Patents

Literature

145results about How to "Fast and even heating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing heat insulation composite material by microwave

InactiveCN101186512AImprove uniformityGuaranteed uniformityOther chemical processesCeramicwareMicrowaveComposite material

The invention provides a method of producing heat insulation composite material by microwave, and relates to a preparation method of heat insulation composite material. The invention solves the problem of poor homogeneity of the material produced by the existing method of producing heat insulation composite material. The method of producing heat insulation composite material applied by the invention has the steps that: 1. stirring; 2. drying and microwave treatment, thus obtaining the heat insulation composite. The heat insulation composite material produced by the invention has good homogeneity.

Owner:HARBIN INST OF TECH

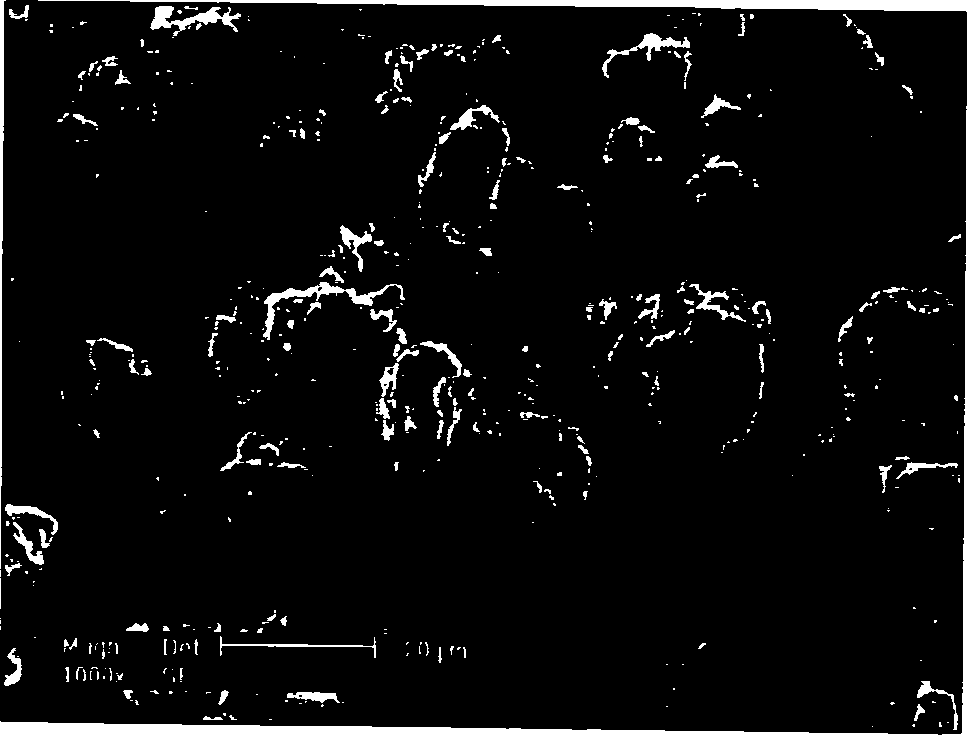

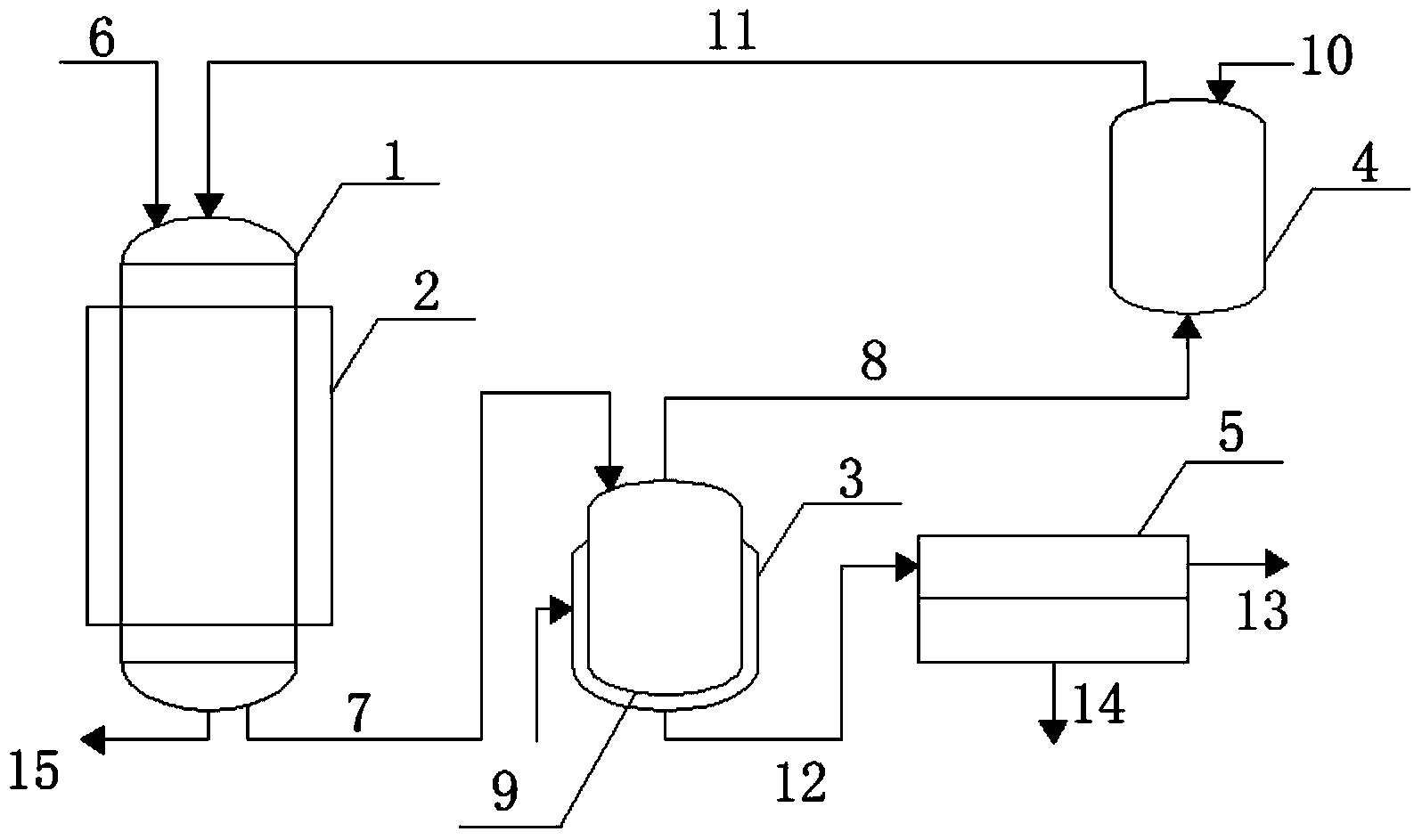

Technique for cracking integral scrap tires

InactiveCN1872953AReduce conveyorFast and even heatingPigmenting treatmentLiquid hydrocarbon mixture productionEngineeringFlammable gas

This invention discloses a technique for pyrolyzing whole waste tires in a specially designed inclined rectangular pyrolysis kettle. The technique comprises: (1) putting whole waste tires into the pyrolysis kettle, and pyrolyzing at 350-450 deg.C and 100-300 mmH2O for 30-60min; (2) cooling and separating the discharged pyrolysis gases to obtain mixed fuel oils and flammable gases; (3) recovering the residual solid materials discharged from the bottom of the pyrolysis kettle to obtain carbon black and steel wires. The technique has such advantages as simple equipment, shortened process flow, low coat and no secondary pollution.

Owner:姚军辉 +1

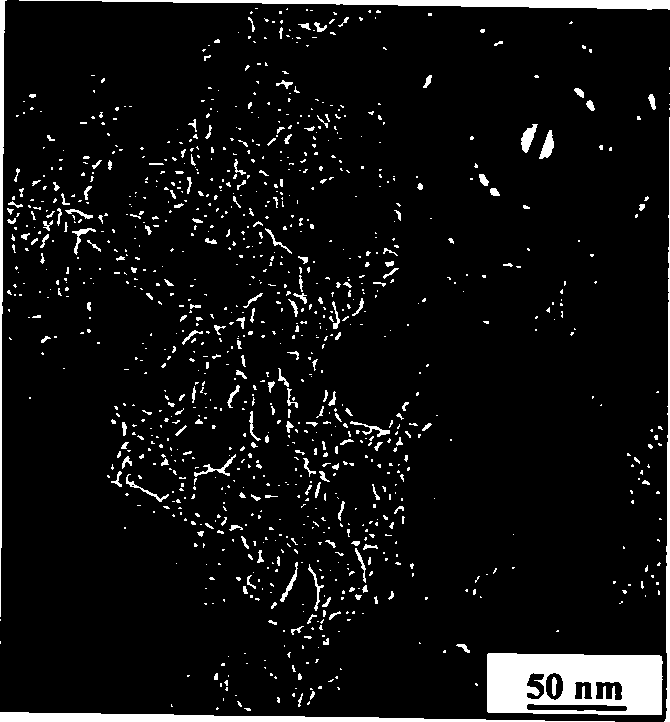

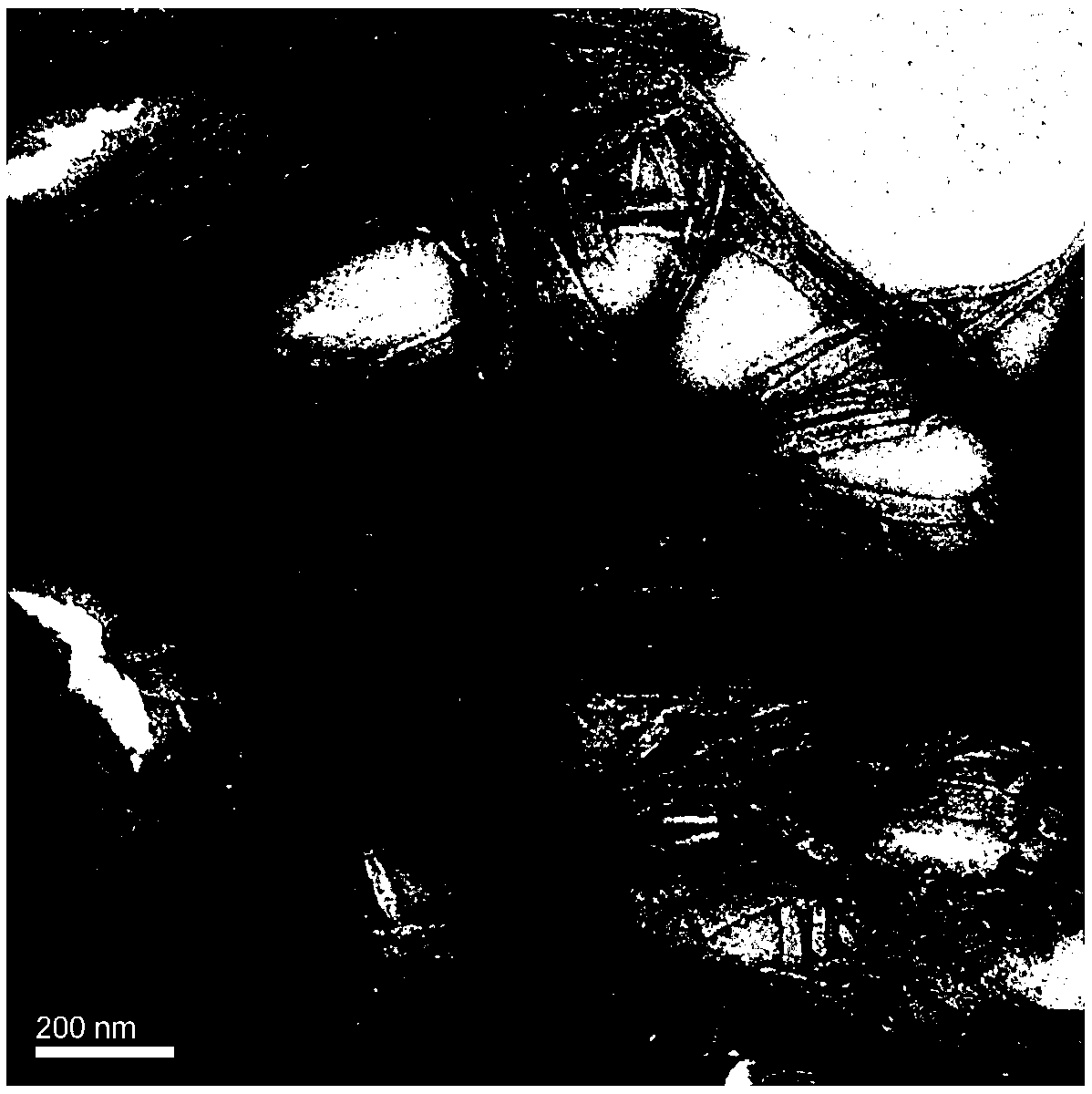

Prepn process of high-performance superfine crystal hard WC-10 wt.% Co alloy

The preparation process of high performance superfine crystalline hard WC-10wt%Co alloy belongs to the field of powder metallurgy technology. The preparation process includes the following steps: ball milling pure Co powder of 30-60 micron size under Ar protection for over 16 hr to obtain micron level Co powder with nanometer crystal structure; mixing 0.2 micron size WC powder and the Co powder in the weight ratio of 9, ball milling the mixture in anhydrous ethanol for 20-24, vacuum drying to obtain mixture powder, filling into mold and cold pressing to form; and sintering in a discharging plasma sintering apparatus. The technological process is simple, and prepared WC-10wt%Co alloy has high performance.

Owner:BEIJING UNIV OF TECH

Device and method for coating small parts

ActiveUS20090017224A1Fast and economical coatingImprove surface qualityRadiation applicationsConfectioneryEngineeringRadiation

The present invention relates to a coating device for small parts, in particular for lacquering mass produced small parts, like e.g. bolts, small plastic parts and similar, and it relates to a method for this purpose with a movable receiver element for receiving and moving the small parts, and a dispenser device, located at the receiver element for continuous or portioned dispensing the coating material into the receiver element, wherein a radiation emitter device is provided in the receiver element for emitting radiation for drying and / or hardening the coating material.

Owner:SPECIAL COATINGS

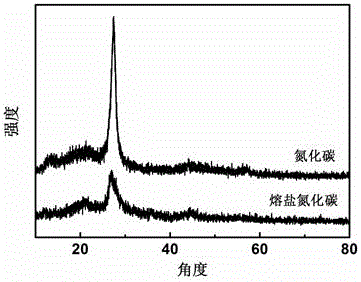

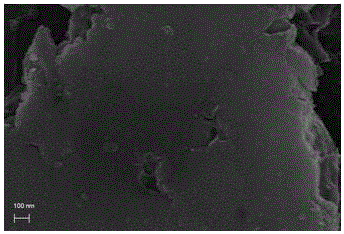

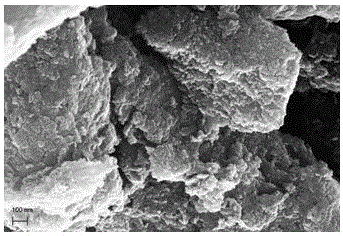

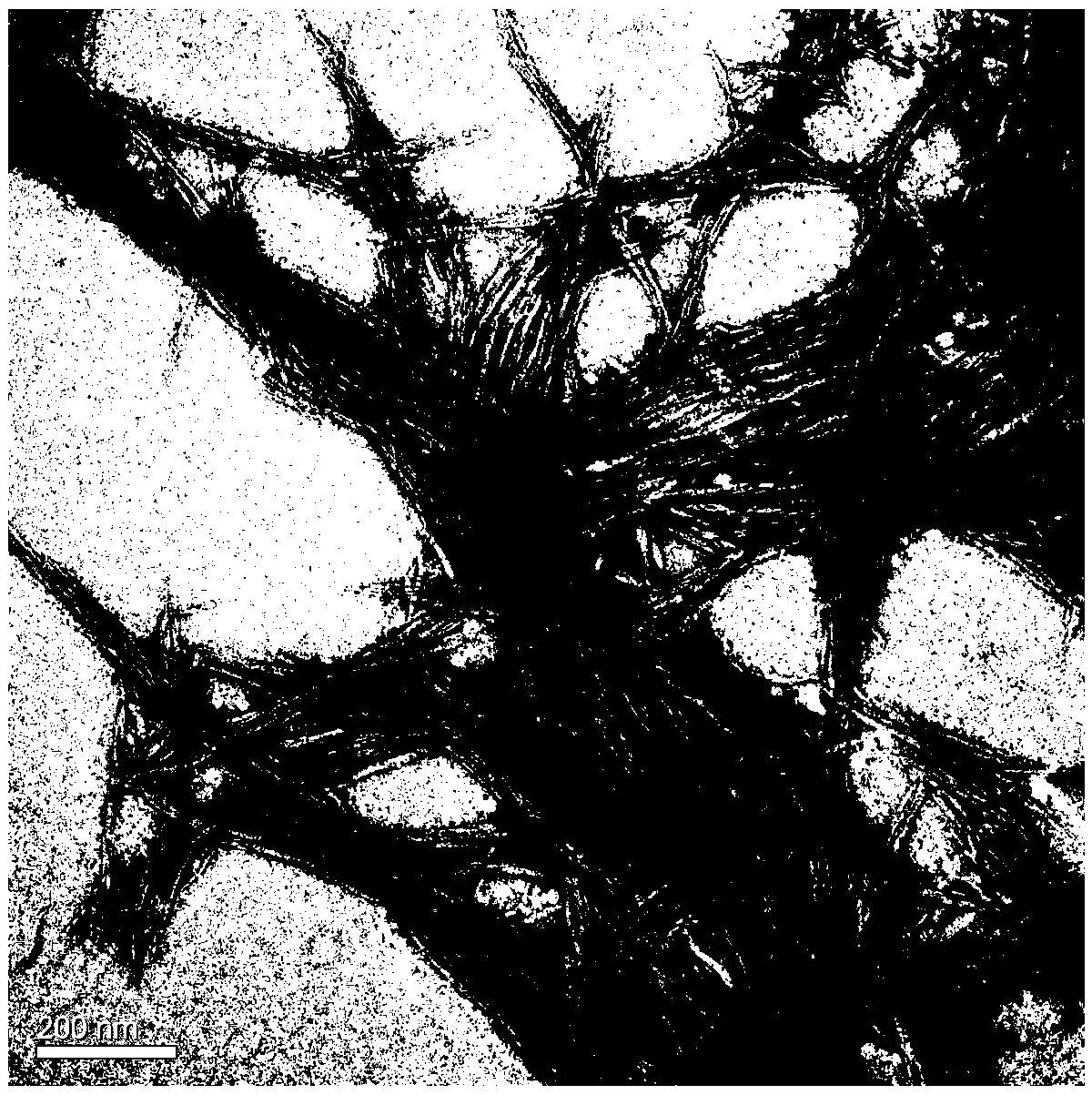

High temperature molten salt method for preparing material with microscopic layered crystal structure

ActiveCN105819413ANot easy to reuniteStable structureNitrogen and non-metal compoundsMolybdenum sulfidesIonCrucible

The invention provides a high temperature molten salt method for preparing a material with a microscopic layered crystal structure. The method comprises the following steps: (1) placing solid salts into an enclosed high temperature resistant crucible, and heating the crucible to melt the solid salts into ionic liquid; (2) introducing inert gas into the enclosed crucible, pressing the precursor of a layered material into a sheet, wrapping the sheet, and adding the sheet into molten salt to carry out reactions in the atmosphere of inert gas; (3) after a while, taking out the reaction products, soaking reaction products in deionized water, centrifugally washing reaction products by deionized water and ethanol for several times, and drying to obtain the layered material. According to the high temperature molten salt method, the layered material is prepared in a high temperature ionic environment, due to the existence of ions, the layered material is not easy to agglomerate; moreover, ions enter the gap between lattice layers, the structure becomes more stable, and a layered material with a better using performance is obtained.

Owner:WUHAN UNIV

Breath alcohol content measurement device

ActiveCN102854303AFast and even heatingQuick activationMaterial analysis by optical meansDiagnostic recording/measuringAlcohol contentMeasurement device

The invention relates to a breath alcohol content measurement device, which comprises a basal body comprising a flow channel for breath air flow, a replaceable nozzle which is used for absorbing the breath air flow from a person and is connected, at an upstream end portion of the flow channel, with the basal body, an alcohol sensor unit which is associated with the basal body and is used for measuring the alcohol content in the breath air flow, a temperature sensor unit for measuring the temperature of the breath air flow, a heating unit for heating the flow channel, ad a control unit which is used to process a measurement signal provided by the temperature sensor unit and to control the heating unit. The basal body and / or the alcohol content sensor unit are / is formed by conductive polymer materials at least in an area adjacent to the flow channel. Multiple contact electrodes are contacted at the basal body and / or the alcohol content sensor unit. Correspondingly, current flows through the contact electrodes via electric wires.

Owner:DRAGER SAFETY

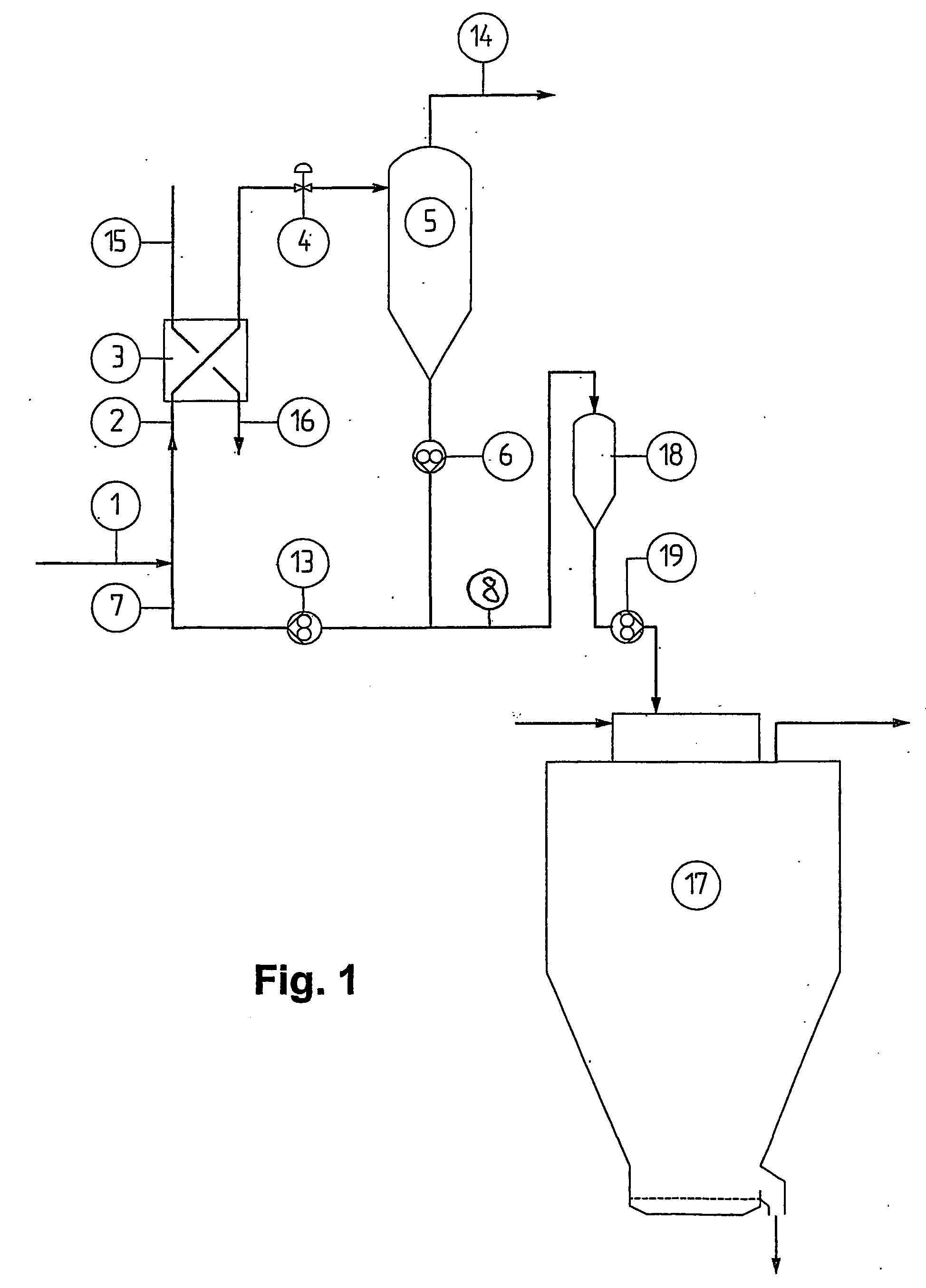

Method and a system for converting liquid products into free-flowing powders with pre-cooling

InactiveUS20040208967A1Promote denaturationPromote reactionAlcoholic beverage preparationOther dairy technologyLiquid productCrystallization temperature

The present invention relates to a method and a system for converting liquid products for the cheese making or casein producing industry into substantially free-flowing powdery products, by subjecting the liquid product to heating to a temperature above the crystallisation temperature of any component in the liquid product in a heat exchanger, flash separating volatile components from said heated liquid product to obtain a past concentrate, pre-cooling a fraction of said past concentrate, and drying said combination product. By the pre-cooling it is possible to create lactose crystals by an extremely rapid in-line pre-cooling without any significant increase in viscosity (which would lead to an un-pumpable paste). It is assumed that only a fraction of the paste gets into contact with the walls of the cooler causing a rapid formation of a high number of seed crystals. Further, it is assumed that the seed promote the formation of lactose crystals during the subsequent drying process.

