Anti-seismic structural steel with yield strength being 550MPa grade, and production method thereof

An anti-seismic structure and yield strength technology, applied in the field of high-strength low-alloy controlled rolling and controlled cooling steel, can solve problems such as local buckling, deformation accumulation of mild steel dampers, design inconsistencies, etc., to achieve outstanding plastic deformation ability and uniform microstructure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below according to the accompanying drawings, which is a preferred embodiment among various implementations of the present invention.

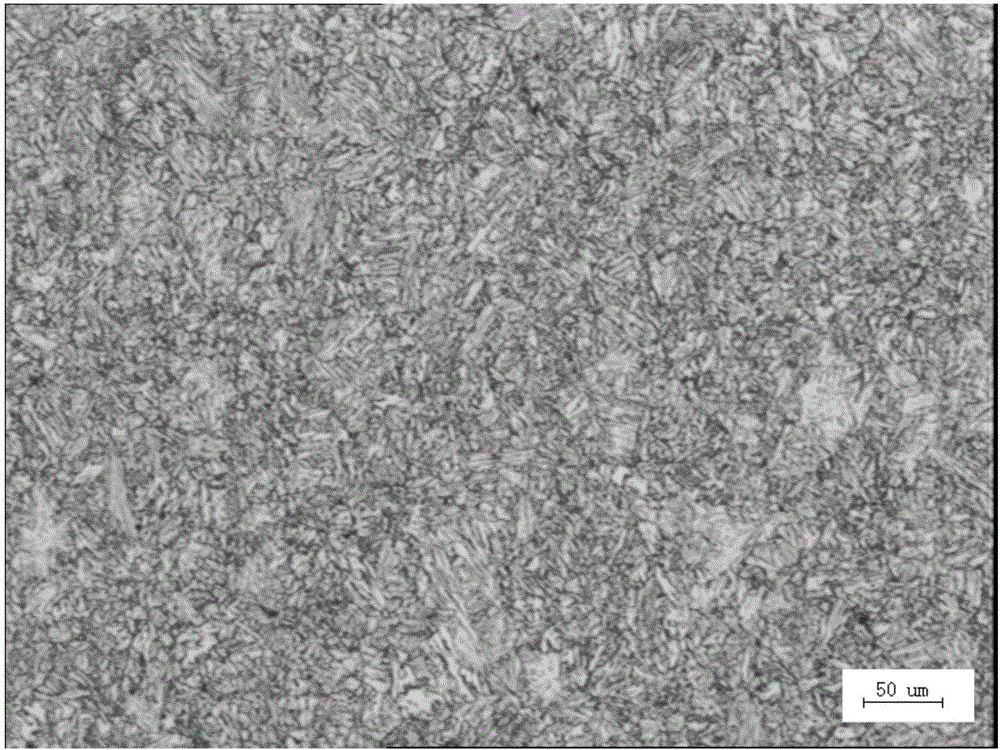

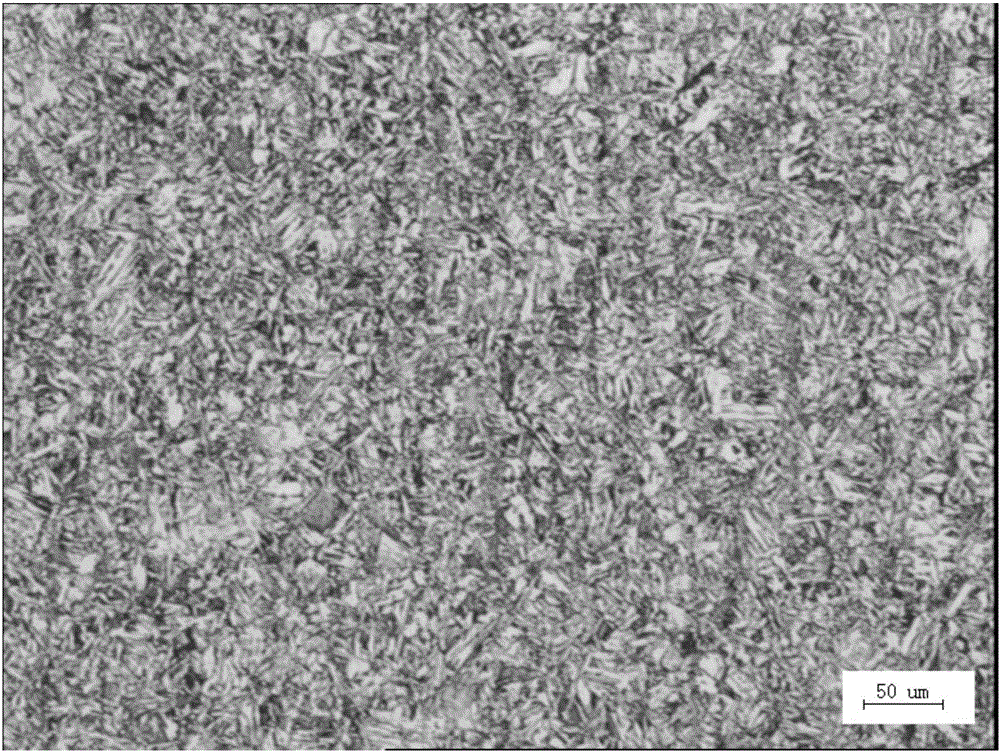

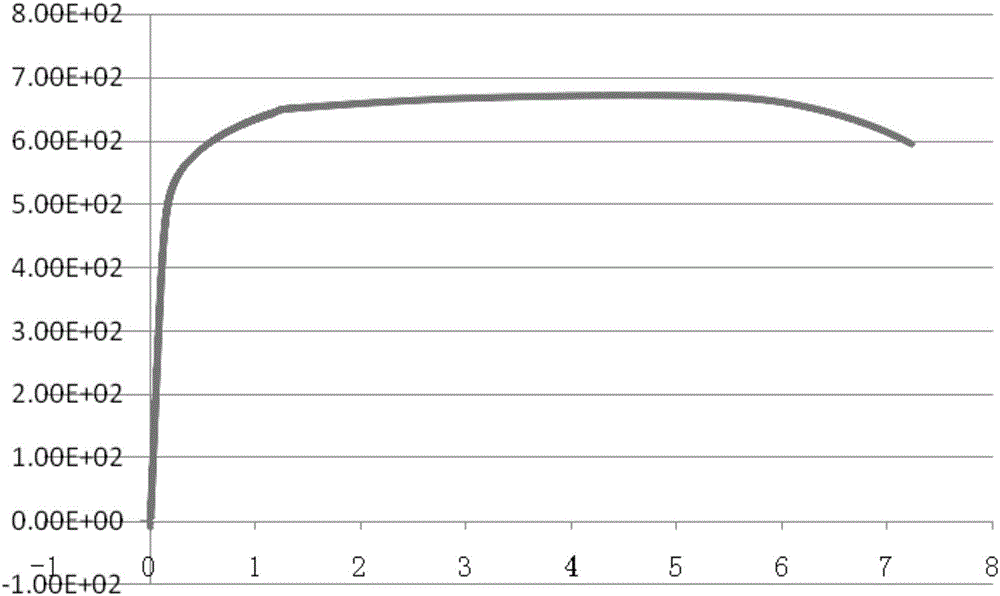

[0033] In a preferred embodiment, under the TMCP process system, through reasonable composition design, controlled rolling and controlled cooling, a fine bainite or a multi-phase structure dominated by 'bainite + voxel body' is obtained, making it It has high strength and outstanding plastic deformation ability, and is mainly used in the manufacture of earthquake-resistant structural parts.

[0034] The main idea of the design of the anti-seismic structural steel in this patent is as follows: First, adopt relatively cheap and widely used alloying elements, which are convenient for large-scale and low-cost production and use. Except for C and Mn, the main elements are Cr and Al, excluding Or do not intentionally add Nb, V, Ti, Mo, Ni and other elements; second, design the rolling and co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com