a scrubber

A gas scrubber and gas scrubbing technology, applied in the field of gas scrubbers, can solve problems such as difficult sewage outlets, discharge, easy slag accumulation at the bottom of the tower, etc., and achieve the effect of long residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

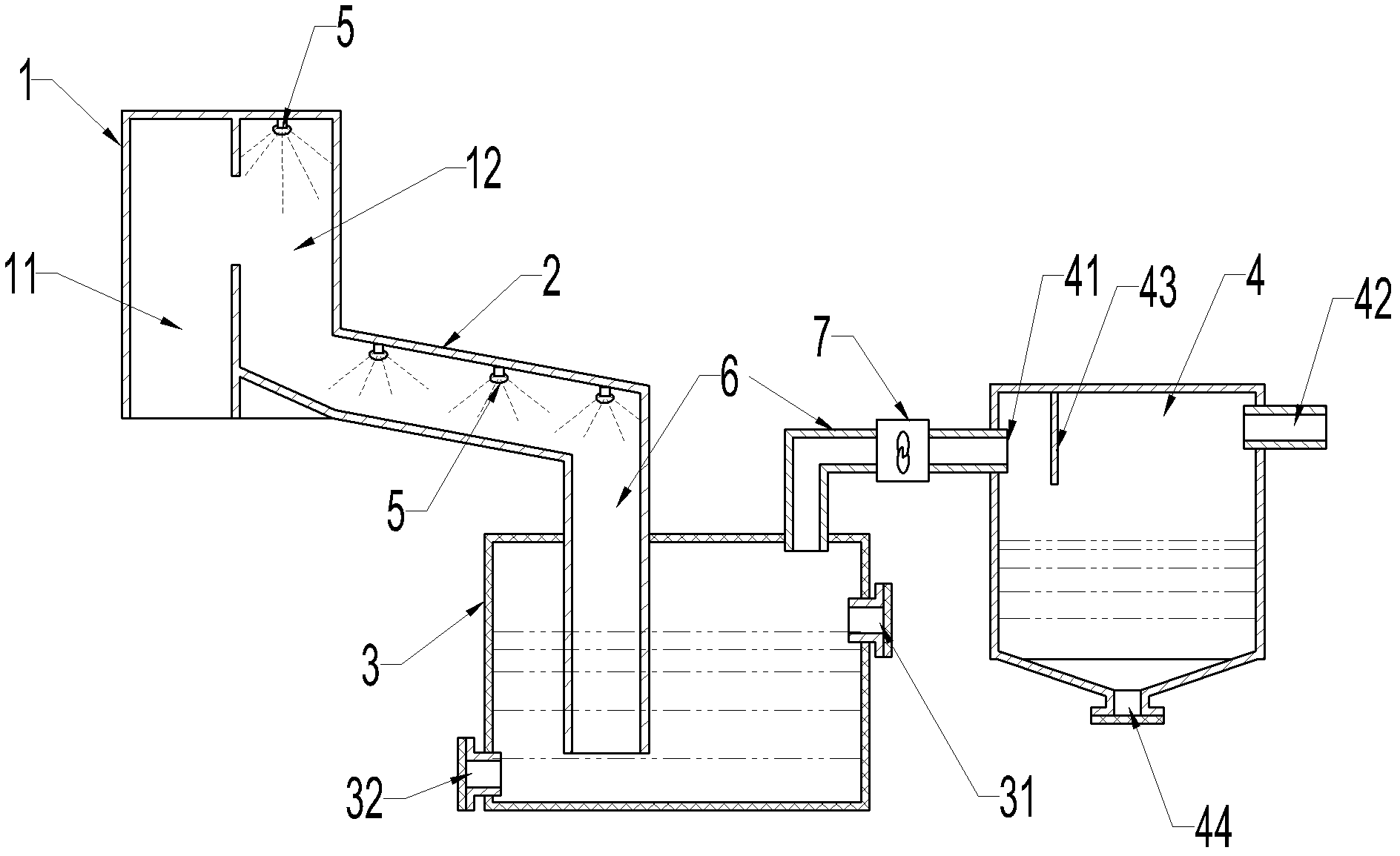

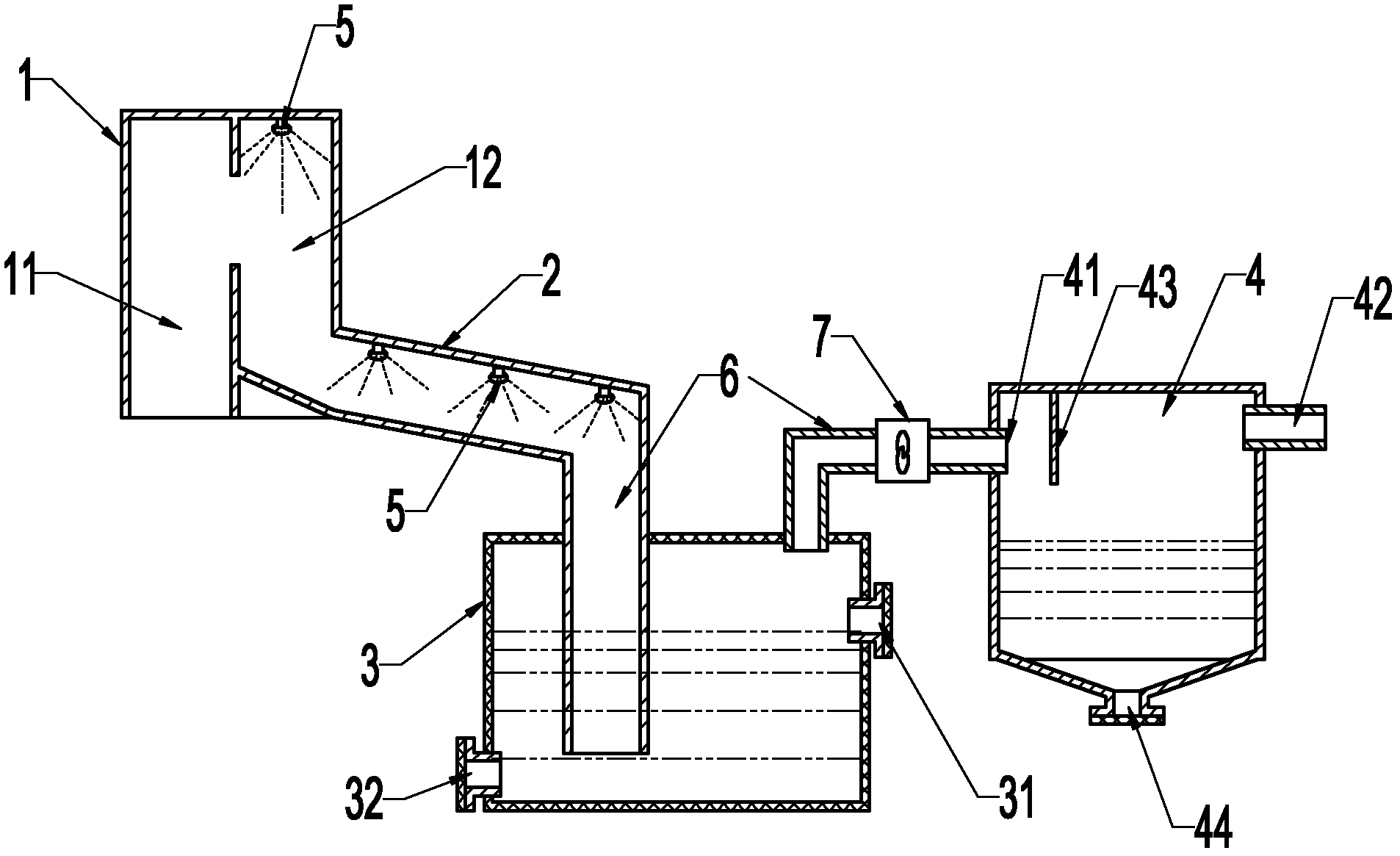

[0018] refer to figure 1 , the gas scrubber includes a vertical tower 1, a horizontal tower 2, a scrubber chamber 3 and an oil-gas separation chamber 4; connected to each other, so that the incoming gas can be fully sprayed, without pipe dead ends, without dust accumulation, the top of the spray chamber 12 is equipped with a sprinkler head 5; the horizontal tower 2 is connected with the bottom of the spray chamber 12, in order to make the Quickly discharge accumulated water, etc., the bottom of the spray chamber 12 is an inclined structure, which is inclined towards the direction of the horizontal tower 2, and the bottom of the horizontal tower 2 itself is at least an inclined structure. The end connected to the spray chamber 12 is high, and the end connected to the pipeline 6 is low. , the high-speed flowing water can quickly take away all kinds of dust, and achieve maintenance-free tower;

[0019] The gas washing chamber 3 is a closed body, the pipeline 6 introduced from th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com