Powder metallurgy tool steel mixing equipment and using method thereof

A kind of mixing equipment and powder metallurgy technology, applied in the field of powder metallurgy, can solve the problems of easy dust and clogging, low qualified rate of steel, etc., and achieve the effect of preventing dust, increasing the frequency of friction, and ensuring air tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

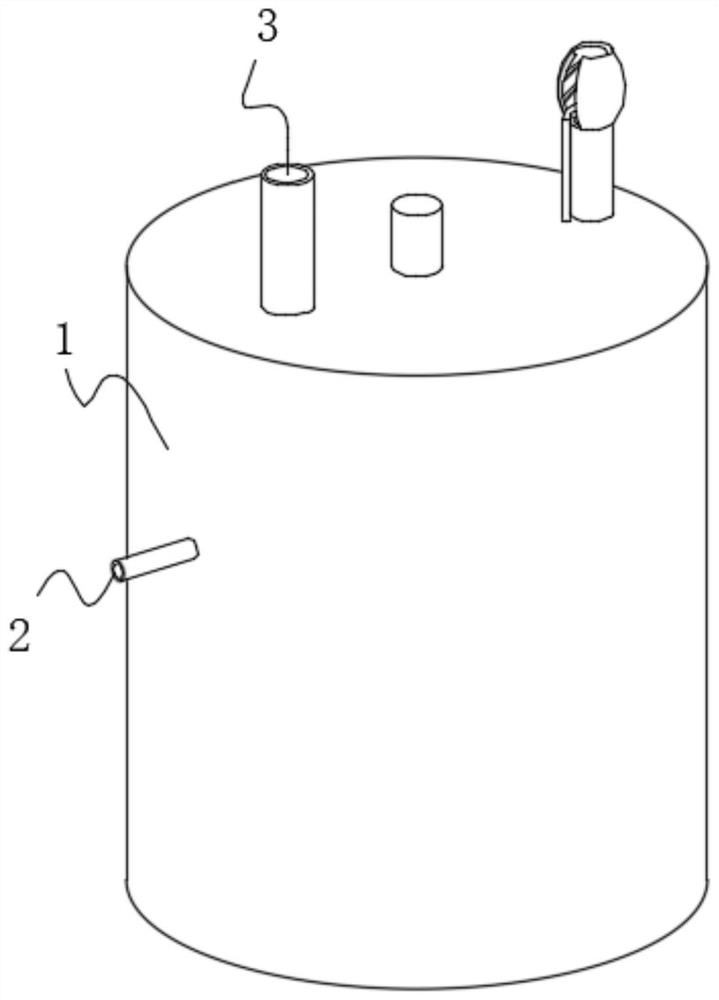

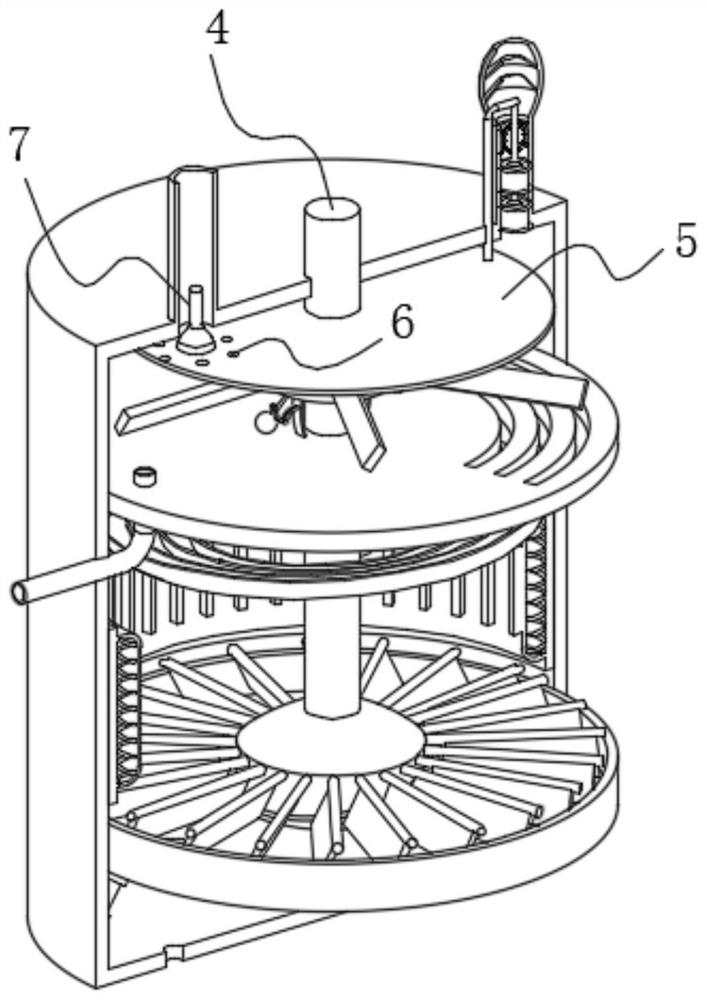

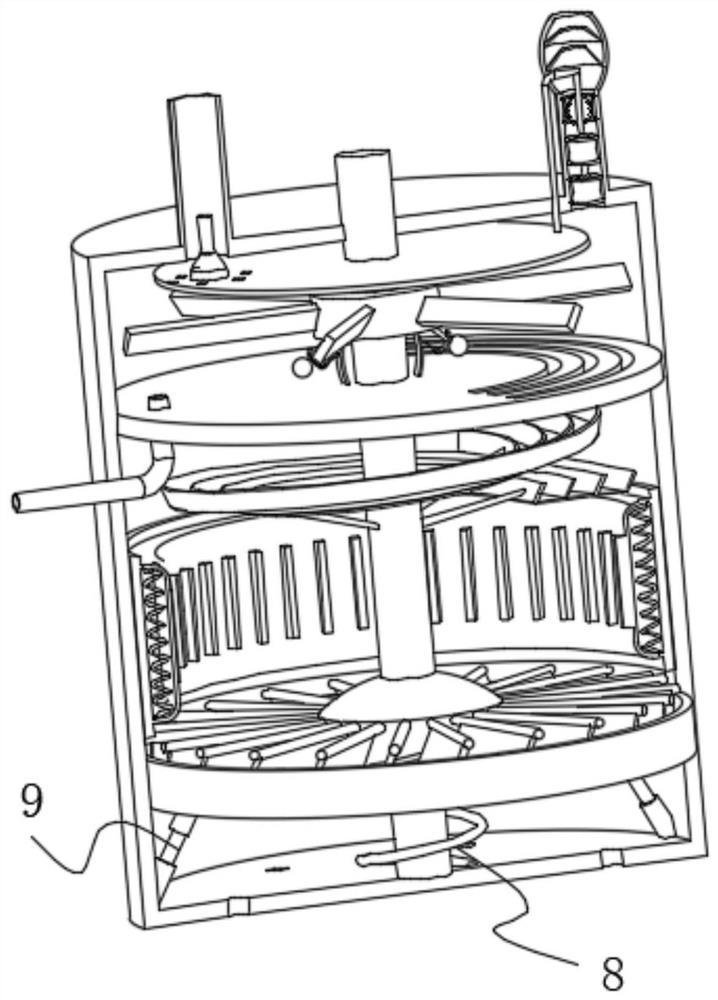

[0033] use Figure 1-Figure 10 A powder metallurgy tool steel mixing equipment and its use method according to an embodiment of the present invention are described as follows.

[0034] Such as Figure 1-Figure 10 As shown, a kind of powder metallurgy tool steel mixing equipment and its use method described in the present invention comprises the following steps:

[0035] S1: Check the airtightness of the mixing equipment, connect the feeding end of the equipment with the external gas pipe, and after ensuring that the sealing effect of the connection is up to standard, detect and observe whether the pipeline exposed to the outside of the mixing equipment is blocked or leaks;

[0036] S2: After the air tightness test of the mixing equipment reaches the standard, start the equipment, and put the powdered raw materials required for metallurgy into the inside of the mixing equipment in sequence according to the actual production needs;

[0037]S3: During the operation of the mixin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com