Intensive cooling control method for hot continuous rolling strip steel

A technology of cooling control and hot continuous rolling, applied in the direction of heat treatment process control, manufacturing tools, heat treatment equipment, etc., to avoid influence and improve strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

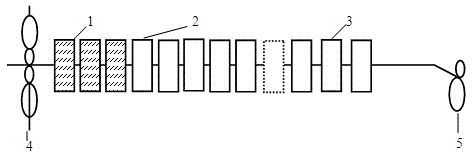

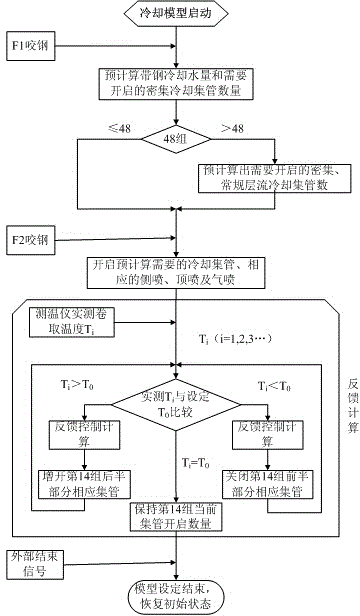

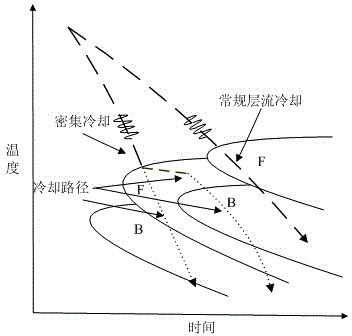

Method used

Image

Examples

Embodiment 1

[0031] A kind of 800MP grade engineering machinery steel, its chemical composition is shown in table 1.

[0032] Table 1800MP grade construction machinery steel chemical composition (% by weight),

[0033] The balance is Fe and unavoidable impurities.

[0034]

[0035] After the continuous casting slab is heated by a walking beam heating furnace, it is rolled into 4.0mm and 8.0mm thick steel plates by hot continuous rolling respectively. Table 2 shows the finish rolling temperature, rolling speed, coiling temperature and cooling speed of strip steel with different thicknesses.

[0036] Table 2 Control parameters of hot rolling and finishing rolling process

[0037]

[0038] The cooling headers are put into use as shown in Table 3.

[0039] Table 3 Cooling header commissioning table

[0040]

[0041] The mechanical properties of the hot-rolled steel plates produced by the intensive cooling control method of the present invention and the conventional laminar flow co...

Embodiment 2

[0049] The composition of Q235 steel was upgraded and rolled to Q345 steel. The chemical composition of Q235 steel is shown in Table 6.

[0050] Table 6Q235 steel chemical composition (% by weight), the balance is Fe and unavoidable impurities.

[0051]

[0052] The heating temperature of the Q235 steel billet is 1200°C, the finishing rolling temperature is set at 810°C, the coiling temperature is 500°C, and the 6.8mm thick steel plate is made by hot continuous rolling.

[0053] Table 7 Cooling header commissioning table

[0054]

[0055] Table 8 shows the mechanical properties of the obtained hot-rolled steel plate after upgraded rolling of Q235 steel by the method of the present invention.

[0056] Table 8 uses the method of the present invention to obtain the hot-rolled steel plate mechanical property after upgrading rolling of Q235 steel

[0057]

[0058] After upgrading and rolling Q235 steel by the method of the present invention, fine ferrite is obtained ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com