Garbage incinerator with heat recovery device

A waste incinerator and heat recovery technology, applied in incinerators, steam generation methods using heat carriers, combustion methods, etc., can solve the problems of harmful gas and particle dust entry, unreasonable overall design, air pollution, etc., to achieve full Effect of waste heat, clean and environmentally friendly garbage incineration, and full absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

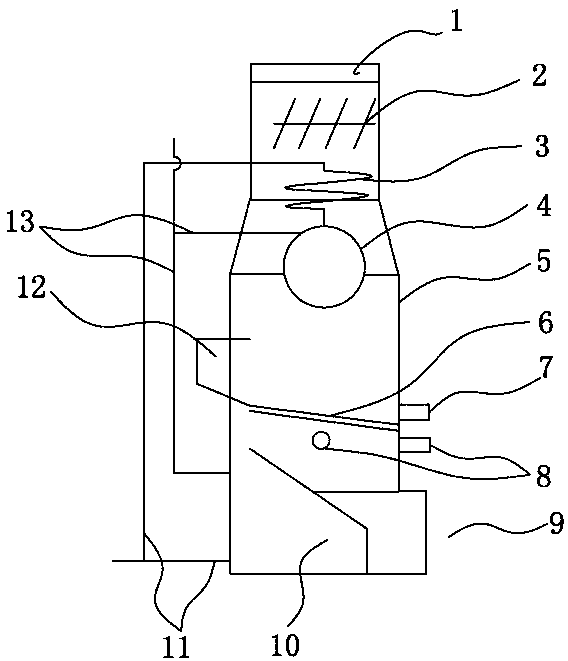

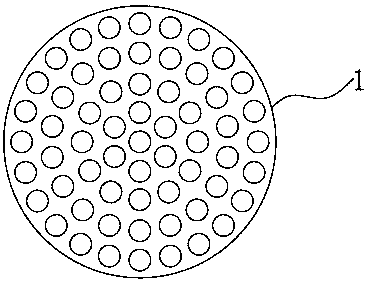

[0018] Such as Figure 1-2 As shown, the garbage incinerator with heat recovery device includes activated carbon plate 1, grid plate 2, water inlet coil 3, water storage tank 4, furnace body 5, grid plate 6, through hole 7, air inlet hole 8 , slag discharge port 9, heat energy recovery device 10, water inlet pipe 11, garbage input port 12 and steam output pipe 13, the inside of the furnace body 5 is provided with a grid plate 6 for supporting the garbage to be burned, while The through holes on the grid plate 6 can drain the burnt ashes, which is convenient for ash discharge from below. The furnace wall above the grid plate 6 is respectively provided with a garbage drop port 12 and a through hole 7, and the through hole 7 is installed to connect fuel. The flamethrower of the tank, through the flamethrower, continuously sprays high-temperature flames to incinerate the garbage;

[0019] The grid plate 6 is arranged obliquely, and the through hole 7 and the garbage delivery port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com