Vortex type sampling needle washing device

A sampling needle and vortex-type technology, which is applied in the field of vortex-type sampling needle washing devices, can solve the problems of sample substance residue, unclean cleaning, slow cleaning, etc., and achieve high cleaning power, improved cleaning effect, and fast cleaning speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with drawings and embodiments.

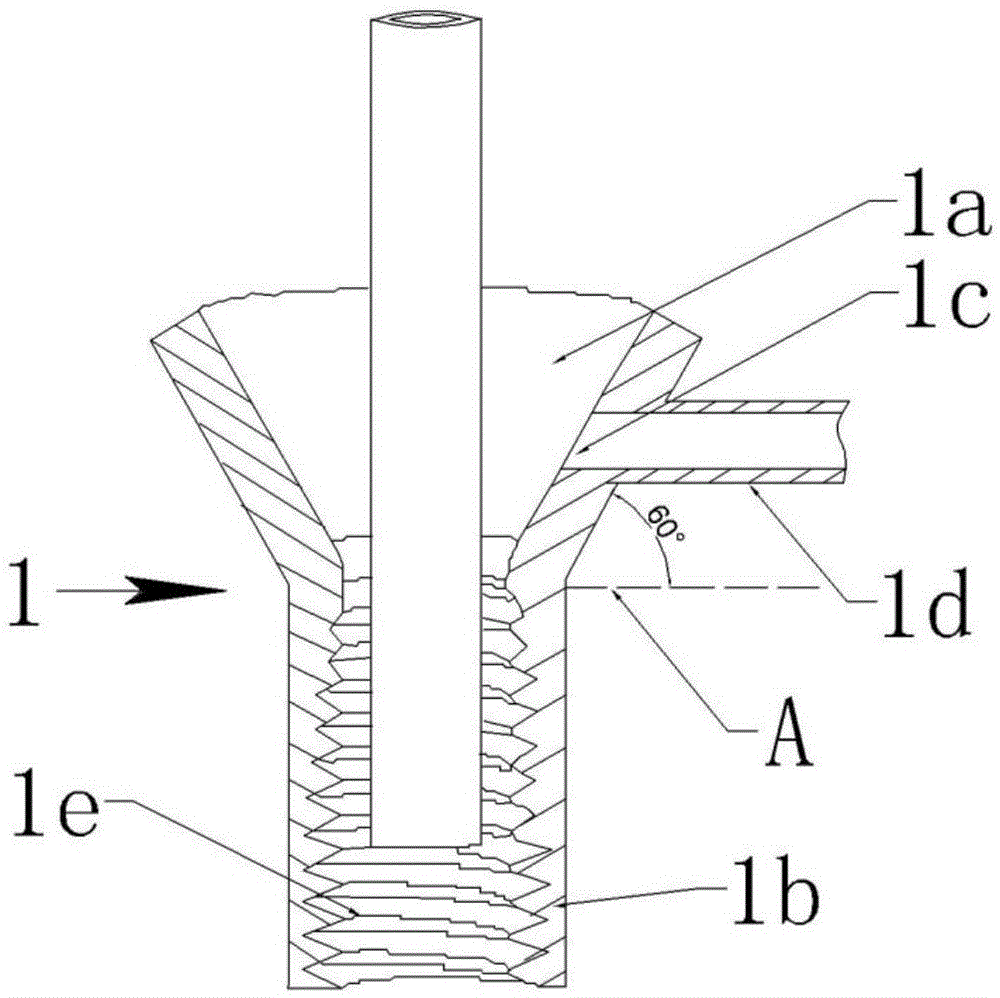

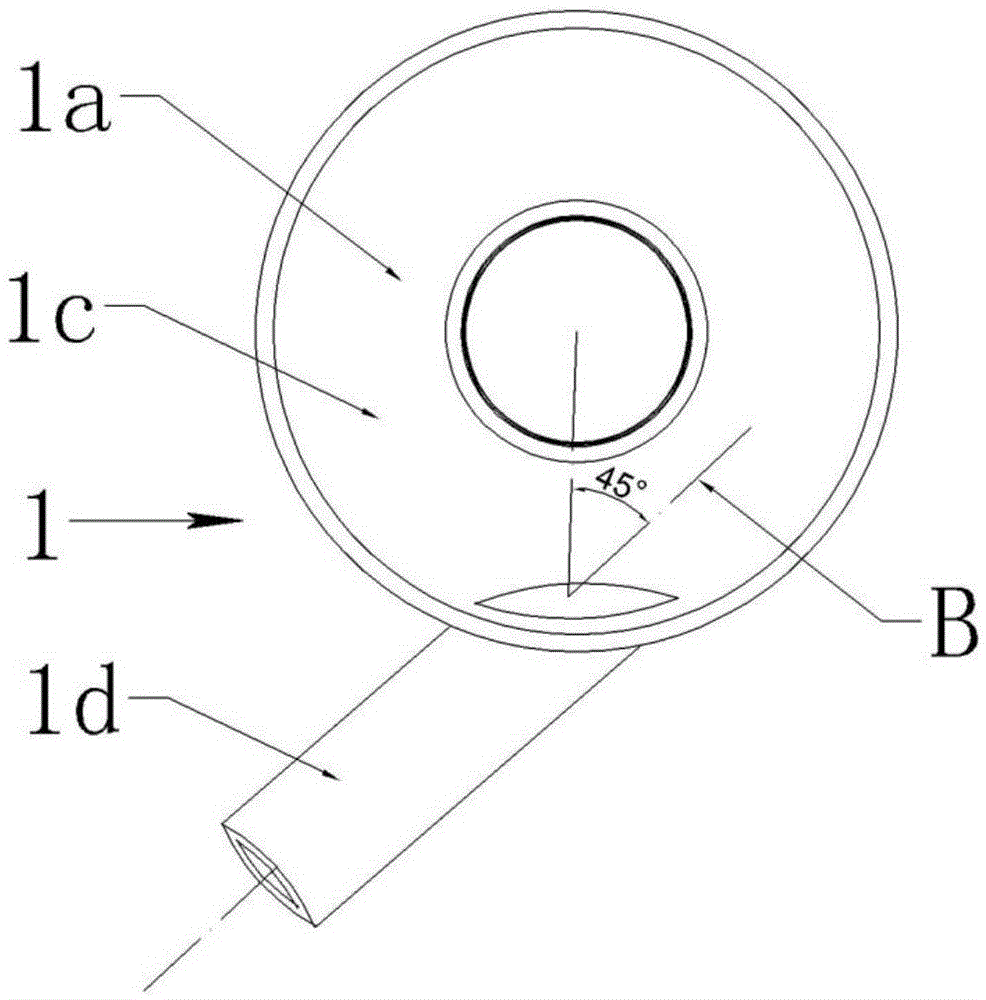

[0015] Such as figure 1 As shown, the needle washer 1 of the present invention includes an upper conical cavity 1a with a large upper part and a smaller lower part and a vertical liquid outlet pipe 1b at the lower part. The upper end of the conical cavity 1a is open, and the conical cavity The inner surface of the side wall of 1a is a polished surface, and the angle between the side wall and the horizontal line A ranges from 25° to 70°, preferably 60° in this embodiment. The side wall of the conical cavity 1a is provided with a liquid inlet hole 1c for cleaning liquid, which runs through the side wall, and a horizontally inclined liquid inlet pipe 1d is arranged outside the liquid inlet hole 1c, and the angle value of the liquid inlet pipe 1d is inclined from 30° to 60° °, preferably 45° in the present embodiment, the range of angle values here is understood as: the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com