Knitted fabric processing device

A technology for processing equipment and knitted fabrics, applied in the field of textile printing and dyeing, can solve the problems of difficult control of the processing quality of knitted fabrics, high tension of the padding device, poor washing method, etc., and achieves easy control of processing quality, uniform response speed, and response speed. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

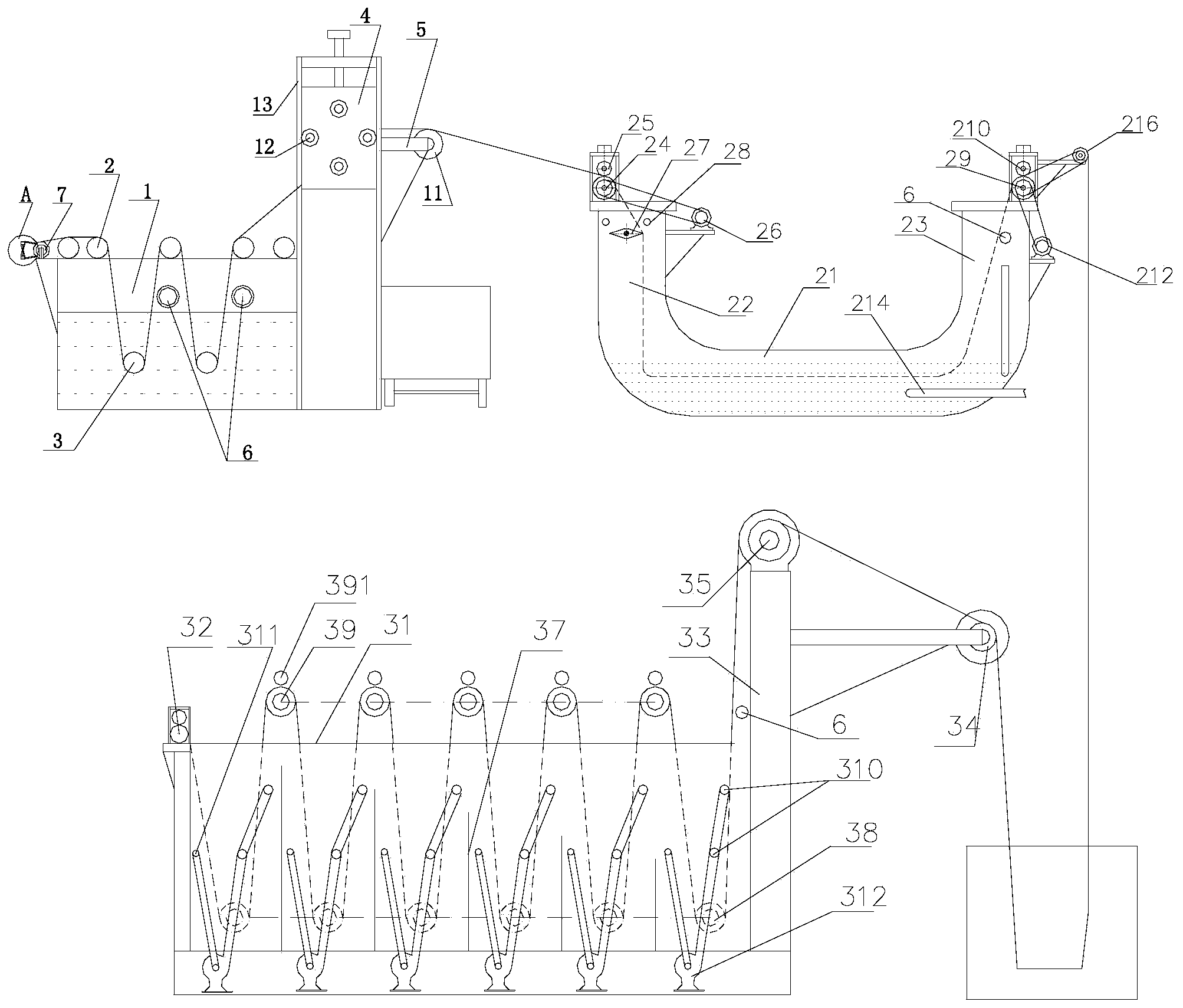

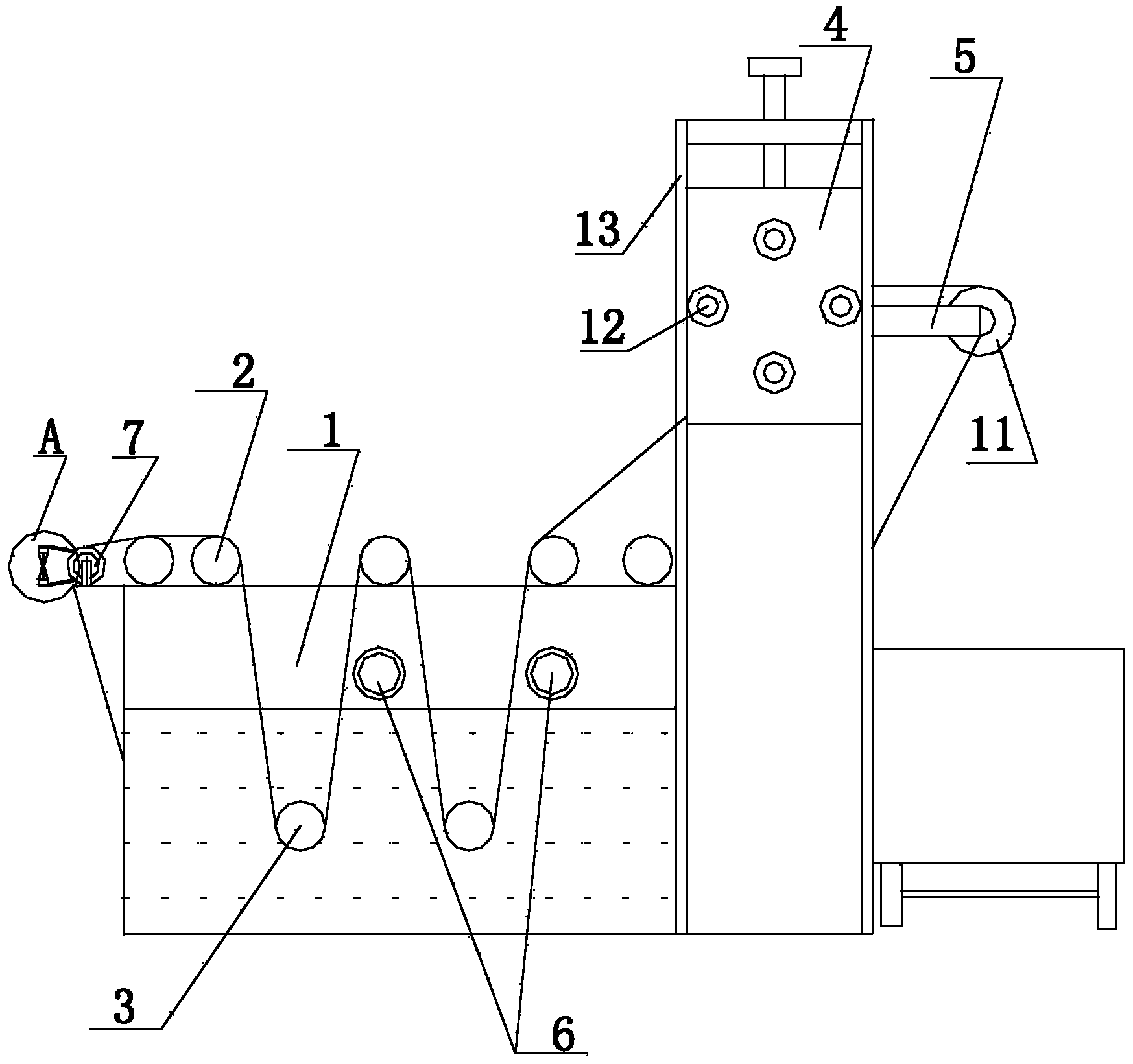

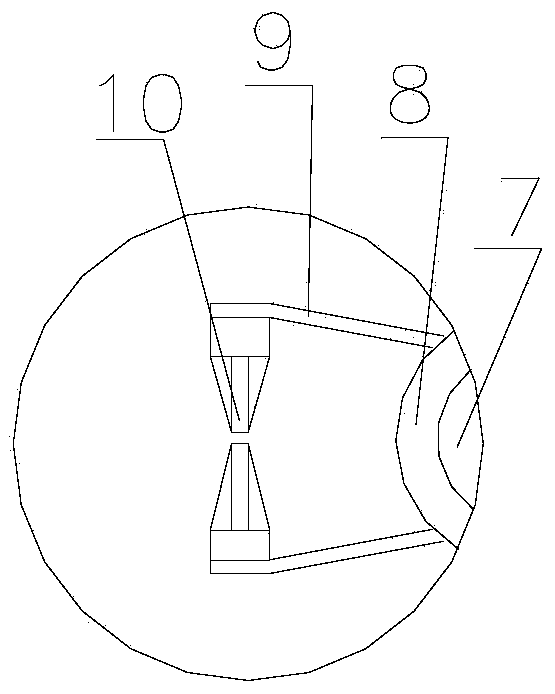

[0037] like figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the knitted fabric processing equipment includes a knitted fabric open-width padding device, a knitted fabric heat treatment device and a knitted fabric tubular open-width water washing device, which are arranged in sequence. The rolling tank 1 of the solution, several upper rollers 2 and lower rollers 3 arranged parallel to each other on the upper and lower parts of the rolling tank 1, and a drag roller device 4 for dragging the knitted fabric to convey in a certain direction, the cloth drop Device 5; knitted fabric heat treatment device, including a stacking box 21 for containing washing and coloring liquid; knitted fabric tubular open-width water washing device includes box body 31; Between the cylinders 3, there is an aeration tube 6 parallel to the upper cylinder 2 and the lower cylinder 3, which is located above the liquid level of the washing and padding solution in the rolling tank 1. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com