Owner:SPX FLOW TECH DANMARK

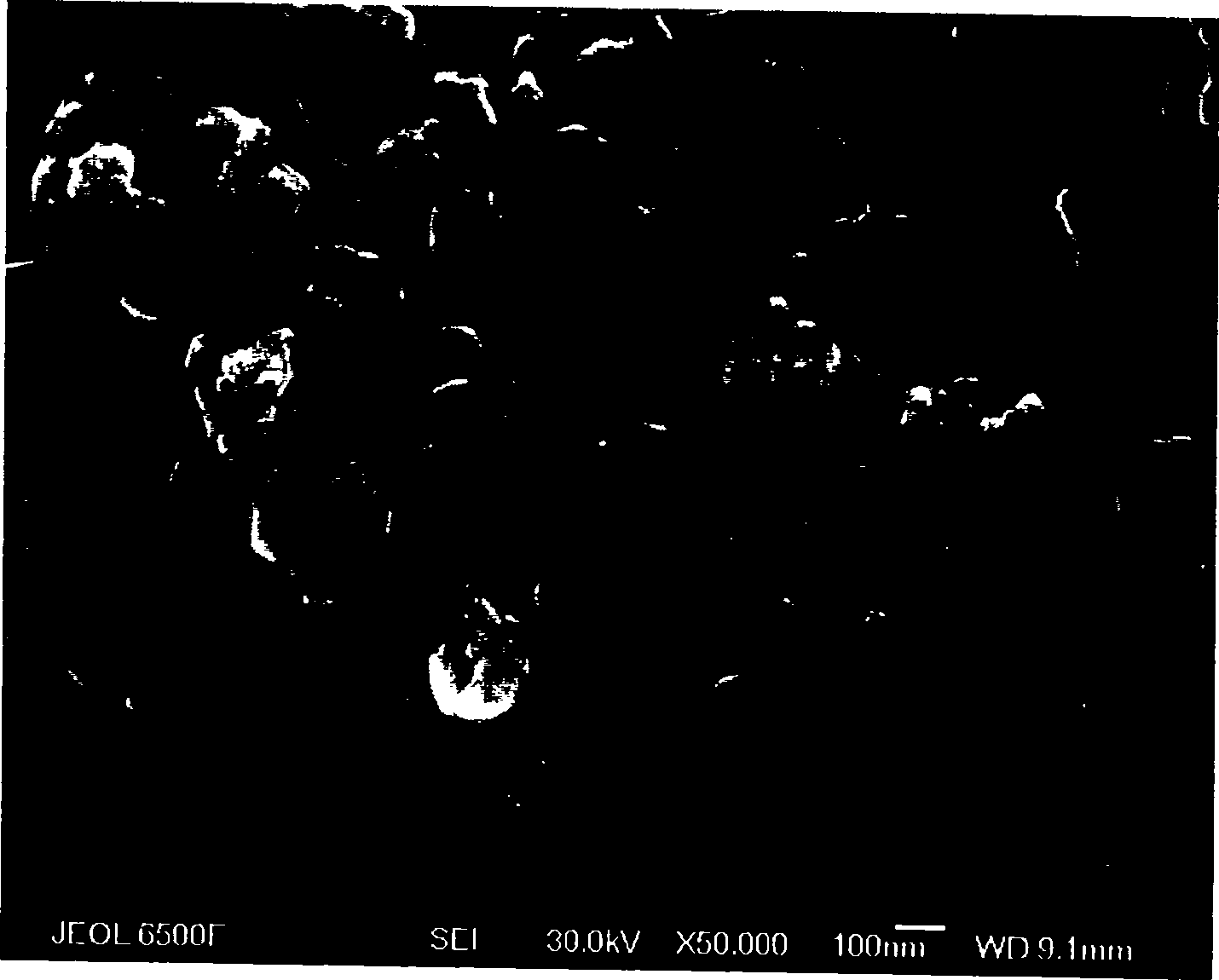

Method for preparing gold nano microgranule powder

The invention discloses the method for preparation of nanometer gold ultramicron powders, comprising the following steps: 1 mixing the polyvinyl pyrrolidon solution and chlorauric acid solution; 2 adding natrium hydroxydatum solution; 3 heating with microwave, getting the nanometer gold sol; 4 evaporating it with vacuum rotatory evaporator and getting nanometer gold ultramicron powders. The method possesses the advantages of low cost, simple technology and wide applications.

