Polyester/cotton interwoven fabric dyeing and fishing process

A process and fabric technology, applied in the field of dyeing and finishing of polyester-cotton interwoven fabrics, can solve the problems of reduced performance, poor environmental friendliness, reduced quick-drying effect, etc., and achieve the effects of improved durability, good color fastness and bright color.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] In the printing process, when mixing pulp, first mix the disperse dyes with cold water, add the paste and stir evenly, then add the reactive dye solution and stir evenly, and at the same time add anti-dyeing salt to prevent the dye from being reduced and discolored during steaming.

[0060] The baking temperature is controlled at 205-215°C, and the baking time is 2-4 minutes, so the fiber and color paste absorb more moisture and swell better, which is conducive to the diffusion of disperse dyes into the fiber, and the slurry is easy to wash off when washing with water.

[0061] Use a fast steamer to fix the color, and the cloth speed of the steamer is controlled at 15-60 m / min. In the case of changes in the steam intake, cloth type, and liquid volume, the temperature is controlled by adjusting the amount of steam entering the steamer. The total heat is for heat balance. The steaming formula is: caustic soda 22g / l, soda ash 148g / l, sodium chloride 98g / l, potassium carbona...

Embodiment 2

[0064] Repeat the same steps as described in Example 1, the baking temperature is 210°C, and the baking time is 3 minutes; the steaming formula is: caustic soda 25g / l, soda ash 150g / l, sodium chloride 100g / l, potassium carbonate 100g / l, the steaming washing temperature is 135°C; the finishing liquid formula is: moisture absorption quick-drying agent 60g / l, fixing agent 20g / l, penetrating agent 2g / l.

Embodiment 3

[0066] Repeat the same steps as described in Example 1, the baking temperature is 215°C, and the baking time is 4 minutes; the steaming formula is: caustic soda 27g / l, soda ash 153g / l, sodium chloride 103g / l, potassium carbonate 105g / l, the steaming washing temperature is 137°C; the finishing liquid formula is: 65g / l of moisture-absorbing quick-drying agent, 24g / l of fixing agent, and 3g / l of penetrating agent.

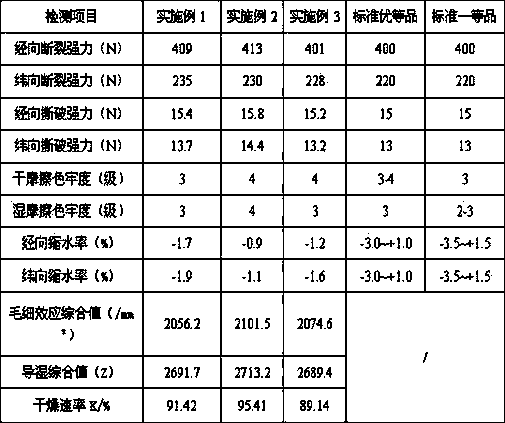

[0067] After the above processes, the fabric samples were taken out for testing.

[0068]

[0069] The basic safety technical indicators are inspected according to the test method specified in GB18401-2010.

[0070] The breaking strength shall be carried out according to GB / T 3923.1-1997: take the sample after the whole dyeing and finishing process, take a 30cm*6cm strip sample, five warps and five wefts, remove the yarn on the long side of the strip sample, so that the long side of the strip sample is continuously contained Yarn, and the effective length of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com