Degradable plastic based on plant fiber starch as well as preparation method and preparation system ofdegradable plastic

A technology of plant fiber starch and degradable plastics, applied in the field of degradable plastics, can solve the problems of food hazards, multiple chemical raw materials, and poor degradability of plastics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

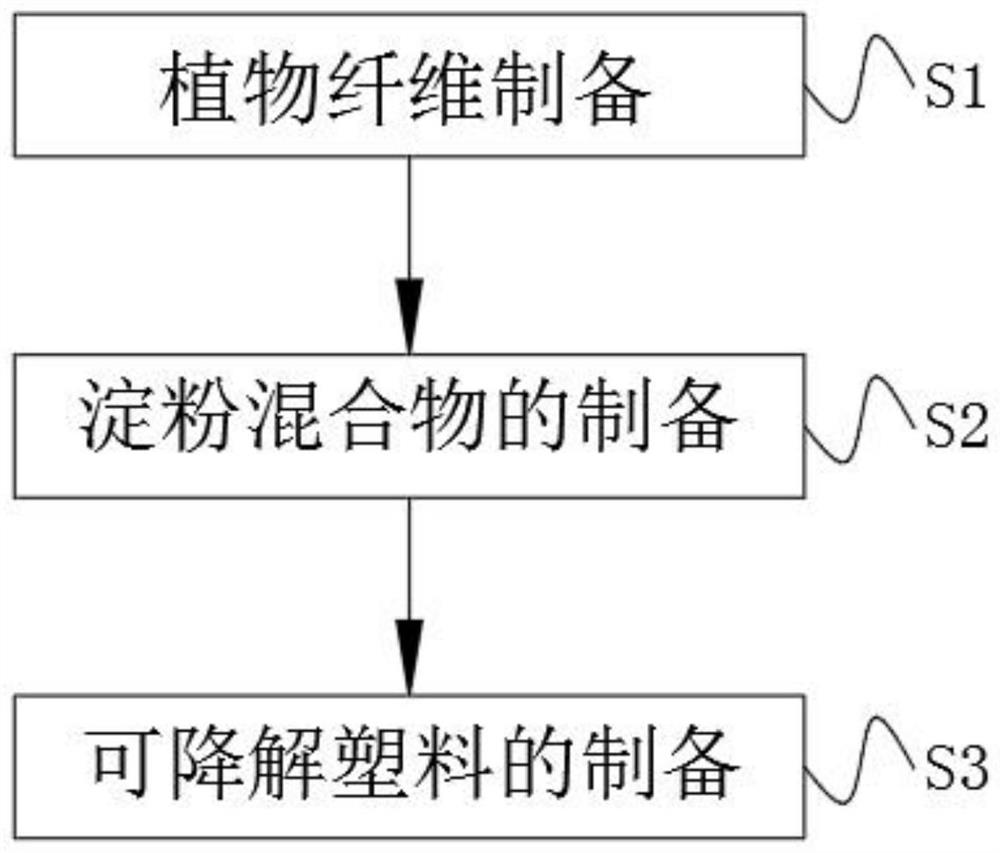

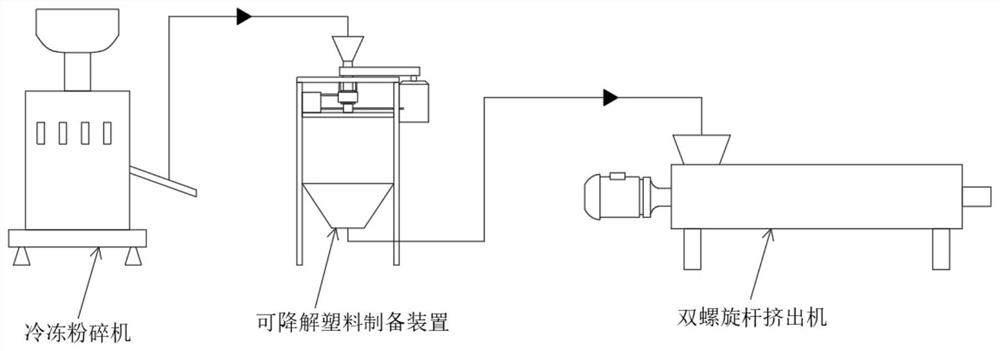

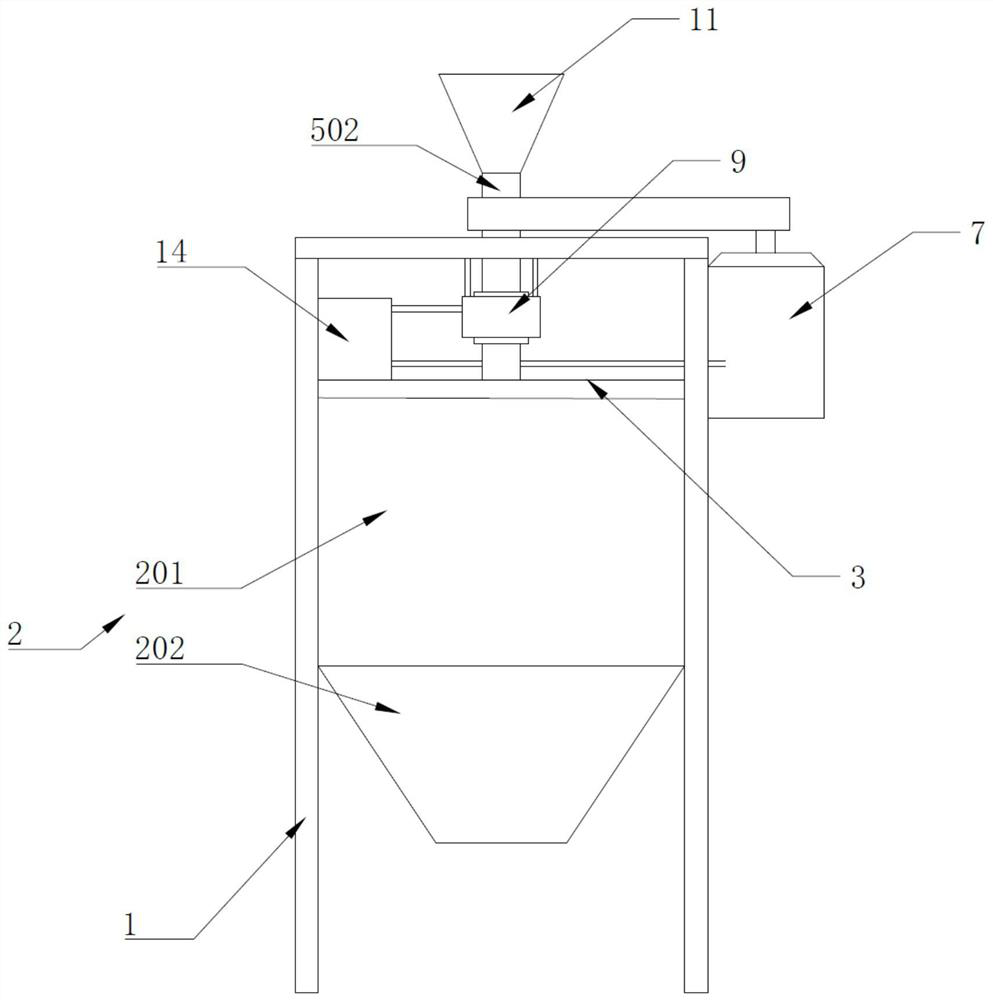

[0042] S1. Plant fiber preparation: select 25 parts of rice straw and 20 parts of straw, pour them into a freezer pulverizer for crushing, after pulverization, pass them through 60-mesh and 100-mesh sieves, and then use a ball mill to pulverize them, then pass through 100 mesh sieves. Mesh and 200 mesh sieves to obtain plant powder, then pour the obtained plant powder into a blender, add 25 parts of deionized water, start the blender for stirring, set the temperature to 200°C during stirring, and control the stirring rate at 200r / min , the stirring time is 40min, then add 17 parts of natural resin powder, set the temperature to 190°C, control the stirring speed at 200r / min, and the stirring time is 45min, and the plant fiber can be obtained;

[0043] S2. Preparation of starch mixture: select 15 parts of tapioca starch and pour it into a blender, then add 45 parts of absolute ethanol for stirring, set the temperature during stirring to 75°C, control the stirring speed at 200r / mi...

Embodiment 2