Owner:INST OF CHEM CHINESE ACAD OF SCI

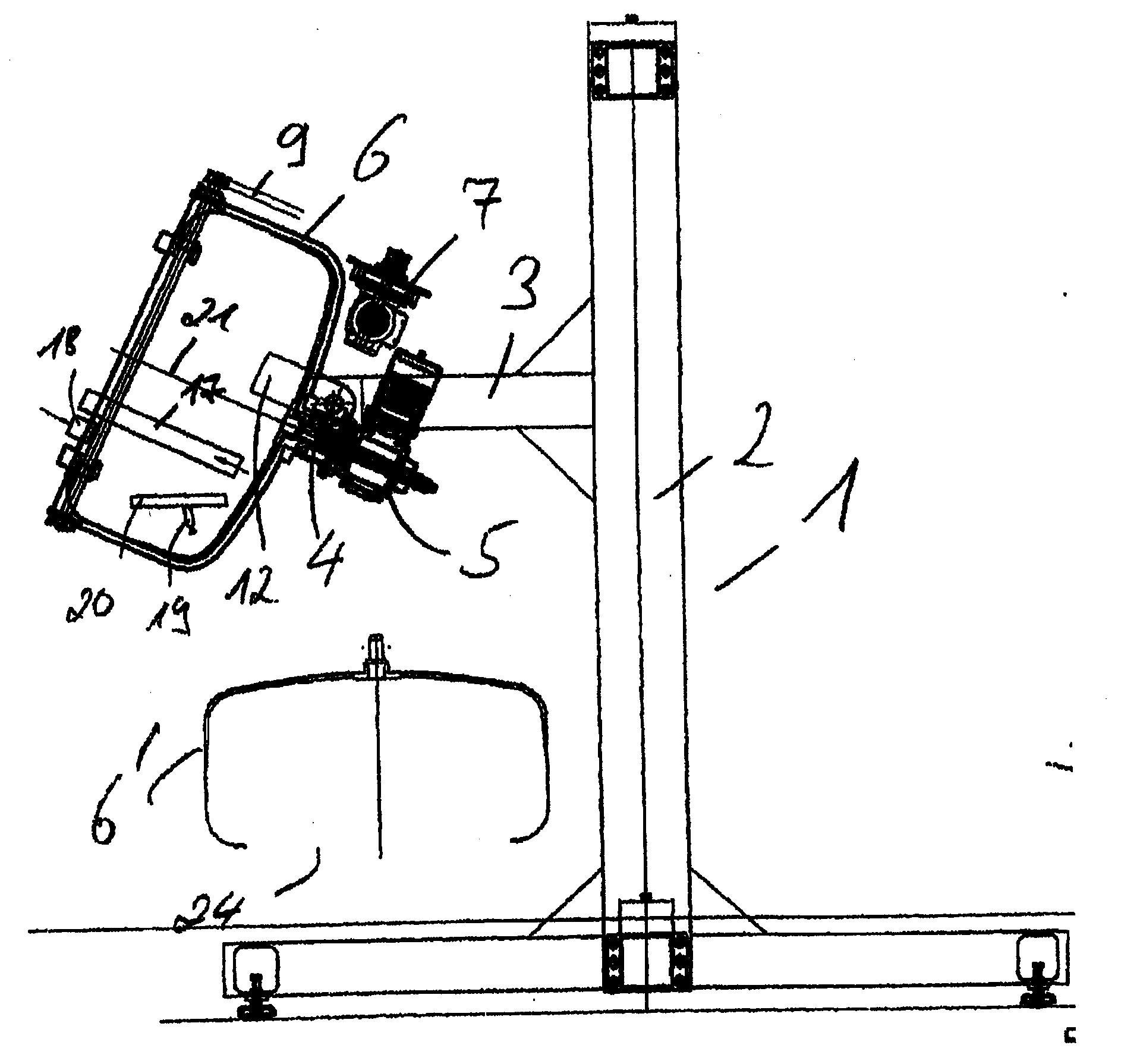

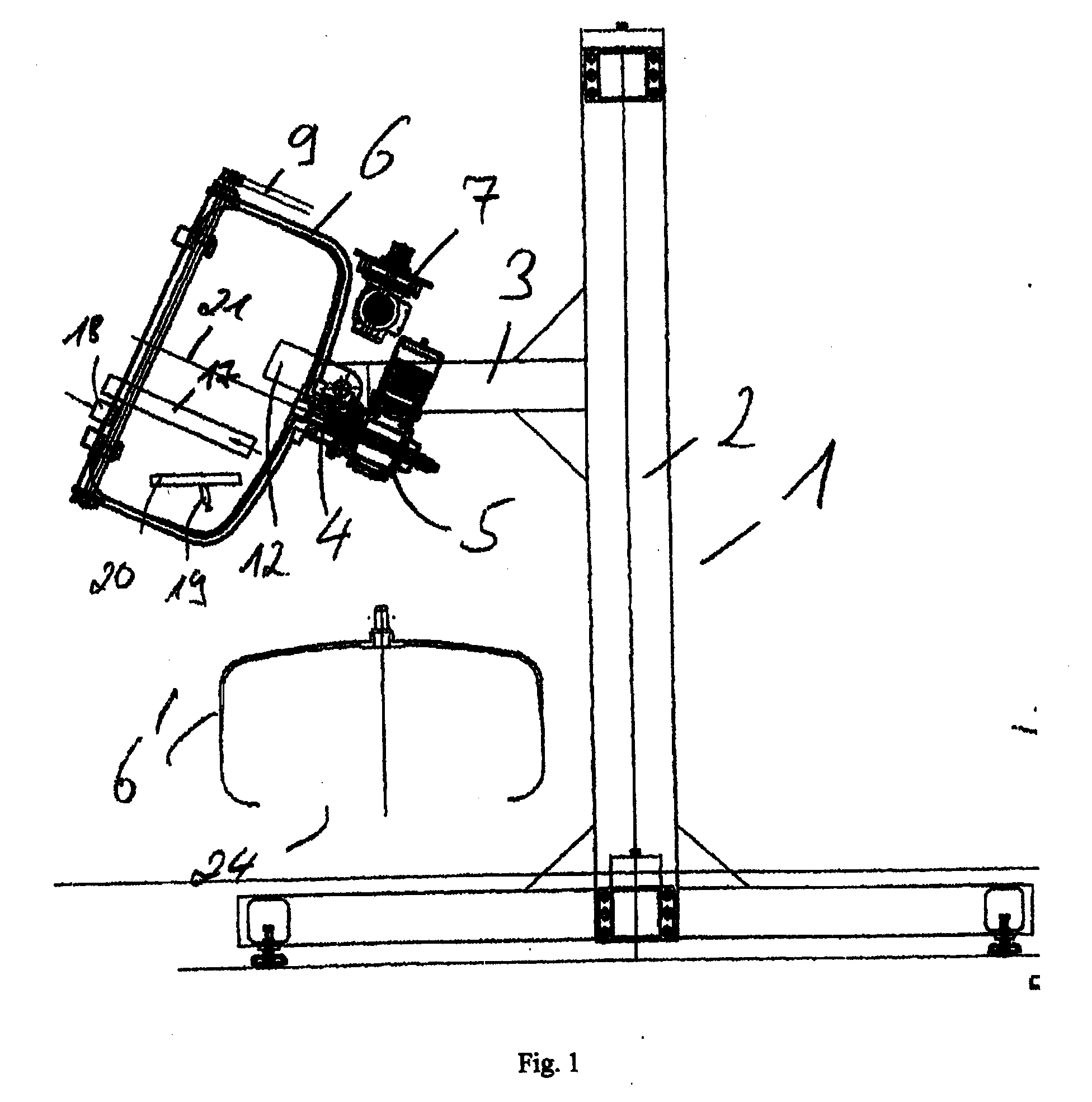

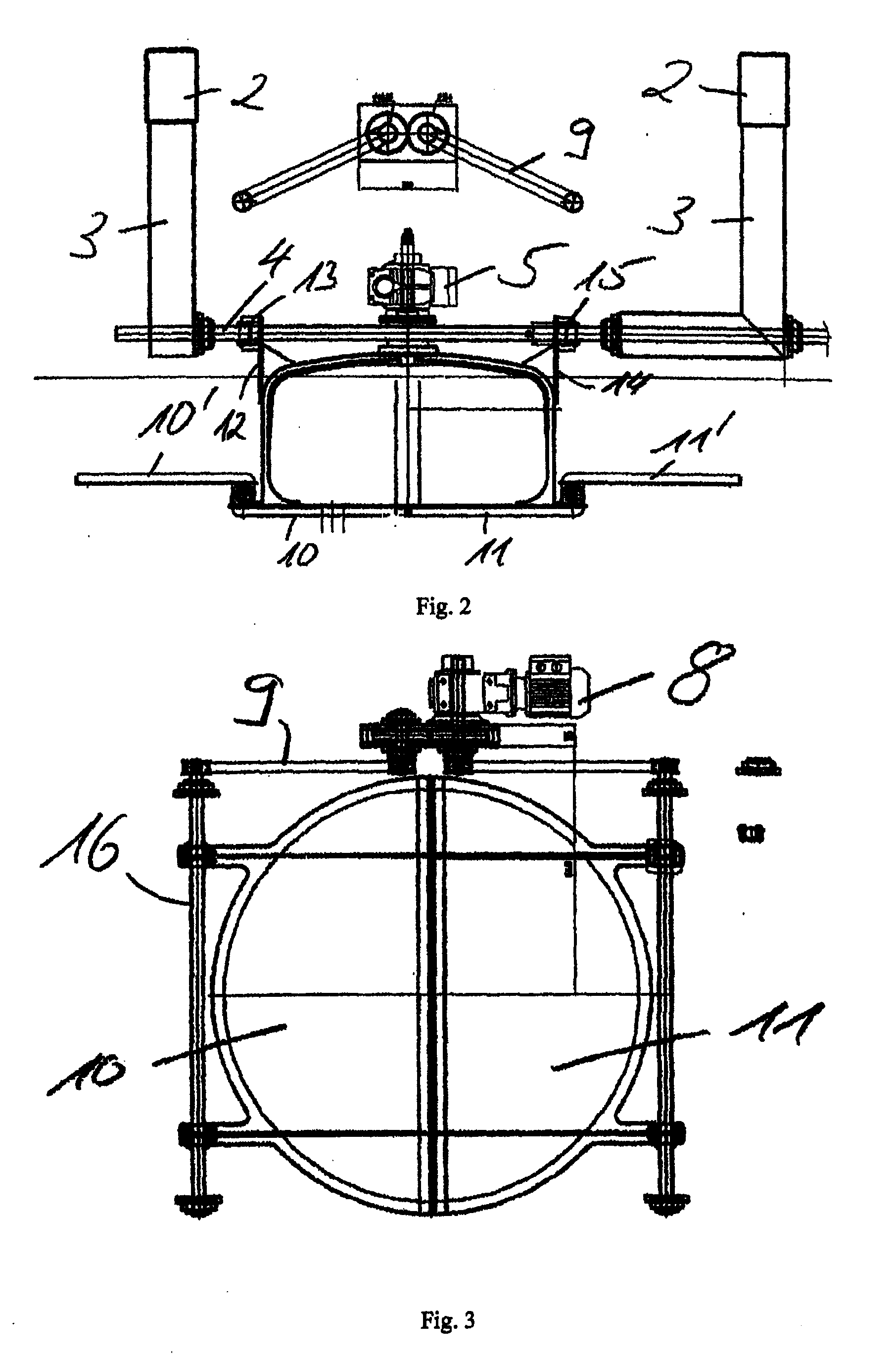

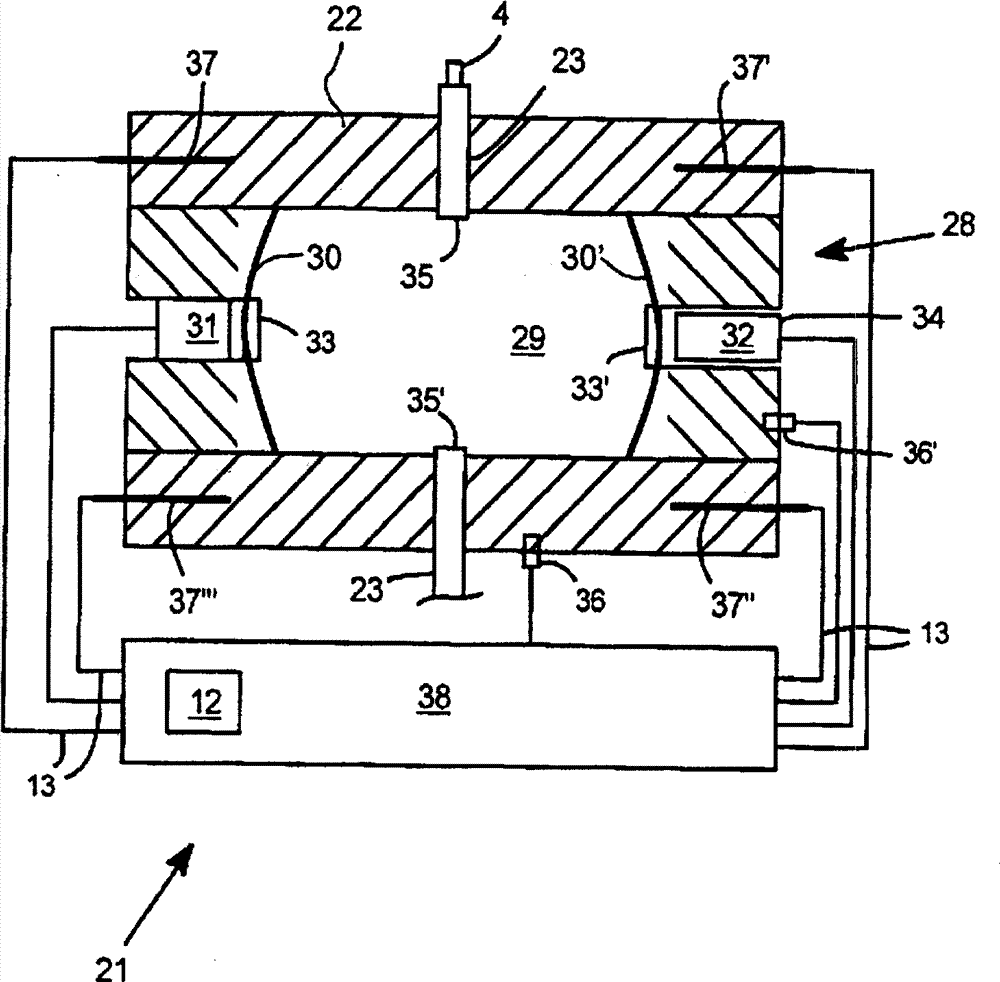

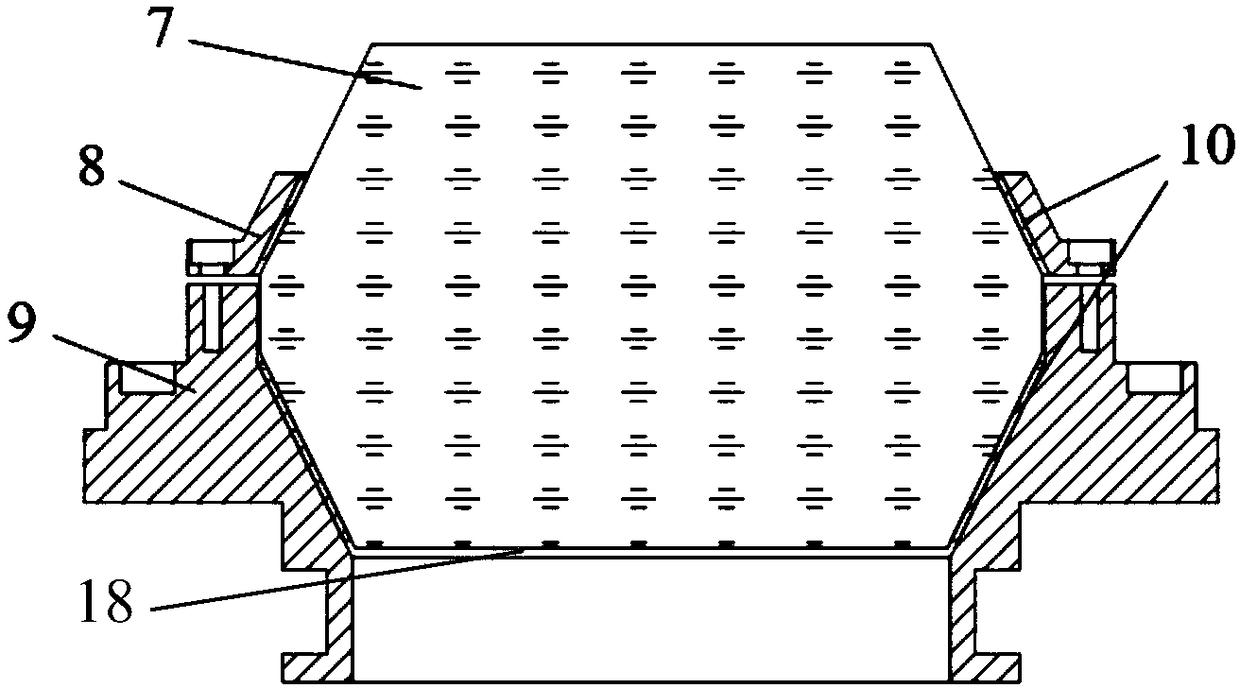

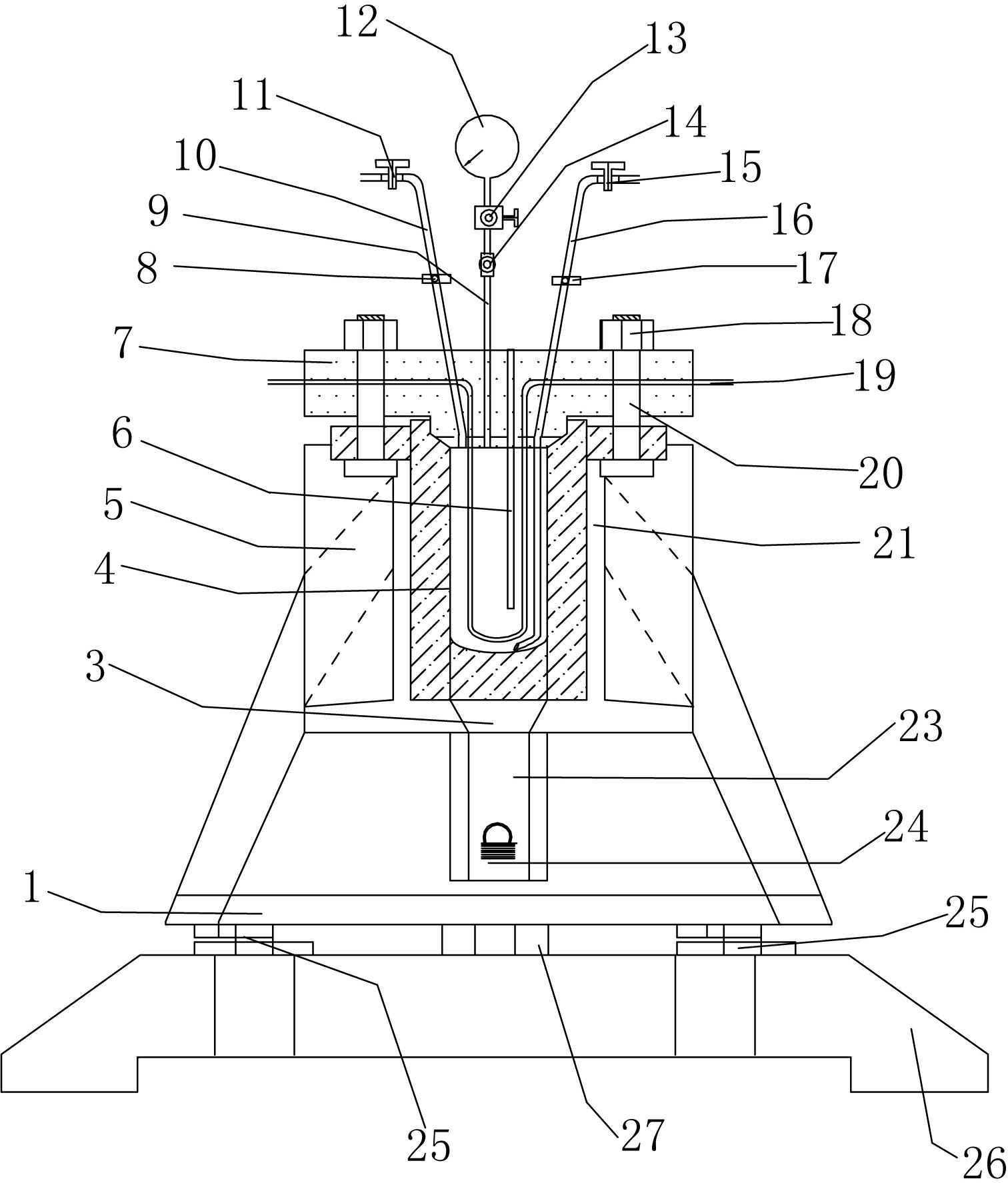

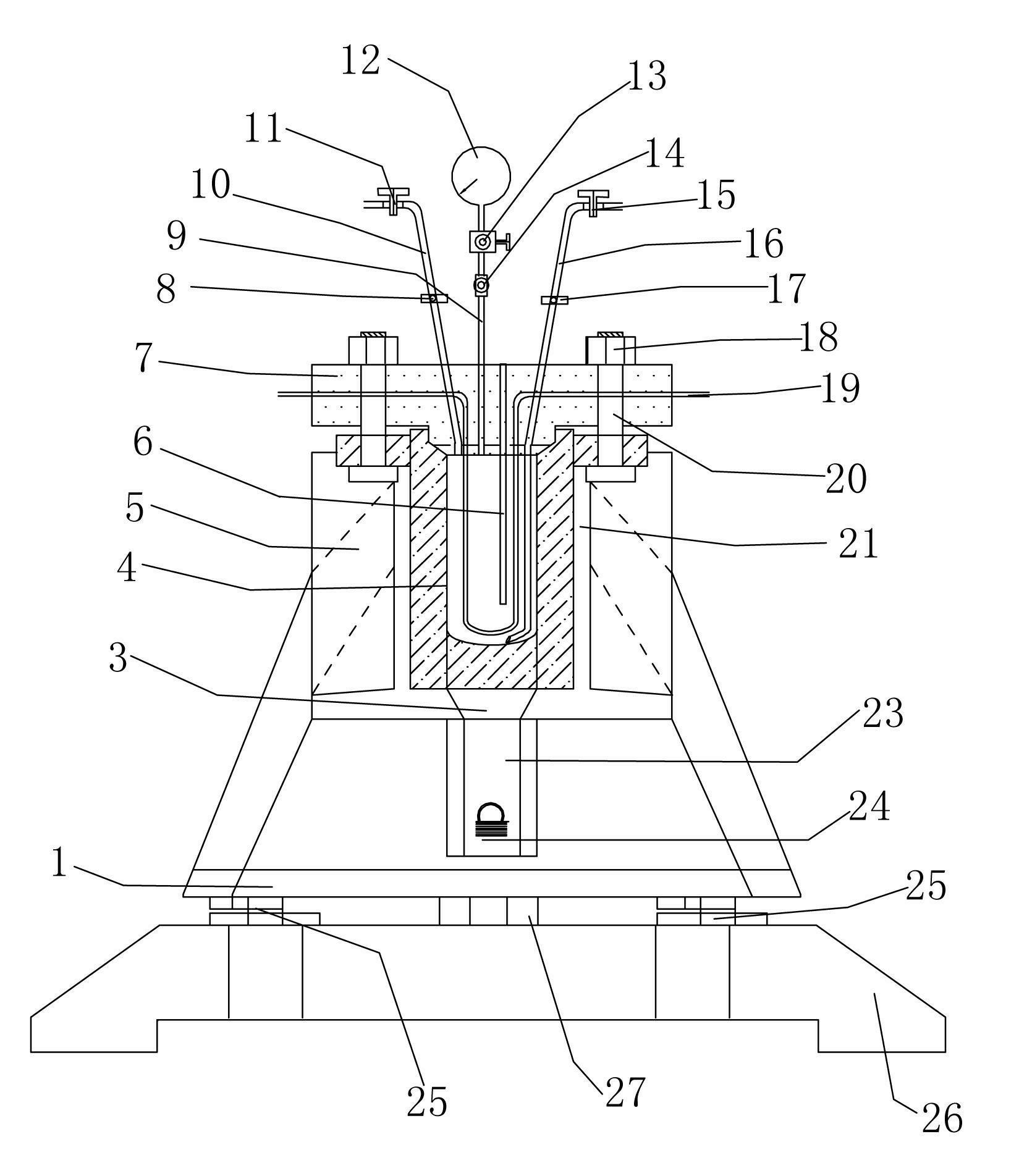

Modular and embedded body-heated constant-volume combustion bomb

ActiveCN109459244AFast and even heatingImprove the heating effectInternal-combustion engine testingEngineeringHeating effect

The invention provides a modular and embedded body-heated constant-volume combustion bomb, which comprises a constant-volume combustion bomb body (1) and a window adapter (2); the window adapter (2) is arranged on the constant-volume combustion bomb body (1); the constant-volume combustion bomb body (1) is provided with a window adapter mounting groove (16); the window adapter (2) is arranged in the window adapter mounting groove (16). Thirty-six heating holes are uniformly formed in twelve edges of the constant-volume combustion bomb body in the modular and embedded body-heated constant-volume combustion bomb, so that a heating rod is installed, and the constant-volume combustion bomb body is rapidly and uniformly heated. According to the constant-volume combustion bomb body in the modular and embedded body-heated constant-volume combustion bomb, the constant-volume combustion bomb body is provided with a wiring groove for wiring a heater, so that an aesthetic effect is achieved; meanwhile, the arrangement of a heat insulation plate on the constant-volume combustion bomb body is facilitated, thereby enhancing the heating effect.

Owner:SHANGHAI JIAO TONG UNIV

Preparation method of polyvinyl chloride resin special for chlorination

The invention relates to the technical field of high polymer materials, and discloses a preparation method of polyvinyl chloride resin special for chlorination. The preparation method comprises the steps of adding a water-containing PVC resin wet material centrifuged by a PVC polymerization production system into a closed container with a stirring function, adding a functional organic solvent, uniformly stirring and mixing, and carrying out freezing treatment, carrying out microwave heating on the frozen primary material at a low temperature, and drying to obtain the PVC resin special for chlorination. PVC resin wet material particles obtained through a water-phase polymerization method contain a large amount of water, the water becomes ice to expand the internal pore diameters of the PVCresin particles during freezing, the ice is sublimated into water vapor during microwave heating, the water vapor compresses the surrounding structures of the PVC resin particles at the early stage tobe closed, breaks through constraint of the PVC resin particles and outer membranes of the particles at the later stage and escapes rapidly. The resin special for chlorination is loose in particle structure, high in plasticizer oil absorption rate and large in specific surface area, can meet the production requirements of CPVC resin, and is more beneficial to chlorination reaction.

Owner:JINCHUAN GROUP LIMITED

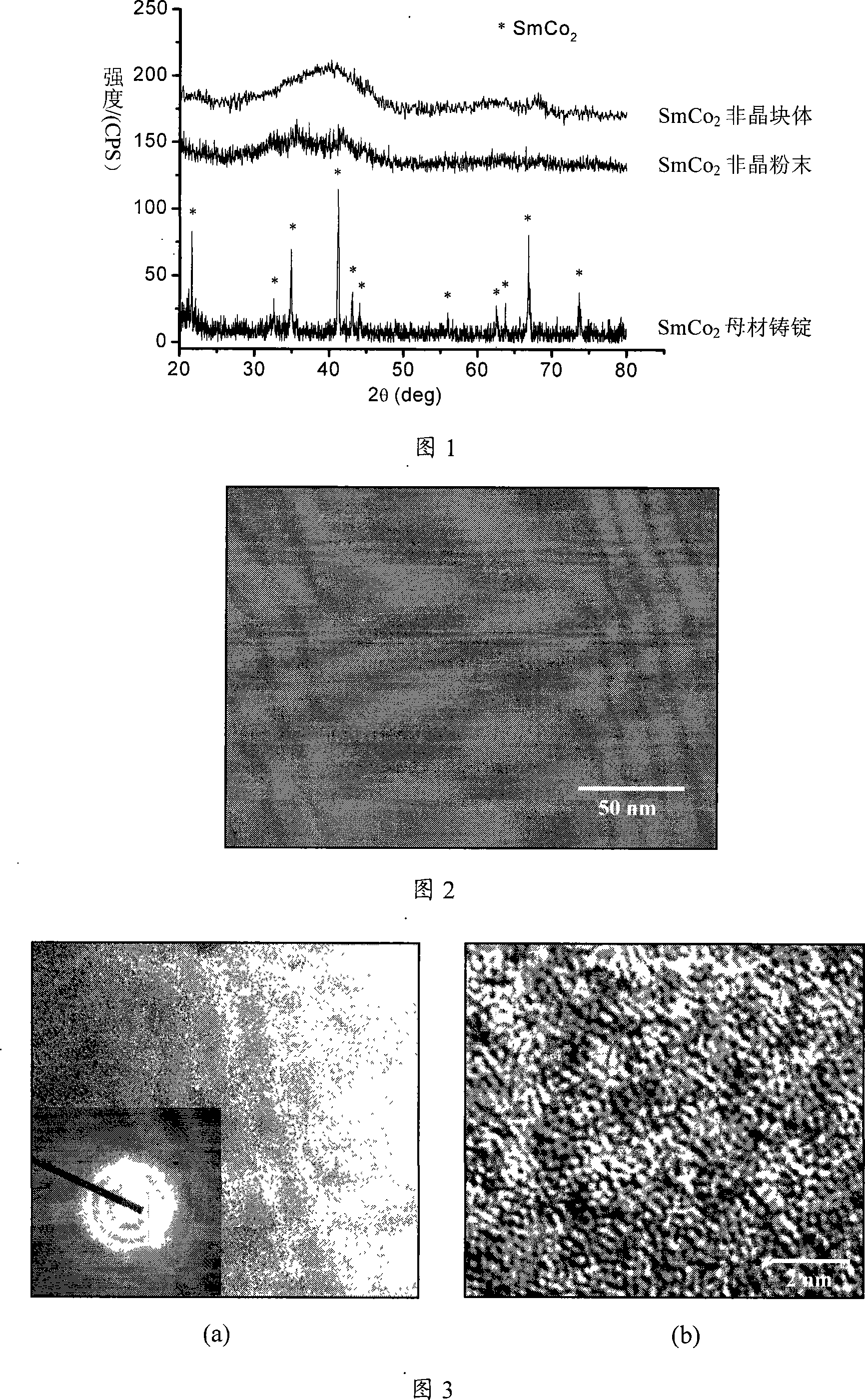

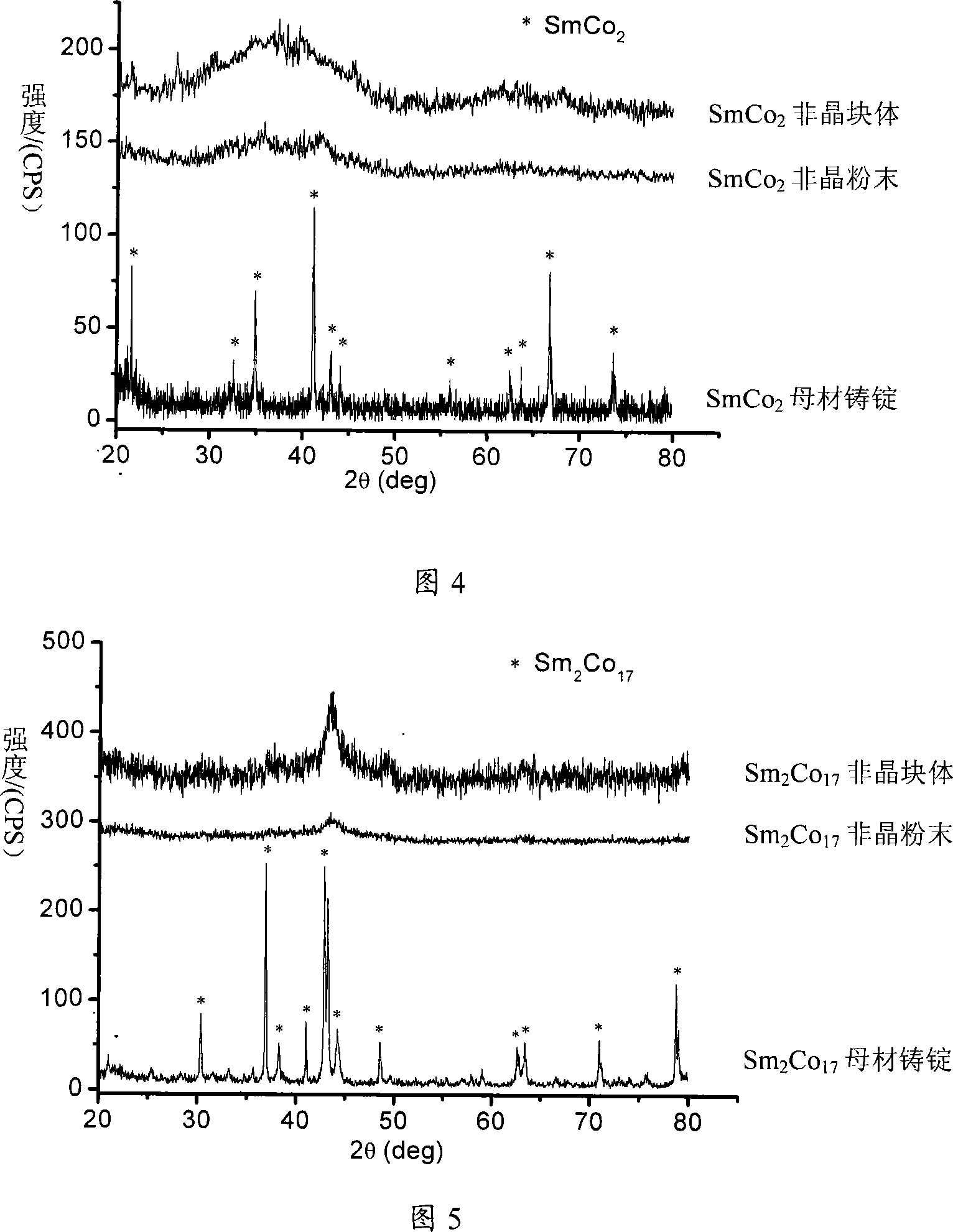

Method for preparing Sm-Co binary alloy amorphous block material

The present invention relates to a preparation method for Sm-Co binary alloy amorphous block body material, and belongs to the powder metallurgy technology field. Because the majority of the binary alloy phase have positive formation enthalpy, the production of amorphous alloy powder with the mechanical alloying method is extremely difficult. The present invention has the steps that pure metals Sm and Co are proportioned and blended according to single phase alloy, and single phase Sm-Co alloy cast ingot is produced by smelting with a vacuum induction furnace; the Sm-Co alloy cast ingot is crushed to be powder grains of below 200 micron, the powder grains are charged into a mill pot with a ball / powder weight ratio of 15:1 to20:1, and after ball milling for eight to twelve hours, the complete amorphous alloy powder can be obtained; under the argon shield, the amorphous alloy powder is charged into a hard alloy die for cold press moulding, is delivered into electric discharge plasma sintering equipment for sintering and densification: the final state sintering temperature is 300-400 DEG C, the temperature rise rate is 80-120 DEG C / min, the sintering pressure is 500 MPa-1 GPa, and heat is not reserved at the final state sintering temperature. The present invention is not limited by the positive formation enthalpy of the binary alloy, and the Sm-Co alloy amorphous block body material has high density and high structural stability.

Owner:BEIJING UNIV OF TECH

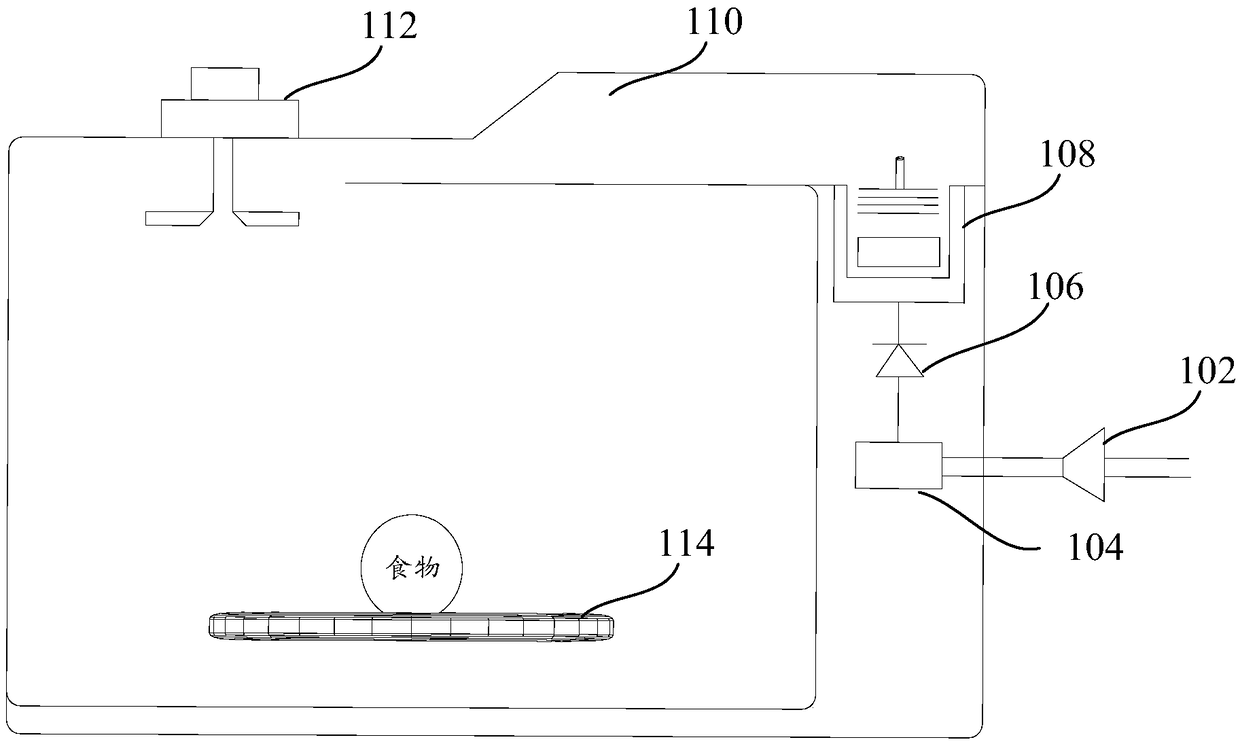

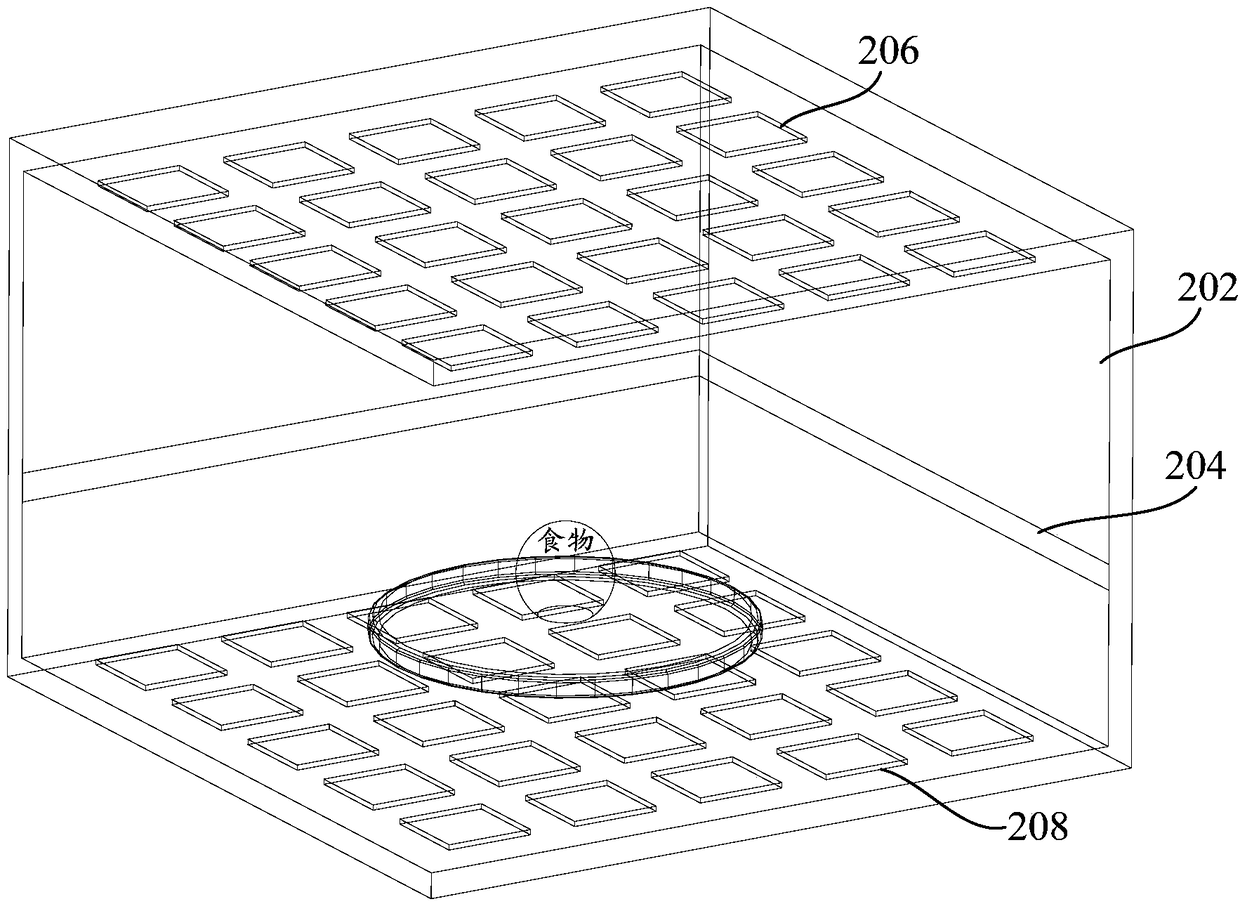

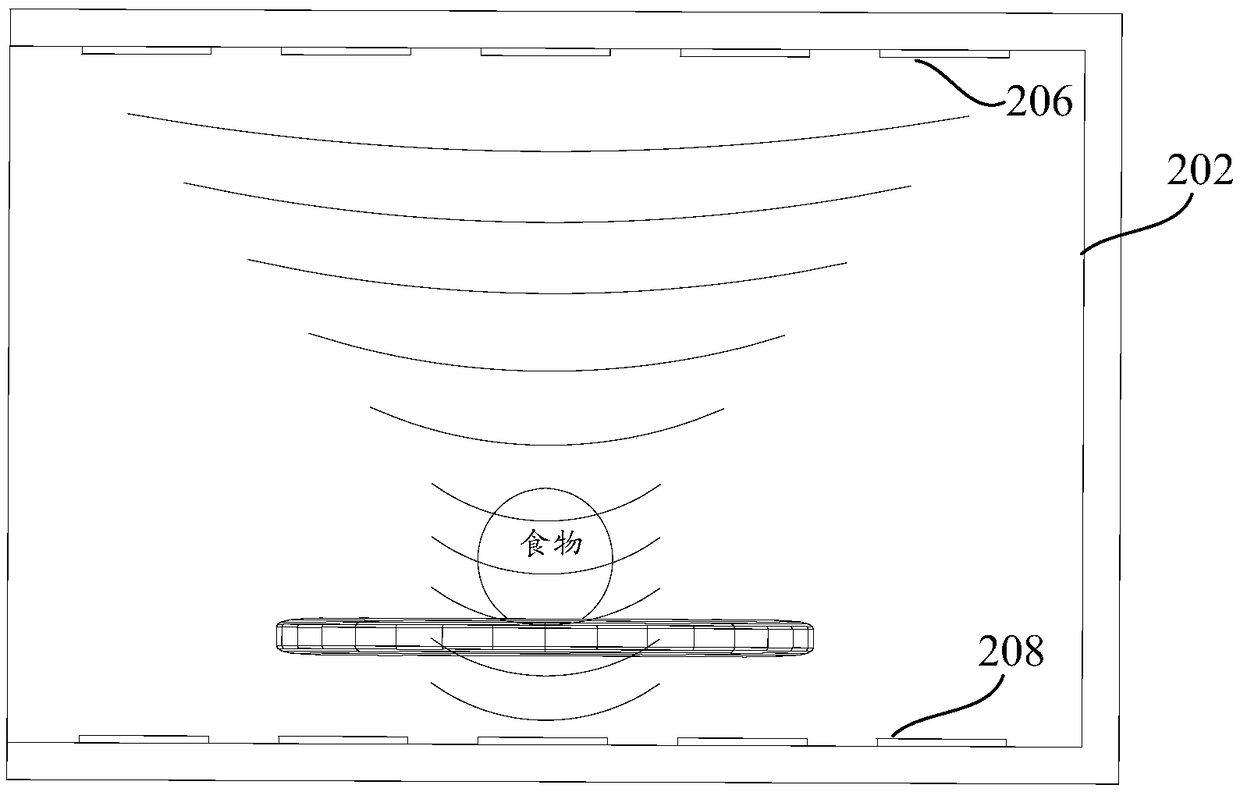

Microwave oven and microwave oven control method

The invention provides a microwave oven and a microwave oven control method. The microwave oven comprises a heating cavity, an information acquisition device, a control device, a phased array transmitting antenna device and a phased array receiving antenna device, wherein the information acquisition device is arranged on the inner wall of the heating cavity and is used for acquiring the position and / or shape information of food in the microwave oven; the control device is connected with the information acquisition device, and determines a transmitting adjustment signal and a receiving adjustment signal according to the position and / or shape information; the phased array transmitting antenna device is arranged on the inner wall of one side of the heating cavity, is connected with the control device and adjusts the antenna transmitting information according to the transmitting adjustment signal so as to feed microwave into the heating cavity according to the antenna transmitting information to heat the food; the phased array receiving antenna device is arranged in the other side inner wall, opposite to the one side inner wall where the phased array transmitting antenna device is located, of the heating cavity, is connected with the control device and is used for adjusting the antenna receiving information according to the receiving adjustment signal, so that microwaves which arenot absorbed by food are received according to the antenna receiving information.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

