Novel coagulation washing kettle used for preparation of carbon dioxide-epoxy propane copolymer

A technology of propylene oxide and carbon dioxide, which is applied in the field of washing kettles, can solve the problems of not being disclosed, failing to separate the polymer from the solvent, reducing the quality and yield of solid polymer products, and achieving the effect of improving the yield and quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

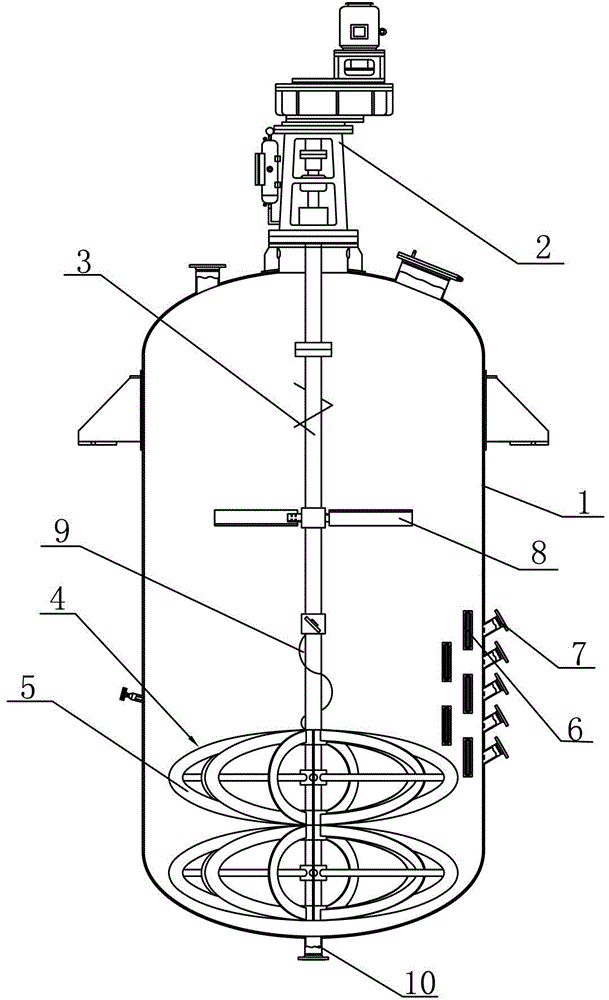

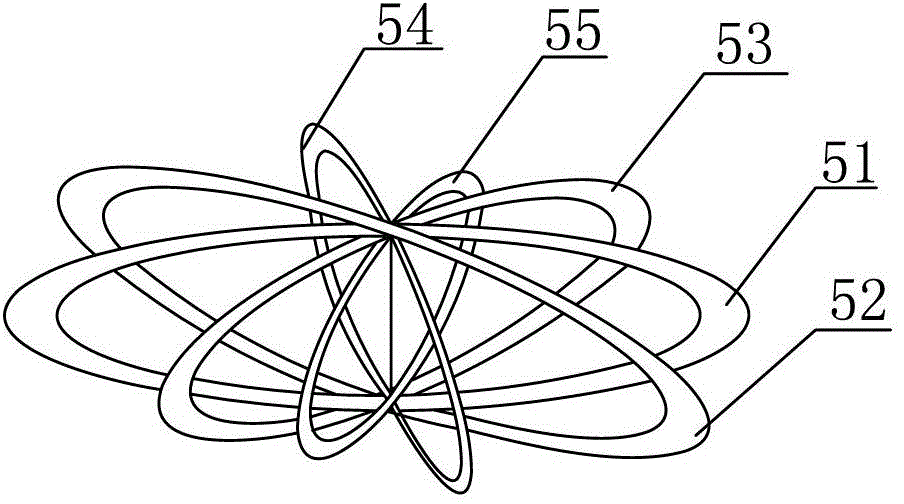

[0018] The present invention is used for the novel coacervation scrubber that carbon dioxide-propylene oxide copolymer prepares, as figure 1 As shown, a cylindrical kettle body 1 is included, and the kettle body 1 is arranged upright. A central rotating shaft 3 connected to an external motor 2 is longitudinally arranged in the kettle body 1, and several layers of ellipsoidal agitators 4 are vertically arranged side by side at the lower end of the central rotating shaft 3. The ellipsoidal stirrer 4 is surrounded by several hollow elliptical stirring frame leaves 5 arranged staggeredly on the central rotating shaft 3. The inner side wall of the kettle body 1 is provided with a filtering device 6, and the outer wall of the kettle body 1 is corresponding to the filtering device 6. The position is provided with a washing liquid discharge pipe 7.

[0019] In this specific embodiment, the angular distances of adjacent elliptical stirring frame leaves 5 are the same, the horizontal di...

specific Embodiment 2

[0021] The present invention is used for the novel coacervation scrubber that carbon dioxide-propylene oxide copolymer prepares, as figure 1 As shown, a cylindrical kettle body 1 is included, and the kettle body 1 is arranged upright. A central rotating shaft 3 connected to an external motor 2 is longitudinally arranged in the kettle body 1, and several layers of ellipsoidal agitators 4 are vertically arranged side by side at the lower end of the central rotating shaft 3. The ellipsoidal stirrer 4 is surrounded by several hollow elliptical stirring frame leaves 5 arranged staggeredly on the central rotating shaft 3,

[0022] A filter device 6 is provided on the inner side wall of the kettle body 1 , and a washing liquid discharge pipe 7 is provided at a position corresponding to the filter device 6 on the outer wall of the kettle body 1 .

[0023] In this specific embodiment, the angular distances of adjacent elliptical stirring frame leaves 5 are the same, the horizontal diam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com