Liquid impact excitation method and device applied to vibration cutting

A technology of vibration cutting and vibration excitation device, applied in the direction of fluid and metal processing using vibration, it can solve the problems of slow commutation speed, high working noise, low power, etc., and achieve good cooling and chip removal effect, energy transfer loss. Small, the effect of reducing system cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

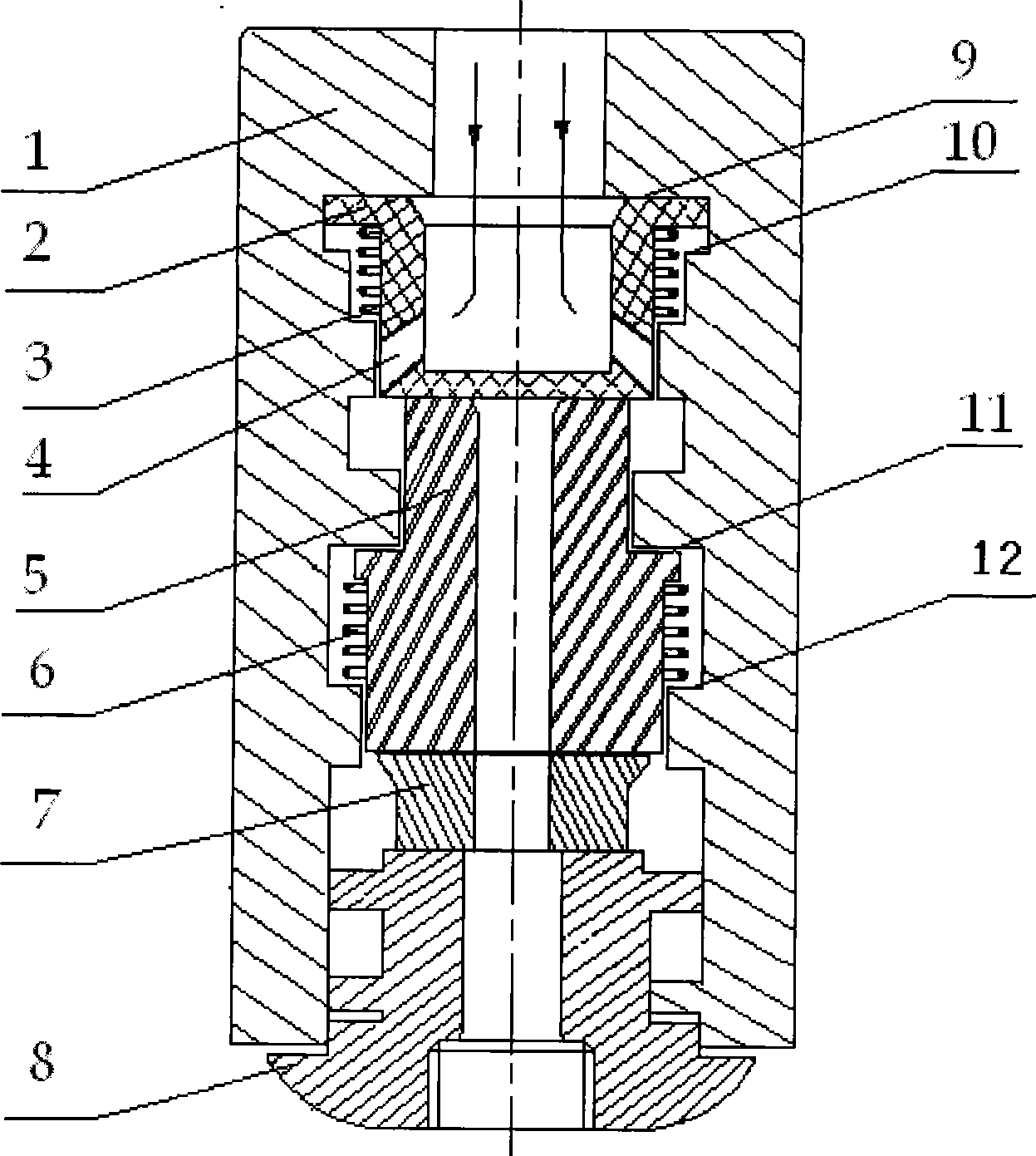

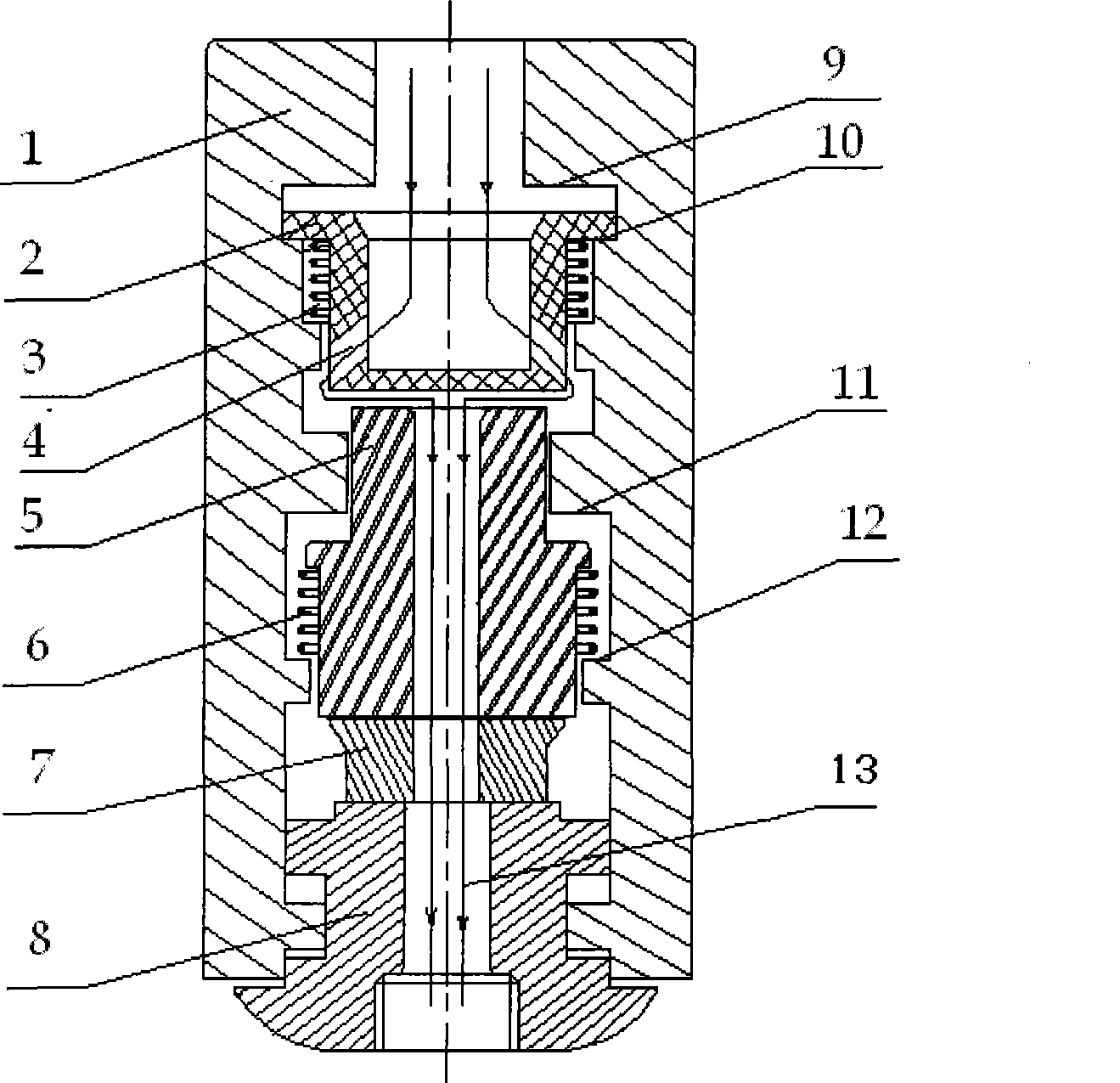

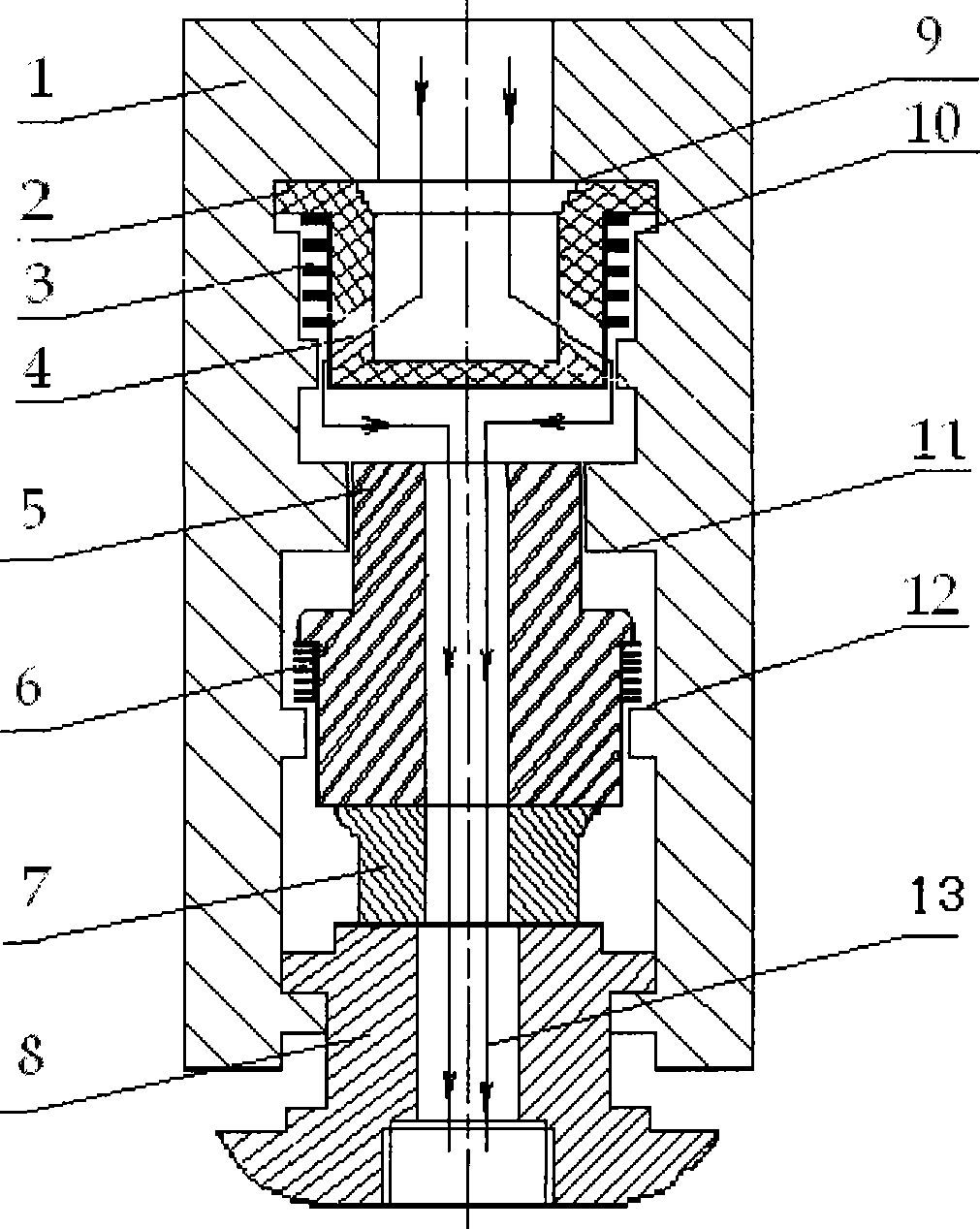

[0034] Embodiment 1: Provide a liquid hammer excitation device of the present invention applied to vibratory cutting, the structure is as follows figure 1 As shown, the device mainly includes a casing (1), and a live valve (2), a live valve spring (3), a piston (5), a piston spring (6), and