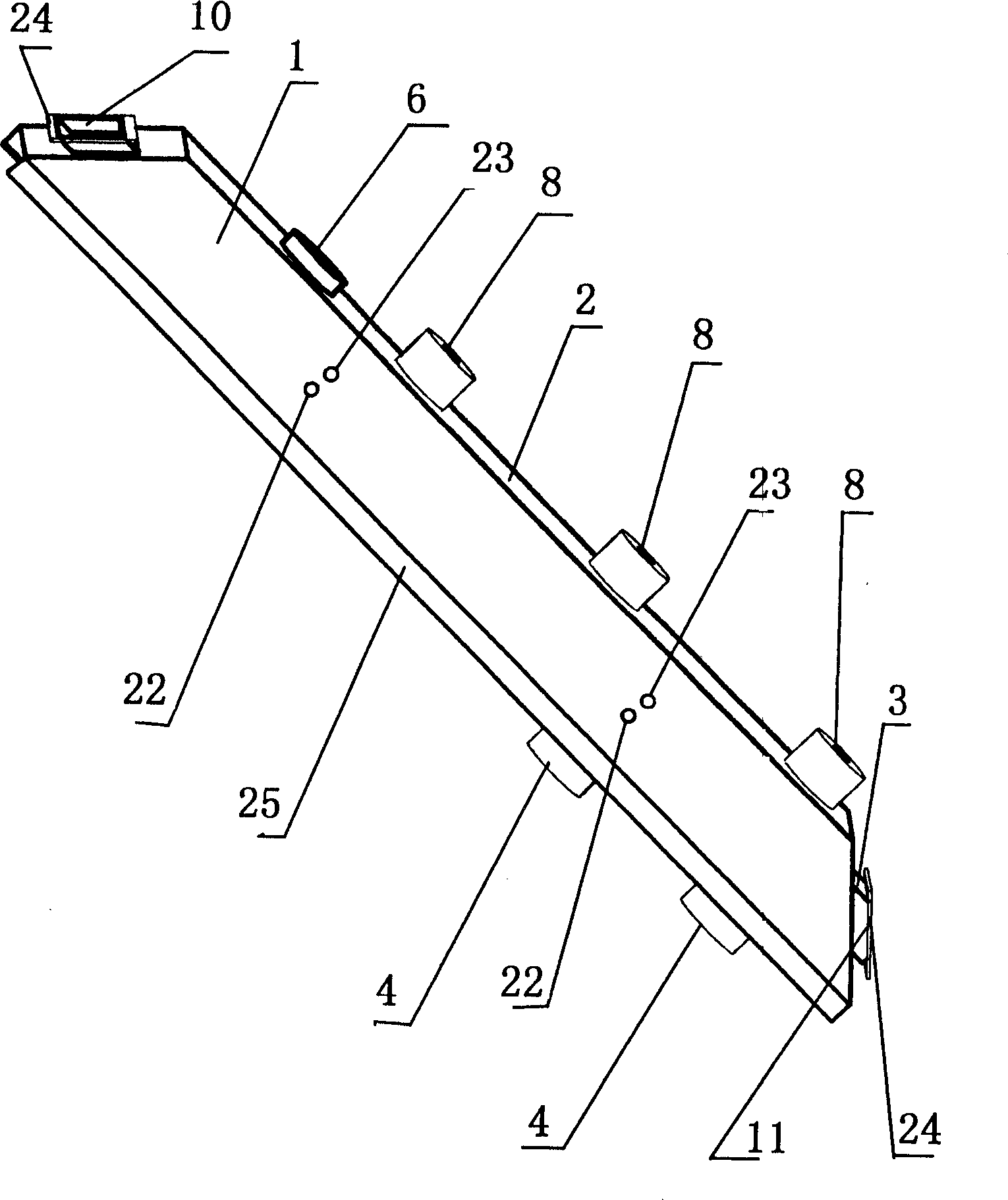

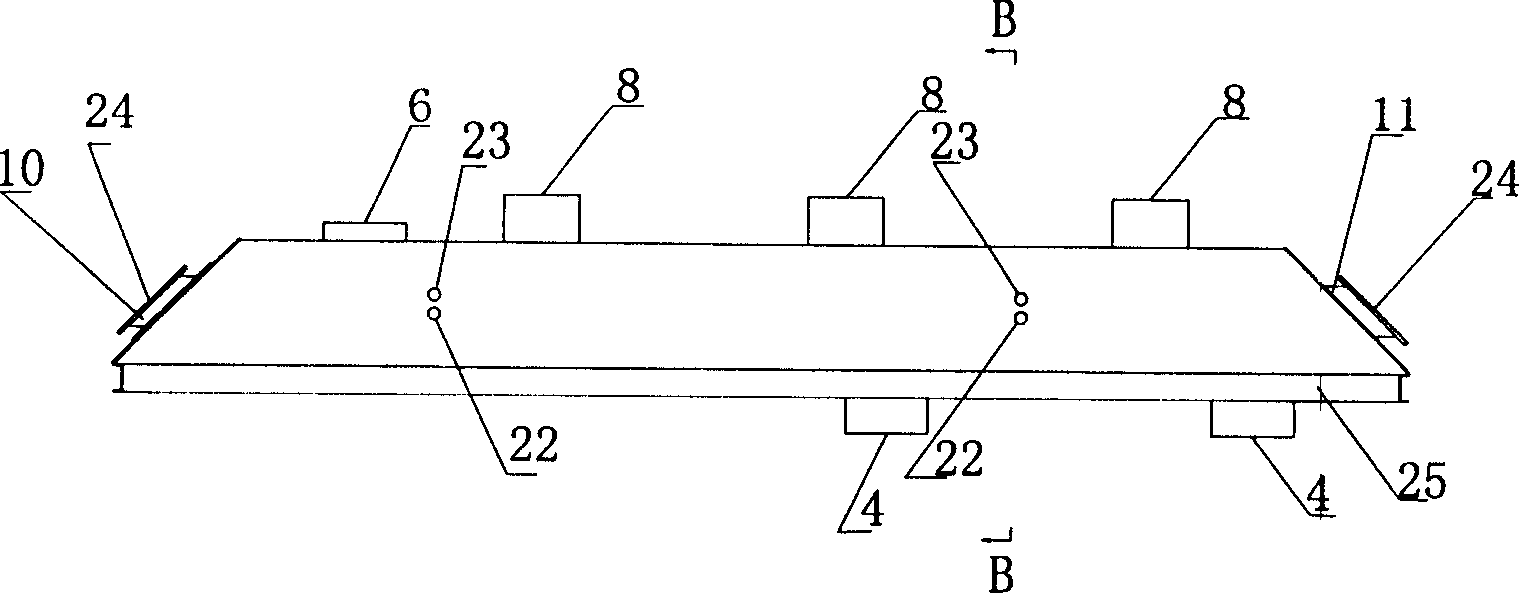

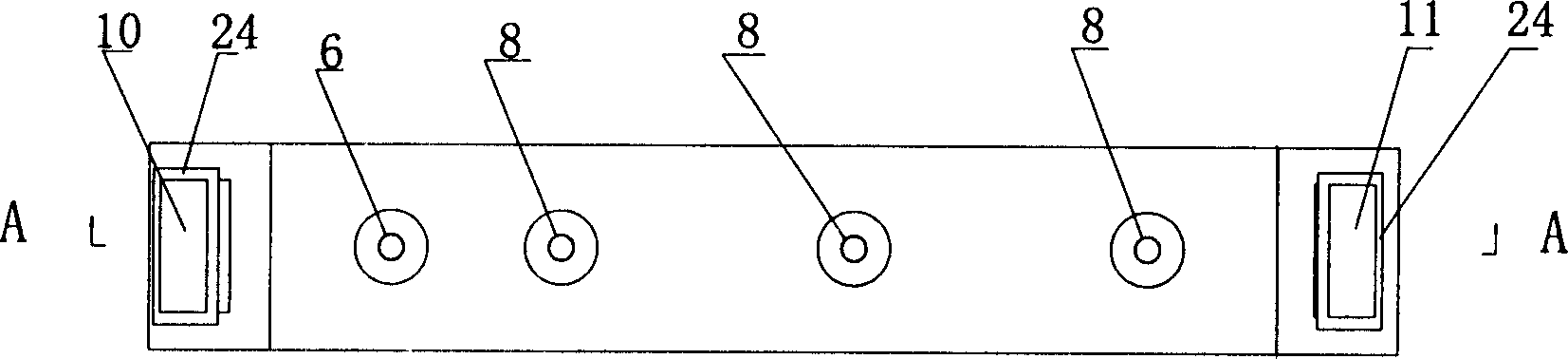

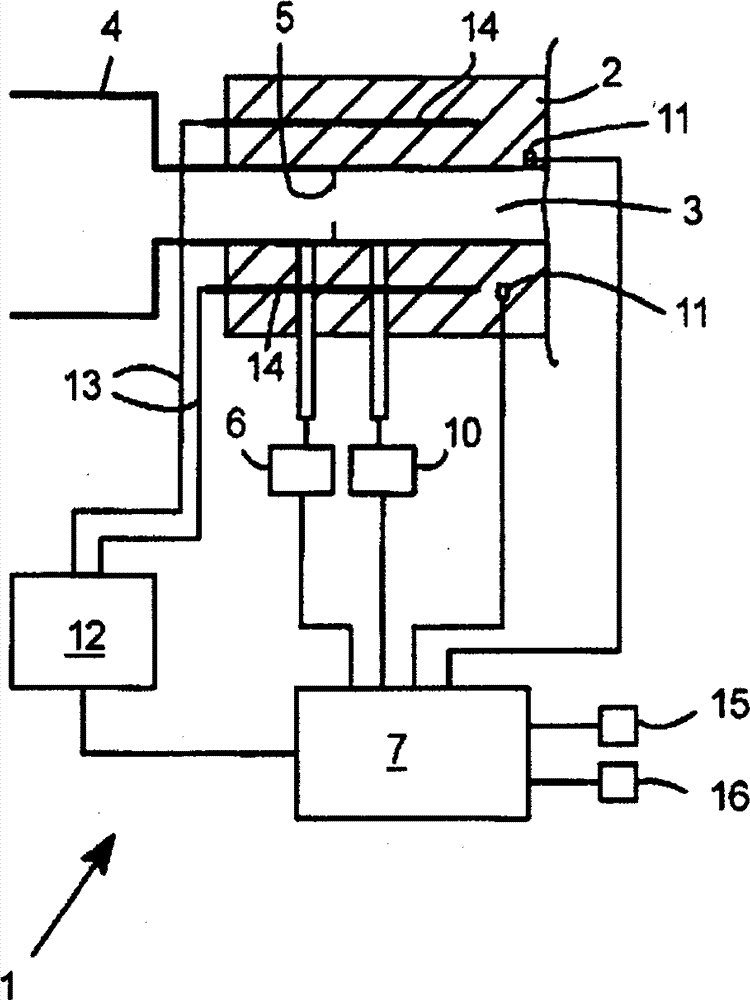

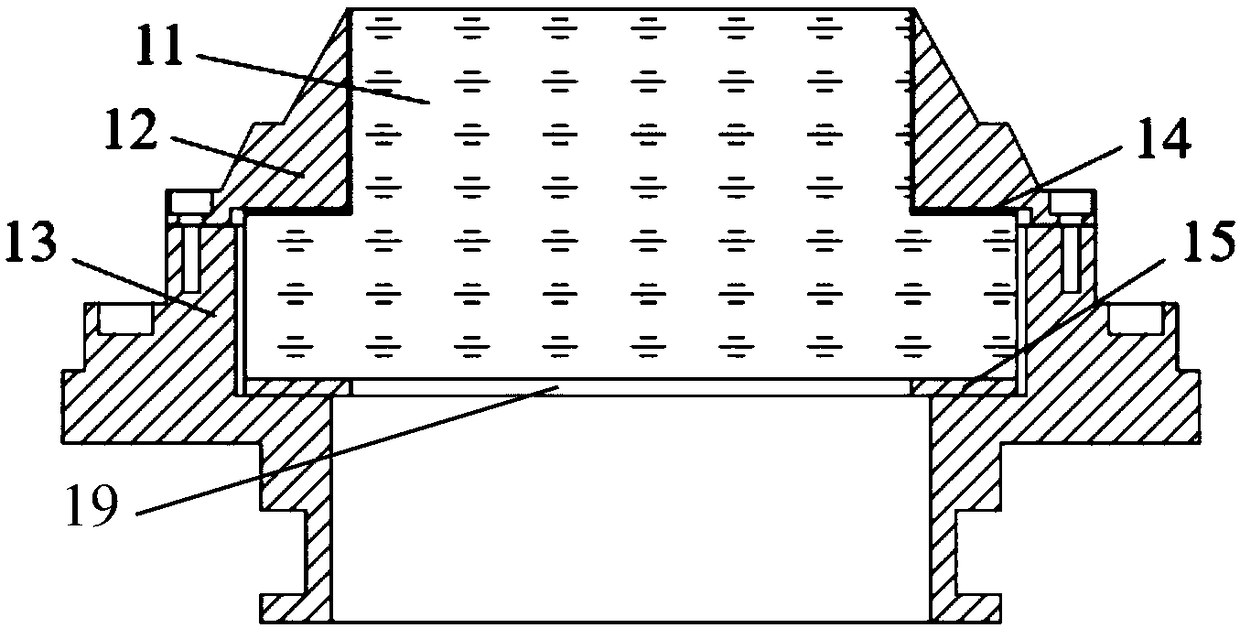

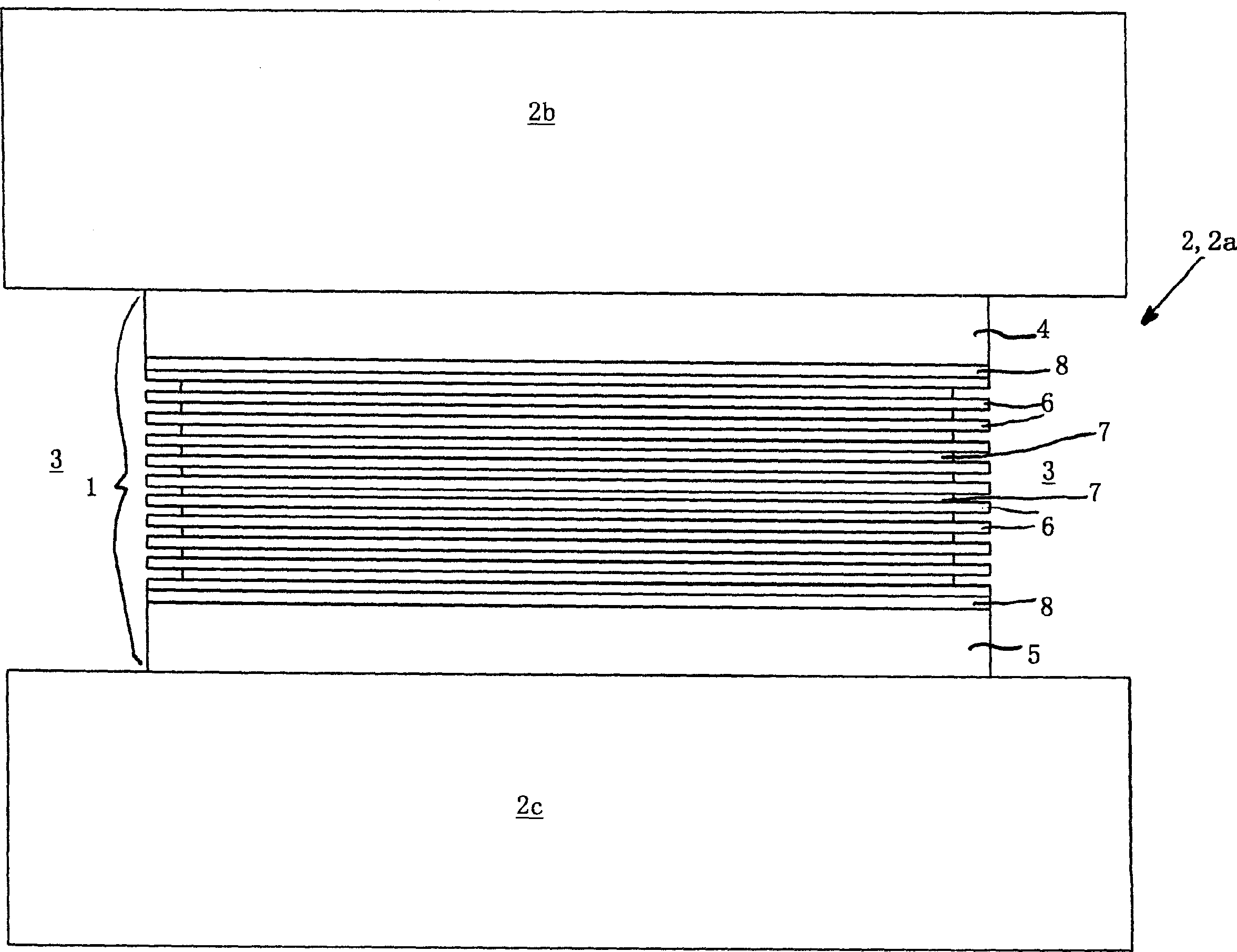

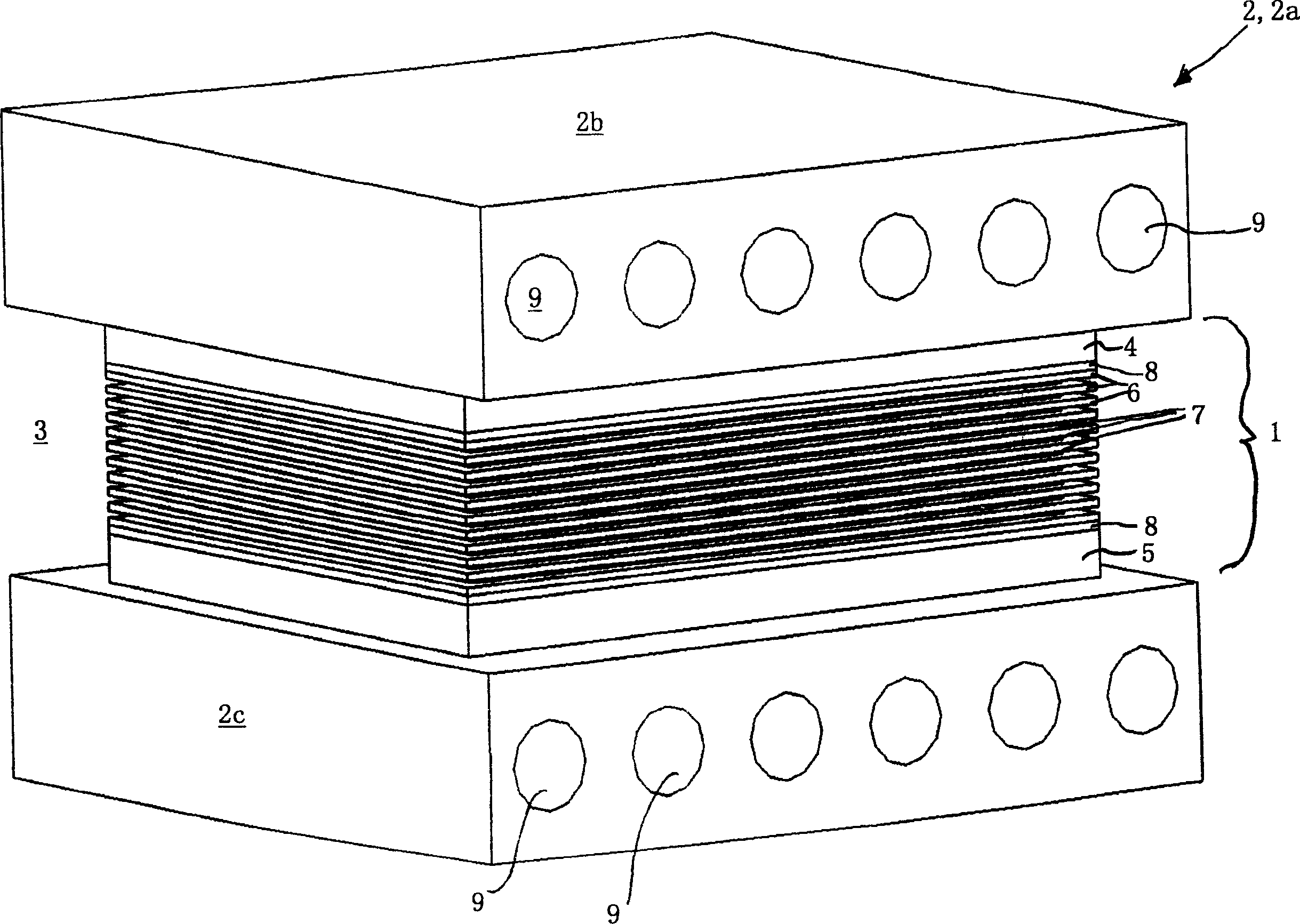

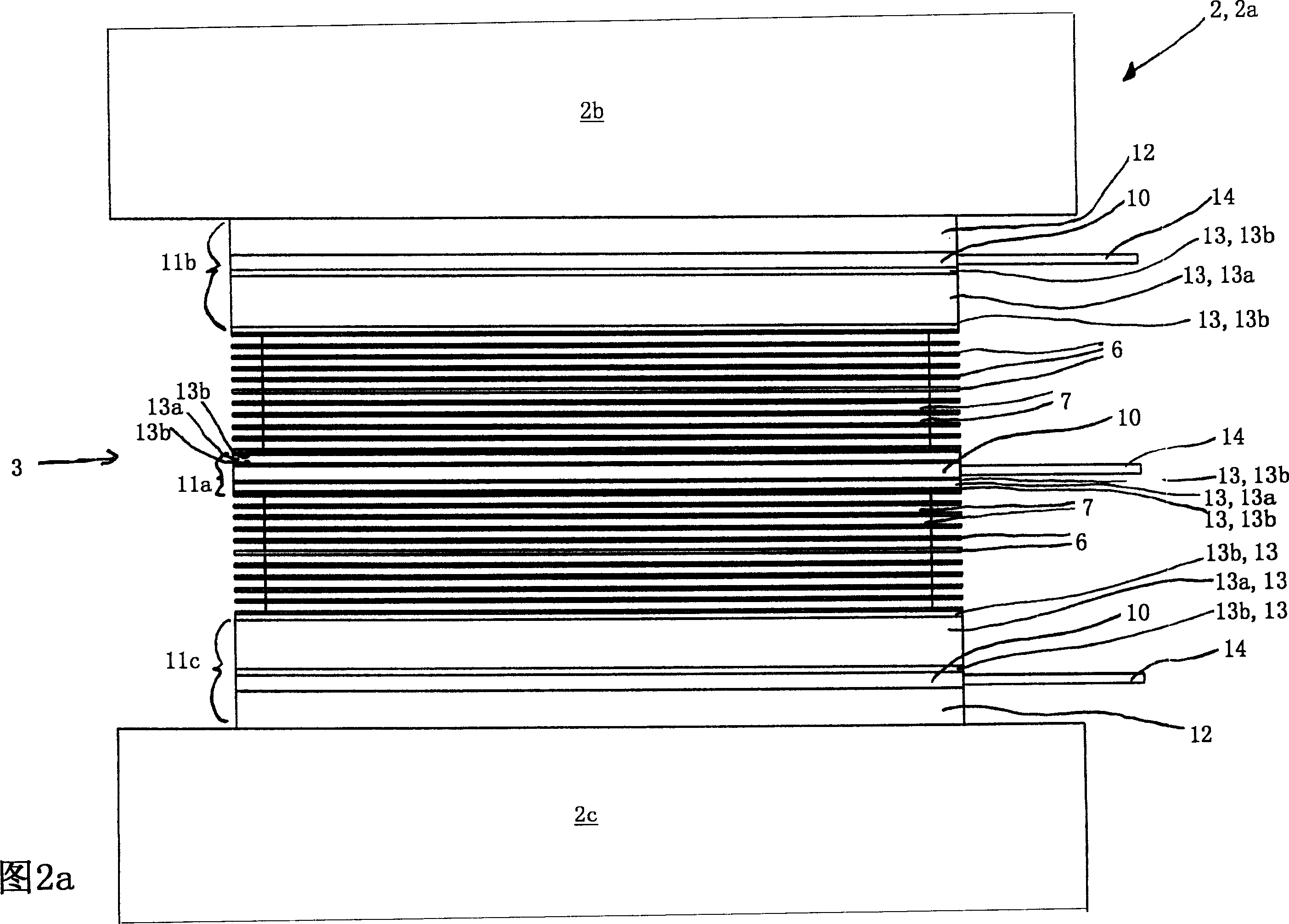

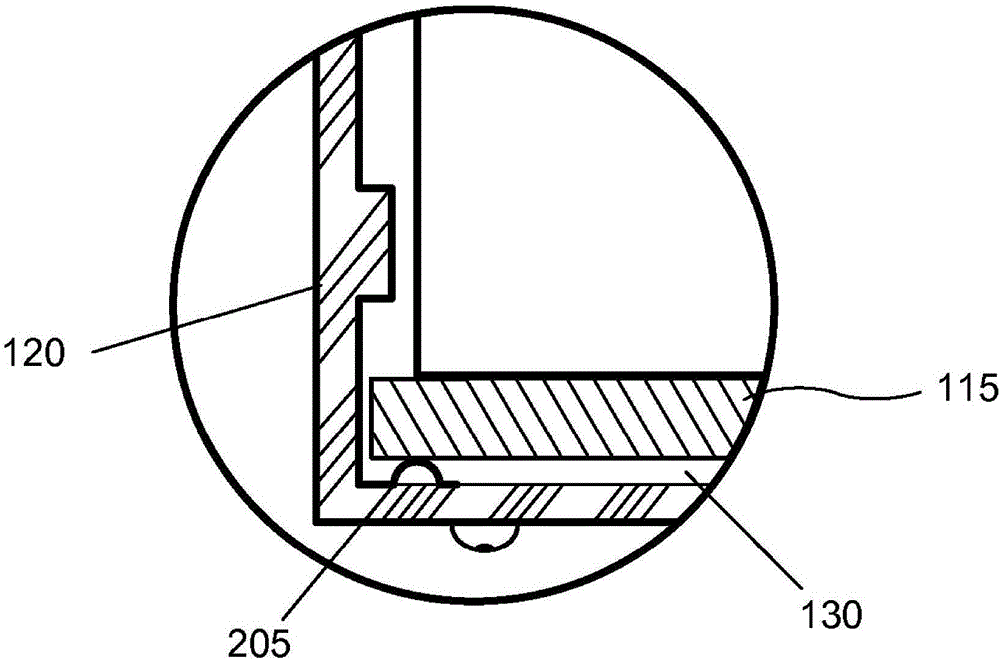

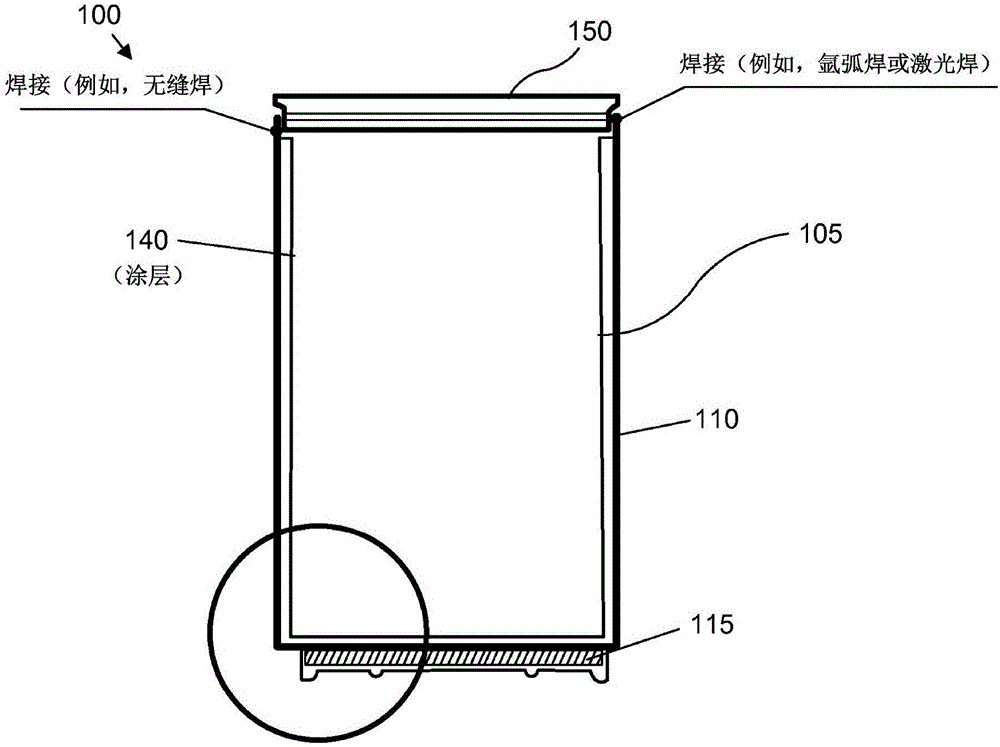

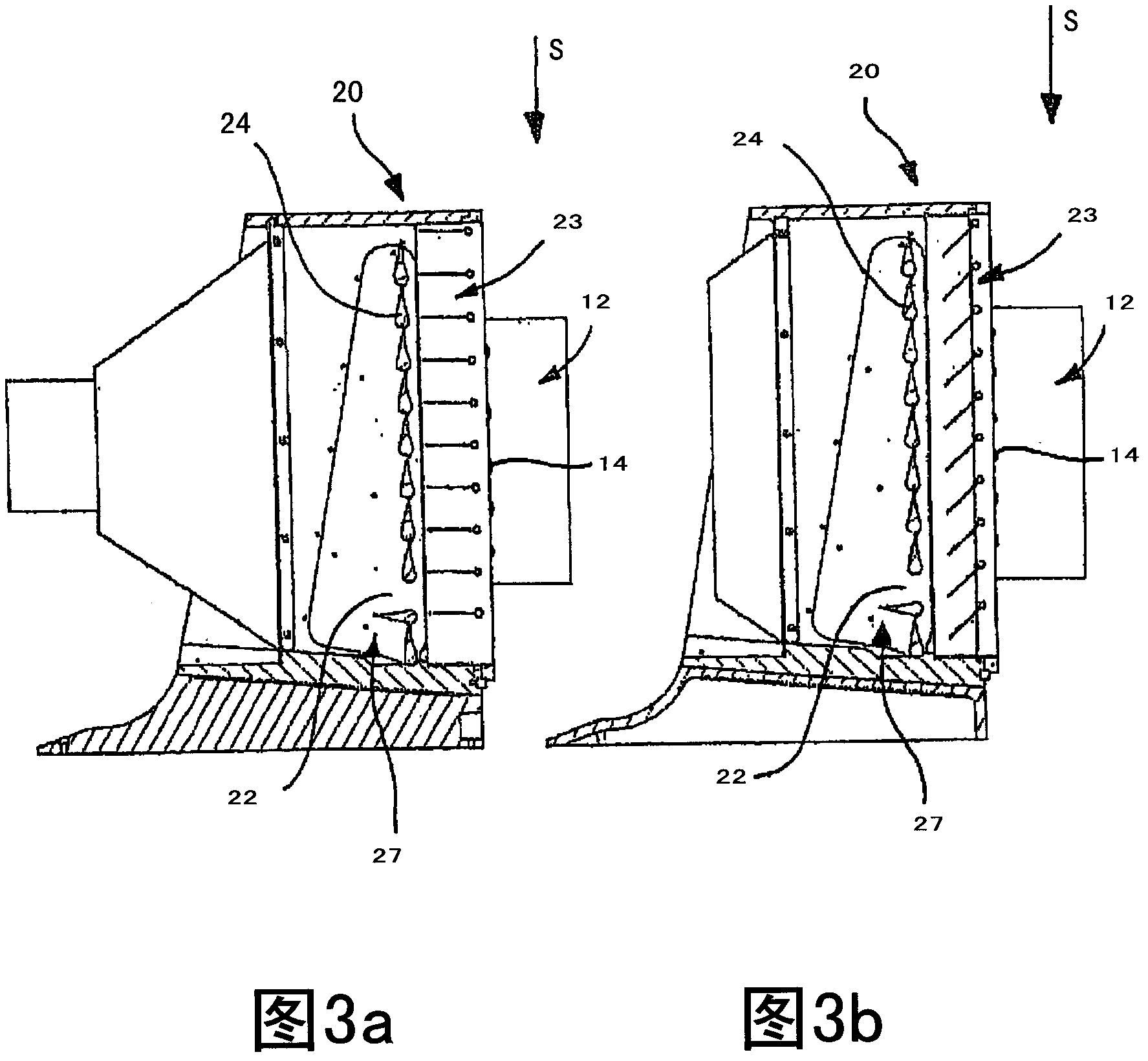

Multilayer press packet, packet structure and multilayer, tool and press for pressing multilayer

InactiveCN1899809AEven heat distributionFast and even heatingLaminationLamination apparatusEngineeringMachine press

The invention relates to a tool (11a, 11b, 11c) for pressing a multilayer press packet (1b), particularly for placing inside a press (2), preferably for inserting into the insertion opening (3) of a multiplaten press (2a). The multilayer press packet (1b), in particular, has a number of multilayers (7) that are separated from one another by at least one separating plate (6). Advantages are achieved by virtue of the fact that the tool (11, 11b, 11c) can be electrically heated. To this end, at least one electrically operable heating element (10) is provided.

Owner:M·巴克豪斯

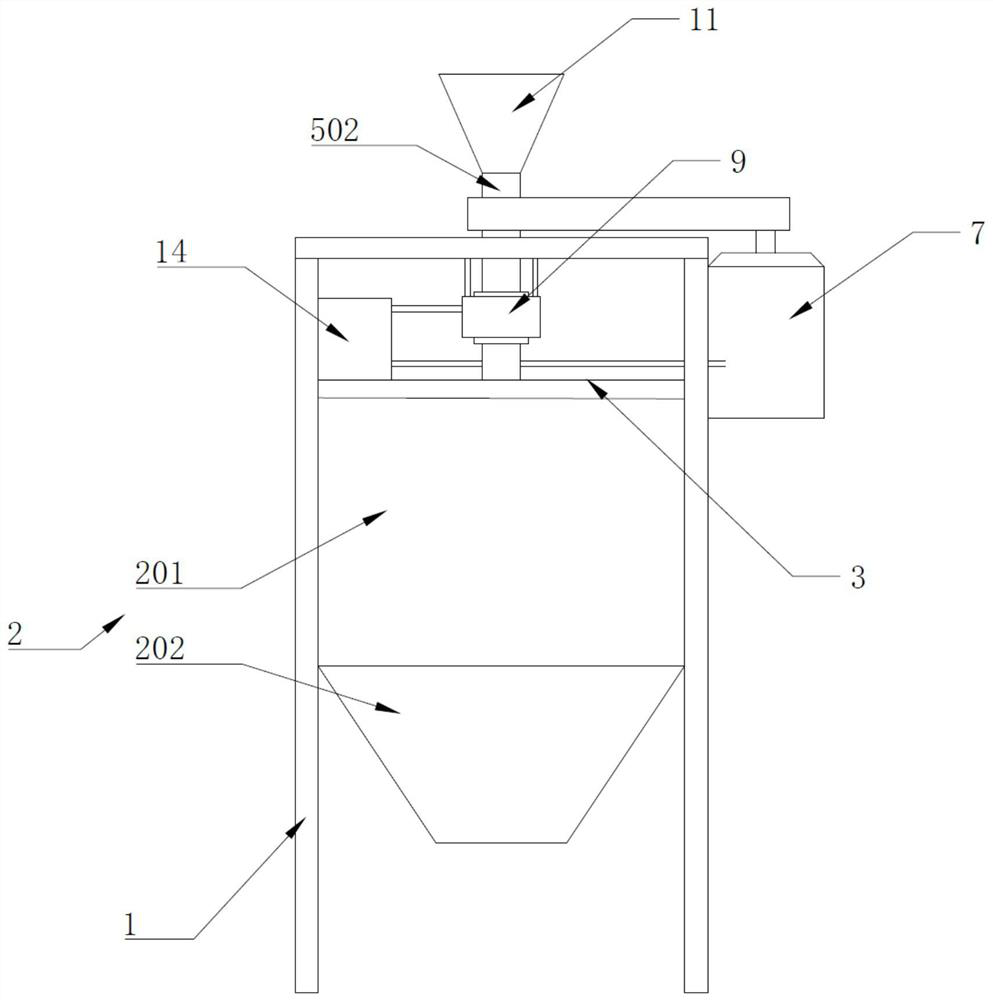

Device for preparing biochar by adopting wet process

ActiveCN102533293AHeating fastNo consumptionBiofuelsSpecial form destructive distillationResonant cavityMicrowave

The invention discloses a device for preparing biochar by adopting a wet process. The device comprises a reaction chamber and a cavity cover, wherein an opening is formed at the upper side of the reactor chamber, and the reactor chamber is provided with a pipeline system through which gas / liquid enters and exits; the cavity cover is used for sealing the opening at the upper side of the reaction chamber; and a microwave generation device is connected to the reaction chamber. According to the device disclosed by the invention, a microwave heating technology is combined with wet process carbonization, microwaves are generated by the microwave generation device, a microwave resonant cavity is defined by the reaction chamber and the cavity cover, biomass added to the reaction chamber can be rapidly heated so that the biomass undergoes a carbonization reaction, and therefore the biochar is prepared. Because a microwave endogenous heating mode is adopted in the carbonization process, the device disclosed by the invention has the advantages of no any heat transfer process, high and uniform heating speed, no extra heat consumption, low energy consumption and high efficiency and can be usedfor preparing the biochar by adopting the wet process.

Owner:GUANGDONG INST OF ECO ENVIRONMENT & SOIL SCI

Preparation method of cationic nanometer cellulose containing lignin

The invention relates to a preparation method of cationic nanometer cellulose containing lignin, and belongs to the technical field of cellulose modification. The preparation method comprises following steps: agricultural waste is crushed, and is mixed with an alkali solution and a cationic etherifying agent, microwave and supersonic wave combined one-kettle method is adopted for reaction, and cellulose nanometer modification is carried out, so that the cationic nanometer cellulose containing lignin is prepared through one-kettle method. The preparation method is simple; reaction temperature is reduced; reaction time is shortened; industrialized production is possible to be realized; at the same time, the obtained cationic nanometer cellulose containing lignin is high in stability, film forming strength, and antibacterial performance, excellent effect can be achieved with the cationic nanometer cellulose containing lignin is used for heavy metal absorption in water, and the applicationvalue of the cationic nanometer cellulose containing lignin in the fields of antibacterial and absorption is extremely high.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

