Lifting rotating spray-washing device

A technology of lifting, rotating and spraying washing device, applied in the field of washing, can solve the problems of increased cost of water, incomplete washing, waste of energy and water sources, etc., and achieves the effects of reliable performance, sufficient washing and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to further understand the content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

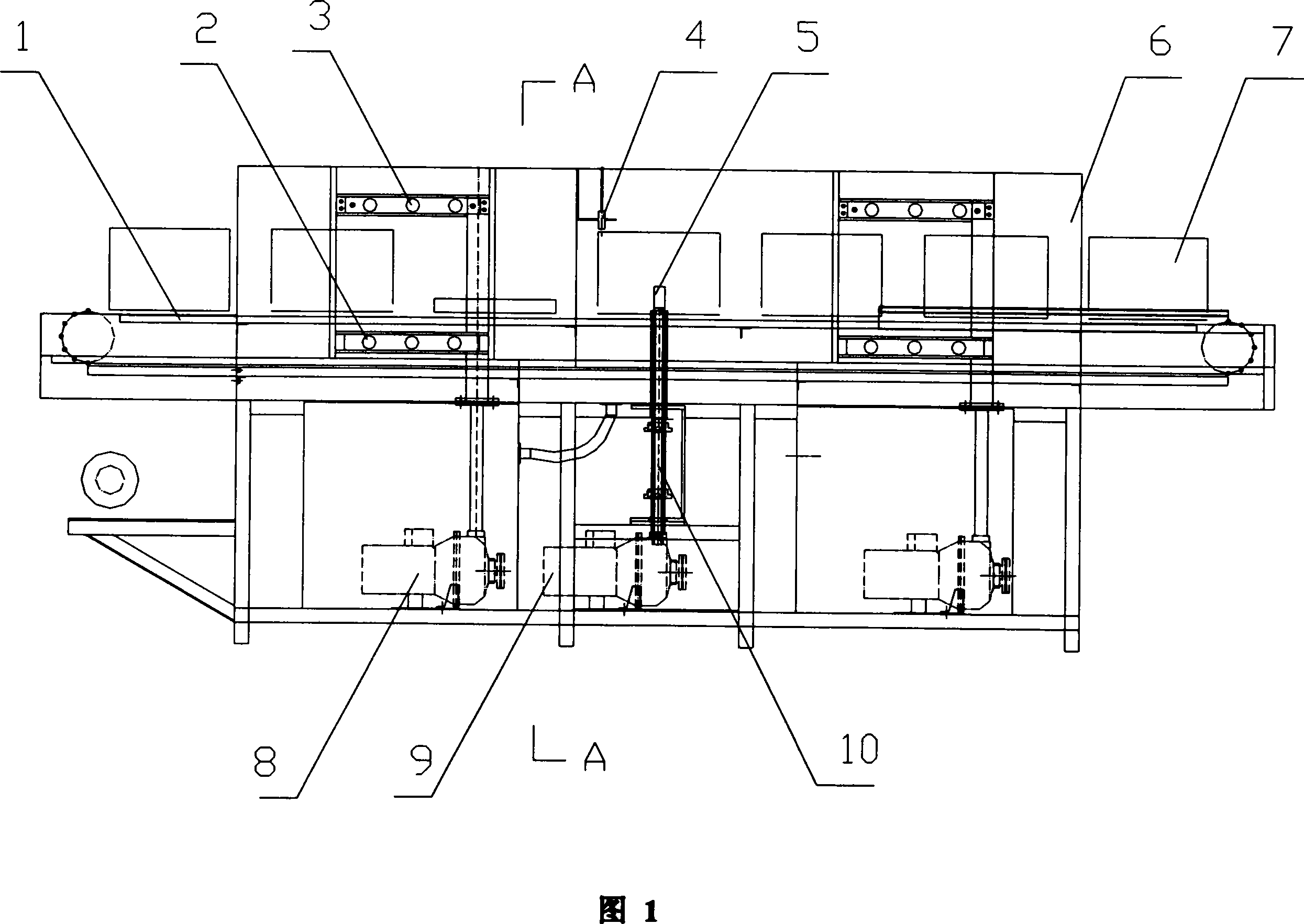

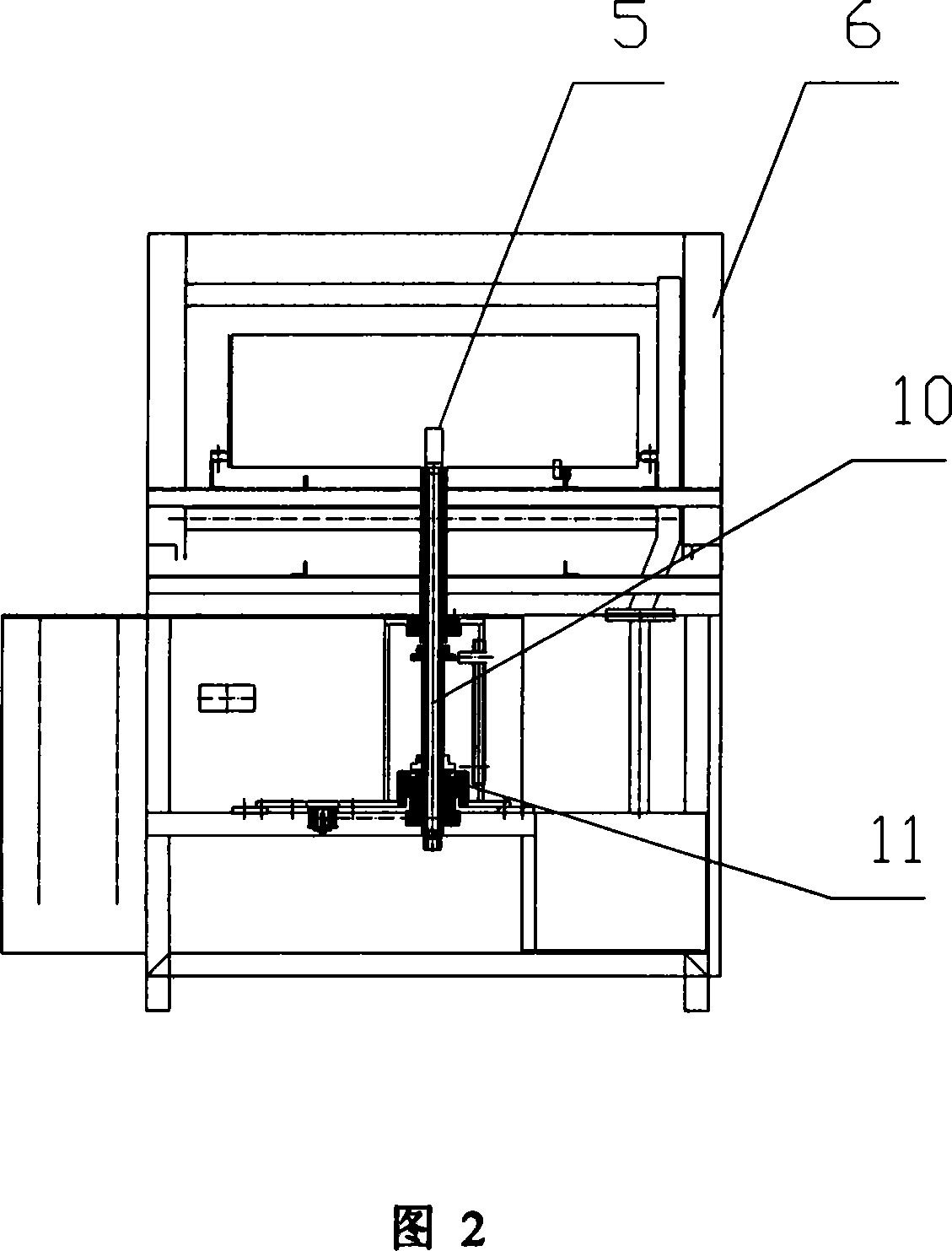

[0018] Refer to accompanying drawing 1 and Fig. 2.

[0019] The lifting and rotating spray washing device includes a fuselage, a conveying device, and a spray washing device, and a conveying device 1 and a spray washing device 3 are installed on the fuselage 6 . Spray mechanism is made up of water tank, water pump 8 and connects lower spray pipe 2 and upper spray pipe 3 through pipeline. The fuselage 6 is equipped with a lifting rotary spray head 5 and a control device, and the control device is connected to control the transmission device 1, the spray washing device and the lifting rotary spray head 5. The lifting rotary nozzle 5 is connected with a high-pressure water pump 9, and the high-pressure water pump 9 is connected with a water tank. The el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com