Cleaning and polishing mechanism and cleaning and polishing system

A polishing mechanism and conveying track technology, applied in the field of cleaning and polishing systems, can solve the problems of incomplete cleaning, affecting the reliability of laser engraving lines of coated glass, etc., to improve the quality of cleaning and polishing, simple structure, and increase cleaning strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to describe the technical content and structural features of the present invention in detail, further description will be given below in conjunction with the implementation and accompanying drawings.

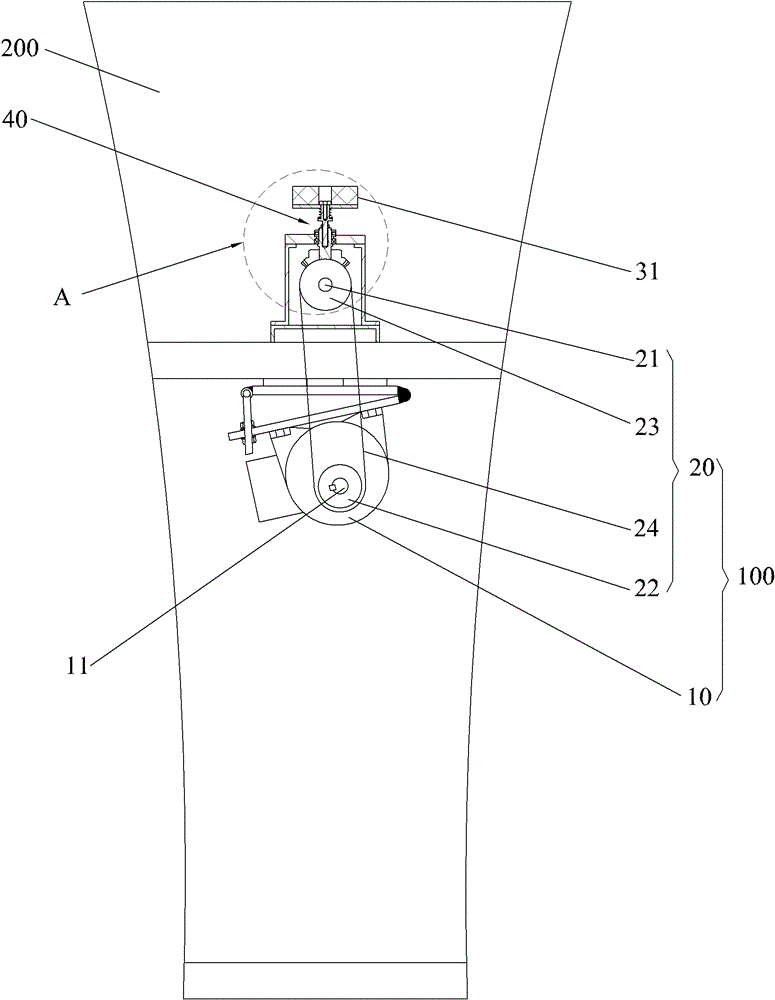

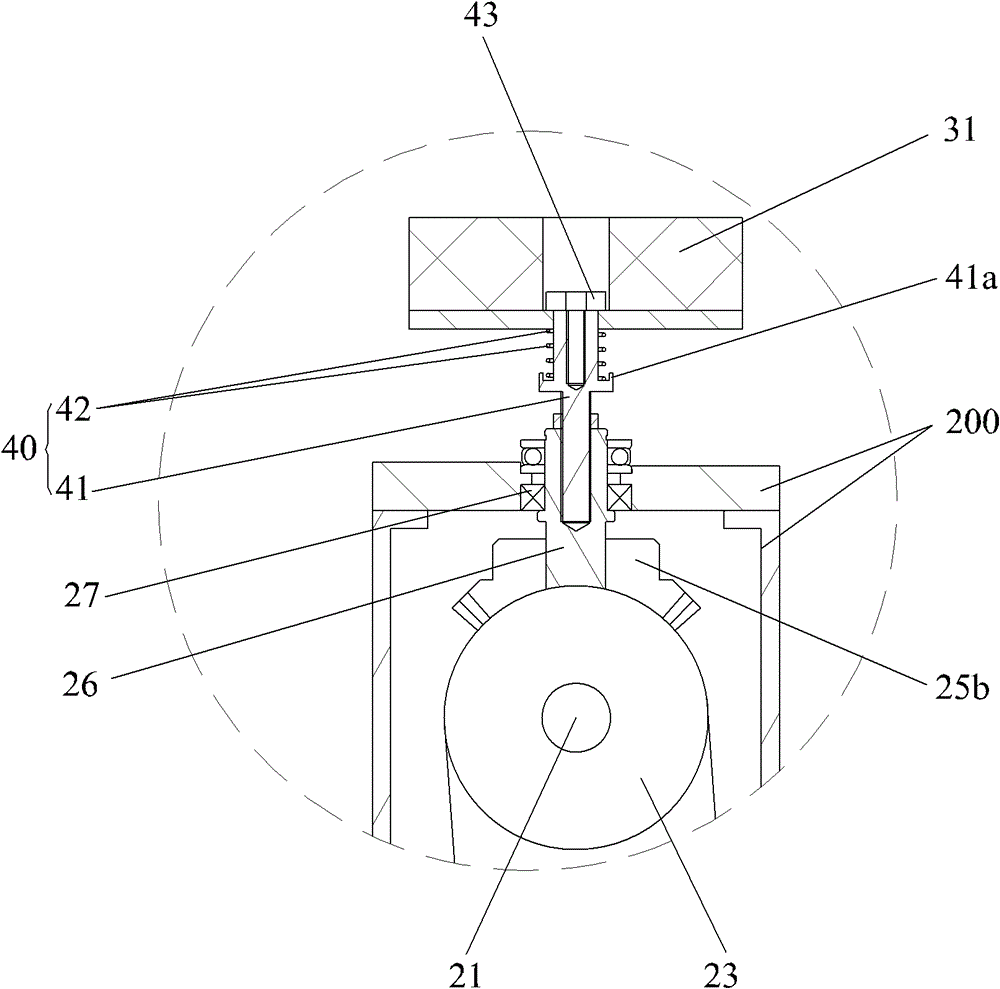

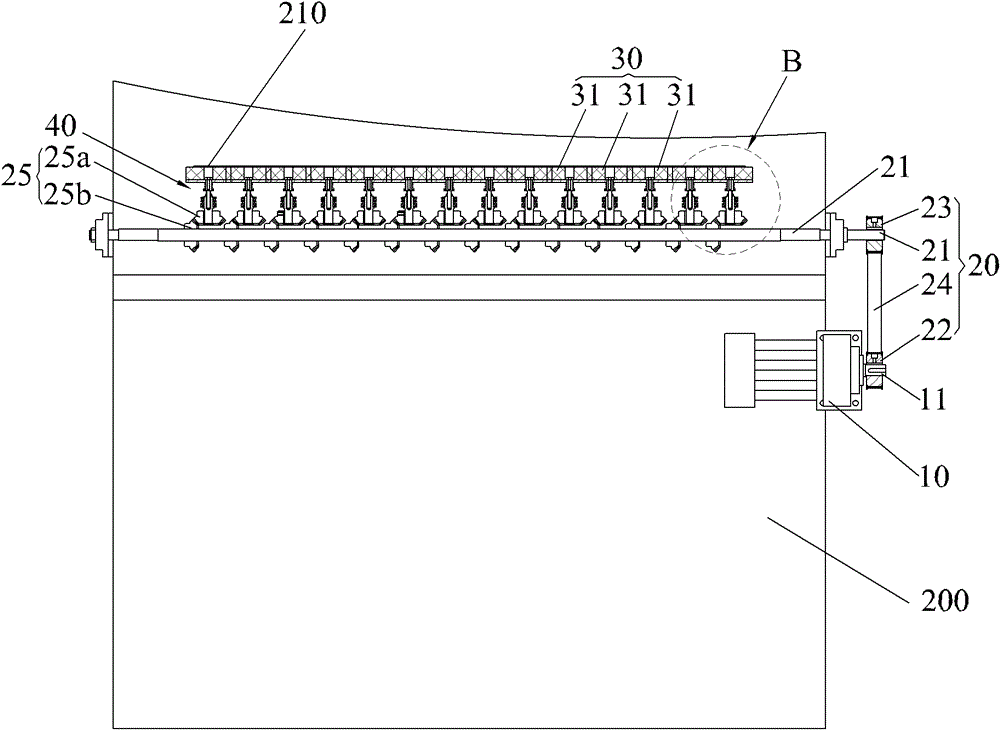

[0027] see Figure 1 to Figure 4The cleaning and polishing mechanism 100 of the present invention is installed on the conveying track 200 arranged in the horizontal direction and cleans and polishes the coated glass 210 for solar cells transported by the conveying track 200, wherein the cleaning and polishing mechanism 100 of the present invention includes Clean the polishing driver 10 , the intermediate conveying assembly 20 and several disc brushes 31 . The number of the disc brushes 31 is flexibly selected by those of ordinary skill in the art according to actual needs. At the same time, the disc brushes 31 are arranged in a row along the intersection direction of the conveying track 200 to transport the coated glass 210 to form a disc brush row 30. The disc ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com