Internal steam conduction apparatus of direct air cooling branch-shaped exhaustion duct system

A steam exhaust pipe and internal diversion technology, applied in steam/steam condensers, sustainable manufacturing/processing, climate sustainability, etc., can solve the problem of unfavorable safe and economical operation of direct air-cooled condensers, and cannot solve the problem of steam flow. Even distribution problems, etc., to prevent excessive pressure loss, ensure safe operation, and reduce thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in conjunction with the accompanying drawings.

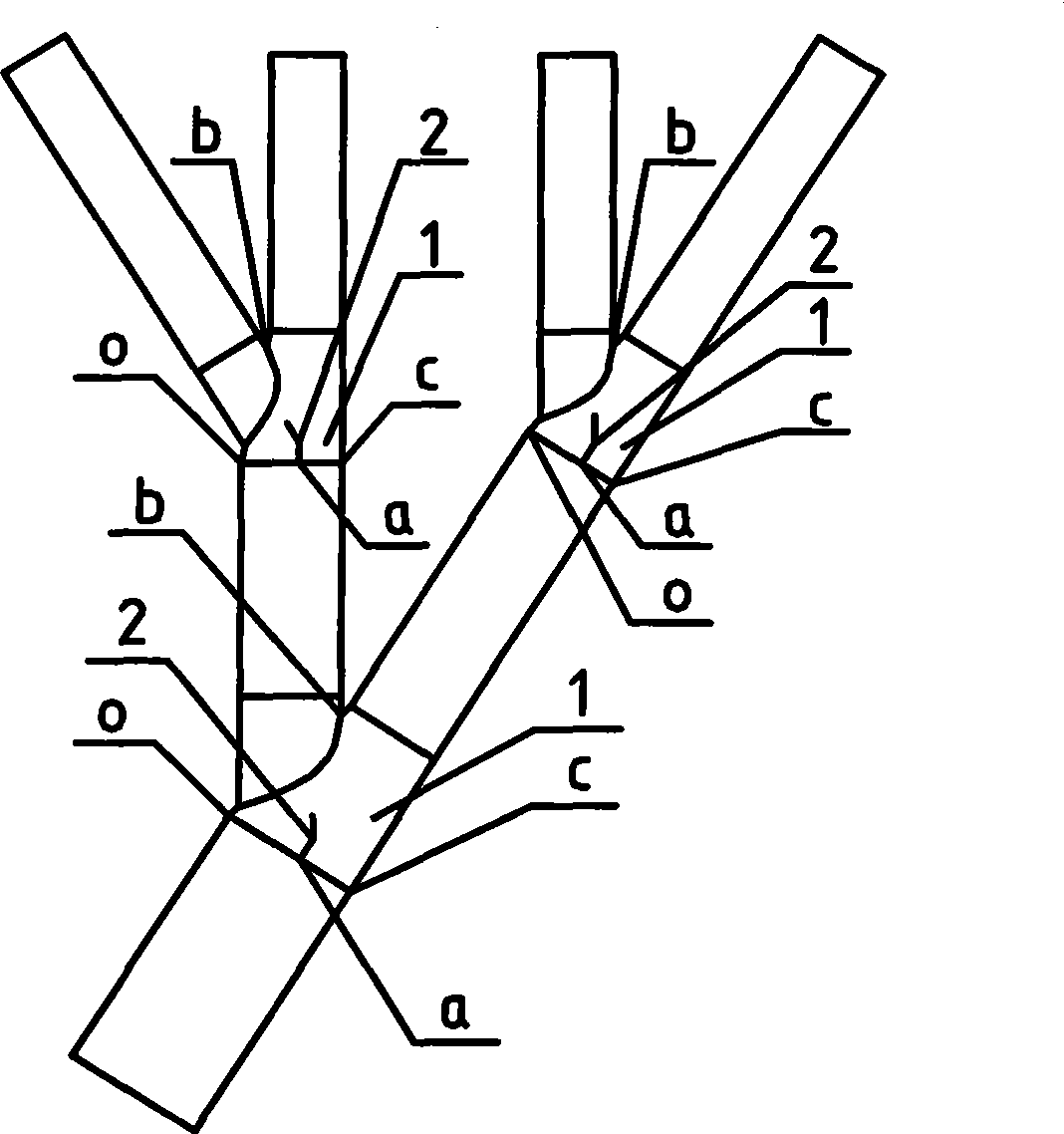

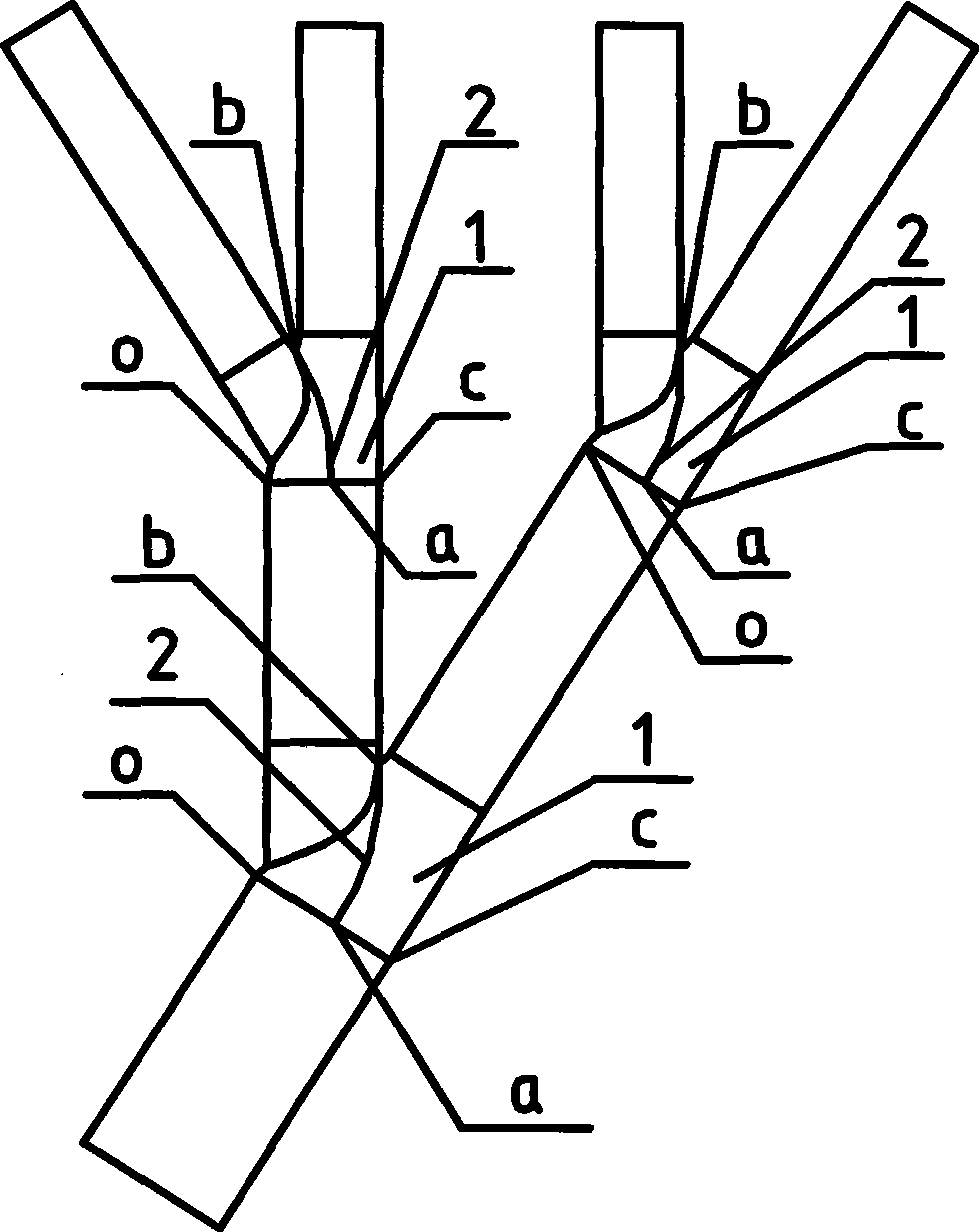

[0029] figure 1 and figure 2 The cross-sections of the short blade and the long blade of the guide device in the direct air-cooled dendritic exhaust pipe system, respectively. The main exhaust pipe is divided into two branch exhaust pipes, and each branch exhaust pipe is branched into two branch exhaust pipes, which are called exhaust distribution pipes. The flow distribution is realized by direct air-cooling the diversion device in the branch exhaust pipe.