Efficient disease prevention pig raising method

InactiveCN106070022AImprove the living environmentKeep coolPowder deliveryDigestive systemAnimal scienceFood material

The invention provides an efficient disease prevention pig raising method. Pigs with the age smaller than two months and the weight of 30 kg or more and pigs with the age of two months or more and the weight of 40 kg or more are fed on disease prevention pig feed different in weight in a pigsty three times a day until the pigs become full grown and ready for slaughter; the pigs are kept in the pigsty each time the diseases prevention pig feed is fed and are stocked to a small hillside outside the pigsty after feeding. The disease prevention pig feed is prepared from powder pig feed, pig phagostimulant and a basic food material by certain weight. The pig raising method has the advantages of being simple, convenient, economical, practical, small in risk and large in benefit, the pigs have few diseases, according to the pigs fed through the method, pork is free of drug residue, high in quality and good in taste, and the win-win effect of consumers and a pig raising entrepreneur can be achieved.

Owner:陆川县新洲养殖场

Preparation method of PVC resin special for chlorination

The invention relates to the technical field of high polymer materials, and discloses a preparation method of PVC resin special for chlorination. The preparation method comprises the steps of adding awater-containing PVC resin wet material centrifuged by a PVC polymerization production system into a closed container with a stirring function, adding a functional organic solvent, uniformly stirringand mixing, carrying out microwave heating and drying on the uniformly mixed primary material, and obtaining the PVC resin special for chlorination. PVC resin wet material particles obtained througha water-phase polymerization method contain a large amount of water, the water is changed into water vapor during microwave heating, the water vapor compresses surrounding structures of the PVC resinparticles to be closed at the initial stage, breaks through constraint of the PVC resin particles and outer membranes of the particles at the later stage, and escapes rapidly. The resin special for chlorination, which is loose in particle structure, high in plasticizer oil absorption rate and large in specific surface area, is obtained, the production requirements of CPVC resin can be met, and chlorination reaction is more facilitated to be carried out.

Owner:JINCHUAN GROUP LIMITED

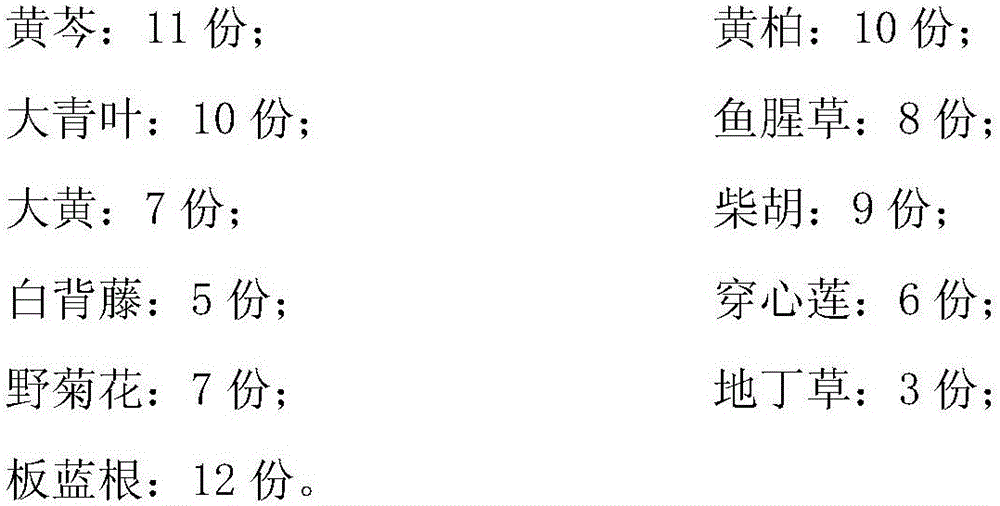

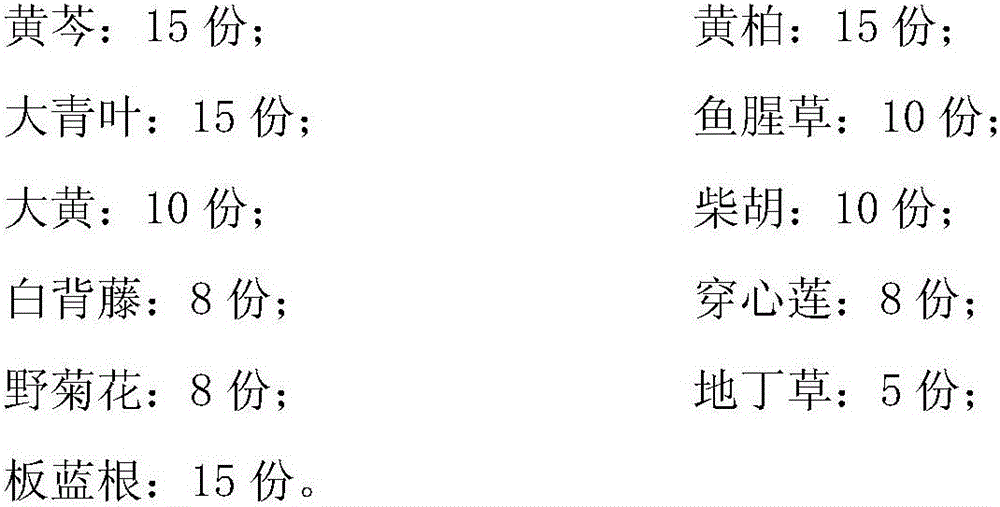

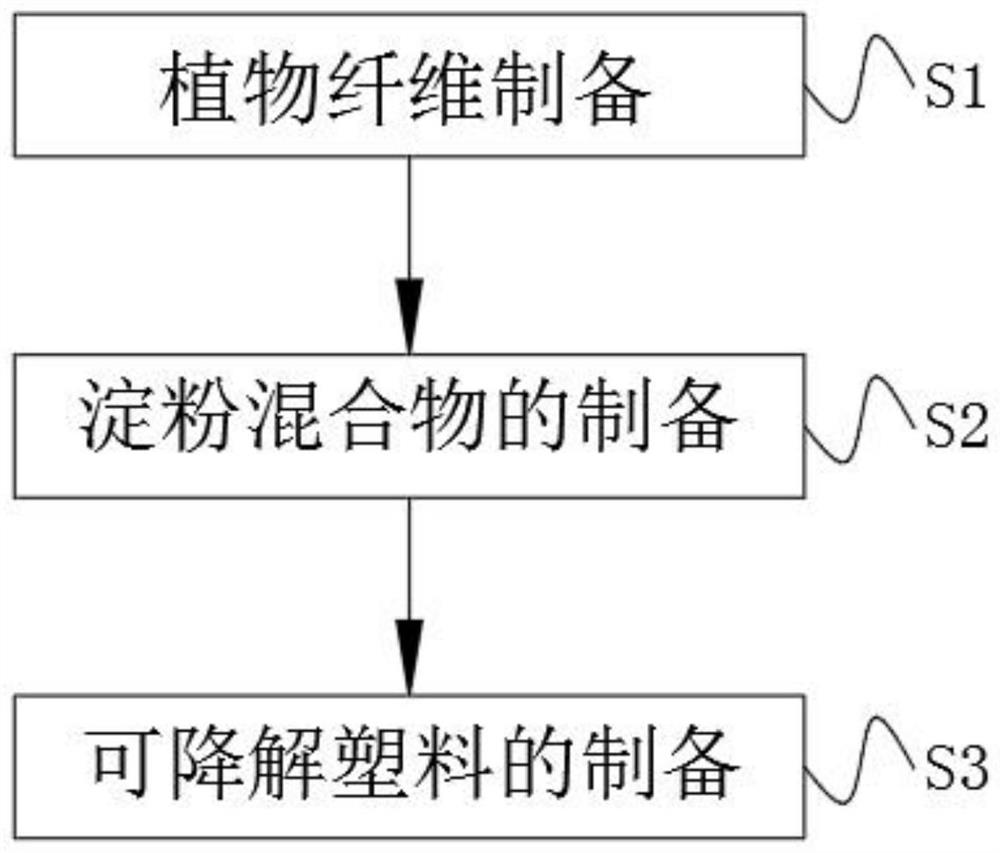

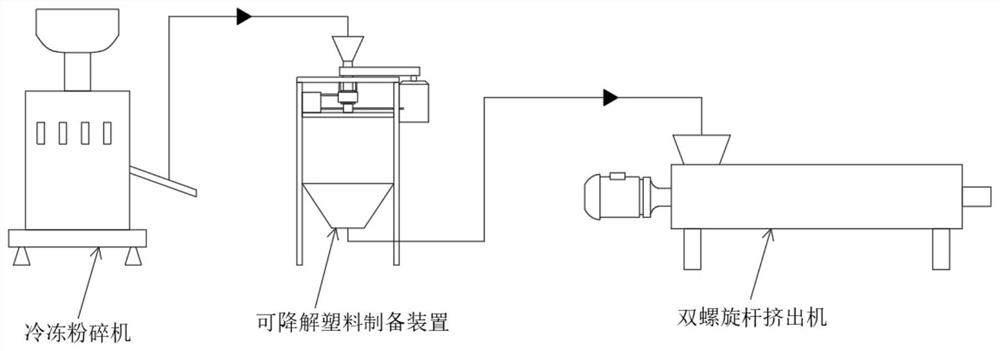

Degradable plastic based on plant fiber starch as well as preparation method and preparation system ofdegradable plastic

The invention discloses degradable plastic based on plant fiber starch as well as a preparation method and preparation system of the degradable plastic. The degradable plastic comprises the following raw materials of: rice straw, straw, cassava starch, absolute ethyl alcohol, deionized water, natural resin powder, bamboo fiber powder, seaweed gel powder, a degradation accelerant, a modified treatment material, a filling agent, a cross-linking agent, polylactic acid, biological enzyme, a dispersing agent, a plasticizer and an antioxidant. The invention belongs to the technical field of degradable plastics. According to the degradable plastic based on the plant fiber starch and the preparation method of the degradable plastic, the use safety of a plastic product can be improved by using the plant fibers as the raw materials, the raw materials have certain environmental friendliness and reproducibility, the plant fibers have excellent biodegradability; and polylactic acid is added, the polylactic acid is a polymer obtained by polymerizing lactic acid serving as a main raw material, the raw material is sufficient in source and can be regenerated, and the production process of the polylactic acid is pollution-free.

