Preparation method of high-ortho-position electronic grade phenolic resin with high hydroxyl content

A technology of phenolic resin and high hydroxyl group, which is applied in the field of preparation of electronic-grade phenolic resin with high ortho position and high hydroxyl content, which can solve the problems of inability to be used as a curing agent, high content of phenolic resin impurities and free phenol, poor adhesion and mechanical properties, etc. problem, to achieve the effect of increasing the reaction crosslinking point, less impurity content, and fast curing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

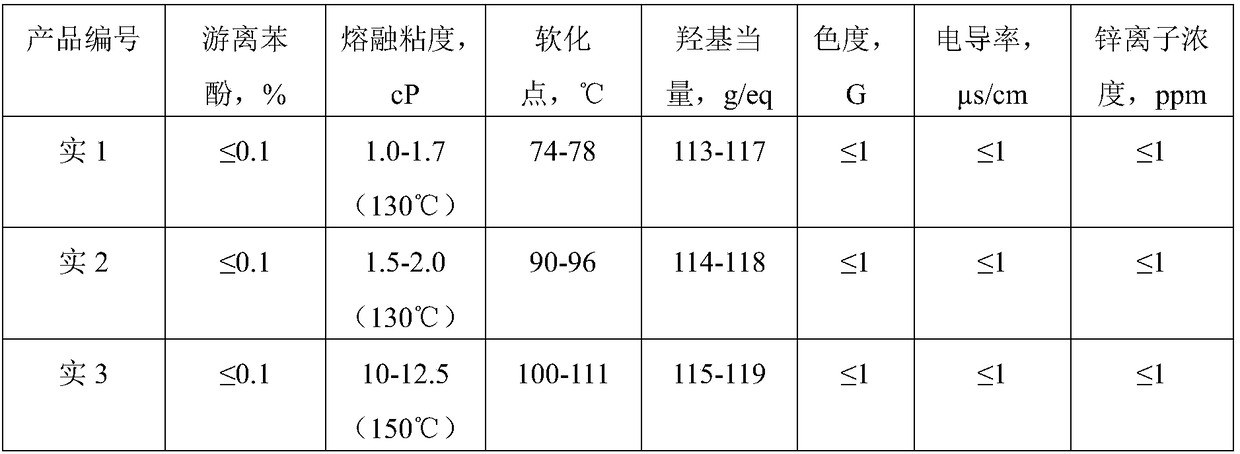

Embodiment 1

[0034] (1) Add 85 kg of phenol, 15 kg of o-cresol, and 1.6 kg of zinc acetate in the reactor, stir and heat up to 90°C;

[0035] (2) Start timing when the temperature reaches 90°C, add 120 kg of 37% formaldehyde solution dropwise continuously within 2 hours, and keep warm for 2 hours after adding;

[0036] (3) After the heat preservation is completed, vacuum dehydration is carried out, and the electronic grade deionized water vapor system is turned on at the same time, and the water vapor is passed into the bottom of the reaction kettle. The temperature of the inner material is controlled at 50-100°C, and the temperature is raised slowly. When the temperature reaches 120°C, the dehydration is stopped;

[0037] (4) Immediately after dehydration, add deionized water at a temperature of 95°C to the reaction kettle, stir for 60 minutes and then stand still, separate the upper layer of water after standing still for 60 minutes, wash with water for 5 times in the same way, and finis...

Embodiment 2

[0041] (1) Add 75 kilograms of phenol, 20 kilograms of m-cresol, 5 kilograms of cardanol and 1.8 kilograms of zinc acetate in the reactor, stir and be warming up to 85 ℃;

[0042] (2) Start timing when the temperature reaches 90°C, add 140 kg of 37% formaldehyde solution dropwise continuously within 2.5 hours, and keep warm for 3 hours after adding;

[0043] (3) After the heat preservation is completed, vacuum dehydration is carried out, and the electronic grade deionized water vapor system is turned on at the same time, and the water vapor is passed into the bottom of the reactor. The pressure of the steam is controlled at 0.60Mpa, and the pressure in the reactor is controlled at -0.07Mpa. The temperature of the inner material is controlled at 50-100°C, and the temperature is raised slowly. When the temperature reaches 130°C, the dehydration is stopped;

[0044] (4) Immediately after the dehydration is completed, add deionized water at a temperature of 90°C to the reactor, st...

Embodiment 3

[0048] (1) Add 60 kg of phenol, 25 kg of nonylphenol, 15 kg of cardanol and 2.3 kg of zinc acetate in the reactor, stir and heat up to 95°C;

[0049] (2) Start timing when the temperature reaches 95°C, add 125 kg of 37% formaldehyde solution continuously dropwise within 1.5 hours, and keep warm for 4 hours after adding;

[0050] (3) After the heat preservation is completed, vacuum dehydration is carried out, and the electronic grade deionized water vapor system is turned on at the same time, and the water vapor is passed into the bottom of the reaction kettle. The temperature of the inner material is controlled at 50-100°C, and the temperature is raised slowly. When the temperature reaches 120°C, the dehydration is stopped;

[0051](4) Immediately after the dehydration is completed, add deionized water at a temperature of 90°C to the reactor, stir for 40 minutes, then stand still, separate the upper layer of water after standing still for 60 minutes, wash with water 5 times in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com