[0046] S1. Plant fiber preparation: select 20 parts of rice straw and 15 parts of straw, pour them into a freezer pulverizer for crushing, after pulverization, pass them through 60-mesh and 100-mesh sieves, and then use a ball mill to pulverize them, then pass through 100 mesh sieves. Mesh and 200 mesh sieves to obtain plant powder, then pour the obtained plant powder into a blender, add 20 parts of deionized water, start the blender for stirring, set the temperature during stirring to 150°C, and control the stirring rate at 150r / min , the stirring time is 30min, then add 10 parts of natural resin powder, set the temperature to 180°C, control the stirring speed at 150r / min, and the stirring time is 40min, and the plant fiber can be obtained;

[0047] S2. Preparation of starch mixture: select 10 parts of tapioca starch and pour it into a blender, then add 30 parts of absolute ethanol for stirring, set the temperature during stirring to 60°C, control the stirring speed at 150r / mi...

Embodiment 3

[0050] S1. Plant fiber preparation: select 30 parts of straw and 25 parts of straw, pour them into a freezer pulverizer for crushing, after pulverization, pass them through 60-mesh and 100-mesh sieves, and then use a ball mill to pulverize them, pass through 100 Mesh and 200 mesh sieves to obtain plant powder, then pour the obtained plant powder into a blender, add 30 parts of deionized water, start the blender for stirring, set the temperature during stirring to 250°C, and control the stirring rate at 250r / min , the stirring time is 50min, then add 25 parts of natural resin powder, set the temperature to 200°C, control the stirring speed at 250r / min, and the stirring time is 50min, and the plant fiber can be obtained;

[0051] S2. Preparation of starch mixture: select 20 parts of tapioca starch and pour it into a blender, then add 60 parts of absolute ethanol for stirring, set the temperature during stirring to 90°C, control the stirring speed at 250r / min, and stir for 30 minu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com