Basal plate cleaning system and method

A technology for cleaning systems and substrates, applied in cleaning methods and utensils, cleaning methods using liquid, chemical instruments and methods, etc. Efficiency reduction, low surface tension effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

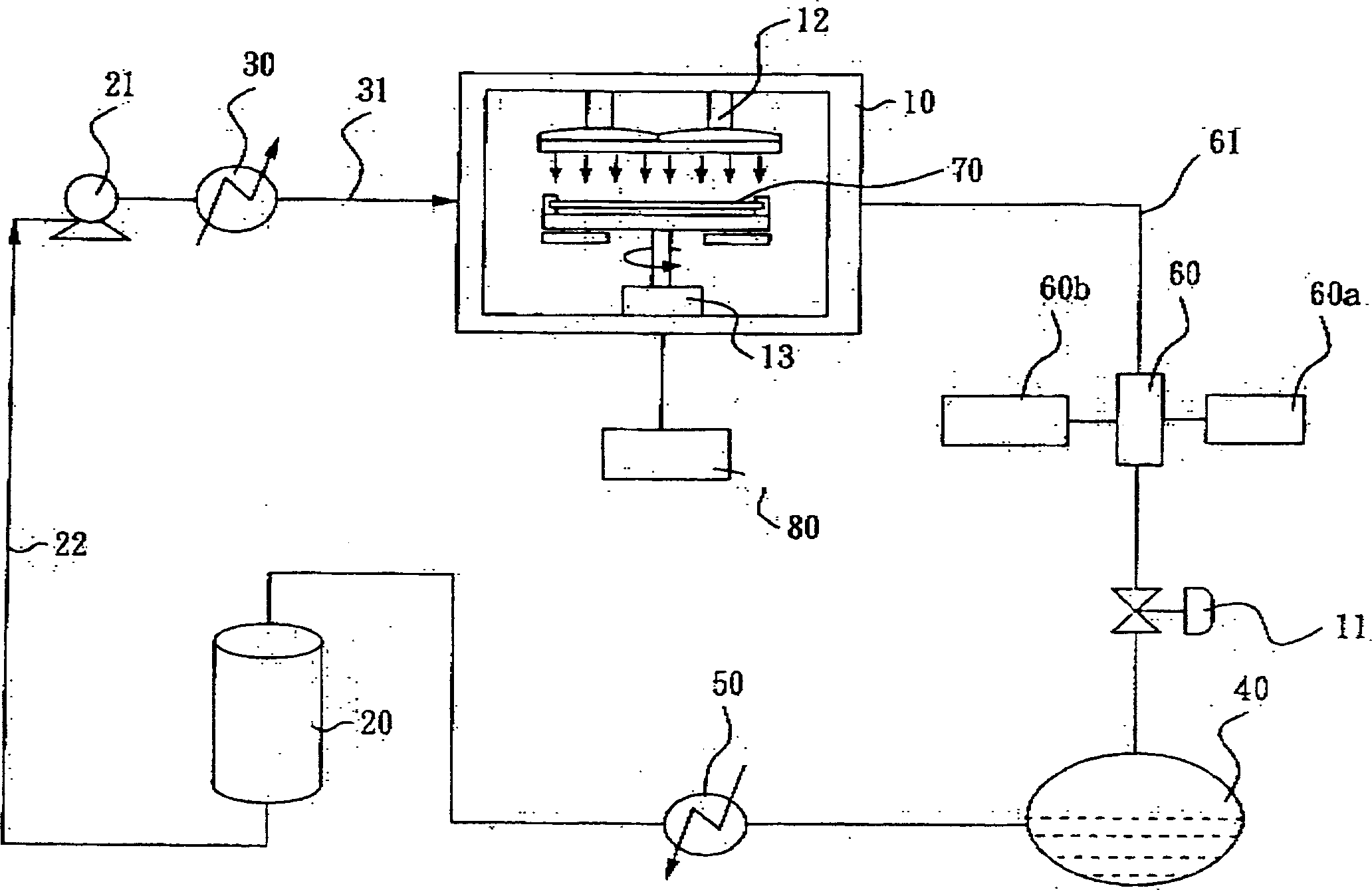

[0029] This embodiment illustrates the use of the substrate cleaning system device of the present invention, please refer to figure 1 Device system diagram.

[0030] figure 1 There is respectively a closed cleaning chamber 10 in it; a lotion supply device 80; a carbon dioxide liquid storage device 20; a pressure control device (delivery pump) 21; a temperature control device 30; and an online monitoring device 60; Device 80 is to supply a surfactant, carbon dioxide liquid storage device 20 is to join with pressure control device 21 with a connecting pipe 22, pressure control device 21 is connected with temperature control device 30, and temperature control device 30 is connected with a through pipe 31 again. Connect with the airtight cleaning chamber 10, send a supercritical carbon dioxide mixed liquid from the carbon dioxide liquid storage device 20 into the airtight cleaning chamber 10, and utilize a plurality of ultrasonic nozzles 12 in the airtight cleaning chamber 10 to ...

Embodiment 2

[0033] Using the apparatus of Embodiment 1, the operation mode of the substrate cleaning system of the present invention will be described.

[0034]First place a substrate 70 (such as a wafer) into the airtight cleaning chamber 10, then use the delivery pump 21 to pressurize the liquid carbon dioxide from the liquid-phase carbon dioxide storage tank 20 to a pressure above 73 atm, and then heat the carbon dioxide through the heater 30 Above the critical temperature of 31.1°C, the liquid carbon dioxide in the mixed liquid reaches a supercritical state, and then the mixed liquid is sent into the airtight cleaning chamber 10. At this time, together with the surfactant from the lotion supply device 80, co-solvent or a chelate A mixed liquid formed by the mixture is sprayed onto the surface of the substrate 70 by several ultrasonic vibrators and movable nozzles 12, and the surface of the substrate 70 is cleaned by utilizing the low surface tension and high permeability of supercritic...

Embodiment 3

[0038] After the cleaning of the substrate is completed, in the high-temperature and high-pressure airtight cleaning chamber, the supercritical carbon dioxide containing pollutants enters the separation tank 40 after being depressurized by the pressure reducing valve 11, and the heavier pollutants will be deposited in the separation tank. At the bottom of 40, the pollutants are collected by the adsorption filter (not shown) in the separation tank 40, and then treated appropriately or by a supercritical water oxidation system; while the filtered carbon dioxide passes through the condenser 50 or is compressed into a liquid, It can enter the carbon dioxide storage tank 20 for recycling and reuse, or be directly discharged into the atmosphere.

[0039] The operating temperature range of the system is 25-200°C, and the operating pressure is 74-250 atm; the operating frequency range of the ultrasonic system is 0.8MHz-3.5MHz; the inside of the airtight cleaning room 10 can further inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com