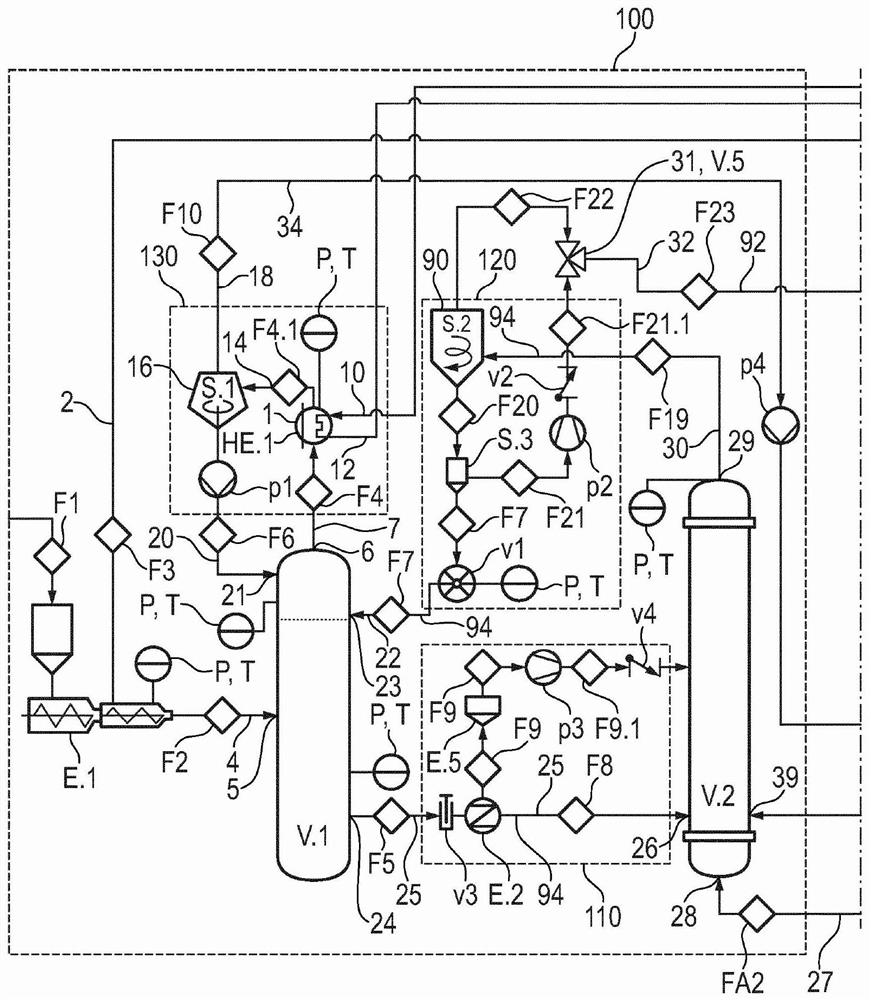

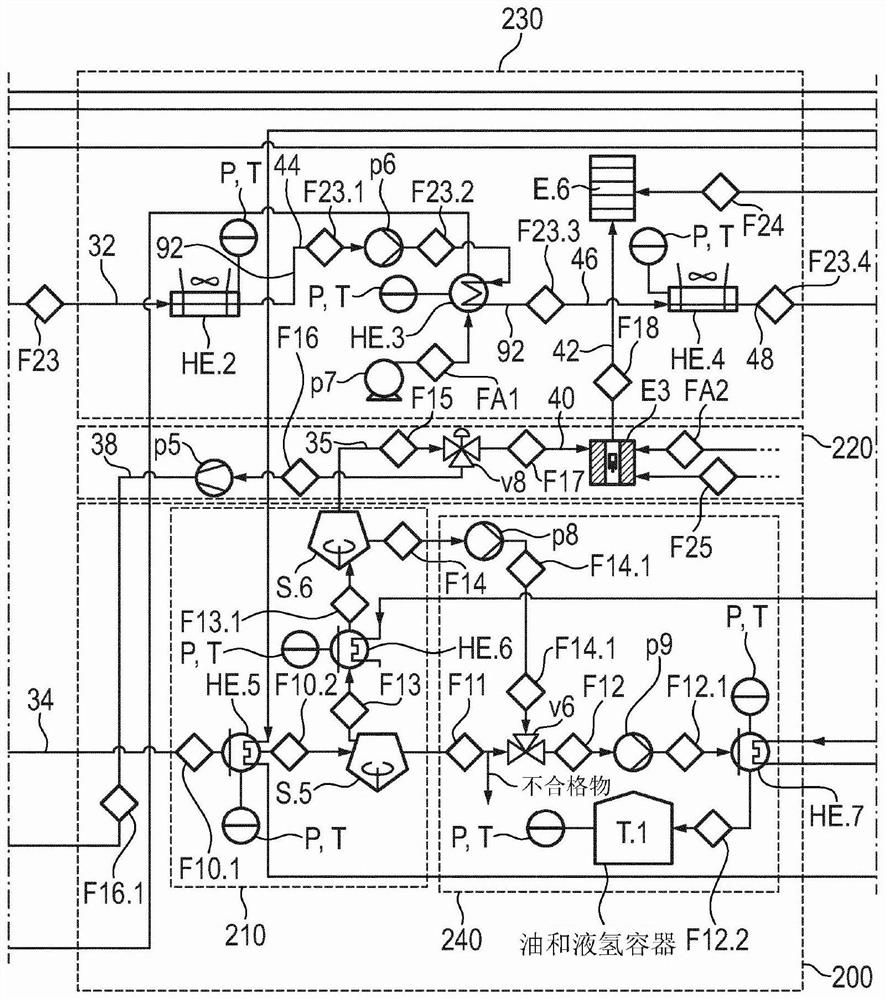

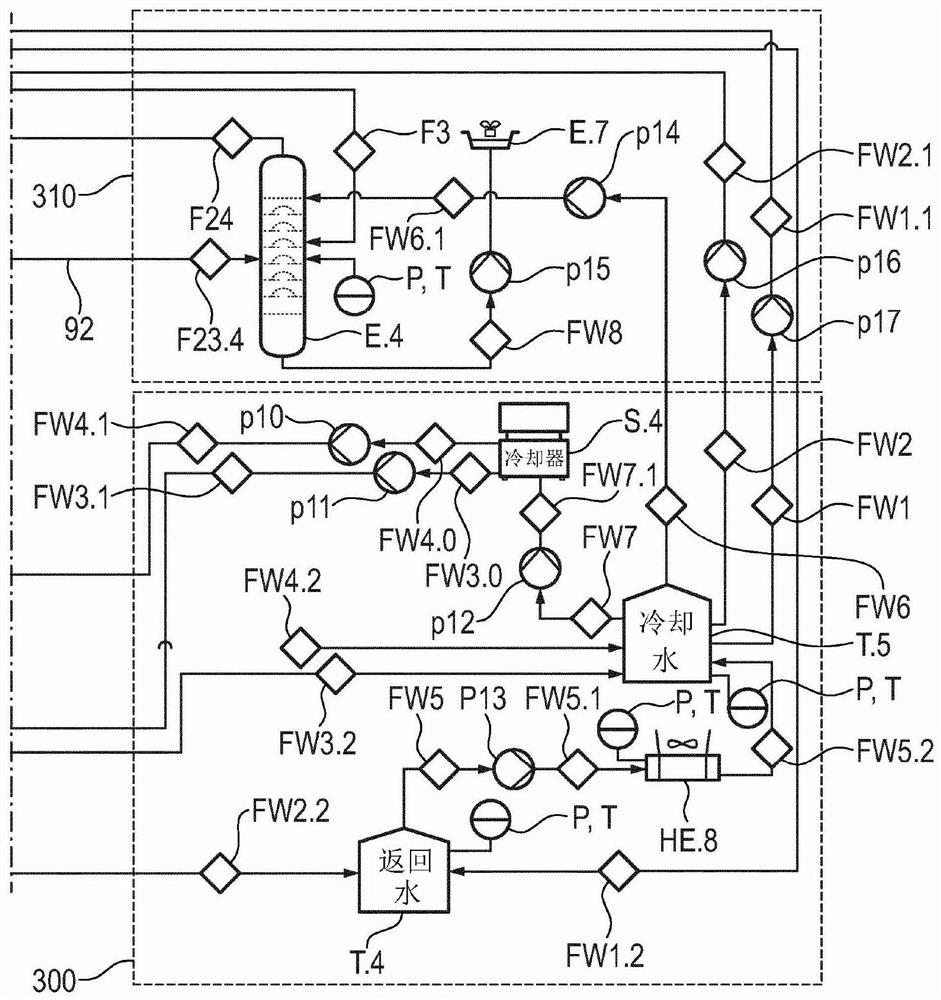

Plastic oiling plant for converting plastic waste into petrochemical products, corresponding cracking reactor and associated method

A technology of cracking reactor and chemical equipment, which is applied in chemical instruments and methods, preparation of liquid hydrocarbon mixtures, petroleum industry, etc., can solve problems such as limiting the maximum capacity of the reactor, save non-renewable raw materials, and achieve fast and uniform heating. , to avoid the effect of carbonization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] The invention is based on the following general observations.

[0075] Plastic waste: market and cost.

[0076] Originally involved in the plastic waste market: Today, small sections are actually sent to mechanical recovery plastics is limited to PET (polyethylene terephthalate) and HDPE (high density polyethylene). The remainder of the polyolefin such as LDPE (low density polyethylene), PP (polypropylene) or polystyrene (PS) market situation is not good and its value is low. All processed polymers, those polymers including heteroatom (oxygen, nitrogen, chlorine, sulfur ...), and other substances are destined to perform energy recovery after the addition of other waste (second fuel).

[0077]Correctly designed the key points of chemical treatment equipment and the plastic source for the feed of chemical processes: how the plastic source must consist, through which polymer is composed, what is the proportion; where to get and how to get, how many garbage Pouring the fee to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com