Device for preventing explosions in electrical transformers

A technology of electronic transformers and transformers, applied in transformer/inductor components, transformer/inductor casings, transformer/inductor cooling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

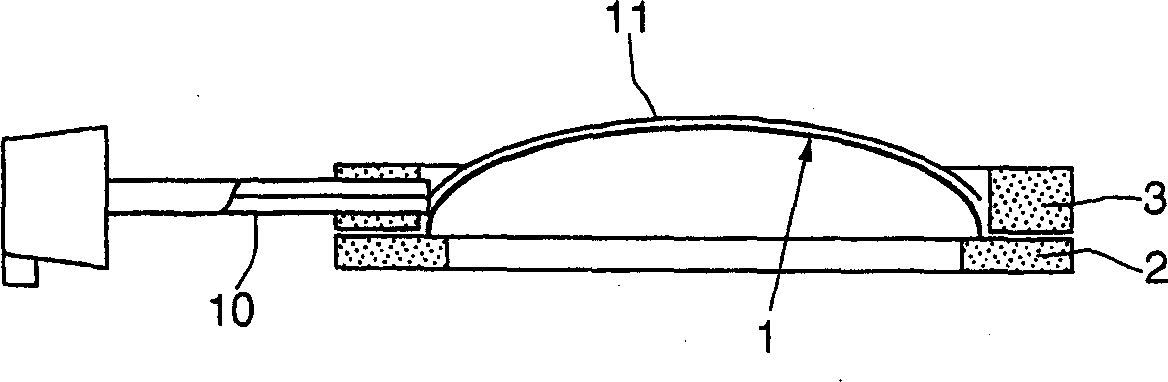

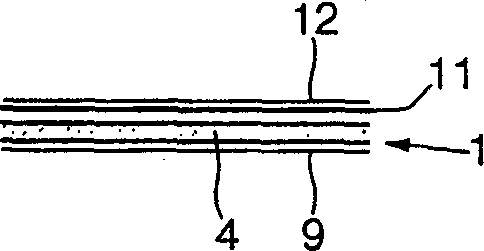

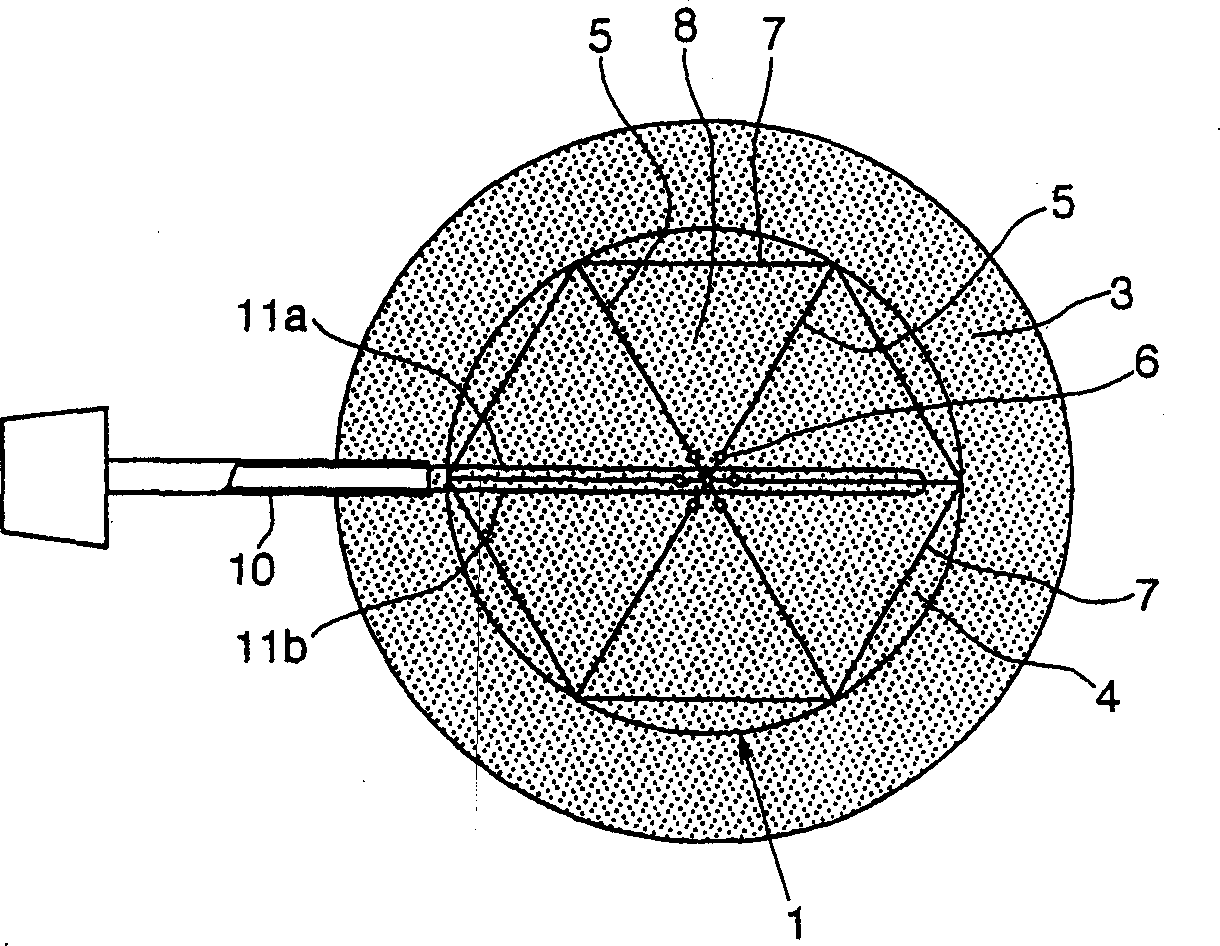

[0035] like Figure 1a , Figure 1b ,and figure 2 As shown, the rupture element 1 has the shape of a dome that protrudes on the downstream side and is used to fit a discharge hole (not shown) containing an insulating fluid housing. The rupture element 1 comprises a holding element 4 in the form of a thin metal sheet, for example made of stainless steel, aluminium or an aluminium alloy. The holding element 4 is tightly clamped between the two disk-shaped flanges 2 , 3 . The rupture element 1 comprises, in addition to the holding element 4, a sealing liner 9 arranged on the upstream side, in other words, covering the concave side of the holding element. For example, the liner 9 is based on polytetrafluoroethylene.

[0036] The holding element 4 is provided with radial lines 5 dividing it into six parts. This radial line 5 is formed hollowly in a portion of the thickness of the holding element 4 so that the rupture occurs without fragments by the holding element 4 tearing al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com