Multilayer press packet, packet structure and multilayer, tool and press for pressing multilayer

A technology of presses and laminates, applied in the field of plate stack structures and presses, can solve the problems of increasing the production cost of multi-layer boards or printed circuit boards, poor thermal conductivity, and time-consuming, so as to reduce processing costs and energy costs , Shorten production and processing time, improve productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

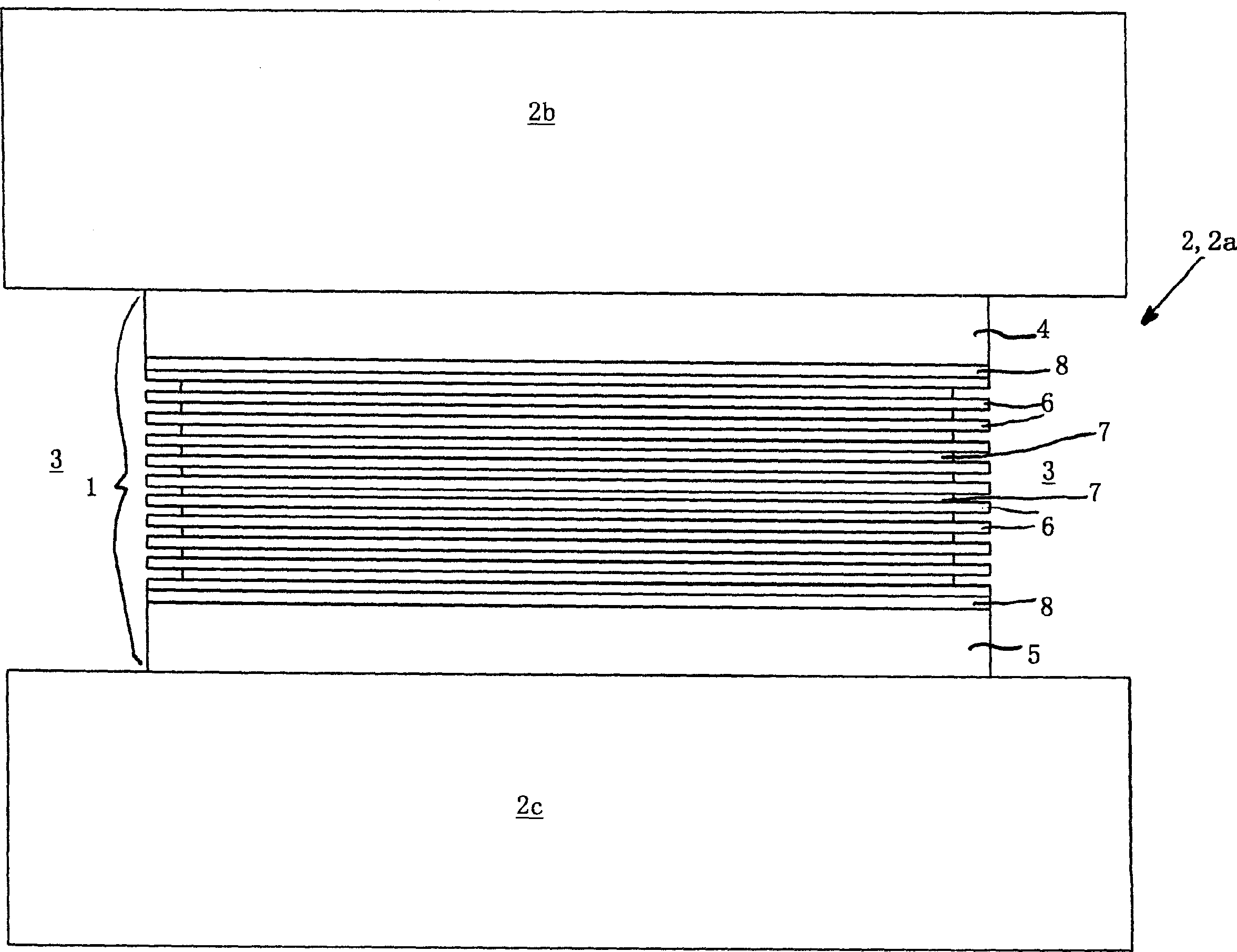

