Emulsified liquid flow dynamic and comprehensive optimization setting method suitable for cold continuous rolling unit

A technology for tandem cold rolling mills and optimized settings, applied in rolling mill control devices, mass flow control devices, metal rolling, etc., can solve problems such as inability to dynamically adjust and allocate fixed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

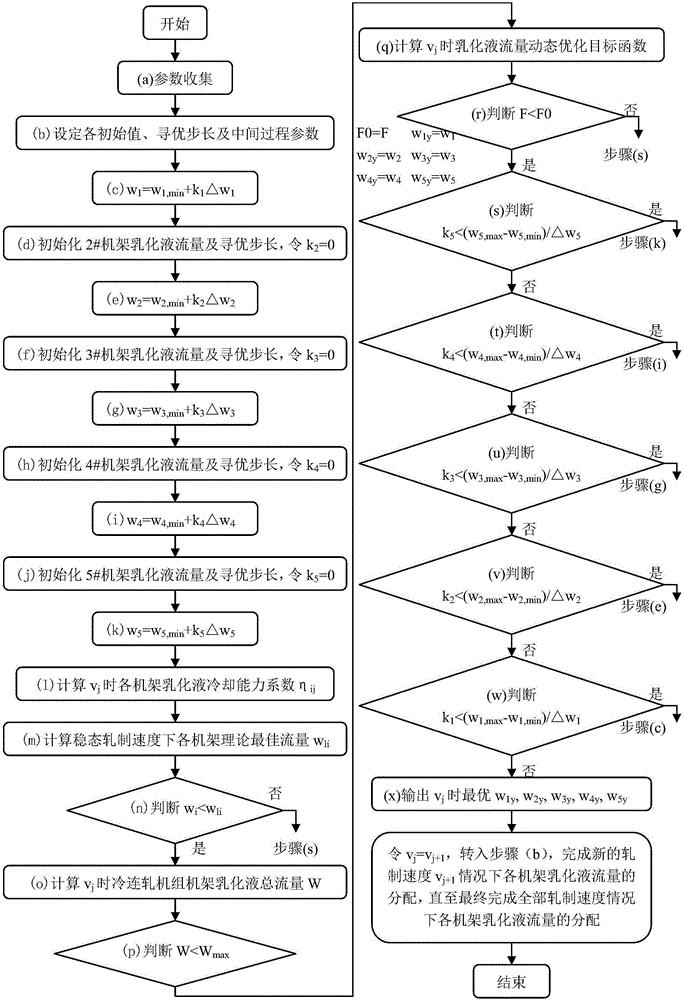

[0053] A dynamic comprehensive optimization setting method of emulsion flow rate suitable for cold tandem mills. The calculation process is as follows figure 1 Shown:

[0054] First, in step (a), the parameters are collected:

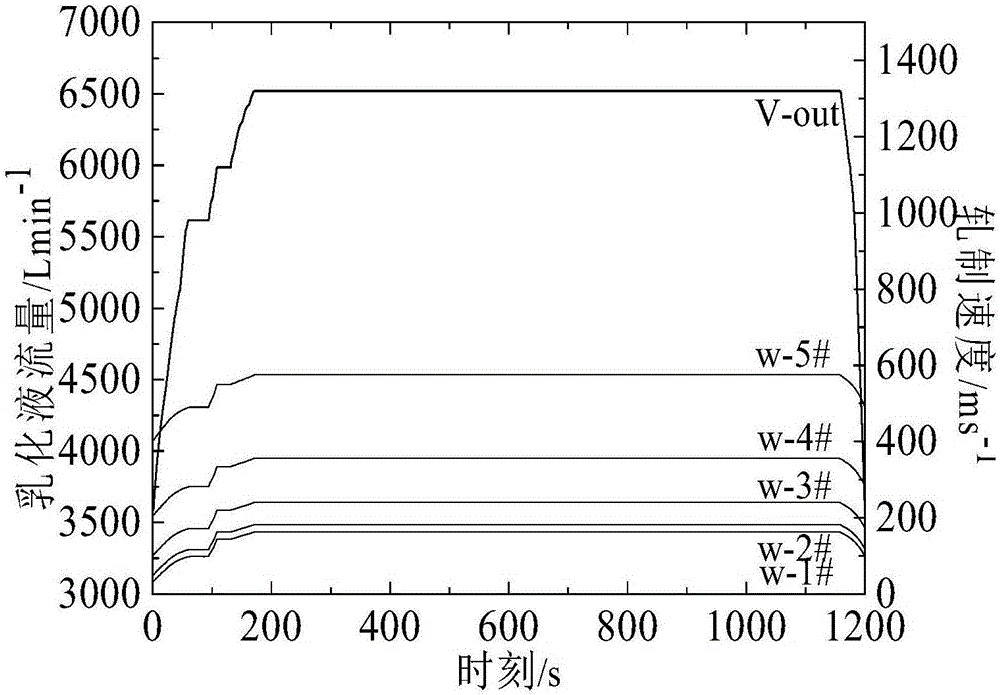

[0055] (a1) Collecting strip parameters, mainly including strip width b=850mm, strip thickness H in and out of each rack i ={2.1,1.17,0.65,0.40,0.27}(mm), h i ={1.17,0.65,0.40,0.27,0.22}(mm), the typical inlet and outlet speeds of strips in each rack (m / s)