a variable valve installed in the hollow cavity of the casing (1). Width mechanism (7) and knife handle fixture (8) six main components, live valve spring (3) is installed on live valve periphery, live valve liquid hole (4) is arranged on live valve wall, live valve upper limit ( 9) There are two key positions of the lower limit position (10) of the live valve. The live valve can move between the upper limit position of the live valve and the lower limit position of the live valve. The inner wall of the shell also has the upper dead center of the piston (11) and the lower dead center of the piston (12). There are two key positions, a piston spring (6) is installed on the outer circumference...

Embodiment 2

[0035] Embodiment 2: The present invention is applied to the vibration excitation method of vibration cutting. This method adopts liquid hammer energy as the excitation source. When this method is applied to vibration cutting, it is firstly equipped with an excitation device provided by Embodiment 1. In addition, Equipped with a hydraulic system that produces high-pressure cutting fluid, especially a hydraulic pump; secondly, select a good high-pressure cutting fluid, which is used as a liquid that generates hydraulic impact energy and is also a coolant for tools and workpieces; thirdly, adjust the cutting fluid Pressure and flow, the amplitude and frequency parameters required to achieve vibration cutting can implement vibration cutting.

[0036] The vibration excitation method of the invention uses liquid impact energy as the vibration source, and has the advantages of low energy transmission loss and high efficiency. The vibration exciting device of the present invention ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com