[0030] The internal guide device of the direct air-cooled dendritic exhaust pipe system includes a tee 1 and guide vanes 2 .

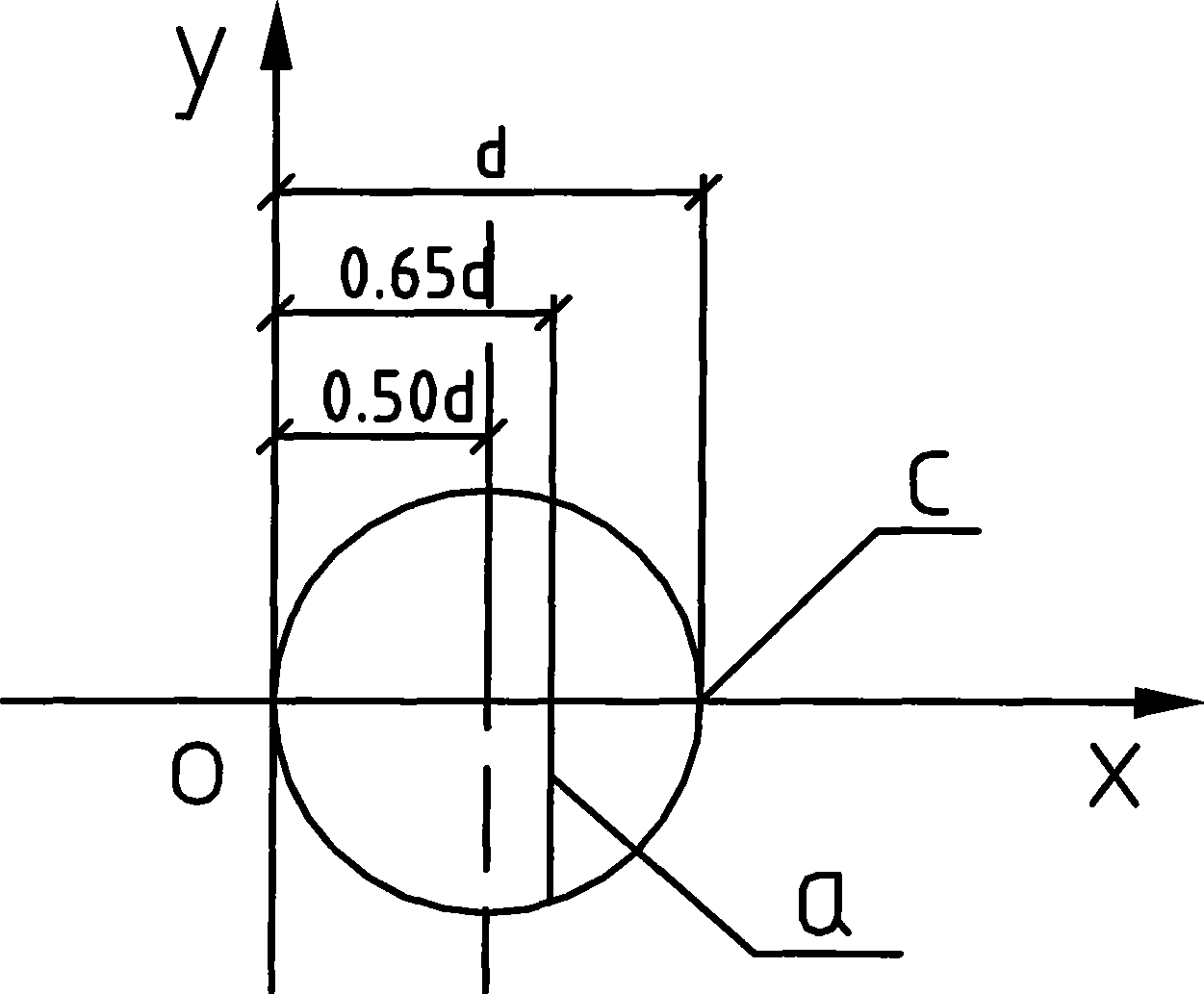

[0031] Such as image 3 As shown, the inlet surface and outlet surface of the tee 1 are perpendicular to the steam flow direction, and the steam flow direction is the positive direction of the z-axis. The contour line of the inlet surface of tee 1 is a circle. Assume that the inner diamet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com