Hot bulging forming method for bearing steel rectangular cross-section ring unit

A technology of rectangular cross-section and ring parts, applied in the field of thermal expansion forming of bearing steel rectangular cross-section ring parts, can solve the problem of difficulty in obtaining high-quality, precise, efficient, environmentally friendly and low-cost ring parts, long production preparation time and production cycle , unable to achieve dimensional accuracy and other problems, to achieve the effect of improved dimensional accuracy, low cost, and improved productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0033] The main chemical element content (percentage by weight) of the bearing steel given in the prior art is: C content 0.95%-1.05%, Mn content 0.2%-0.4%, Si content 0.15%-0.35%, S content content ≤ 0.020%, P content ≤ 0.027%, Cr content 1.30% ~ 1.65%, and the balance is Fe.

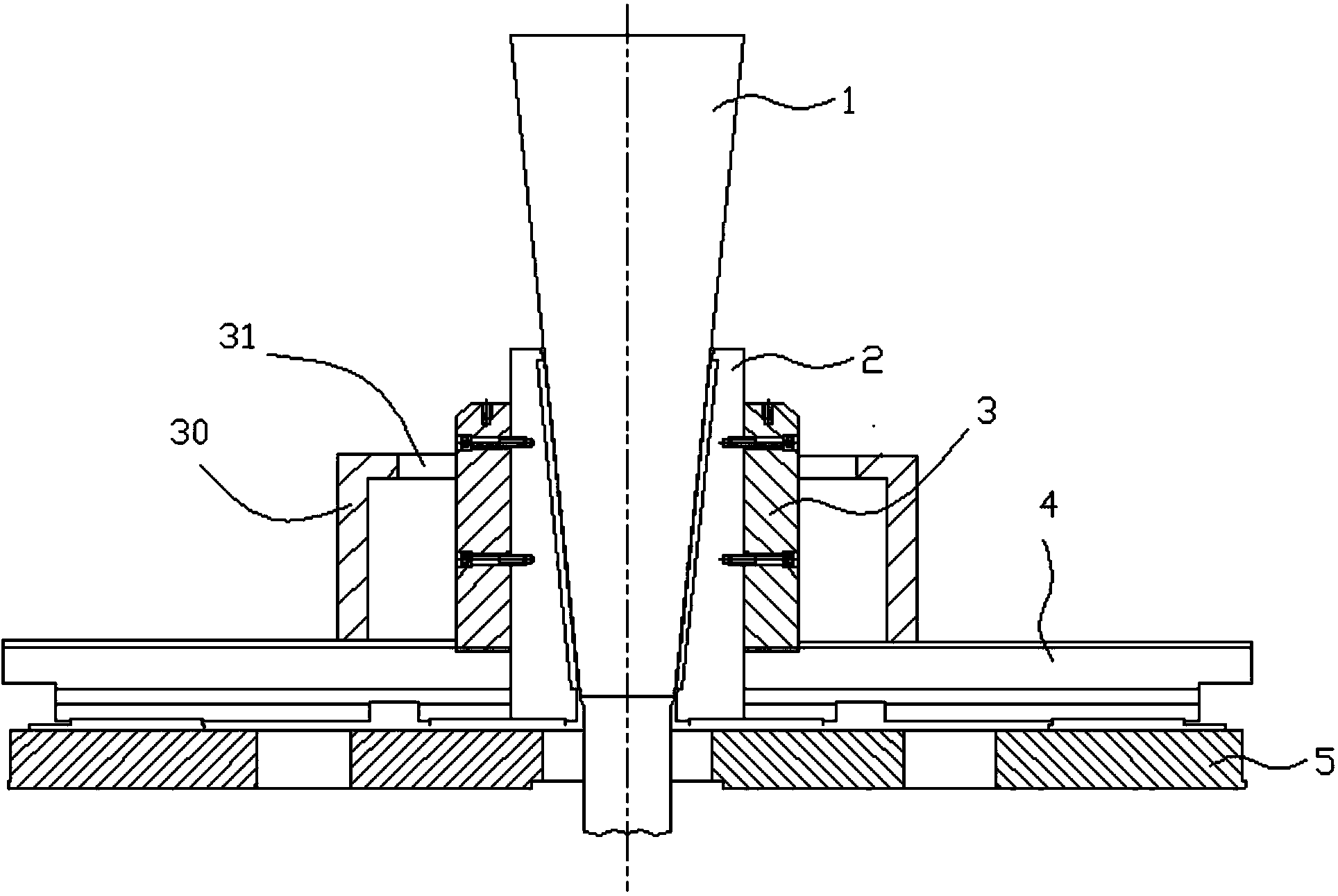

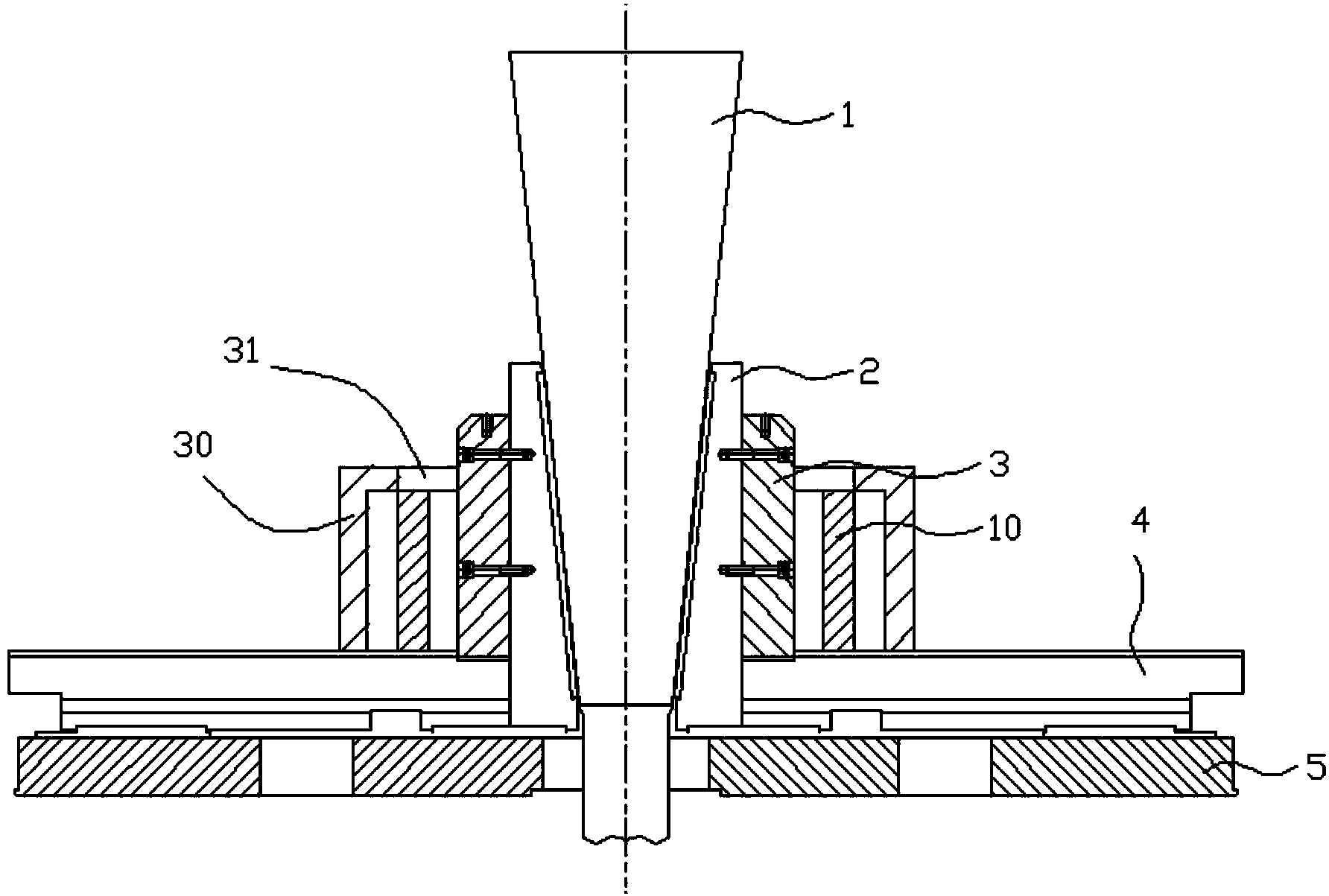

[0034] The structural diagram of the used bulging machine for implementing the thermal bulging method of the present invention provided in the prior art is as follows: figure 2 As shown, the bulging machine is mainly composed of a mandrel slider 1, a radial slider 2, a bulging block 3, a workbench 4 and a guide rail 5. The mandrel slider 1 is conical and is set in the radial slider 2 to cooperate with the conical inner peripheral surface of the radial slider 2. The mandrel slider 1 can be driven by the hydraulic cylinder of the bulging machine on the radial slider 2. Move up and down in the axial direction and squeeze the radial slider 2; the radial slider 2 is installed on the guide rail 5 of the bu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com