[0056] v 0 , i = 1 # 44.1 , 93.4 , 147.5 , 330 , 219 ; 2 # 79.4 , 203.3 , 285.4 , 483.2 , 375.3 ; 3 # 112.6 , 317.3 , 448.1 , 642 , 622.8 ; 4 # 163.2 , 437.8 , 615.5 , 813.2 , 741.1 ; 5 # 213.3 , 583.3 , 821.4 , 1015.3 , 1126.2 ,

[0057] v 1 , i = 1 # 79.4 , 203.3 , 285.4 , 483.2 , 375.3 ; 2 # 112.6 , 31...

Embodiment 2

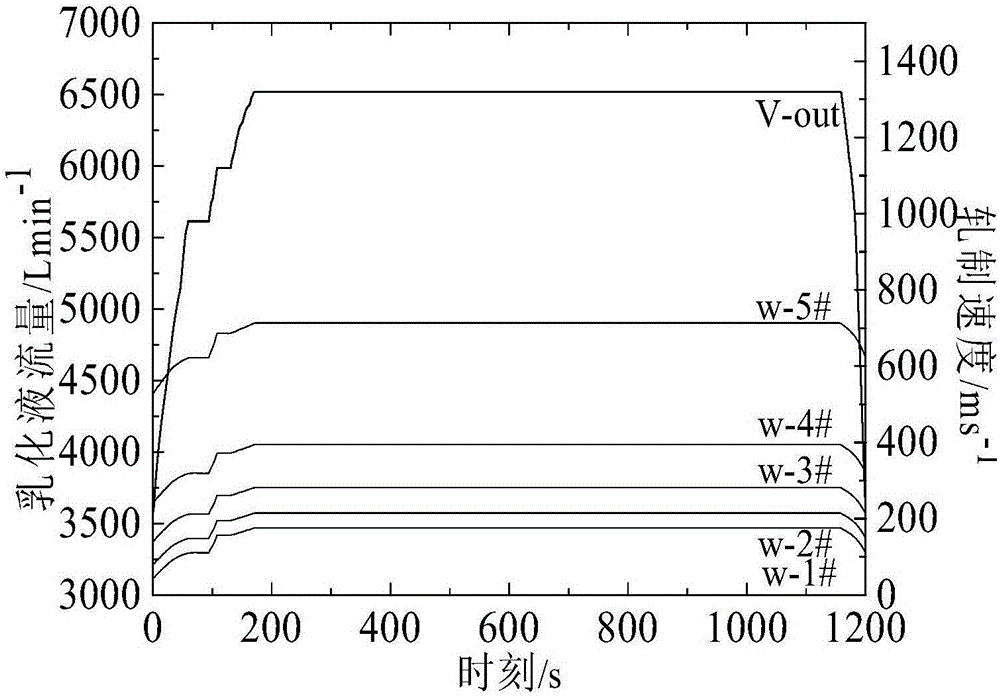

[0102] First, in step (a), the parameters are collected:

[0103] (a1) Collecting strip parameters, mainly including strip width b=975mm, strip thickness H in and out of each rack i ={2.1,1.17,0.65,0.40,0.27}(mm), h i ={1.17,0.65,0.40,0.27,0.22}(mm), the typical inlet and outlet speeds of strips in each rack (m / s)

[0104] v 0 , i = 1 # 32.4 , 82.4 , 135.7 , 320 , 208 ; 2 # 56.9 , 182.6 , 264.5 , 462.3 , 359.3 ; 3 # 88.6 , 285.3 , 412.8 , 611 , 592.8 ; 4 # 124.3 , 398.7 , 576.5 , 774.3 , 730.1 ; 5 # 166.3 , 533.3 , 771.4 , 968.5 , 974.1 ,

[0105] v 1 , i = 1 # 56.9 , 182.6 , 264.5 , 462.3 , 359.3 ; 2 # 88.6 , 285.3 , 412.8 , 611 , 592.8 ; 3 # 124.3 , 398.7 , 576.5 , 774.3 , 730.1 ; 4 # 166.3 , 533.3 , 771.4 , 968.5 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com