Owner:ZHEJIANG FORESTRY UNIVERSITY

Frying pan

ActiveCN109106197AFast and even heatingReduce yellowingCooking-vessel materialsEpoxy resin coatingsMaterials scienceFrying-pans

A frying pan comprises a pan body and a pan handle, wherein the pan body comprises a first heating layer, a second intermediate layer, a third heating layer and a non-sticking layer in ascending orderfrom a bottom layer, wherein the pan handle, the first heating layer and the third heating layer are all made of stainless steel material. The frying pan of the invention is fast in heating and evenly heated. Furthermore, non-stick coating is safe and environmentally friendly.

Owner:NINGBO BEEFIT KITCHENWARE

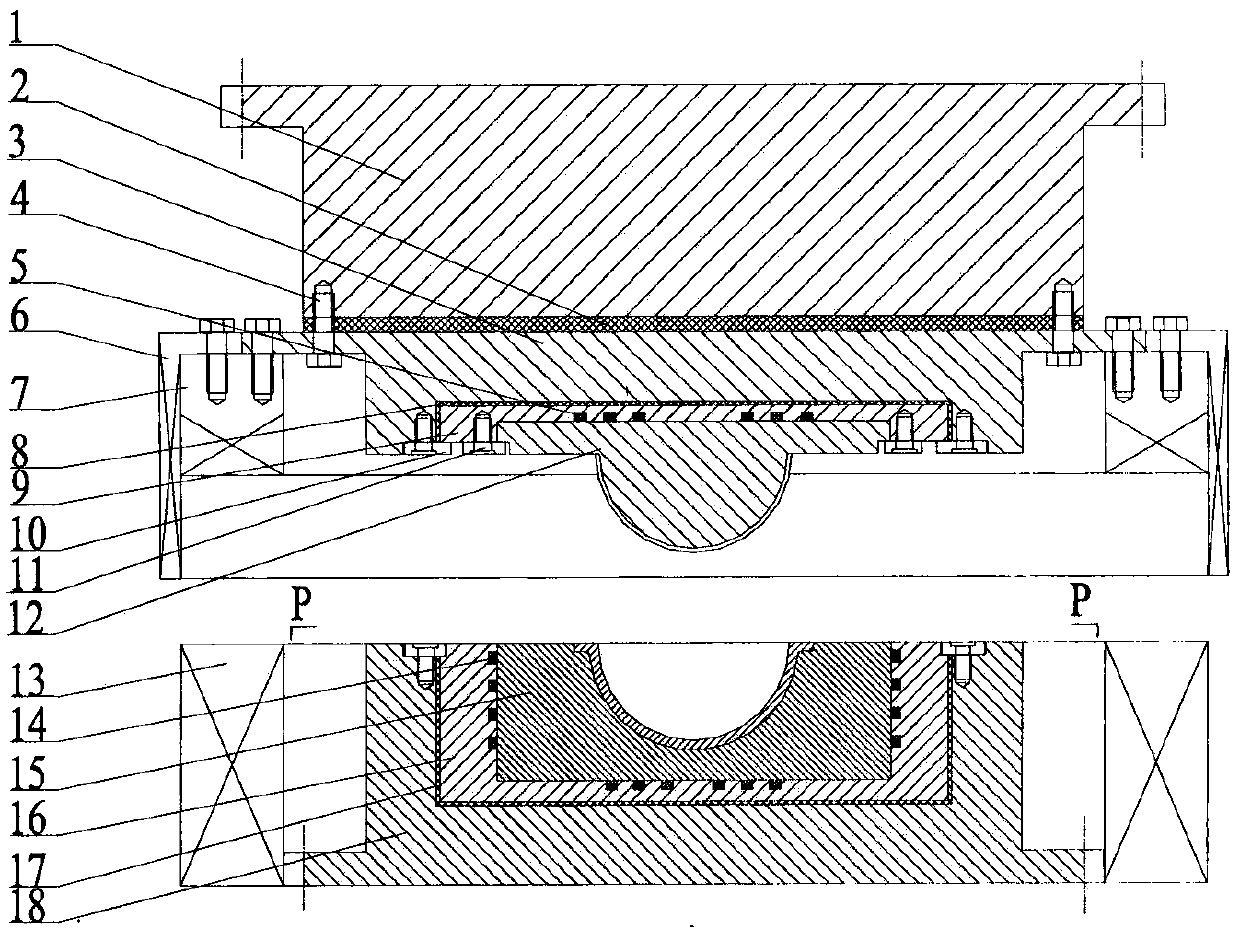

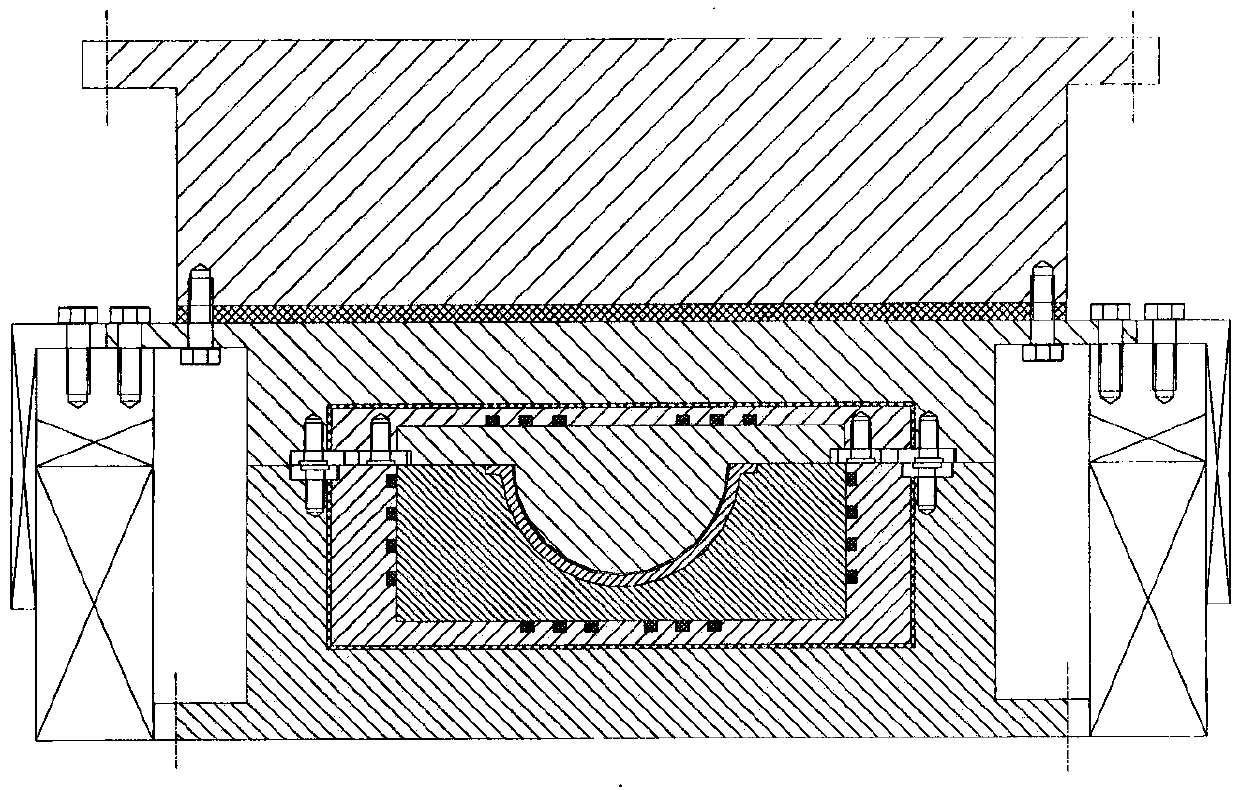

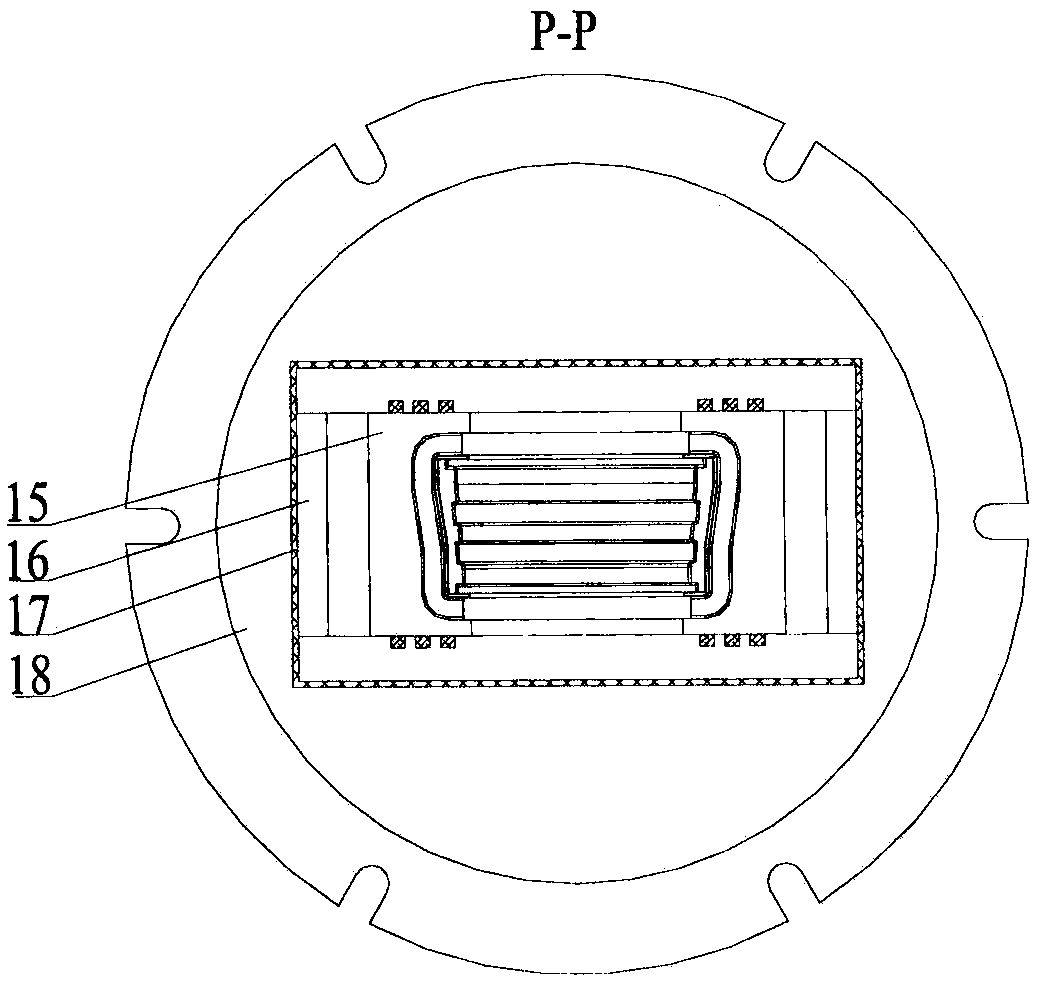

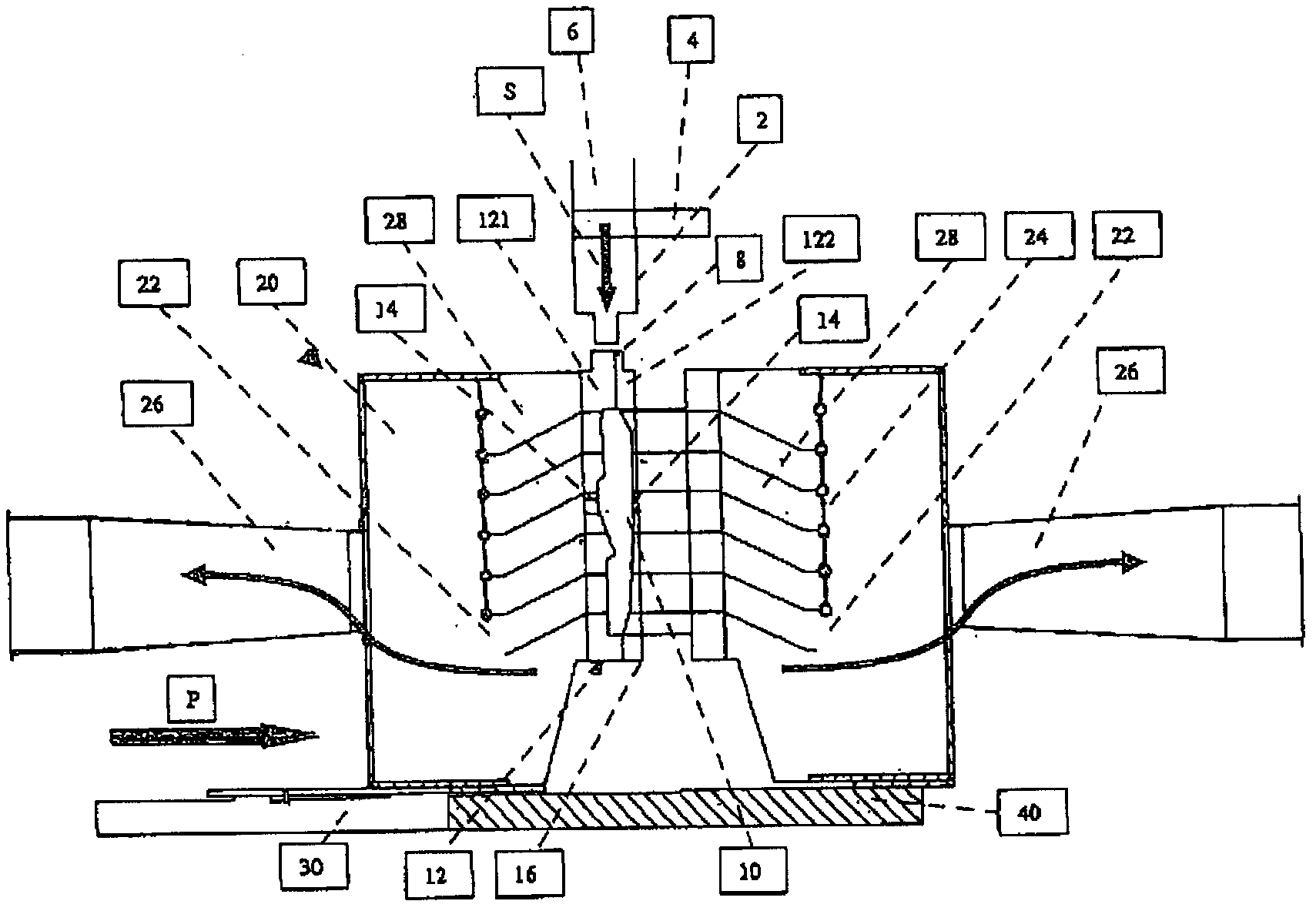

Isothermal forging die for complex aviation thin-walled part

InactiveCN103990755AReduce lossMeet the requirements of warm forgingForging/hammering/pressing machinesHeating/cooling devicesAviationHeater Rod

An isothermal forging die for a complex aviation thin-walled part comprises an upper padding plate, an upper die seat, an upper die sleeve, an upper die, an L-shaped insulation barrel, a lower die seat, a lower die sleeve, a lower die, a lower insulation barrel, an upper heating bar and a lower heating bar. Due to the number of the heating bars and the designed layout, the constant temperature of the die and a forging stock can be guaranteed, and the temperature of the forging stock in the forging process can be always kept within the best forging temperature range. The L-shaped insulation barrel is adopted, heat loss can be reduced, and it is ensured that the temperature of the die and the temperature of the forging stock are the same. The isothermal forging die for the complex aviation thin-walled part is simple and strong in universality.

Owner:CENT SOUTH UNIV

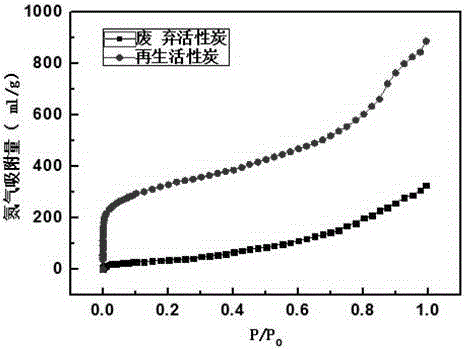

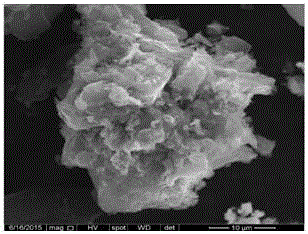

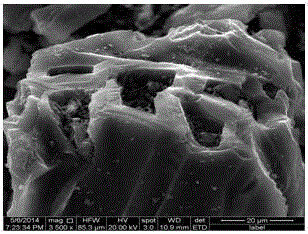

Regeneration method of waste active carbon for monosodium glutamate by supersonic wave and spray

ActiveCN105293489AImprove performanceRealize resource utilizationCarbon compoundsMonosodium glutamateActivated carbon

The invention relates to a regeneration method of waste active carbon for monosodium glutamate by supersonic wave and spray, and belongs to the field of a comprehensive utilization technology of resources. Waste active carbon for monosodium glutamate is dried at 105+-0.5 DEG C for 1.5 hours and is cooled to room temperature, the waste active carbon is placed in a microwave oven with a stirrer, when the temperature rises to 700-800 DEG C, a supersonic wave spraying apparatus is started, the normal temperature spray flow velocity is adjusted to 1-3ml / min, after 5-20 minutes of spraying, the microwave oven is closed, nitrogen is used for cooling to room temperature, and the waste active carbon for monosodium glutamate is regenerated. The waste active carbon for monosodium glutamate is used as a raw material, and spray generated by supersonic wave is used with the microwave oven, and the regeneration effect of the active carbon is greatly improved.

Owner:KUNMING UNIV OF SCI & TECH

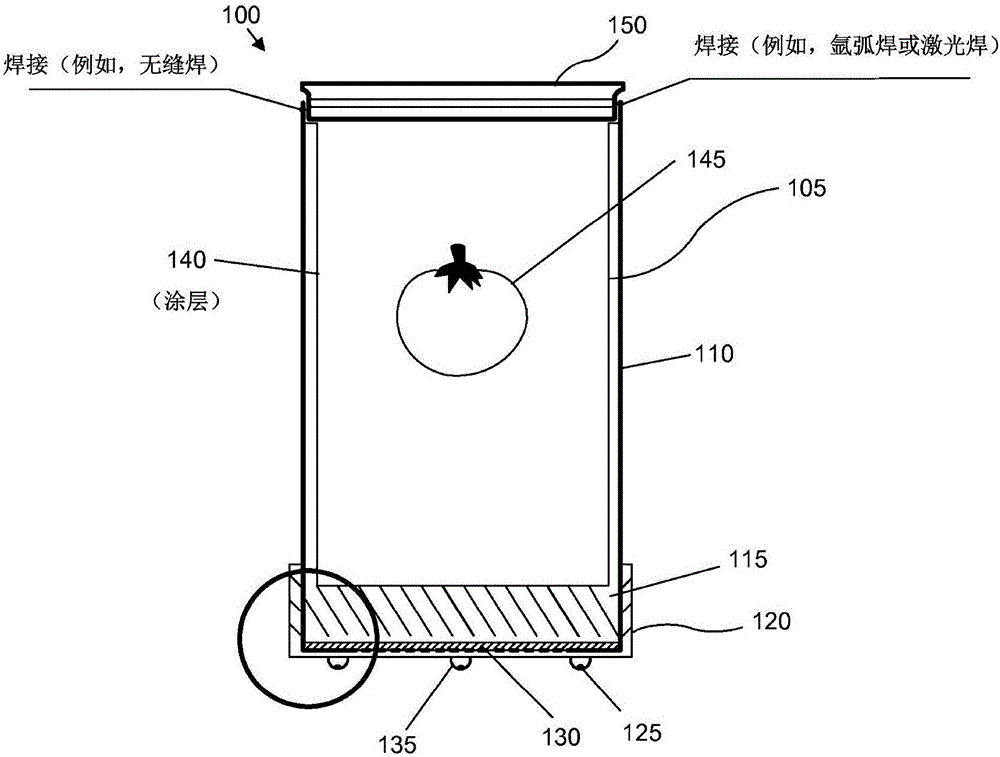

Microwaveable vessel

ActiveCN106797682AFast and even heatingFast and even cookingCooking vesselsMicrowave heatingMicrowave ovenEngineering

Some embodiments provide a microwaveable vessel that can quickly and evenly heat or cook different types of food. In some embodiments, the vessel includes a metallic body adapted to hold food or drinks. The outer portion of the body is coated with a layer of heat-generating glaze. In some embodiments, the vessel also includes a heat-resistant outer cover that covers the heat-generation layer. The vessel of some embodiments has a multi-layered structure with inner and outer shells that are joined together to form a cavity between the shells.

