Starting and stopping control system and control method for electronic fuel injection engine of excavator

A start-stop control, engine technology, applied in engine control, machine/engine, mechanical equipment, etc., can solve problems such as insufficient lubrication and cooling, damage to the engine, operator discomfort, etc., to reduce the risk of accidents and prolong service life Lifespan, removes transient inconsistency effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention are further described below, but the claimed scope is not limited to the description.

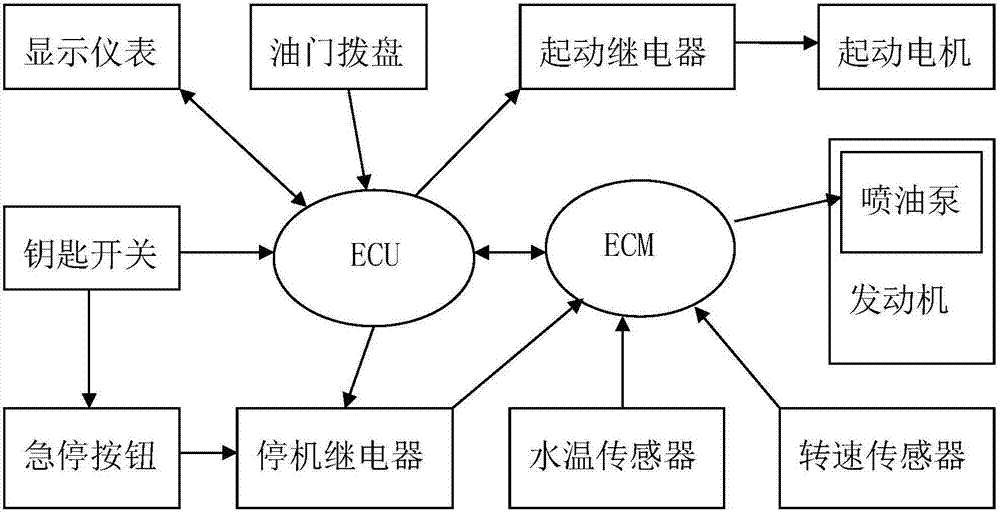

[0027] like figure 1 As shown, a start-stop control system for an excavator EFI engine includes an engine, an ECM, an ECU, a display instrument, a key switch, a speed sensor, a water temperature sensor, a throttle dial, a starter relay, a stop relay, a starter motor, and a throttle dial. The disc is connected to the ECU, and the gear position information of the accelerator is transmitted to the ECU; the key switch is connected to the ECU through a wire, and sends a start-stop signal to the ECU; the display instrument is connected to the ECU, and receives the signal from the ECU for display; the ECU is connected to the ECM, and sends to the ECM Control signal; ECM is connected with stop relay, water temperature sensor and speed sensor; engine is connected with ECM; starter motor is connected with starter relay.

[0028] Also includes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com