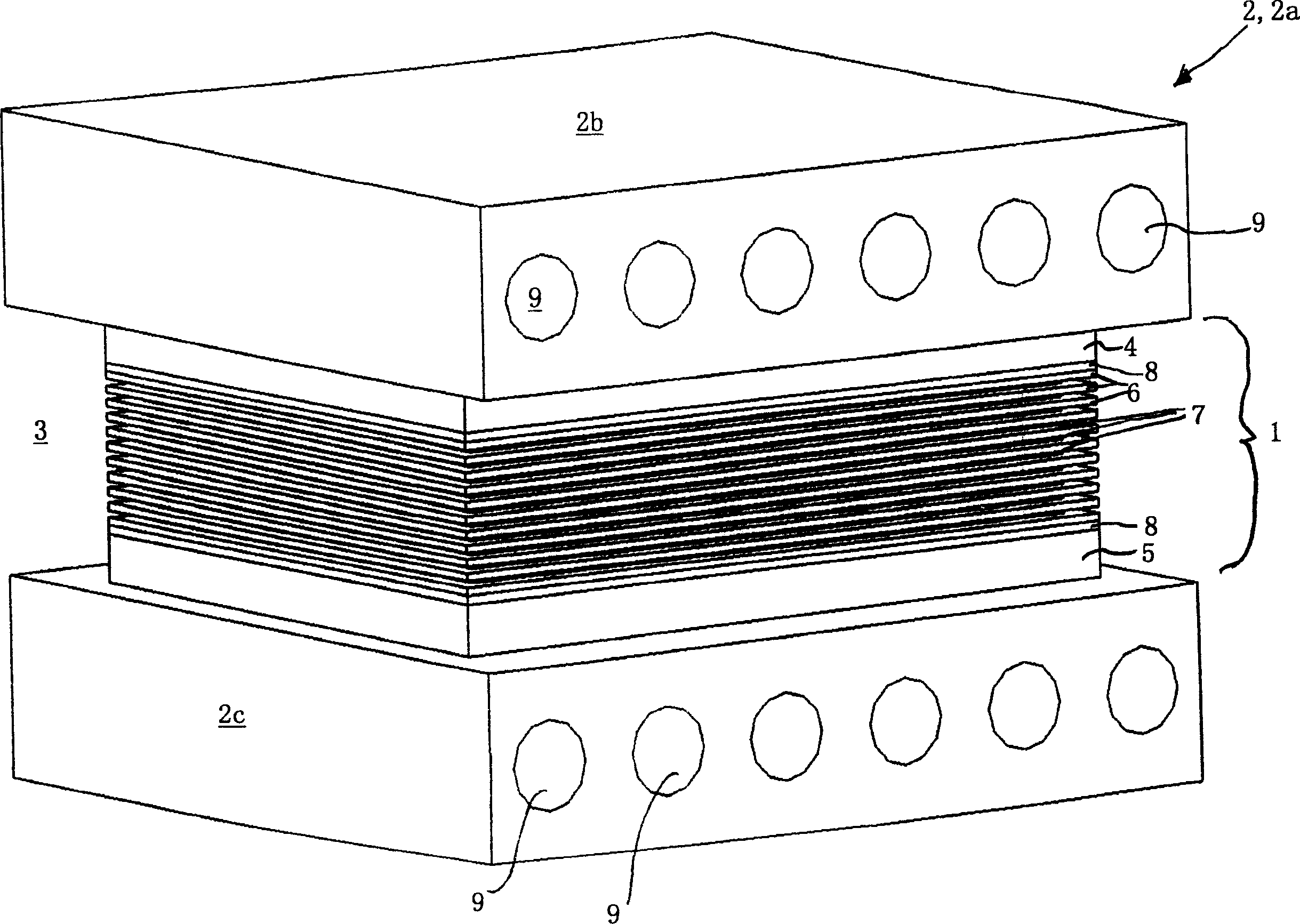

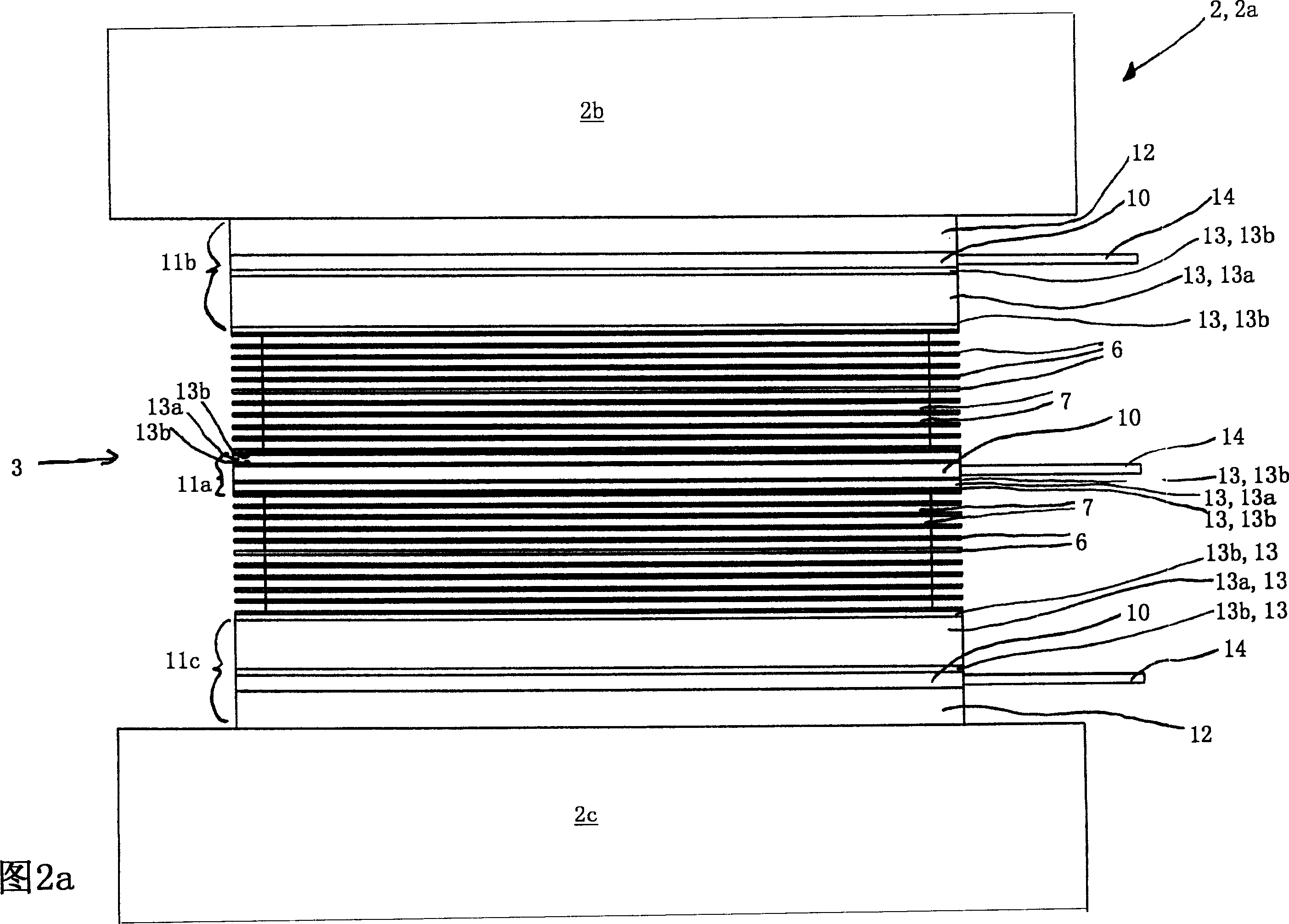

[0041] Figure 1a and 1b A side view and a perspective view, respectively, of a hitherto prior art laminate stack, wherein in the only partially shown press 2 the insertion opening 3 for inserting the only partially shown multilayer press 2a is shown here The inner plate stack structure 1.

[0042] It can be seen from the figure that the laminated core 1 known from the prior art has two tools 4 and 5 , an upper tool 4 and a lower tool 5 . Arranged between the two tools 4 and 5 are respective multi-layer plates 7 separated from one another by respective partition plates 6 .

[0043] In a press 2 conventionally used in the prior art, the thickness of the upper pressing plate 2 b and the lower pressing plate 2 c is substantially each approximately 40 mm. The tools 4 and 5, which are preferably made of low-grade alloyed steel sheets, essentially have a thickness of approximately 10 mm. Also arranged between the tools 4 and 5 and the respective adjacently arranged partition plates...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com