Owner:朴钟道

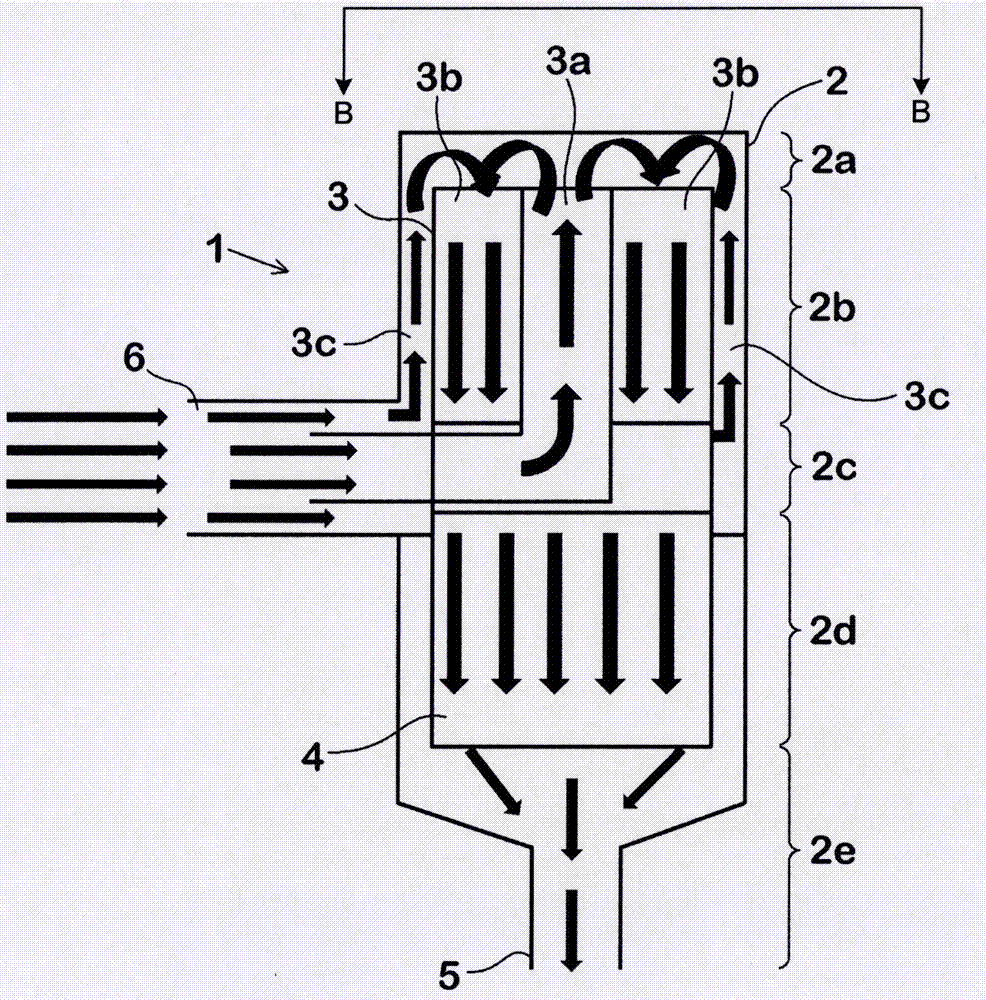

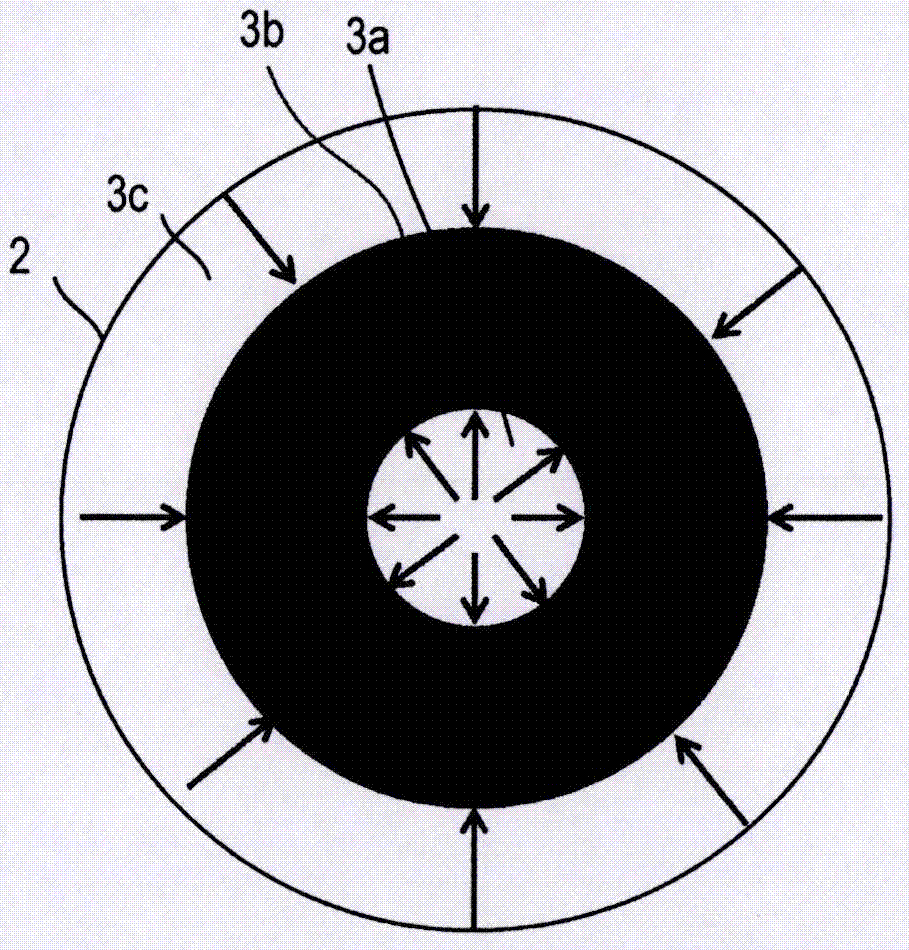

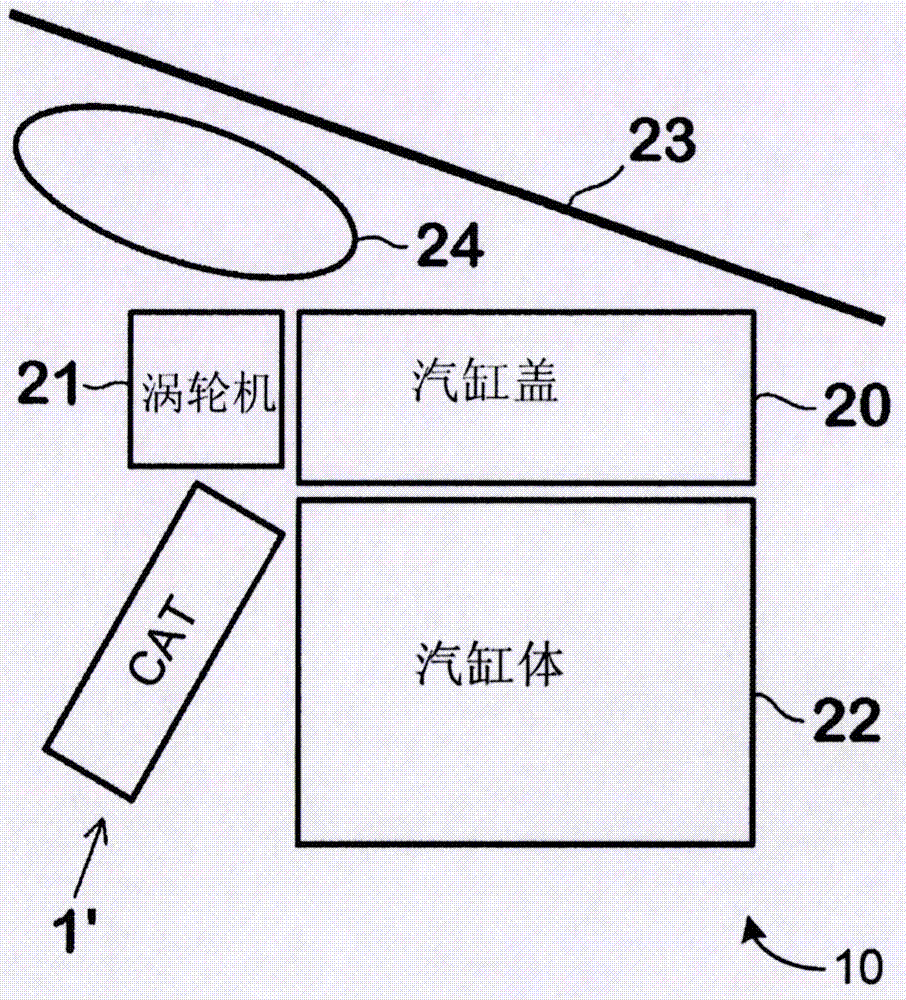

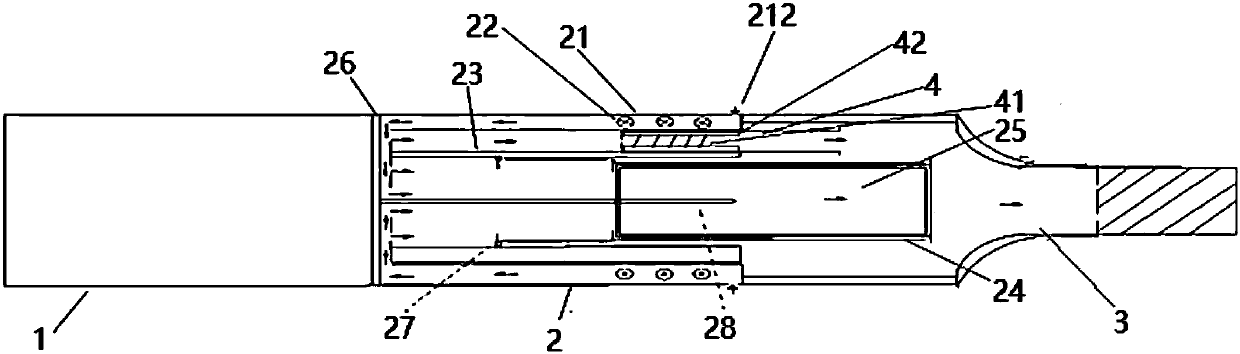

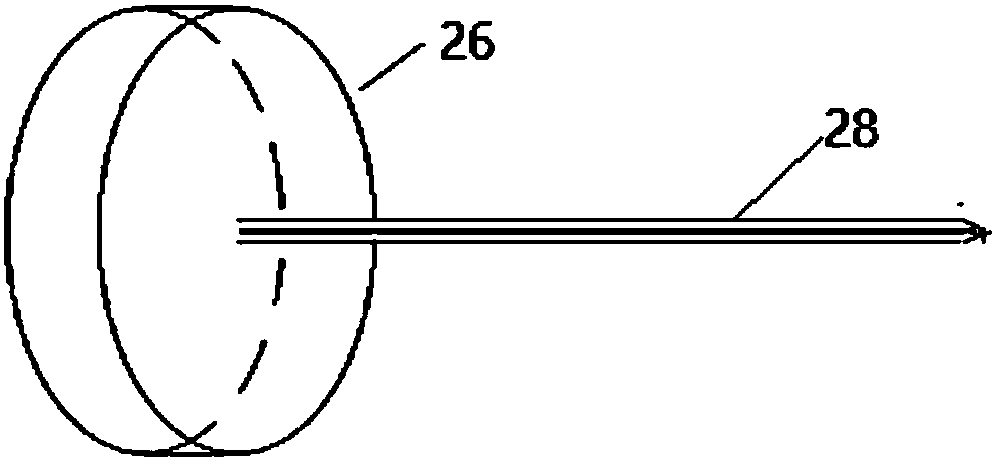

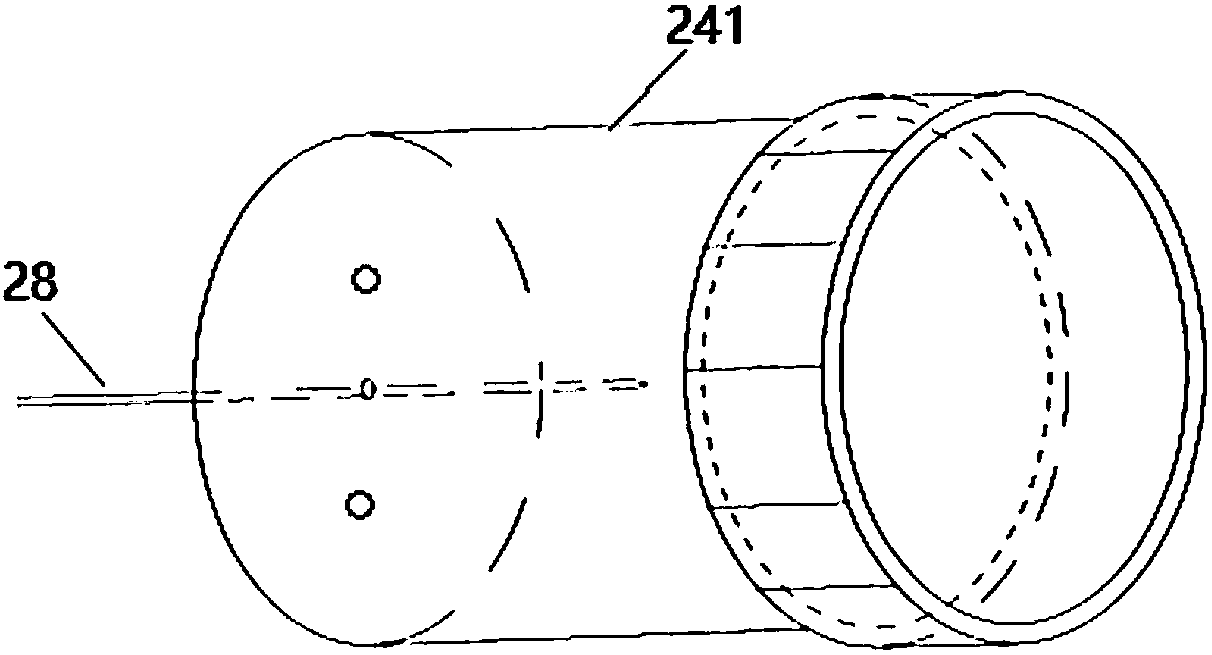

Methods and systems for an exhaust aftertreatment device

ActiveCN107035482AFaster and more focused heatingEasy to meet ignition conditionsInternal combustion piston enginesExhaust apparatusMobile vehicleParticulates

The invention relates to methods and systems for an exhaust aftertreatmetn device. Systems are provided for an exhaust gas aftertreatment device, in particular in a motor vehicle, having a catalyst accommodated in a housing which, along its length, has a first end section, a catalyst section, and a connecting section. The housing further comprises a particulate filter located downstream of the catalyst.

Owner:FORD GLOBAL TECH LLC

Method for fast and selectively nitrifying meta-xylene through microwave radiation

InactiveCN105037163AFast and even heatingHigh selectivityNitro compound preparationAcetic anhydrideGas phase

The invention relates to a method for fast and selectively nitrifying meta-xylene through microwave radiation. The method comprises the following steps of under the magic stirring, adding 4 to 8ml of chloroform into a round bottom flask; then, sequentially adding 2.0 to 4.0 mmol of meta-xylene, 3.0 to 9.0 mmol of acetic anhydride, 1.0 to 3.0 mmol of Bi(NO3)3 5H2O and 0.10 to 0.50g of zeolite molecular sieve catalysts Hbeta (500); stopping the reaction after the microwave heating for 30 to 180s; removing the catalysts through filtering; performing gas phase color spectrum analysis after the dewatering drying. A microwave technology is applied to the meta-xylene nitrifying process; the reaction process is greatly accelerated; the reaction selectivity is effectively improved; the yield reaches 56.3 percent at the 60s; the 4- / 2- ratio reaches 18.2. The method has the advantages that the operation is easy; the energy is saved; the efficiency is high; the control is easy; the method belongs to a green environment-friendly meta-xylene nitrifying method.

Owner:HEFEI NORMAL UNIV +1

Magnetic inductive composite puffing device

The invention relates to a magnetic inductive composite puffing device suitable for electronic cigarettes and low-temperature cigarettes. The magnetic inductive composite puffing device comprises a power supply control part, an atomizing part and a puffing part which are sequentially connected, wherein the atomizing part comprises a hollow outer shell; a base is arranged at one end of the outer shell; a first magnetic induction coil is arranged in the outer shell; a solid smoke forming substance is arranged in a cavity surrounded by the first magnetic induction coil; a first heating element isarranged in a part of the solid smoke forming substance corresponding to the first magnetic induction coil; the magnetic inductive composite puffing device also comprises a tobacco juice atomizing mechanism; and the tobacco juice atomizing mechanism is arranged inside or outside the cavity surrounded by the first magnetic induction coil. The magnetic inductive composite puffing device provided bythe invention can heat the solid smoke forming substances of the low-temperature cigarettes and the tobacco juice of the electronic cigarettes to form smoke at the same time, can effectively combinethe advantages of the low-temperature cigarettes and the electronic cigarettes, overcomes a defect that the low-temperature cigarettes need to wait for more than ten seconds or even longer to form thesmoke, and can be adopted to guarantee a puff number and consistency before and after puffing to the greatest extent.

Owner:CHINA TOBACCO HUNAN INDAL CORP

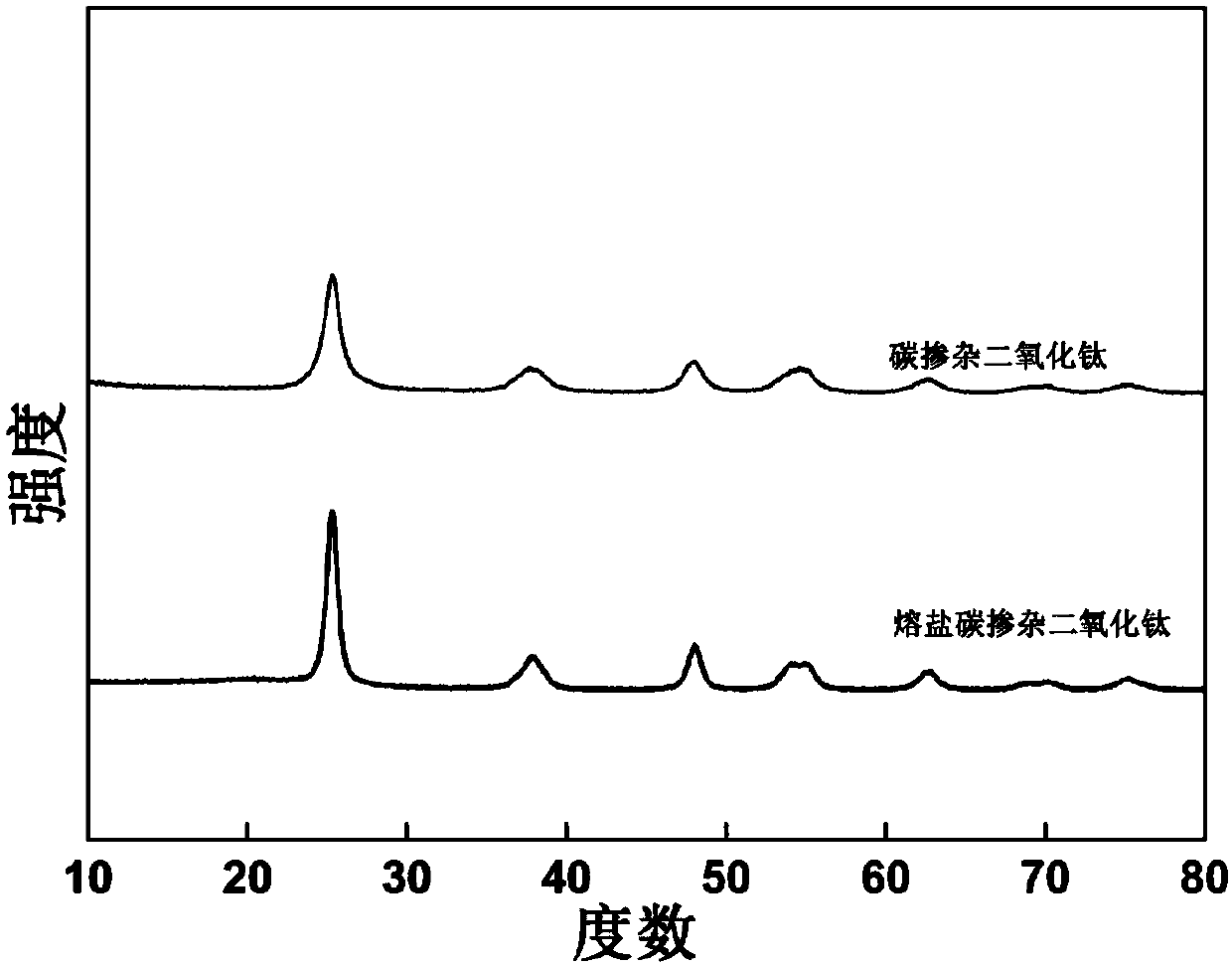

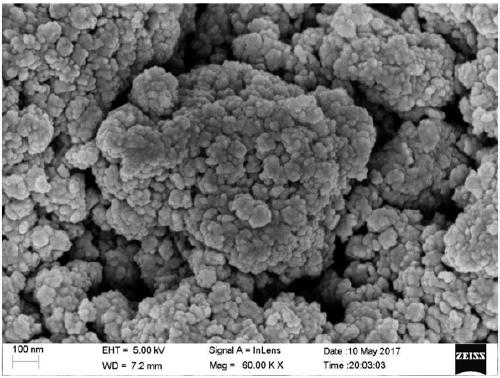

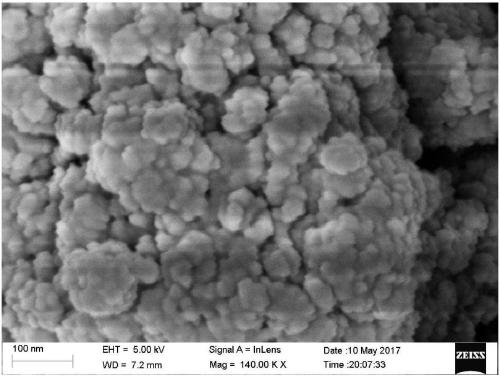

Method for preparing visible-light responsive TiO2-doped high-temperature molten salt

InactiveCN110227527AEasy to useFast and even heatingPhysical/chemical process catalystsHydrogen productionFluorescenceUv vis absorbance

The invention provides a method for preparing a visible-light responsive TiO2-doped high-temperature molten salt. The method comprises the following steps: heating a solid salt in a sealed high-temperature-resistant crucible to melt the solid salt into an ionic liquid; uniformly mixing a precursor containing a non-metallic element and a precursor material containing titanium, placing the mixture into the molten salt, and performing a reaction in an inert-gas atmosphere; and putting the obtained product into deionized water for soaking, performing centrifugal washing by using deionized water and ethanol for multiple times, and performing drying to obtain the photocatalytic material. According to the method provided by the invention, the photocatalytic material obtained by the method has obviously-enhanced ultraviolet-visible absorption spectrum (UV-vis) absorption, greatly-enhanced fluorescence performance and improved photocatalytic performance, has less gas pollution in the reaction process and cheap and reusable raw materials, and is suitable for industrial production.

