Manufacturing method of high-toughness hot-rolled plate coil for welded gas cylinder

A technology for hot-rolled coils and steel for gas cylinders is applied in the field of manufacturing hot-rolled coils of high-toughness welded steel for gas cylinders, and can solve the problem of reducing the impact toughness level and stability of low-carbon bainitic steel, high cost, The strength and toughness of steel coils are difficult to control, so as to achieve the effect of uniform structure and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

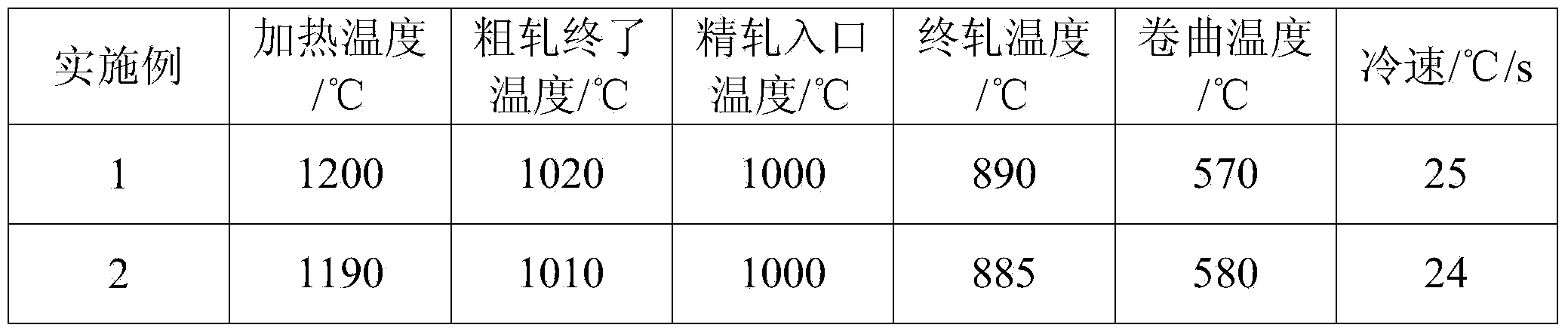

[0031] The manufacturing method of the hot-rolled coil of steel for the high-toughness welded gas cylinder, the composition ratio of the hot-rolled coil is shown in Table 1;

[0032] The manufacturing process of hot-rolled coils is: smelting - molten iron pretreatment - LF furnace refining - continuous casting - heating - rolling - coiling;

[0033] The smelting is carried out in the converter, the smelting control P is 0.013%, the final furnace temperature is 1620°C, the slag blocking operation is strengthened during the smelting process, and the slag amount is 4kg / t;

[0034] The molten iron pretreatment control S is 0.005%, the front slag removal and the rear slag removal, and the bright side of the rear slag removal is 88%;

[0035] The LF furnace refining control S is 0.010%, and the white slag operation ensures the full reduction of ladle top slag. Ensure that the total weak stirring time before and after feeding the calcium line is 12 minutes;

[0036] Heating tempera...

Embodiment 2

[0041] The manufacturing method of the hot-rolled coil of steel for the high-toughness welded gas cylinder, the composition ratio of the hot-rolled coil is shown in Table 1;

[0042] The manufacturing process of hot-rolled coils is: smelting - molten iron pretreatment - LF furnace refining - continuous casting - heating - rolling - coiling;

[0043] The smelting is carried out in a converter, the smelting control P is 0.012%, and the final furnace temperature is 1635°C. During the smelting process, the operation of tapping and slag is strengthened, and the amount of slag is 3.5kg / t;

[0044] Hot metal pretreatment control S is 0.004%, front slag removal and rear slag removal, the bright side of rear slag removal is 90%;

[0045] The LF furnace refining control S is 0.008%, and the white slag operation ensures the full reduction of ladle top slag. Ensure that the total weak stirring time before and after feeding the calcium line is 13 minutes;

[0046] Heating temperature and...

Embodiment 3

[0051] The manufacturing method of the hot-rolled coil of steel for the high-toughness welded gas cylinder, the composition ratio of the hot-rolled coil is shown in Table 1;

[0052] The manufacturing process of hot-rolled coils is: smelting - molten iron pretreatment - LF furnace refining - continuous casting - heating - rolling - coiling;

[0053] The smelting is carried out in the converter, the smelting control P is 0.012%, the final furnace temperature is 1630°C, the operation of tapping and slag is strengthened during the smelting process, and the slag amount is 3.2kg / t;

[0054] Hot metal pretreatment control S is 0.004%, front slag removal and rear slag removal, the bright side of rear slag removal is greater than 85%;

[0055] The LF furnace refining control S is 0.007%, and the white slag operation ensures the full reduction of ladle top slag. Ensure that the total weak stirring time before and after feeding the calcium line is 14 minutes;

[0056] Heating temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com