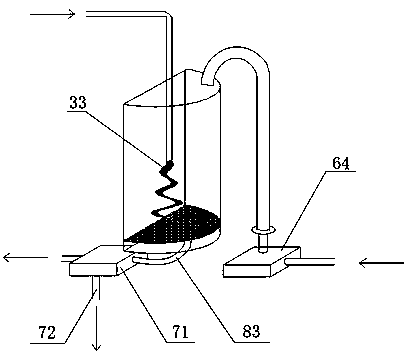

[0041] likefigure 1 and figure 2 As shown, a device for quickly measuring floating color on the surface of textiles includes a control module, a control panel, a test container, a stirring device, an electronic balance, an automatic liquid addition device, a suction filtration liquid collection device, and a liquid drainage cleaning device.

[0042] The control panel 1 is arranged on the front of the device and is connected with the control module. Through the control panel connected with the control module, actions can be selected to be performed, such as adding liquid, stirring, draining, suction filtration, cleaning, etc., and can also be set Determine the experimental parameters, such as the weight of the object to be tested, the test bath ratio, the test time, the stirring speed, the amount of the filtrate, etc.

[0043] The test container 2 is a transparent container with a semicircular cross section, and the plane part is white, which can be used as a colorimetric back...

Embodiment 2

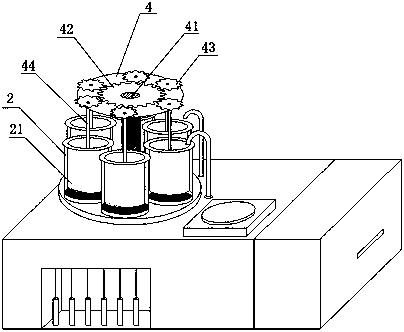

[0051] like image 3 and Figure 4 As shown, a device for quickly measuring floating color on the surface of textiles includes a control module, a control panel, a test container, a stirring device, an electronic balance, an automatic liquid addition device, a suction filtration liquid collection device, and a liquid drainage cleaning device.

[0052] The outer wall of the test container 2 is a cylindrical transparent container with an opening at the top, and a cylindrical white object 21 can be put into the top opening as a rating background, and the upper edge of the cylindrical white object is provided with a raised portion. It can be snapped on the upper edge of the outer wall of the test container. The white object is made of water-repellent, non-staining, and easy-to-clean materials, such as ceramics and plastics. The upper part of the cylindrical white object has a cover, and the cover is provided with several ventilation holes. The outer wall of the cylindrical white...

Embodiment 3

[0059] The only difference between embodiment 3 and embodiment 1 is that the stirring device is a mechanically driven stirring device as described in embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com