Owner:WUHAN UNIV

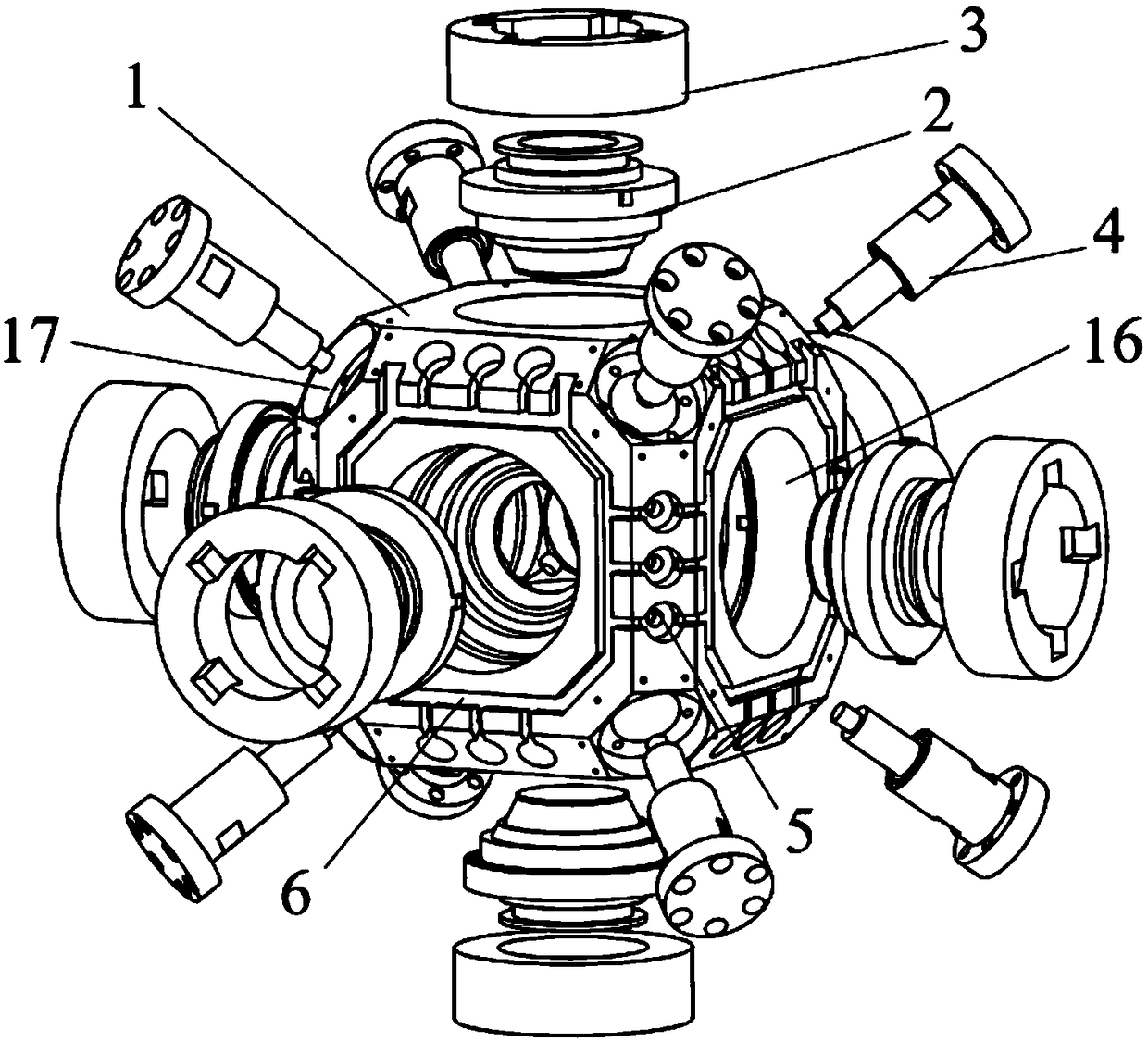

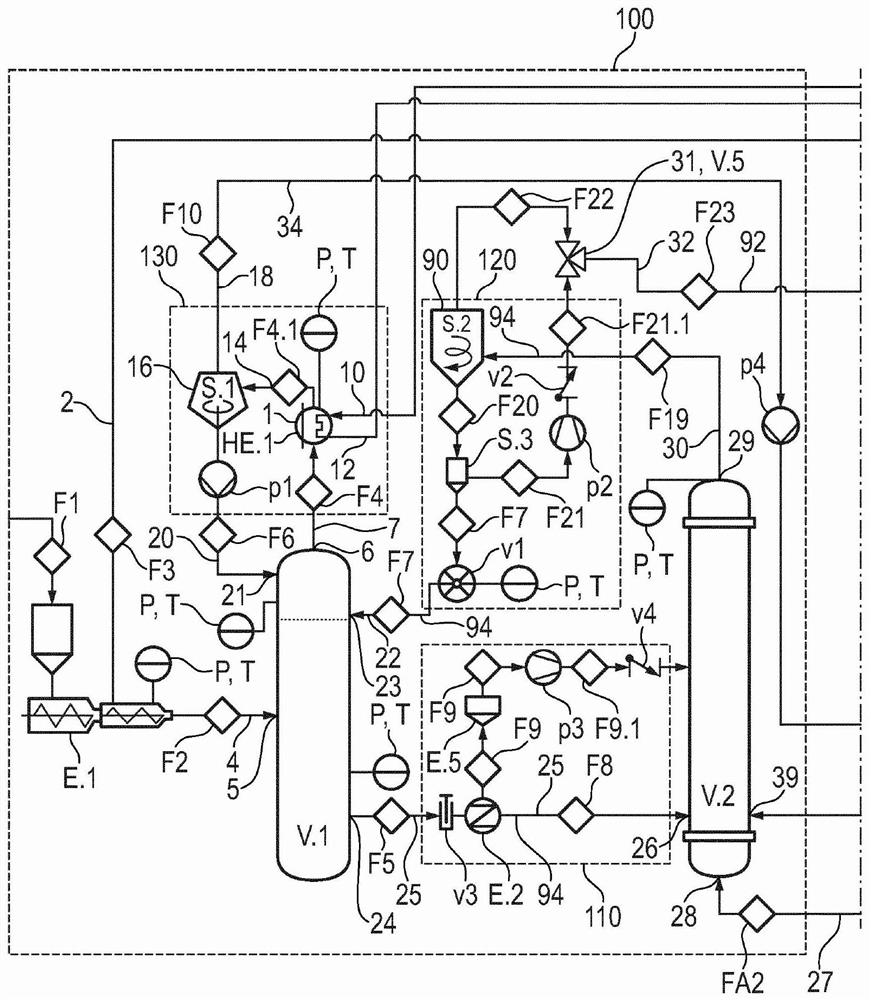

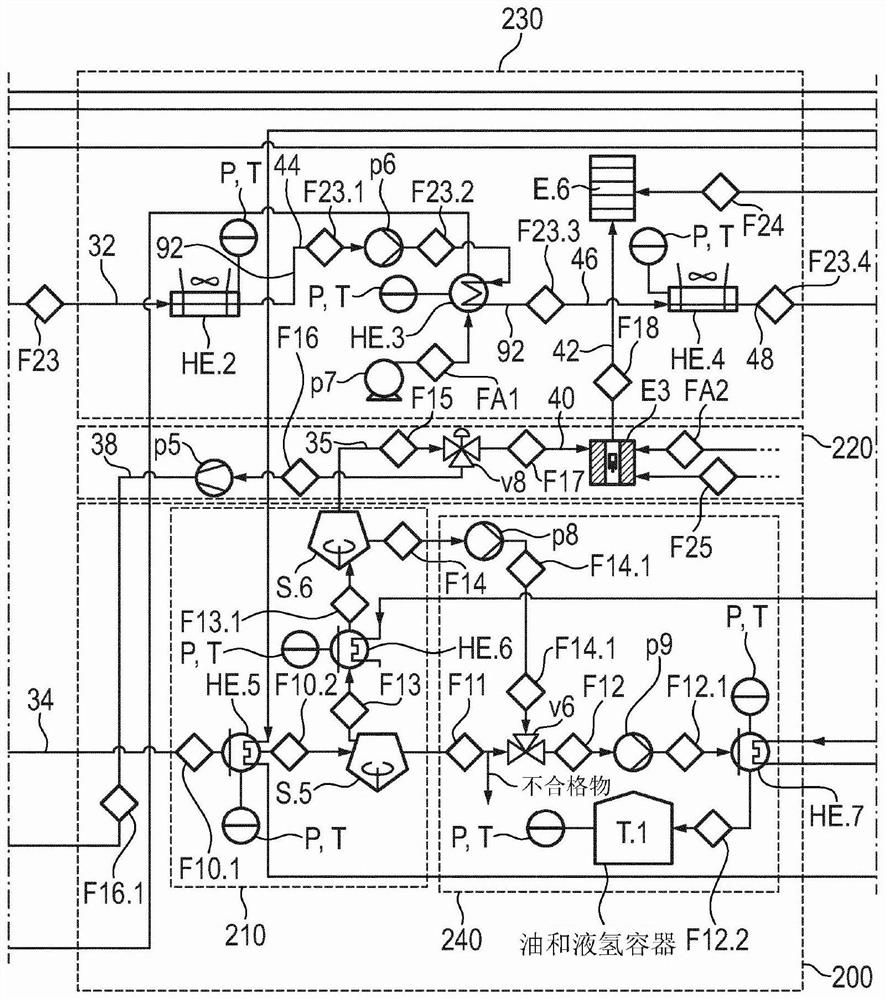

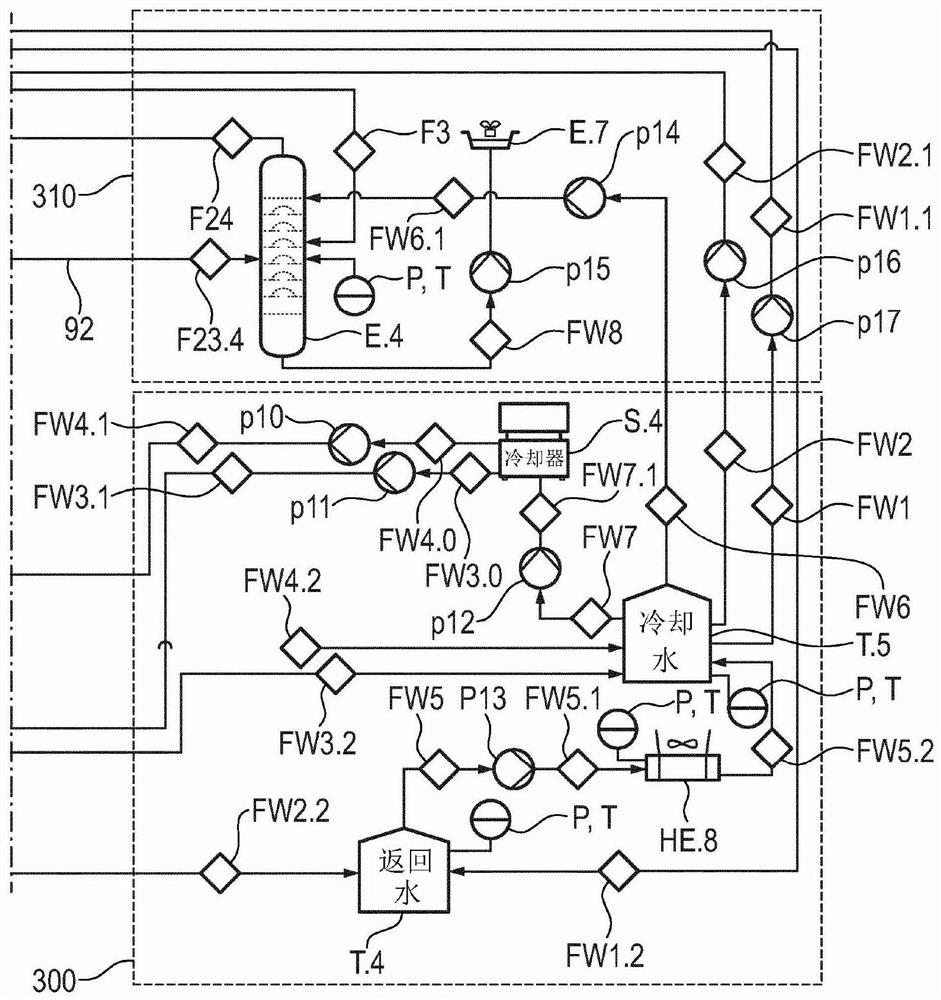

Plastic oiling plant for converting plastic waste into petrochemical products, corresponding cracking reactor and associated method

A plastic oiling plant for converting plastic into petrochemical products will be easy to build, easy to operate and easy to maintain. Operation will be energy and resource efficient. In order to achieve this object, the invention provides a system for the oiling of plastics, comprising a cracking reactor (V.1) for a pyrolysis reaction, in which plastics, in particular polyolefins, are converted into at least gasified pyrolysis products and scorched products, and further comprising a separate burner (V.2), the cracking reactor (V.1) comprises a plastic inlet port, in particular a plastic melt inlet port (5), a pellet inlet port (23), a pyrolysis product outlet port (6) and a scorch and pellet outlet port (24), and the burner (V.2) comprises a scorch and pellet inlet port (26), a combustion air inlet port (28) and a combustion product and pellet outlet port (29), the scorch and particle outlet port (24) of the cleavage reactor (V.1) is connected to the scorch and particle inlet port (26) of the burner (V.2) and the combustion product and particle inlet port (29) of the burner (V.2) is connected to the particle inlet port (23) of the cleavage reactor (V.1), the cleavage reactor (V.1) and the burner (V.2) thus being part of a particle circuit (94) containing a large number of solid particles, the pyrolysis reactor (V.1) is designed such that the mixing in the pyrolysis reactor (V.1) is mainly promoted by a flow of said particles fed at the top of the pyrolysis reactor (V.1), essentially counter-current to the flow of the pyrolysis product, without the need for mechanical mixing means, in such a way that, during operation, the particles are circulated from the pyrolysis reactor (V.1) to the burner (V.2) and are returned, the pyrolysis reactor (V.1) being designed such that the mixing in the pyrolysis reactor (V.1) is mainly promoted by a flow of said particles, which is fed at the top of the pyrolysis reactor (V.1), essentially counter-current to the flow of the pyrolysis product.

Owner:PRUVIA GMBH

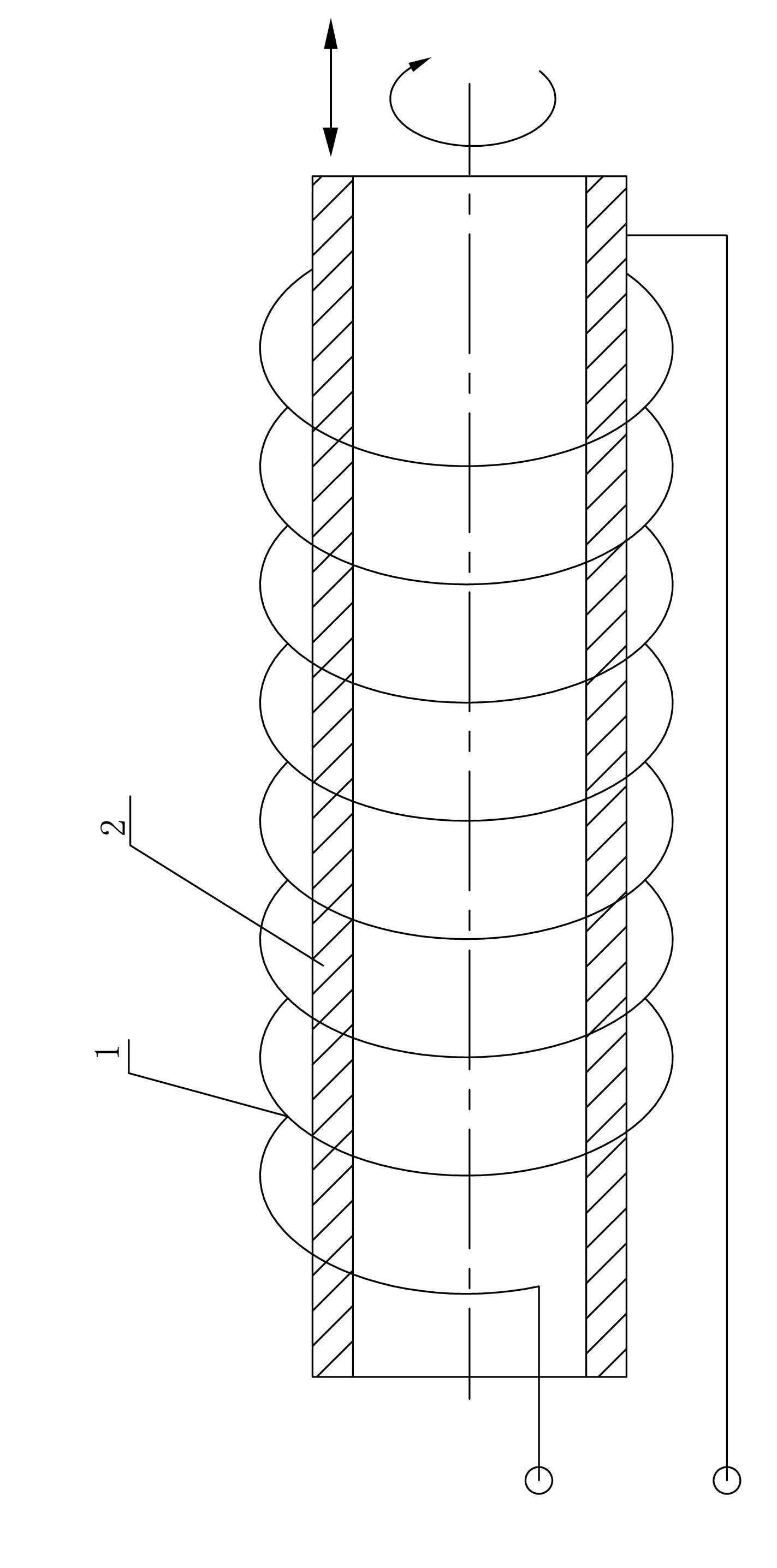

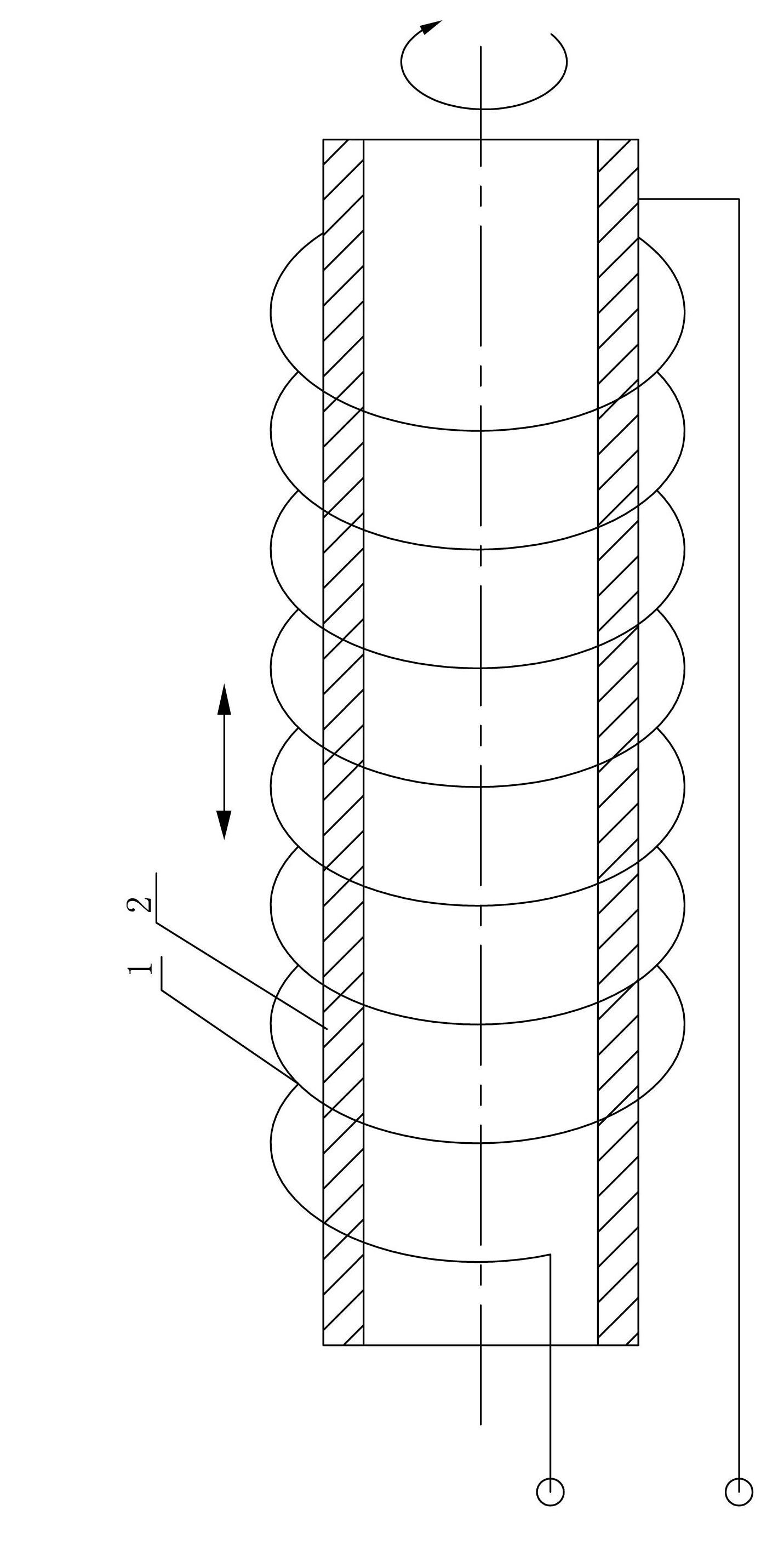

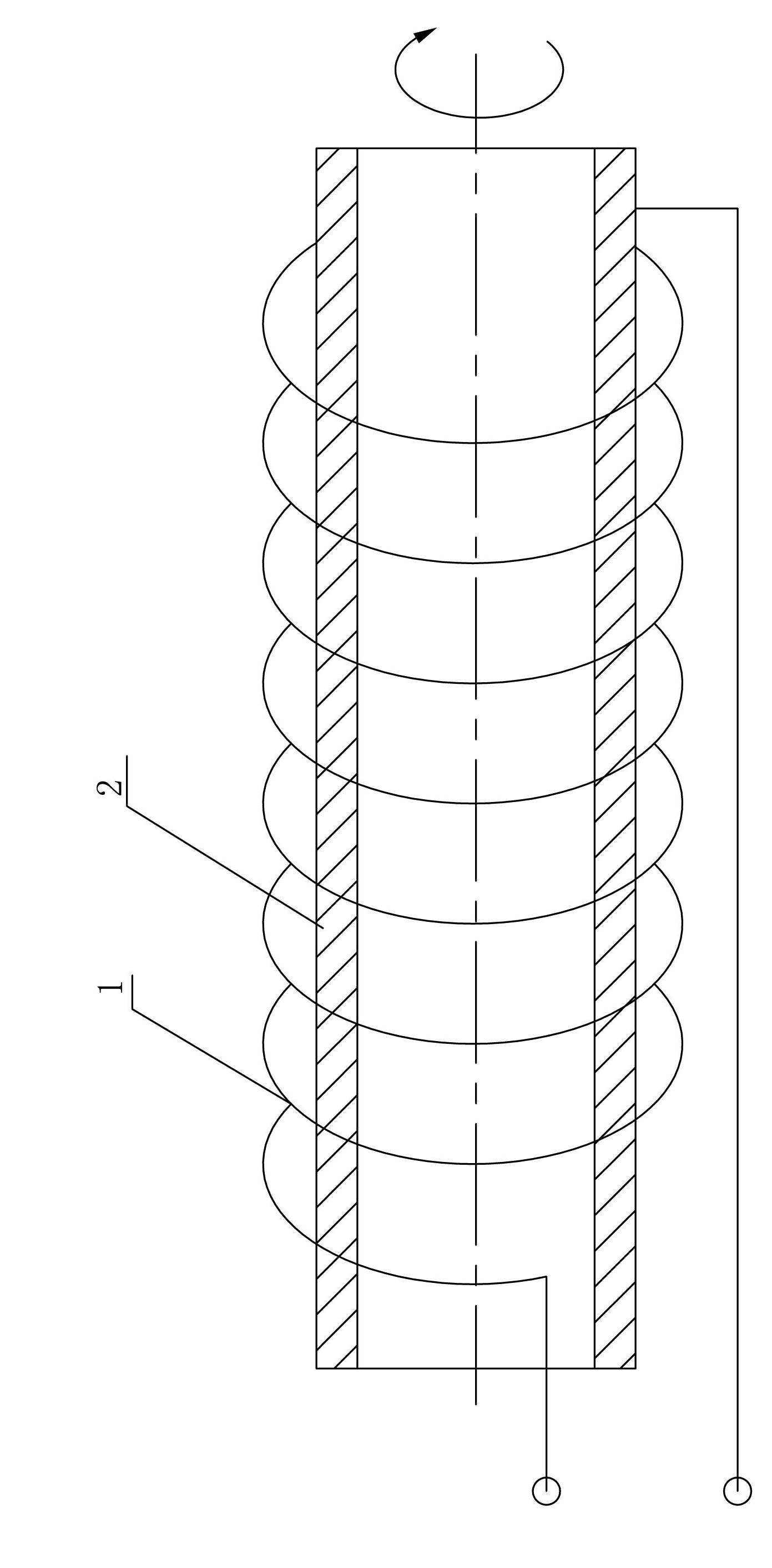

Rapid uniform heating method for metal tube

The invention relates to a heating method for a metal tube, in particular to a rapid uniform heating method for the metal tube. The heating method comprises the steps that firstly, the metal tube to be heated is placed into an induction heating coil; secondly, the induction heating coil is energized, and the metal tube is heated; thirdly, the metal tube and the induction heating coil are moved relatively when the metal tube is heated; and fourthly, the heating is stopped when the heated temperature of the metal tube reaches 300 DEG C to 1100 DEG C, and the metal tube is taken out of the induction heating coil. The rapid uniform heating method is applicable to heating metal tubes and capable of solving the problems that the circumference temperature and the axial temperature of metal tubes are unevenly distributed and the forming of the metal tubes are influenced by the uneven distributed temperatures in prior induction heating methods of the metal tubes.

Owner:HARBIN INST OF TECH

Method for removing lignin

ActiveCN103924469AFast heatingHeating speed and uniformPulping with inorganic basesChemistryMicrowave

The invention relates to a method for removing lignin. The method comprises the following steps of 1. performing alkaline treatment and microwave treatment on raw material particles so as to remove the lignin from the raw material particles, and generating hydrolysate containing the lignin; and 2. performing solid-liquid separation on solid particles retained from the raw material particles subjected to lignin removal and the hydrolysate. According to the method for simultaneously executing alkaline treatment and microwave treatment, the treatment period is short, the treatment capacity is high and the efficiency is high; furthermore, due to solid-liquid separation, the solid particles without the lignin can be used as raw materials for a subsequent technology, such as ethyl alcohol production.

Owner:中石油吉林化工工程有限公司

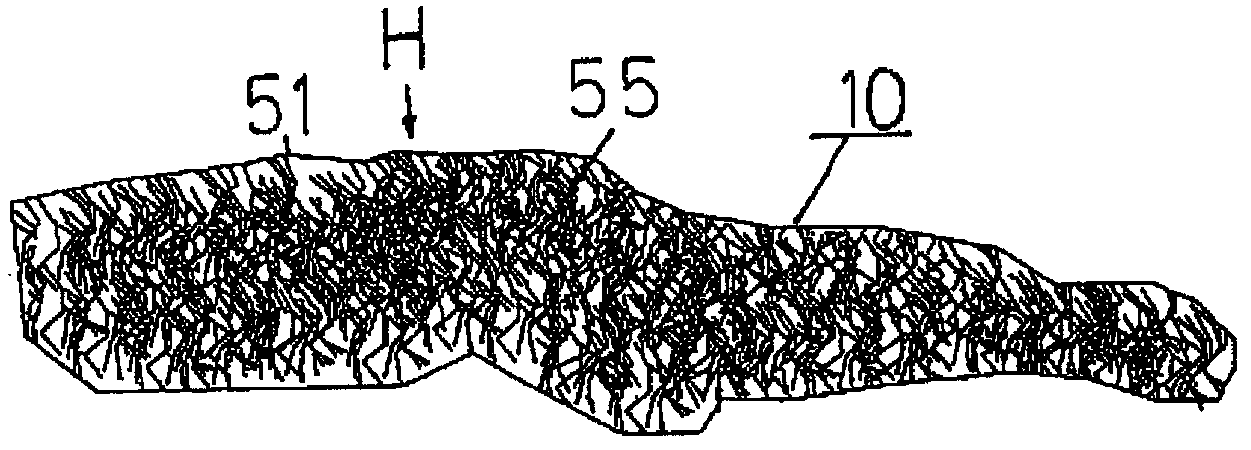

Device and method for producing a molded pulp part and molded pulp part

InactiveCN103384735AFast and even heatingSmall flow sectionWoven fabricsDomestic articlesMolded pulpFiber

The invention relates to a device for producing a molded pulp part (10), comprising a pneumatic fiber feeding apparatus (2) having an associated heating apparatus (4) having at least one heat exchanger (6) for heating up heating air and a mold (12), which has through-flow holes (14) for the transport air on at least one side, wherein the mold (12) has an outlet controller (20) arranged on the side of the through-flow holes (14), said outlet controller having a plurality of outlet openings (22), which can be closed and which are arranged one behind the other in the feeding direction of the fibers.

Owner:GRIMM SCHIRP GS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com