Novel semi-graphitization silicon nitride carbide brick and its production method

A technology of silicon carbonitride bricks and semi-graphitization, applied in the field of refractory materials and their production, can solve the problems of low strength, thermal shock spalling, poor cooling effect, etc., and achieve the effect of improving economic efficiency and prolonging life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

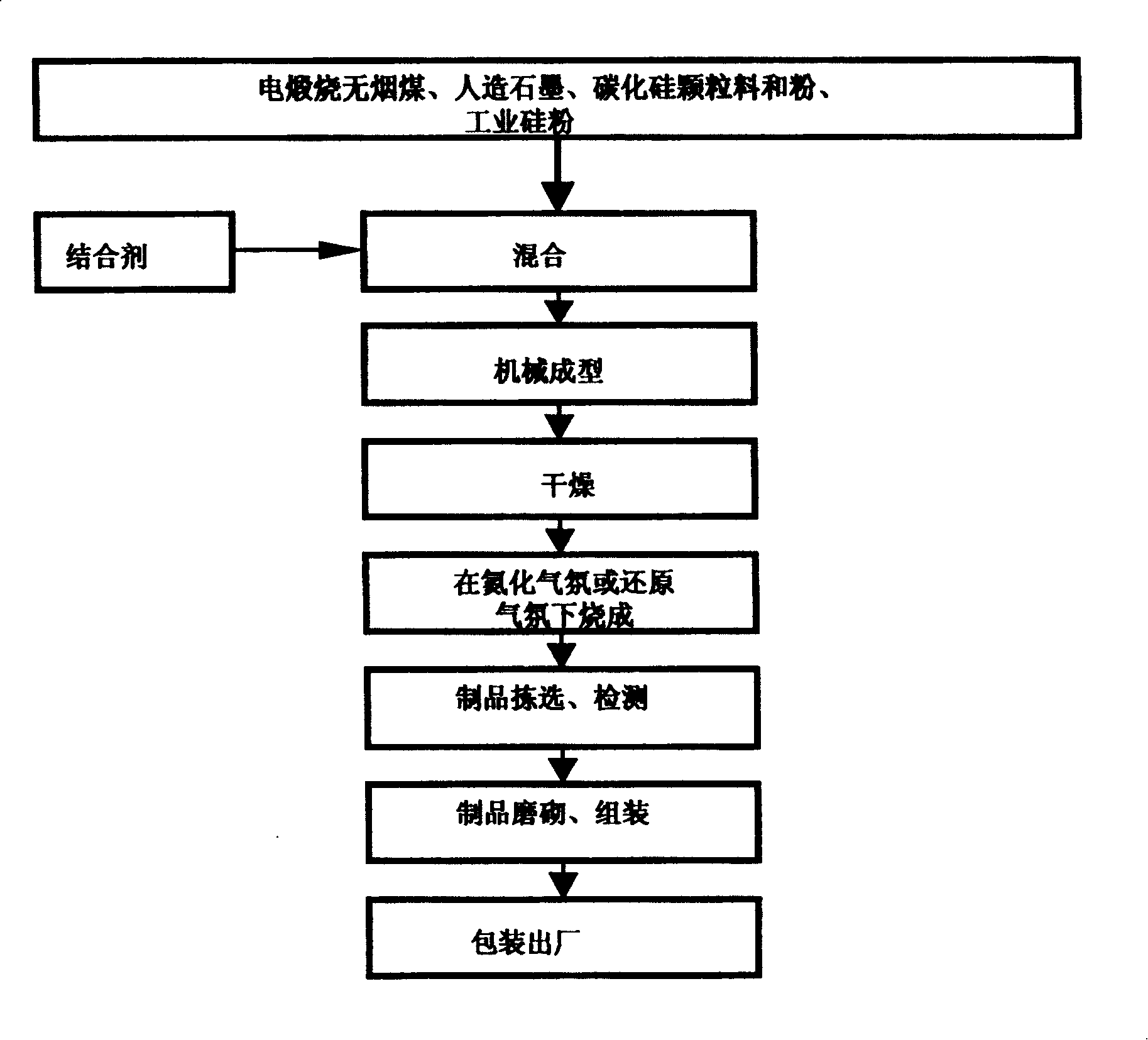

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: Weigh 20% of electrically calcined anthracite with a particle size of 0.074 to 10mm, 40% of graphite with a particle size of 0.074 to 3mm, 30% of industrial silicon with a particle size of not more than 320 mesh, and carbonized carbonized coal with a particle size of 0.074 to 2.5mm by weight percentage. 10% of silicon is put into the mixer, plus 20% of the total weight of the above raw materials is thermosetting phenolic resin,

[0027] After the raw materials are mixed evenly, they are pressed and molded, dried and put into a kiln. Nitrogen gas with a pressure of 0.15 MPa is filled in the firing kiln, and the temperature is kept at 1200°C for 24 hours. The product is cooled out of the kiln.

[0028] After the products are out of the kiln, their physical and chemical properties, surface quality and external dimensions are inspected; the products that pass the inspection are processed according to the size standards or contract requirements; finally, the pro...

Embodiment 2

[0029] Embodiment two: basically the same as embodiment one, the similarity is no longer described, and the difference is:

[0030] Weigh raw materials according to the formula: 50% of electric calcined anthracite with a particle size of 0.074-10mm, 20% of graphite with a particle size of 0.074-3mm, 15% of industrial silicon with a particle size of no more than 320 mesh, 15% of silicon carbide with a particle size of 0.074-2.5mm, Put into mixer, add the thermosetting phenolic resin that accounts for 20% of above-mentioned raw material gross weight,

[0031] After mixing evenly, it is pressed into shape, dried and loaded into a kiln, filled with nitrogen at a pressure of 0.2 MPa, kept at 1800°C for 8 hours and fired, and the product is cooled out of the kiln.

Embodiment 3

[0032] Embodiment three: basically the same as embodiment one, the similarity is no longer described, and the difference is:

[0033] Weigh raw materials according to the formula: 30% of electric calcined anthracite with a particle size of 0.074-10mm, 30% of graphite with a particle size of 0.074-3mm, 30% of industrial silicon with a particle size of no more than 320 mesh, 10% of silicon carbide with a particle size of 0.074-2.5mm, Put it into a mixer, add resin accounting for 17% of the total weight of the above raw materials, mix evenly, press and shape, dry and put it into a kiln, fill the firing kiln with nitrogen at a pressure of 1.0MPa, and heat it at 1300 ° C The temperature is kept for 10 hours and fired, and the product is cooled out of the kiln with the furnace.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com